Polypropylene/cellulose intercalation nanometer crystal masterbatch, preparation method and application thereof

A nanocrystal and cellulose technology, applied in the field of polypropylene composition, can solve the problems of surface succinic anhydride-modified CNCs poor dispersion, CNCs phase tolerance, affecting the quality of reinforced polypropylene materials, etc., to avoid thermal degradation reactions and improve the interface Compatibility, effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

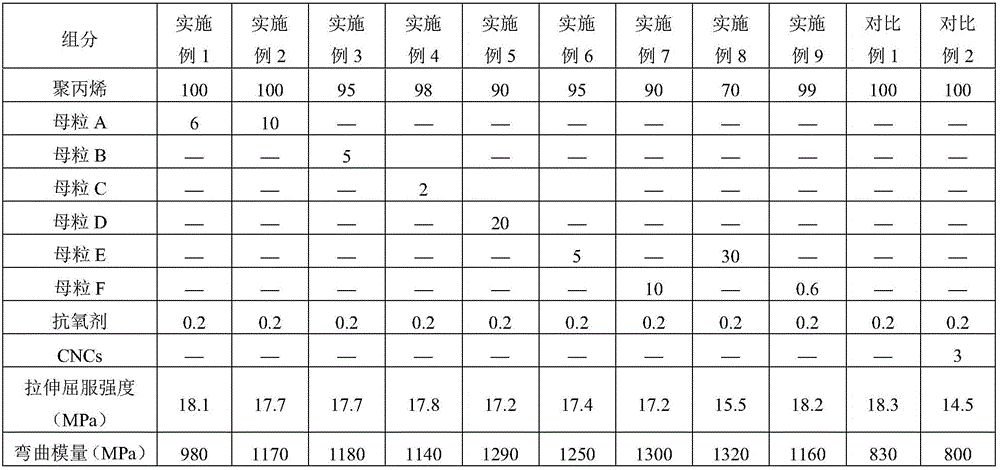

Examples

Embodiment 1~9

[0056] Masterbatch A

[0057] The cellulose intercalation nanocrystals (average length 80nm, average width 4nm, average height 70nm, the substitution degree of long-chain alkane substituted CNCs hydroxyl functional group is 67%, the thermal degradation initiation temperature (N 2 Atmosphere) is 240°C, sulfur content is 0, Chinese Academy of Forestry Wood Industry Research Institute) and the antioxidant (antioxidant 1010, belongs to hindered phenolic antioxidant, the chemical name is four [β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and antioxidant 168, which belong to phosphate antioxidants, the chemical name is tris(2,4-di-tert-butylphenol) Phosphite, the weight ratio of antioxidant 1010 and antioxidant 168 is 1:2, and both are fully mixed to obtain described premix from Germany BASF company)); Then the described premix obtained and polypropylene (K8303, homopolypropylene, Sinopec Beijing Yanshan Branch, 2.5g / 10min) was put into a high-speed mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com