Deep hole blasting vibration reduction method

A technology of deep hole blasting and blasting, which is applied in blasting and other directions, can solve problems such as affecting the effective utilization rate of blast energy, and achieve the effect of improving blasting effect, novel design, and beneficial to uniform crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

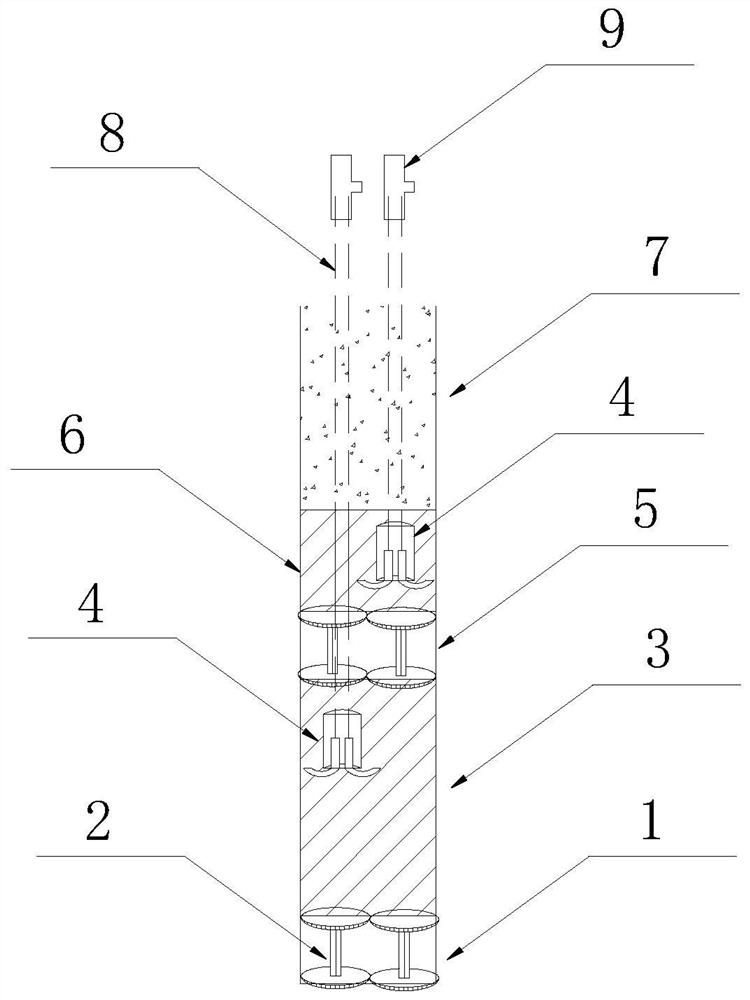

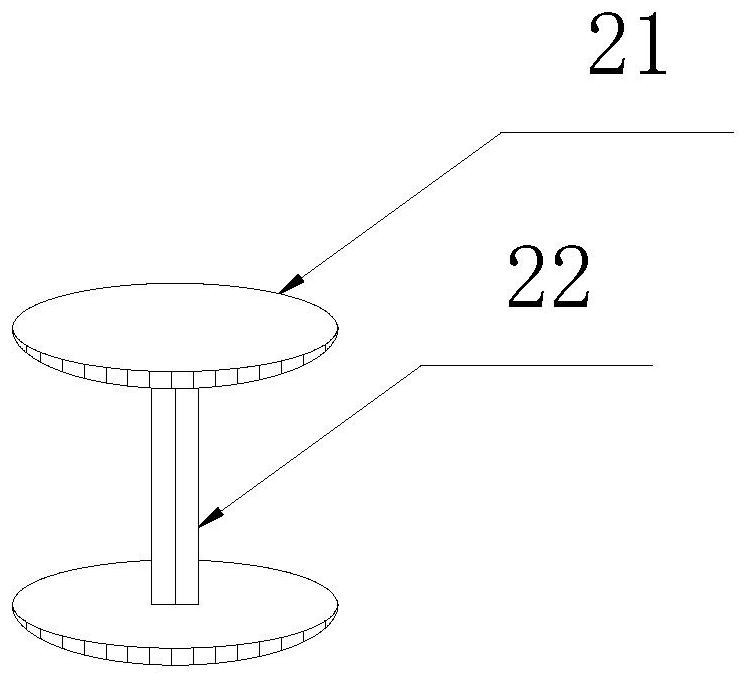

[0045] like figure 1 and figure 2 As shown in the figure, a deep-hole blasting vibration-damping charge structure of the present invention includes a blasting hole 11, and the blasting hole 11 is respectively set from bottom to top as a hole bottom supporting interval 1, a lower explosive filling section 3, and a supporting interval between the holes. Section 5, inter-hole explosive filling section 6 and rock powder filling section 7; the hole-bottom support interval section 1 and the inter-hole support interval section 5 are respectively provided with a number of support frames 2. A spaced section with air or water is formed between the bottom and the hole; the rock powder filling section 7 is formed by filling with rock powder; the lower explosive filling section 3 and the explosive filling section 6 between the holes are respectively formed by filling explosives, and the two explosives are filled with The tops of the sections are respectively provided with detonating char...

Embodiment 2

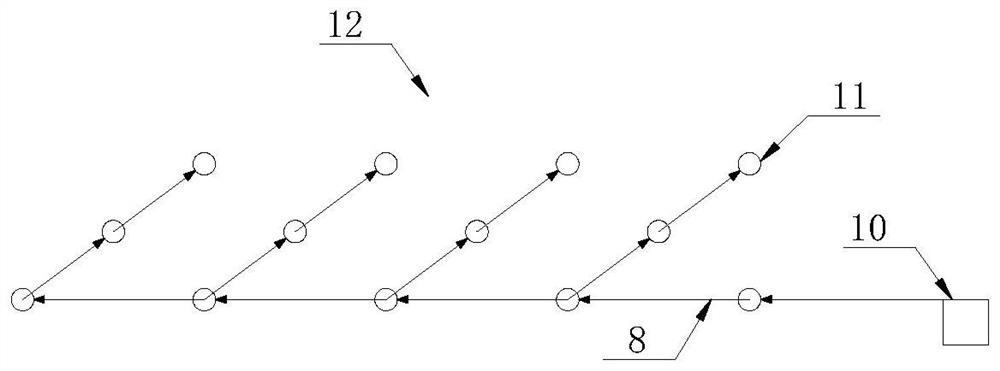

[0050] like Figure 1 to Figure 3 As shown, a deep hole blasting vibration damping structure of the present invention is composed of the deep hole blasting vibration damping charge structures described in several embodiments 1. Connectors 9 are connected to each connector 9, and each connector 9 is connected to a shot area network 12 through a detonating cord 8, and a detonator 10 is connected to the shot area network 12.

