Patents

Literature

57results about How to "Reduce finishing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

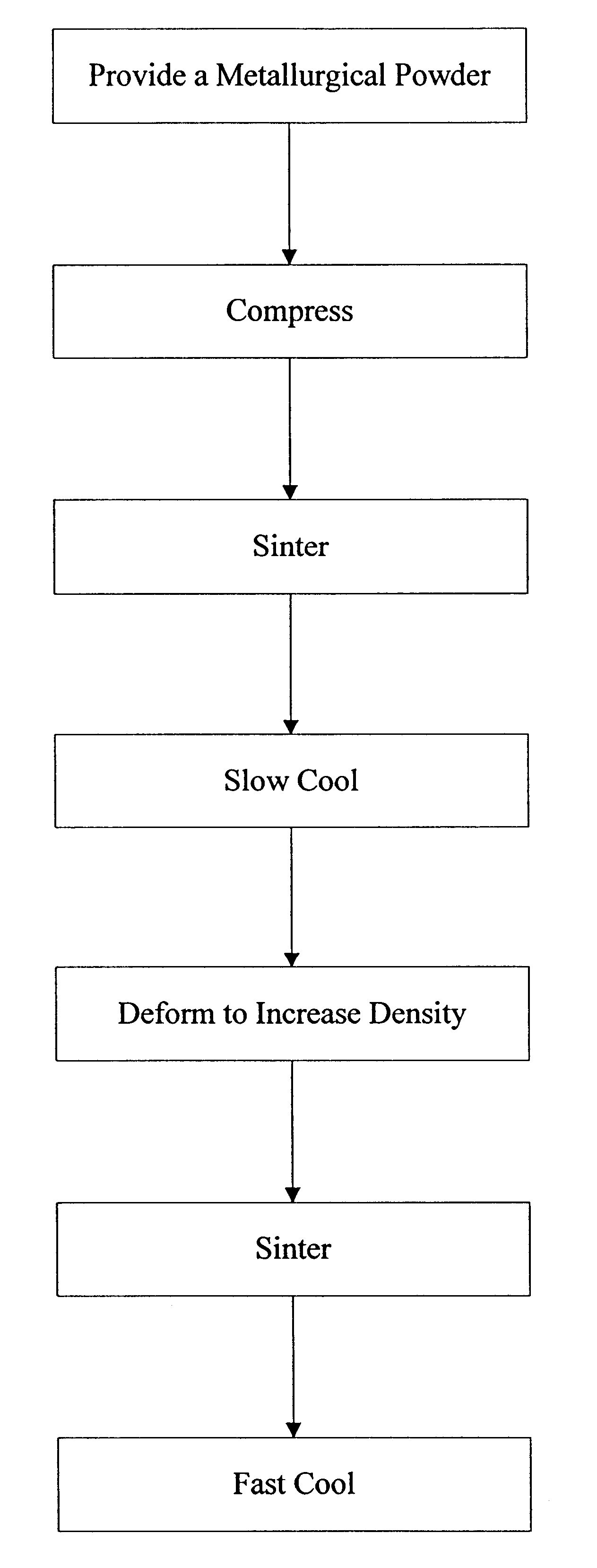

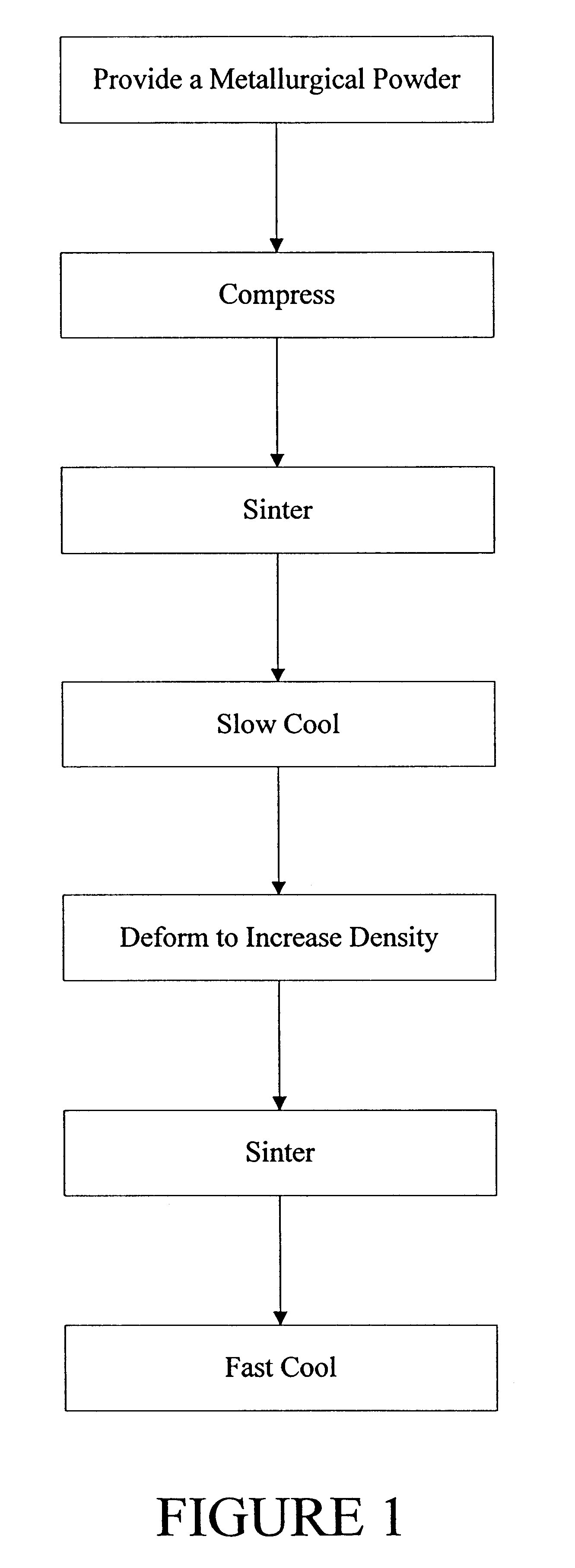

Method for producing powder metal materials

A method for producing a material includes providing a metallurgical powder including iron, 1.0 to 3.5 weight percent copper, and 0.3 to 0.8 weight percent carbon. At least a portion of the powder is compressed at 20 tsi to 70 tsi to provide a compact, and subsequently the compact is heated at high temperature and then cooled at a cooling rate no greater than 60° F. per minute to increase the surface hardness of the compact to no greater than RC 25. The density of at least a region of the sintered compact is increased, by a mechanical working step or otherwise, to at least 7.6 grams / cc. The sintered compact is then re-heated to high temperature and cooled at a cooling rate of at least 120° F. / min. so as to increase the surface hardness of the compact to greater than RC 25, and preferably at least RC 30. Material made by the method of the invention also is disclosed.

