Scratch-resistant polypropylene composition and preparation method thereof

A polypropylene composition and scratch-resistant technology, which is applied in the field of polypropylene composition and its preparation, can solve the problems of product appearance and adverse effects of use, surface stickiness and frosting, lubricant precipitation, etc., and achieve good impact resistance , low cost, good scratch resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] 1. Preparation of scratch-resistant agent

[0027] Fully vulcanized powdered styrene-butadiene rubber (Beijing Chemical Industry Research Institute, VP101, average particle size 0.1 μm) was heated to 80 ° C, placed in a high-speed mixer, and under high-speed stirring, naphthenic oil (Tianjin Dagang Oil Refinery, Circosol 410) and / or linear polymethylsiloxane lubricant (Beijing Second Chemical Factory, 201), stirred for 30 seconds, released and placed at room temperature for 24 hours to obtain a scratch-resistant agent. The weight ratio of the components is shown in the respective examples.

[0028] 2. Preparation of scratch-resistant polypropylene

Embodiment 1

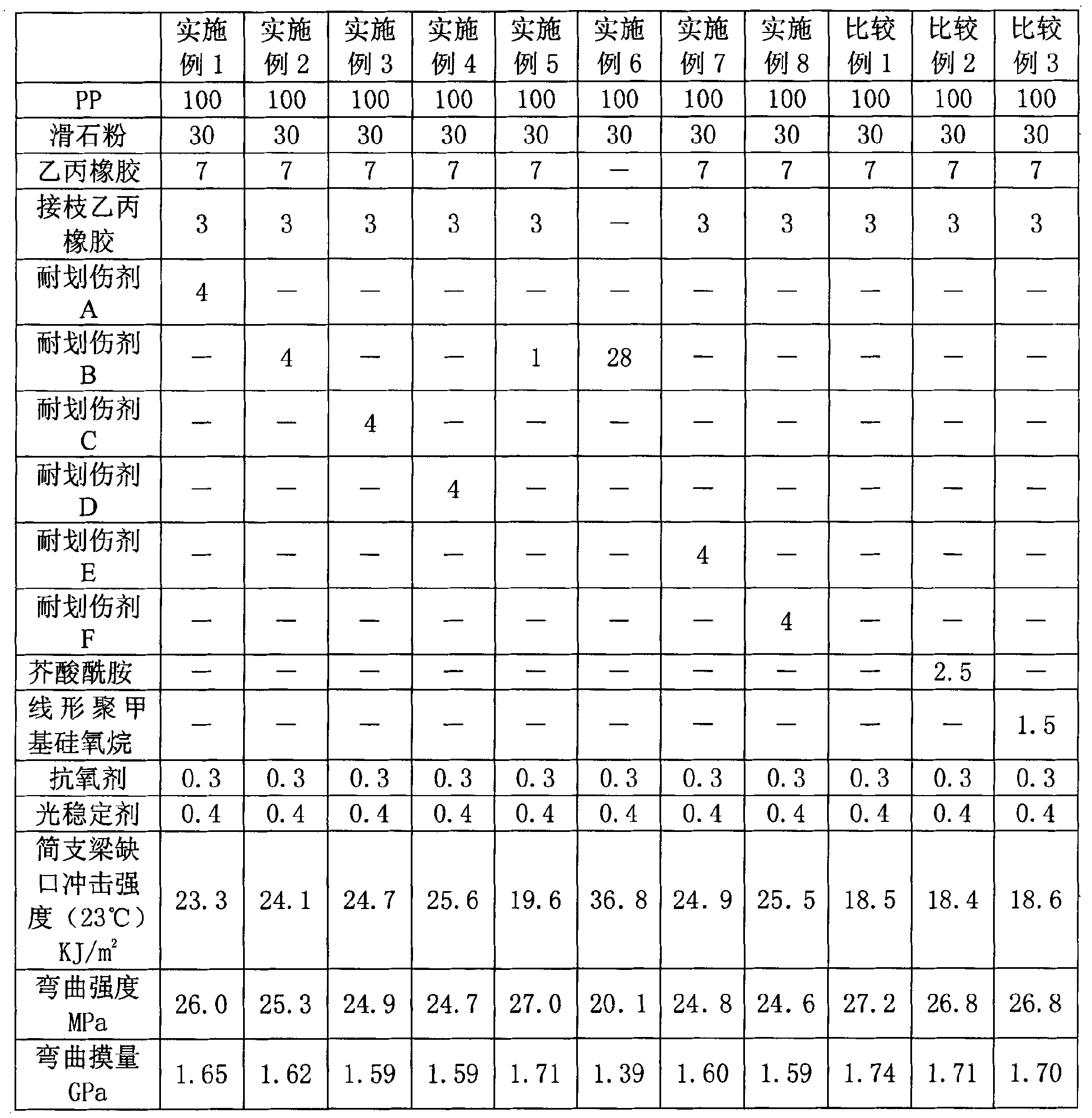

[0030] Polypropylene (Sinopec Beijing Yanshan Petrochemical Company, brand: K9020, melt index 20g / 10min), talc powder (Dalian Fuji Mining Co., Ltd., 2500 mesh), ethylene-propylene rubber (Dow Chemical Company, NORDEL IP), Branched ethylene propylene rubber (Compton Company of the United States, 498), anti-scratch additive A (the weight ratio of fully vulcanized powder rubber and naphthenic oil is 100:50), antioxidant (Swiss Ciba Specialty Chemical Company, B225 ), a light stabilizer (TINUVIN XT 855 from Ciba Specialty Chemicals, Switzerland) were evenly stirred, and extruded and granulated using a twin-screw at 190-230°C. The samples were prepared by injecting the injection machine, and the mechanical properties, scratch resistance and other properties were tested. The results are shown in Table 1. The specific formula is shown in Table 1, wherein the contents of each component are calculated in parts by weight.

Embodiment 2

[0032] Except that the anti-scratch additive B (the weight ratio of fully vulcanized powder rubber and linear polymethylsiloxane lubricant is 100:35) was used to replace the anti-scratch additive A. All the other are the same as in Example 1, and the specific formula and test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com