[0051] Further, each blast hole 11 can be connected by detonating cord 8 to realize hole-by-hole differential blasting, specifically: several blast holes 11 are arranged in a row, the distance between adjacent blast holes 11 is 8-9m, and each row of blast holes is 8-9m apart. The holes 11 are evenly arranged at parallel intervals, and the row spacing of two adjacent rows of gun holes 11 is 5.5-6m. The connectors 9 connected to the detonating cords 8 on the detonating charge packs 4 in the outermost row of gun holes 11 are connected by the detonating cords 8...

Embodiment 3

[0053] like Figure 1-Figure 3 As shown, a deep hole blasting vibration damping method of the present invention, the steps are as follows:

[0054] S1. On the step where blasting is required in the open-pit iron ore, determine the position of each blast hole 11 according to the blasting requirements, and use a roller cone drill to carry out the perforation operation of each blast hole 11. According to the designed blasting parameters, until the perforation operation of each blast hole 11 is completed, The depth of the blast hole 11 is usually set to 14.5-15m, and the diameter is 250-310mm. Each blast hole 11 is set from bottom to top as the hole bottom support interval 1, the lower explosive filling section 3, the hole support interval 5, Inter-hole explosive filling section 6 and rock powder filling section 7;

[0055] S2. Slowly put several support frames 2 into the positions of the pre-designed interval sections at the bottom of the gun hole 11 through the string to form t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com