Owner:KEYSTONE INVESTMENT CORP

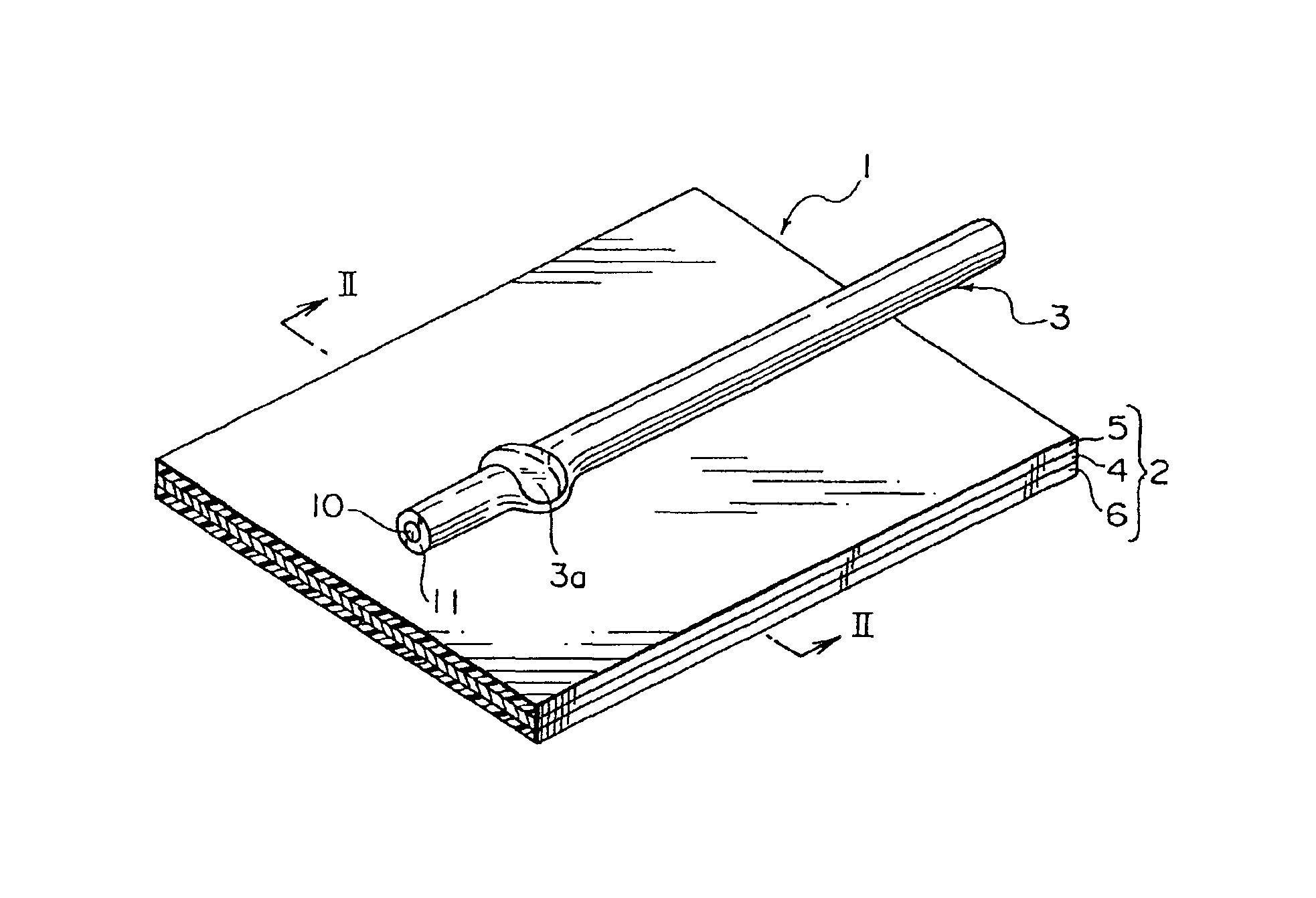

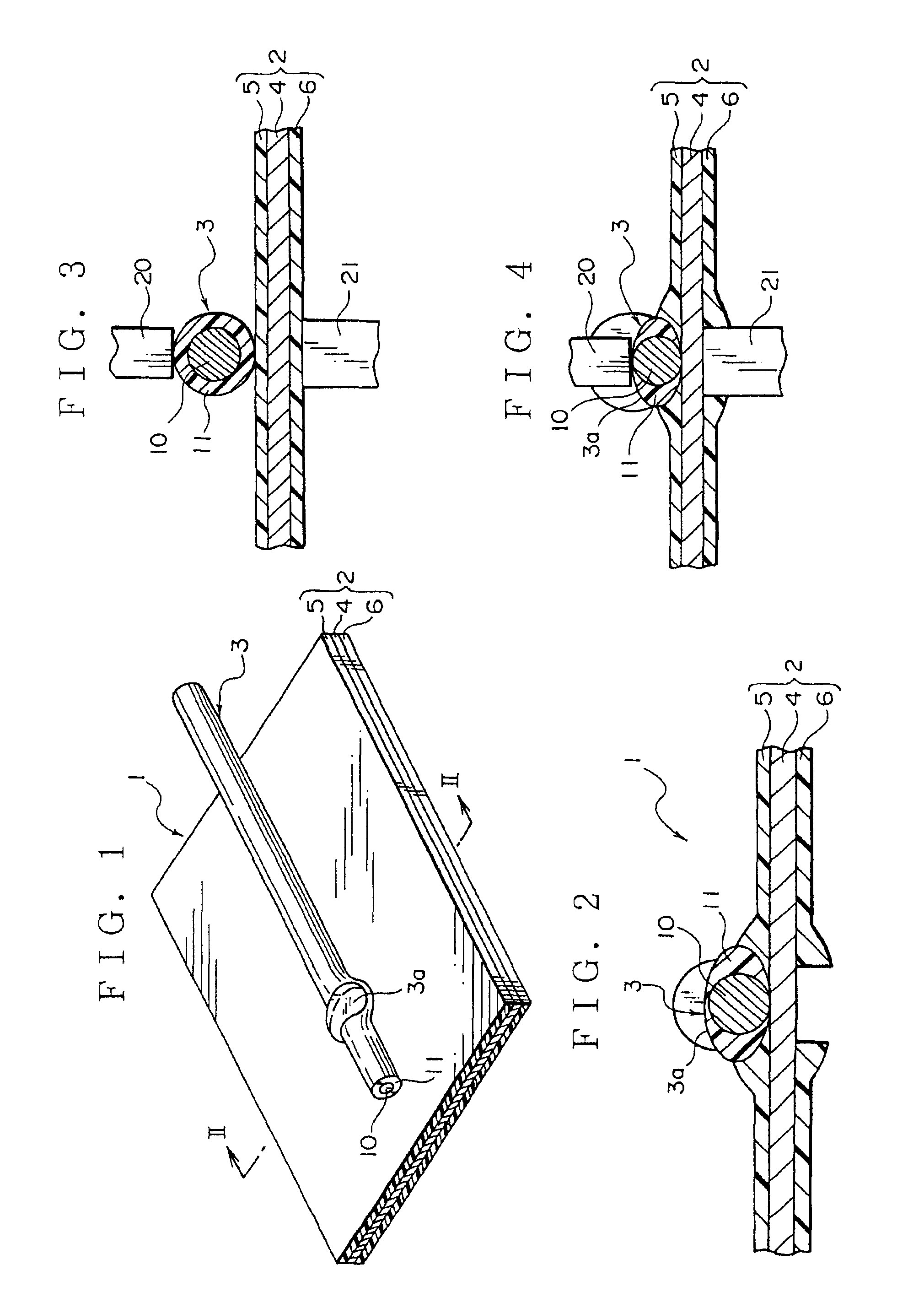

Cable-enrolling conductive thin-film sheet and manufacturing method thereof

InactiveUS6858804B2Lower assembly costsLow costPrinted circuit assemblingNon-insulated conductorsElectrical conductorUltrasonic welding

The cable-enrolling conductive thin-film sheet 1 consists of a conductive thin film 2 and an insulated cable 3. The conductive thin film 2 has a conductor layer 4 and first and second insulating layers 5, 6. The first insulating layer 5 is laminated on one face of the conductor layer 4, while the second insulating layer 6 is laminated on the other face of the conductor layer 4. The insulated cable 3 has an electrically conductive core wire 10 and an insulating sheath 11 covering the core wire 10. The insulated cable 3 laid on the first insulating layer 5 is partially welded to the sheet 2 by ultrasonic welding to obtain the cable-enrolling conductive thin-film sheet 1. The first insulating layer 5 is welded to be secured to the sheath 11, and the conductor layer 4 is mechanically connected to the core wire 10 by the ultrasonic welding.

