Sulfuric acid dew point corrosion resisting steel capable of avoiding surface cracks and rolling technology of sulfuric acid dew point corrosion resisting steel capable of avoiding surface cracks

A surface crack and dew point corrosion technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of cost increase, waste of resources, affecting the welding performance and service life of sulfuric acid dew point corrosion resistant steel pipes, etc., to reduce precision The effect of reducing the overall cost, reducing the heating time, and shortening the holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

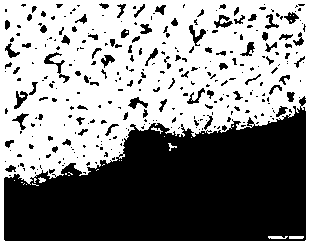

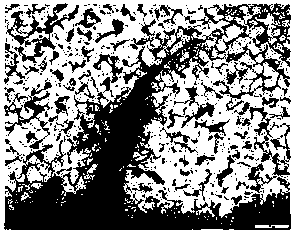

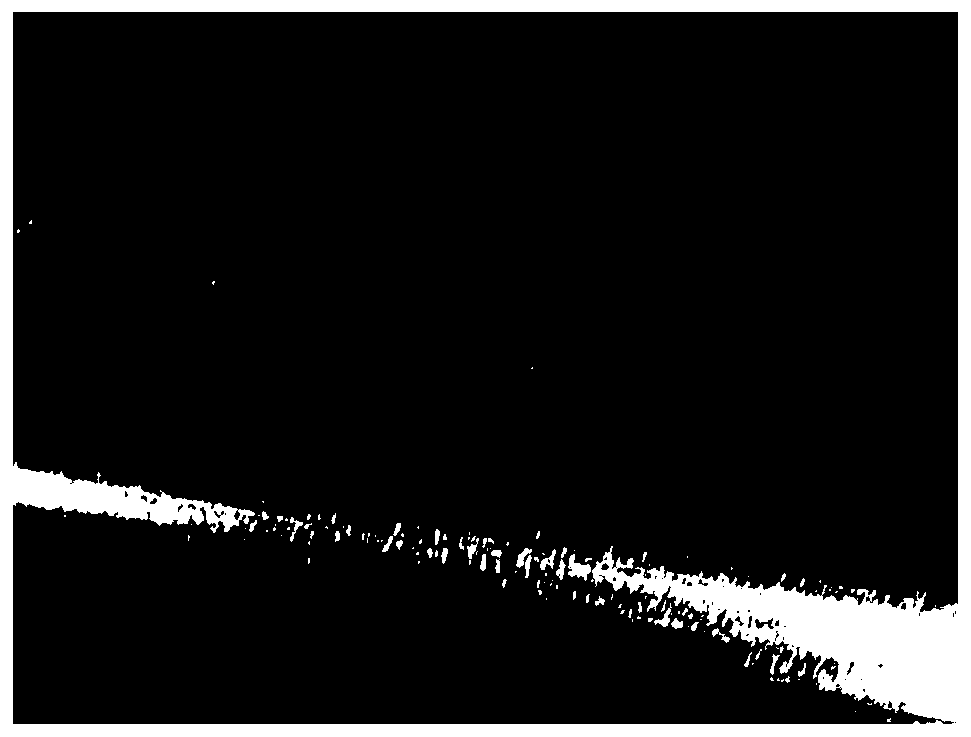

Image

Examples

Embodiment 1

[0031] A sulfuric acid dew point corrosion-resistant steel for avoiding surface cracks, comprising the following components by mass percentage:

[0032] C: 0.07%, Si: 0.28%, Mn: 0.48%, Cr: 0.93%, Cu: 0.30%, Sb: 0.078%, P: 0.010%, S: 0.003%, Al: 0.020%, N: 0.0045%, The balance is Fe and unavoidable impurities.

[0033] The rolling process of the above-mentioned sulfuric acid dew point corrosion-resistant steel for avoiding surface cracks comprises the following steps:

[0034] 1) The cold billet of Φ300mm×6000mm is heated in the heating furnace. The inner width of the heating furnace is 13m, the effective length of the furnace is 41.2m, and the step distance is 0.4m / piece, a total of 102 steps. A walking beam heating furnace with double rows of material distribution, upper and lower heating, and side entry and side exit; the heating furnace is divided into a preheating section, a heating section, a second heating section, a soaking section and a soaking section 2 along the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com