Makrolon/ABS composite material and preparation method thereof

A technology of polycarbonate and composite materials, applied in the field of modified polycarbonate/ABS composite materials and its preparation, can solve the problems of unsatisfactory material performance and limited performance improvement, and achieve excellent comprehensive mechanical properties and low cost The effect of low and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

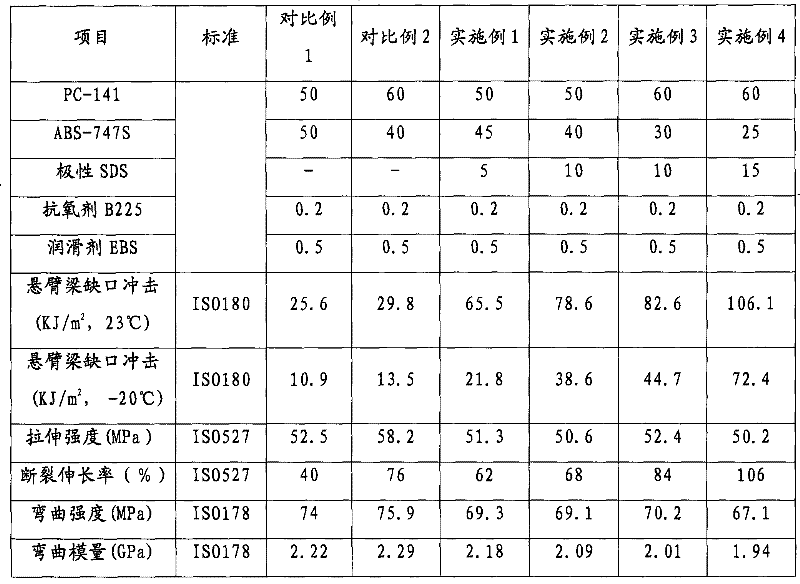

[0026] Polycarbonate (PC-141, American GE Company), ABS (ABS-747S, Taiwan Chimei Company), polarized SDS (SDS, Baling Petrochemical Co., Ltd., its number average molecular weight is 84,300, polarity Block weight content 3.0%), antioxidant (B225, Swiss CIBA company), lubricant (EBS, Shanghai), put into a low-speed mixer and stir evenly, so that all components are fully mixed evenly. Then the above mixed material was extruded and granulated in a twin-screw extruder (TE-30, Nanjing Ruiya Company) at a temperature of 220° C. to 260° C. The extruded pellets were dried in a constant temperature oven at 95°C for 6 hours, and then injected into standard specimens at a temperature of 230°C to 270°C for various mechanical property tests. The content of each component is calculated in parts by weight. The test standards and mechanical performance results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com