Owner:YAZAKI CORP

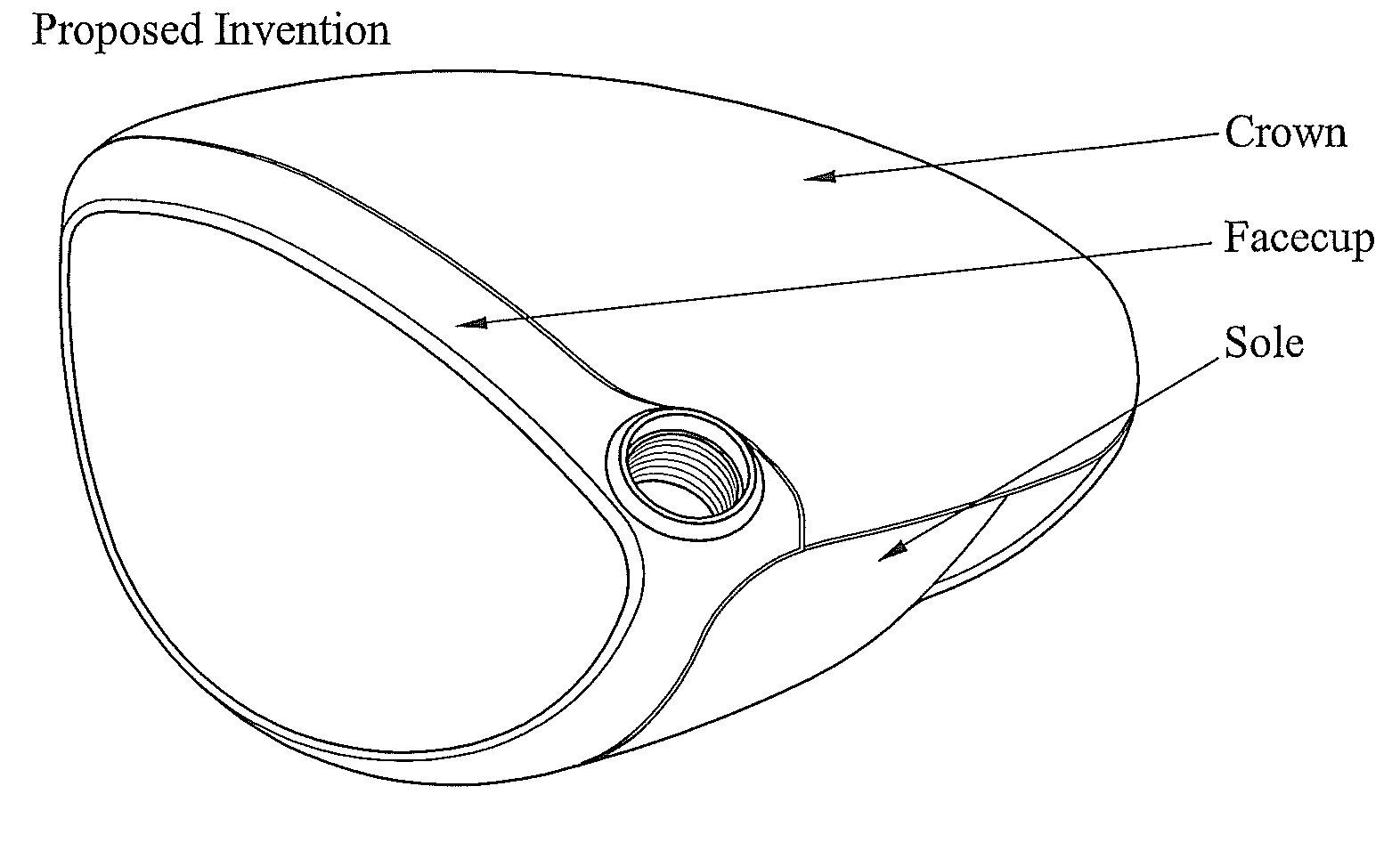

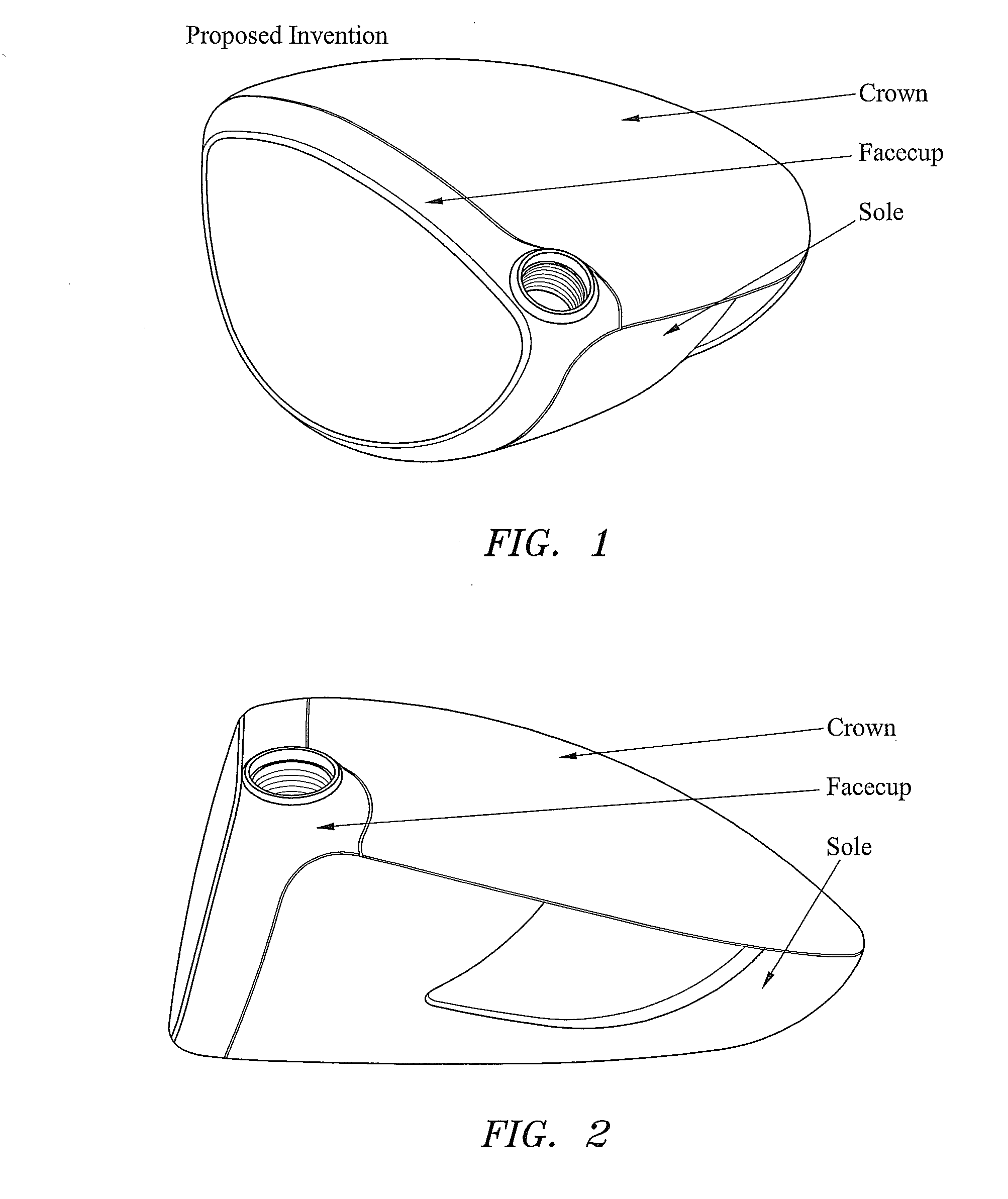

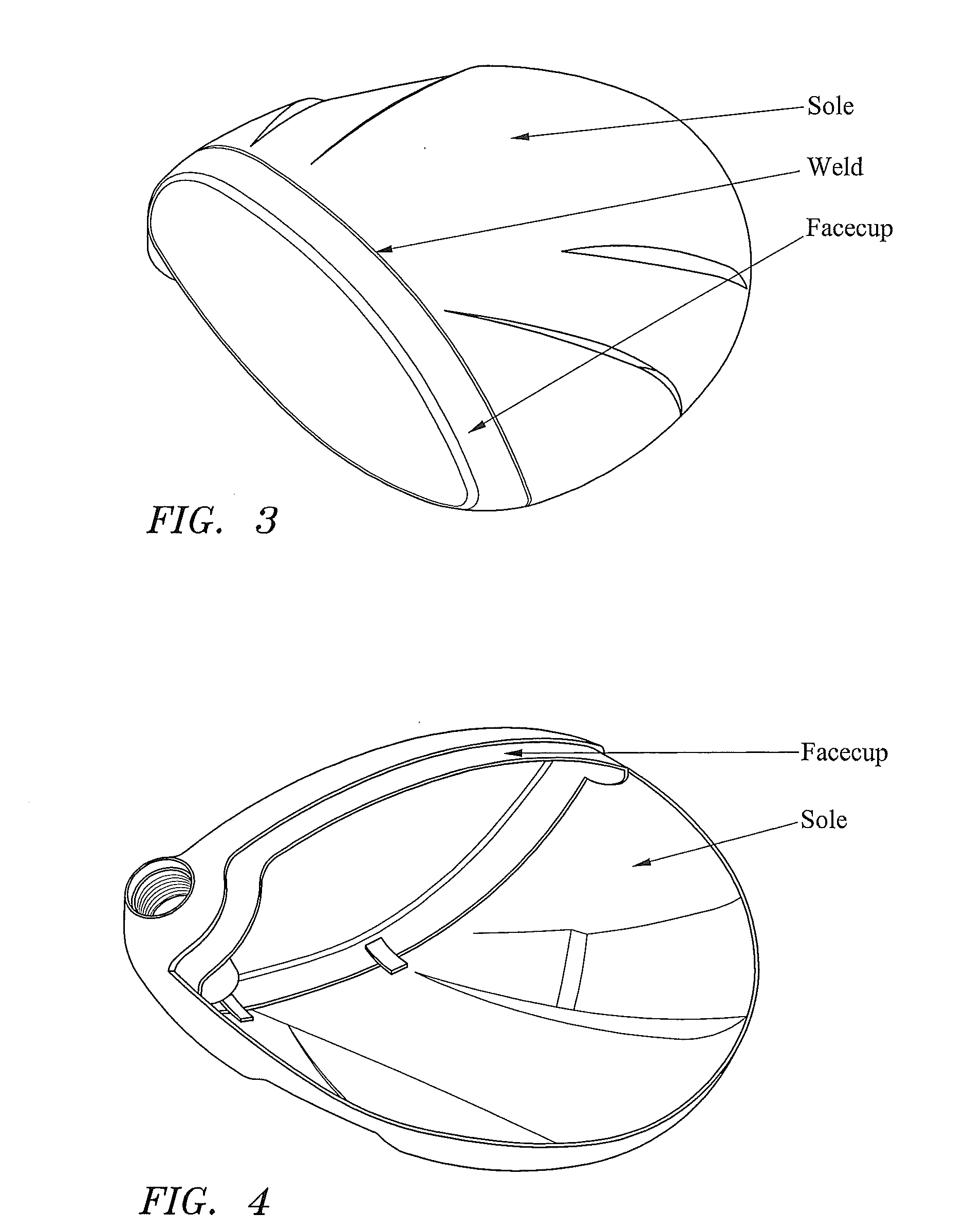

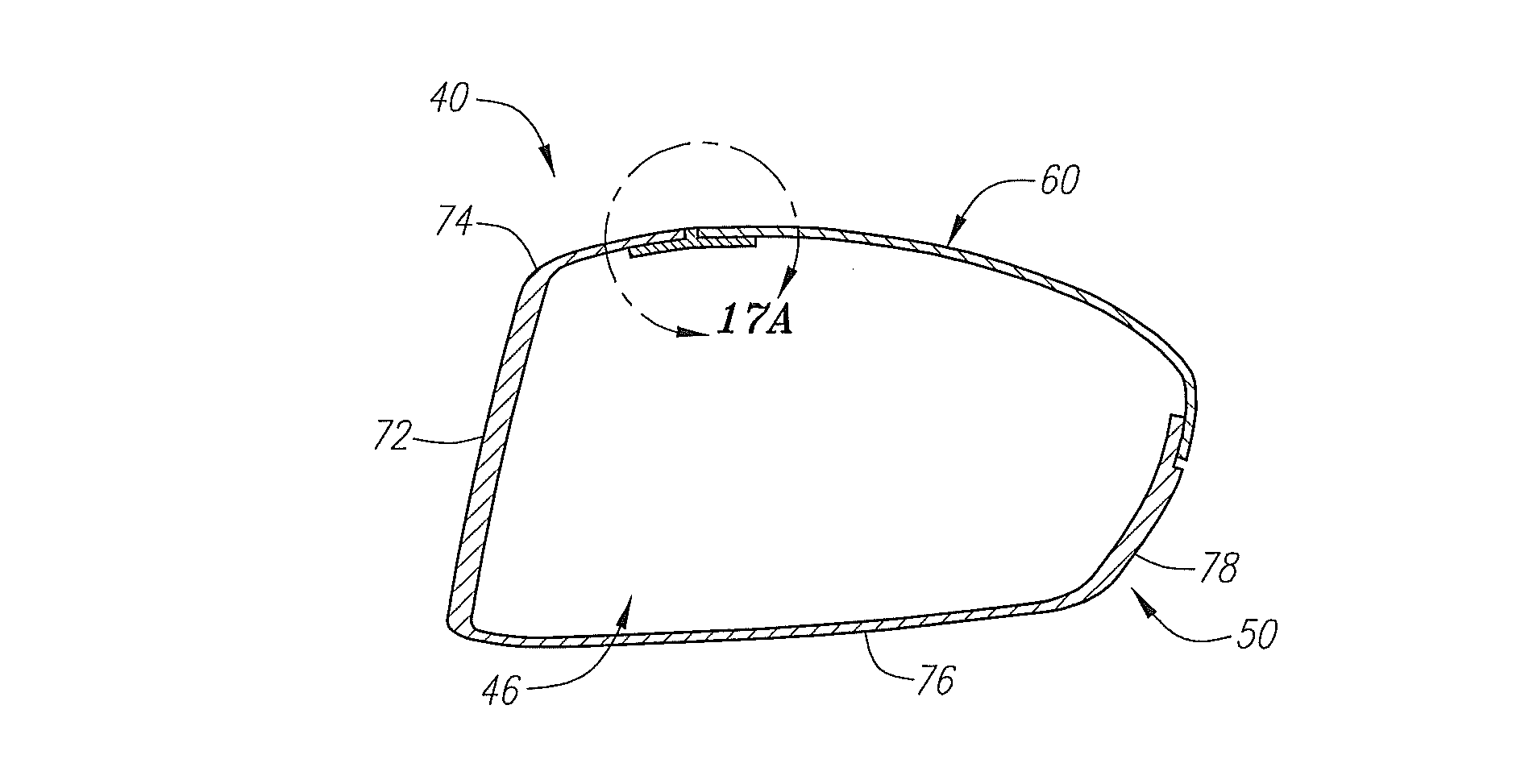

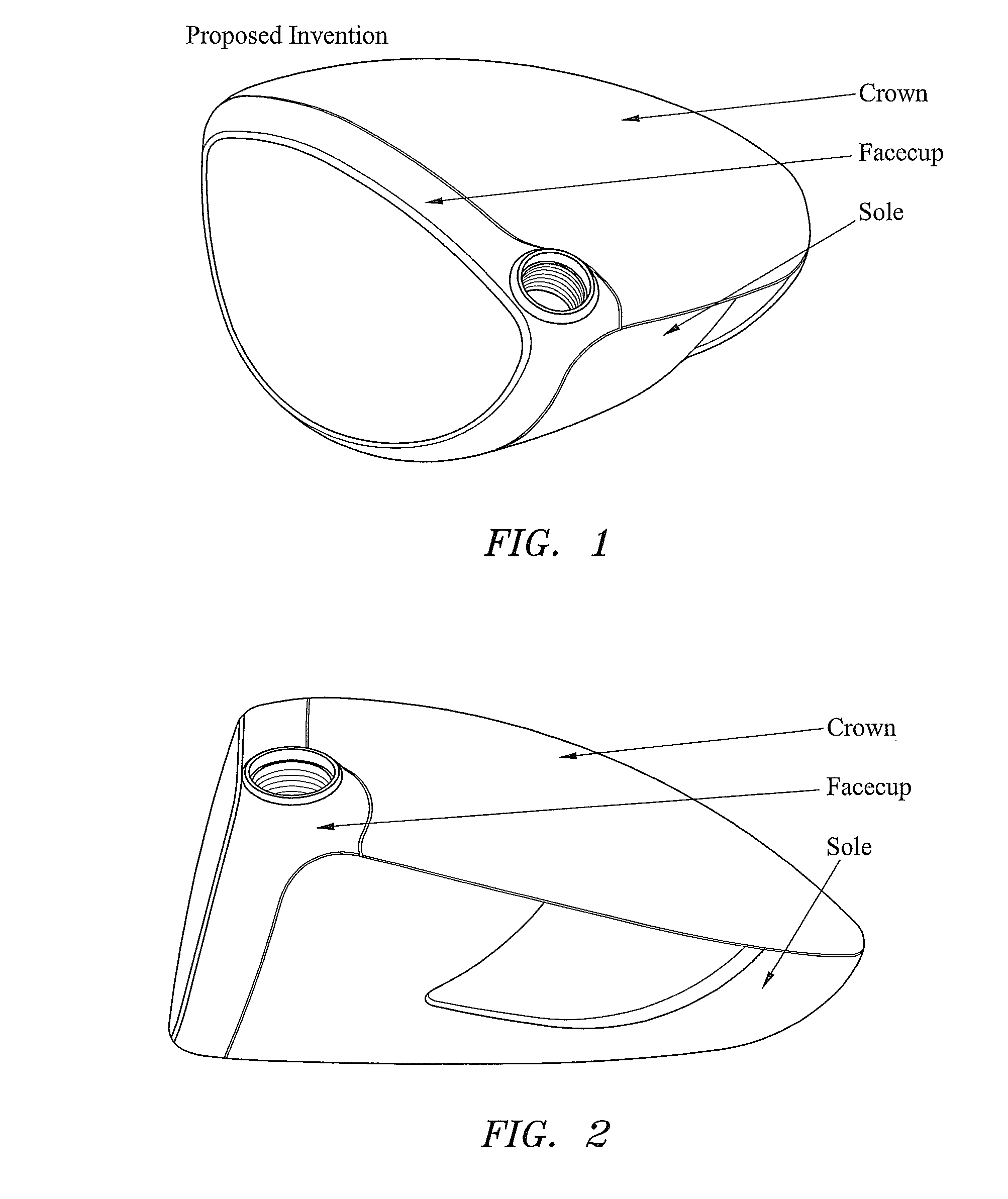

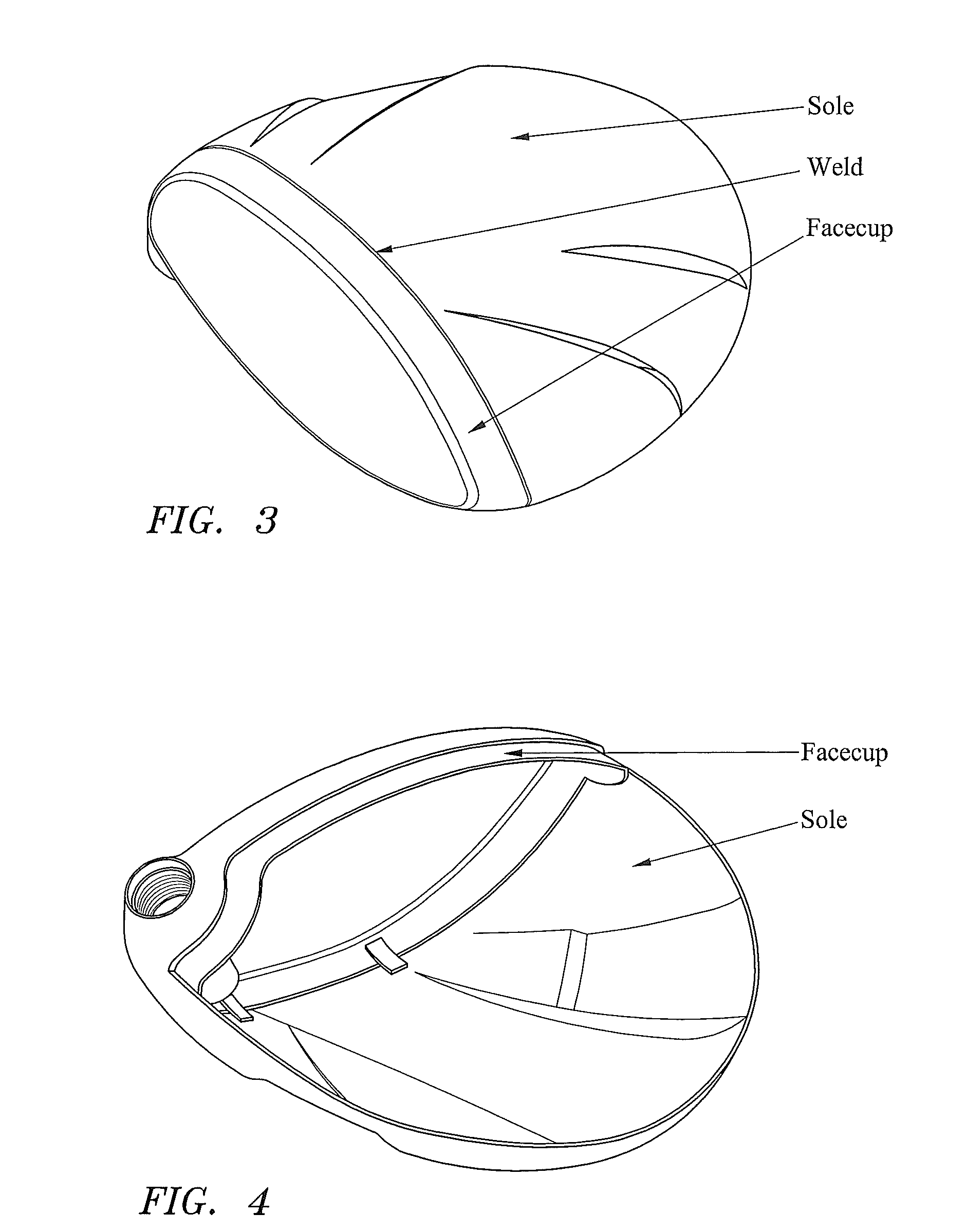

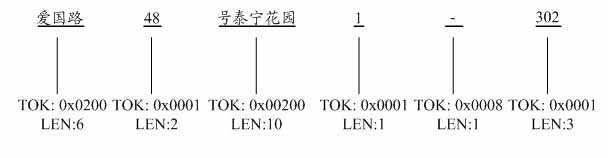

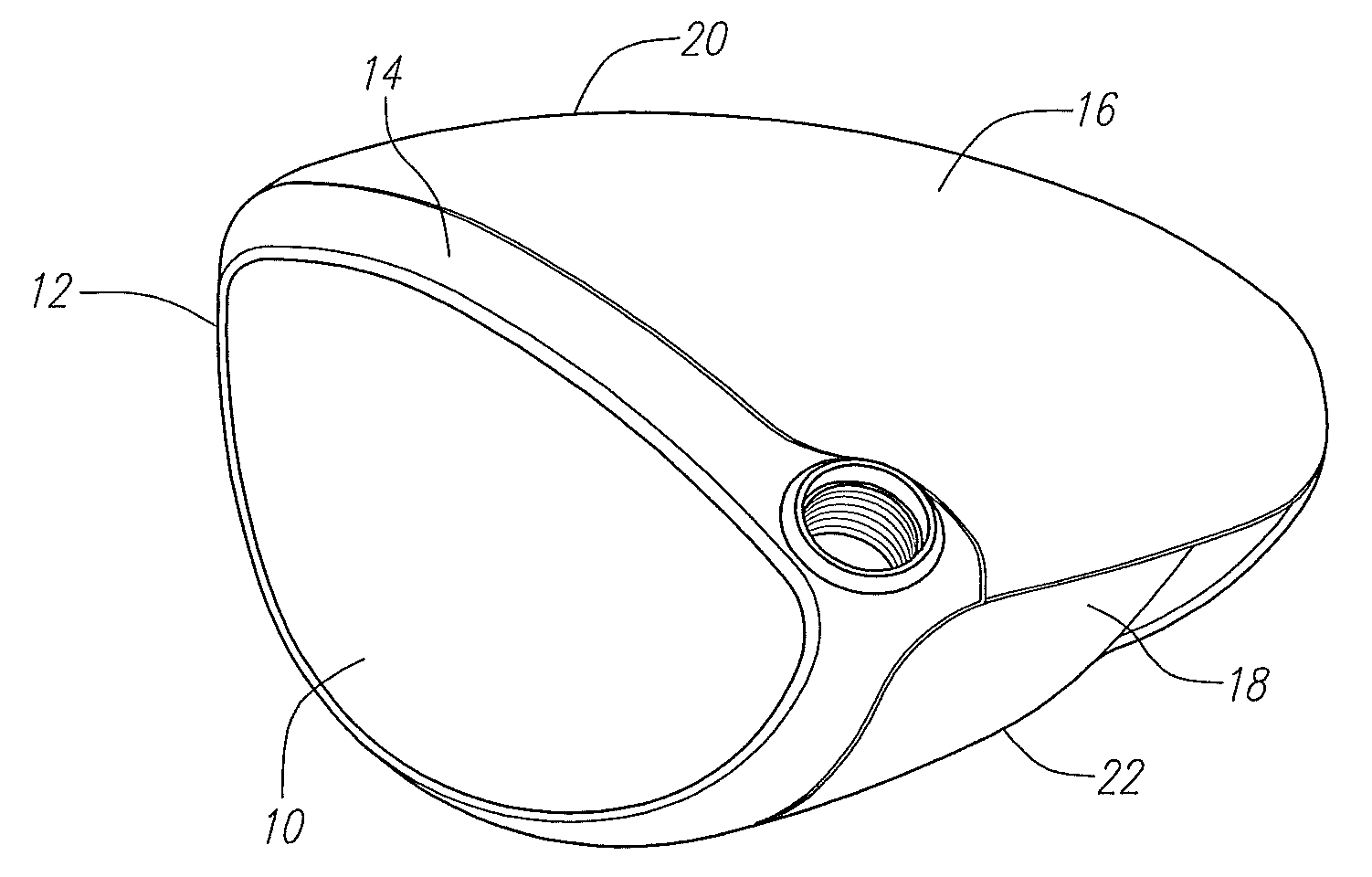

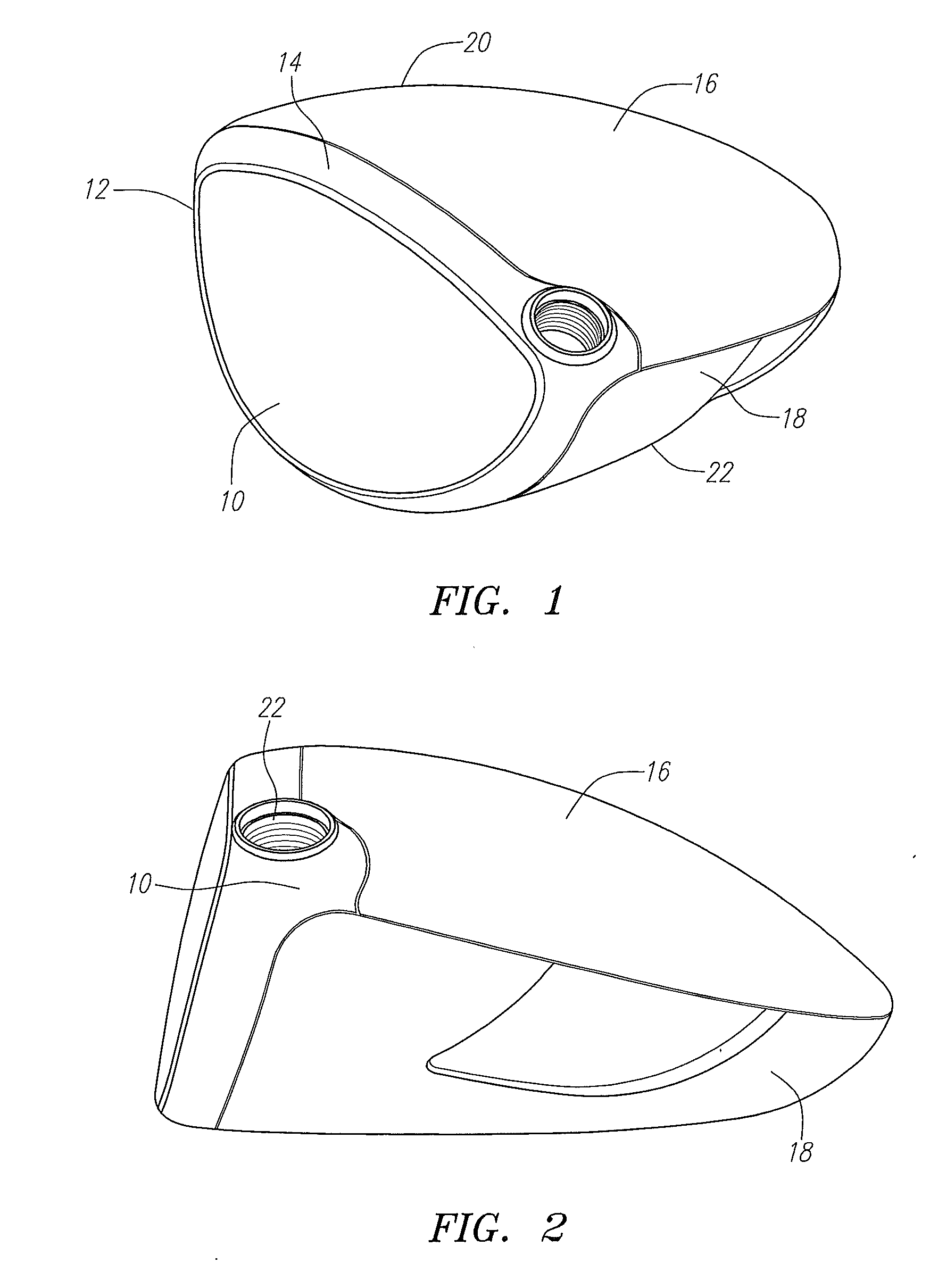

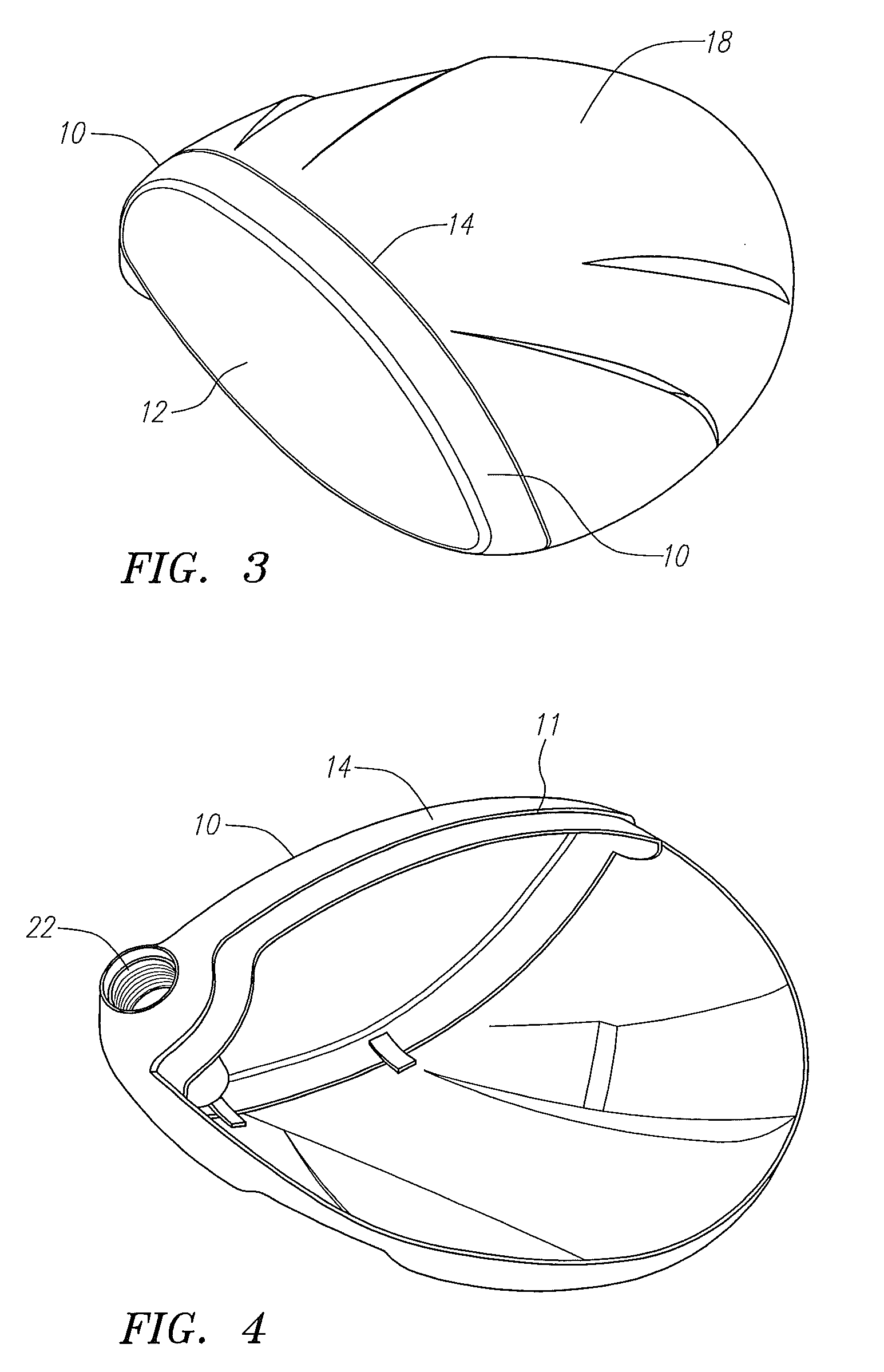

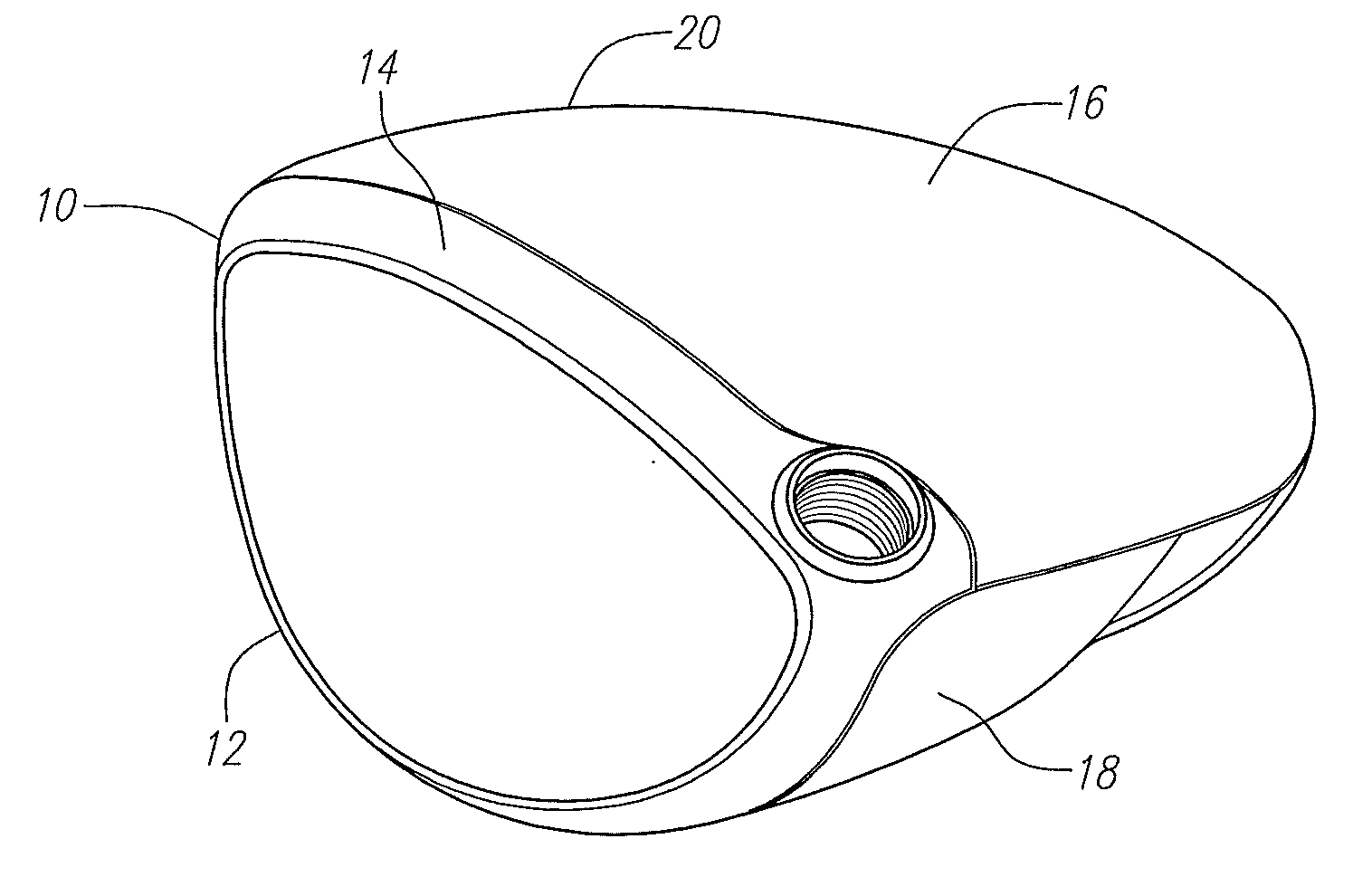

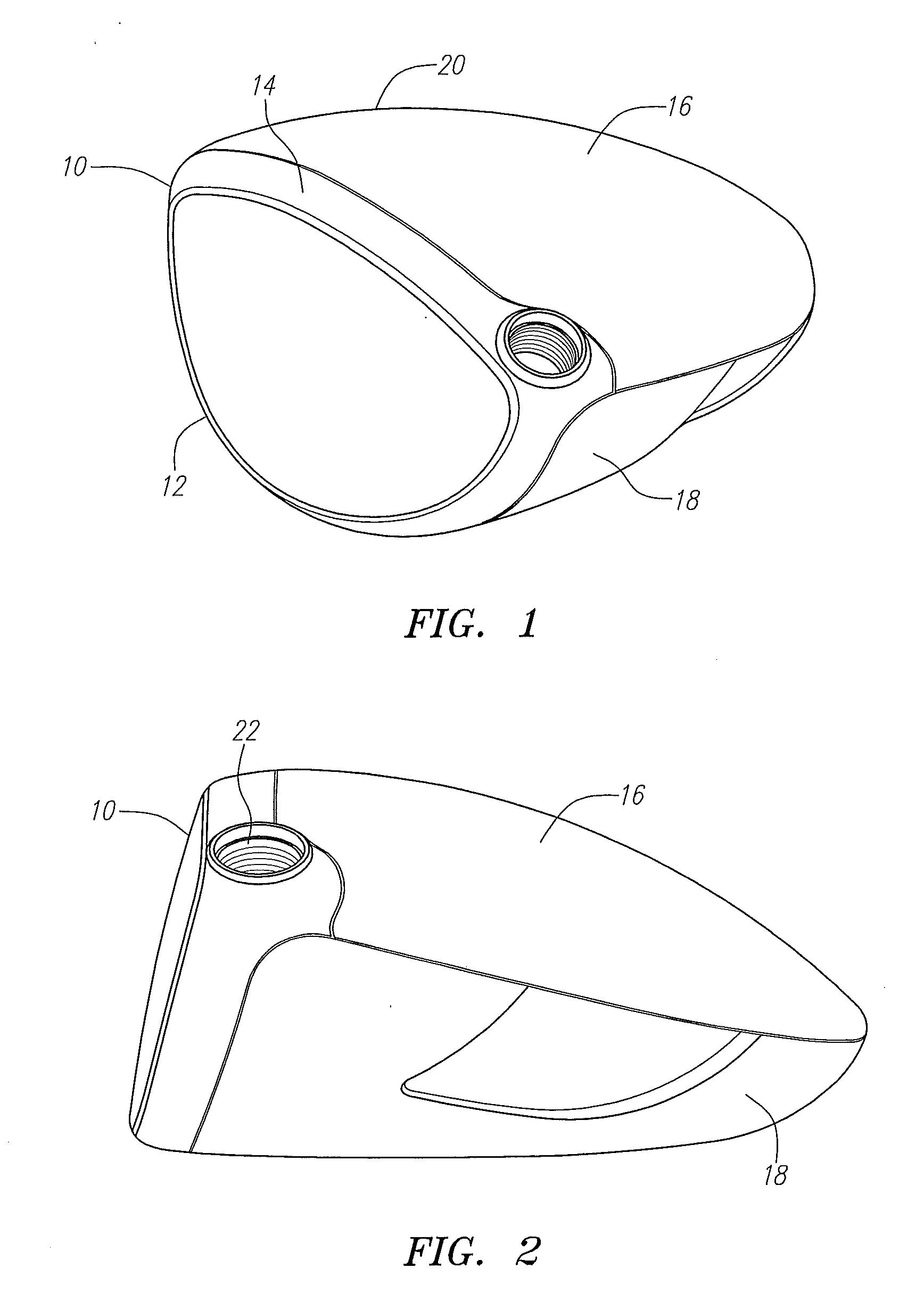

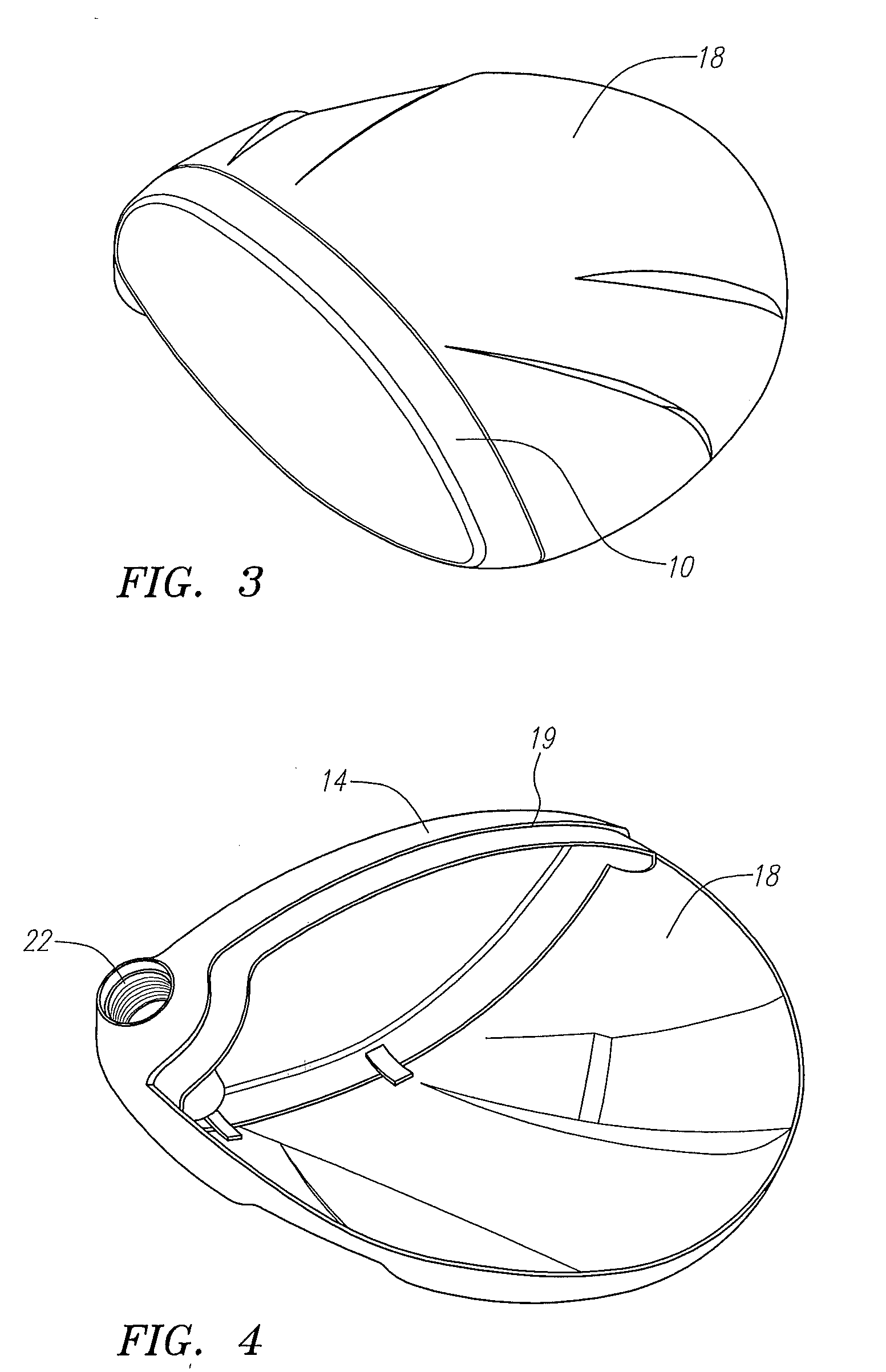

Multiple material golf club head and a method for forming a golf club head

ActiveUS20110065528A1Increase costNot to wasteMetal rolling stand detailsMetal working apparatusMetal sheetEngineering

A method for forming a golf club head having a volume of approximately 460 cubic centimeters, the method comprising the steps of casting a face component, attaching a bonding flange, stamping a metal sheet of titanium alloy to form a sole component, welding the sole component to the face component to create a golf club head subassembly having a weld line of approximately six inches and polishing the weld line.

Owner:CALLAWAY GOLF CO

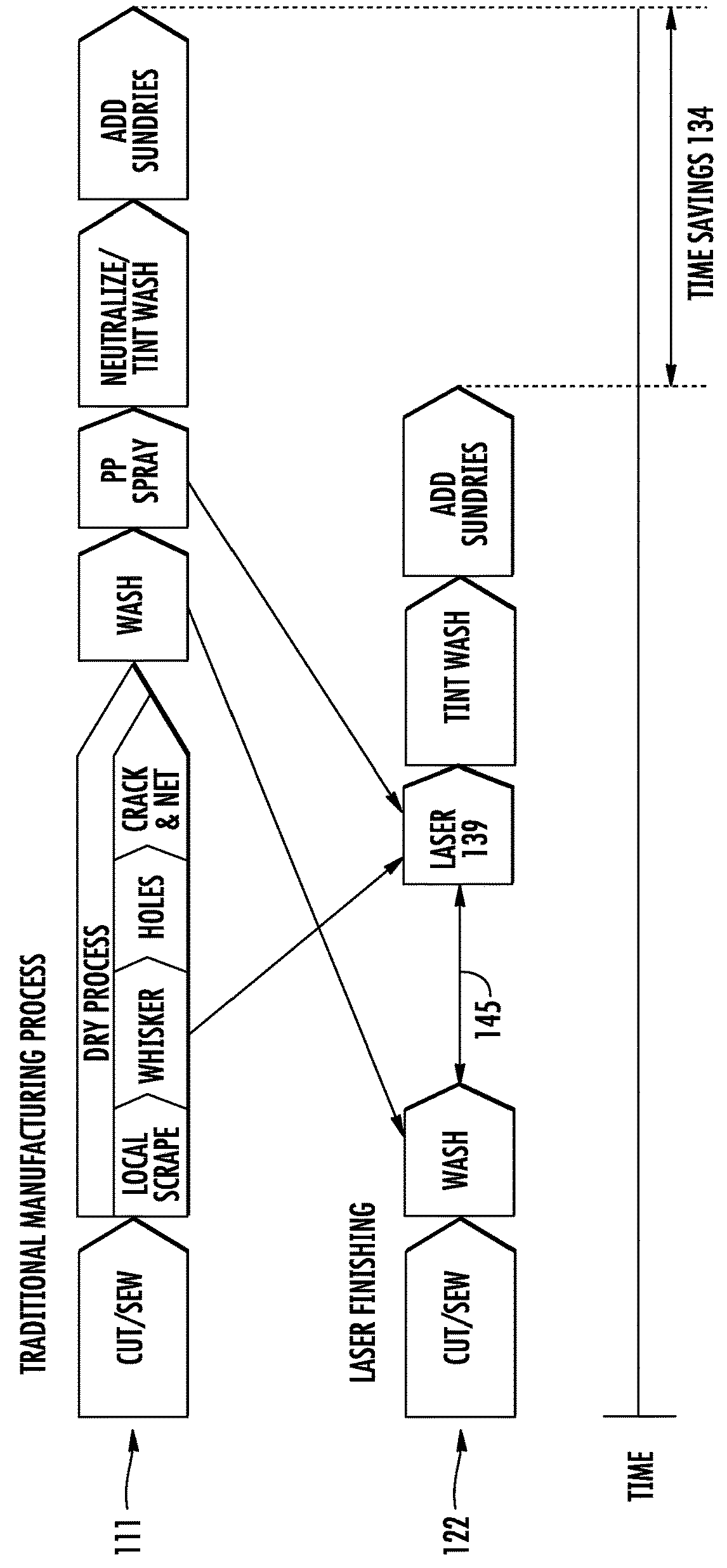

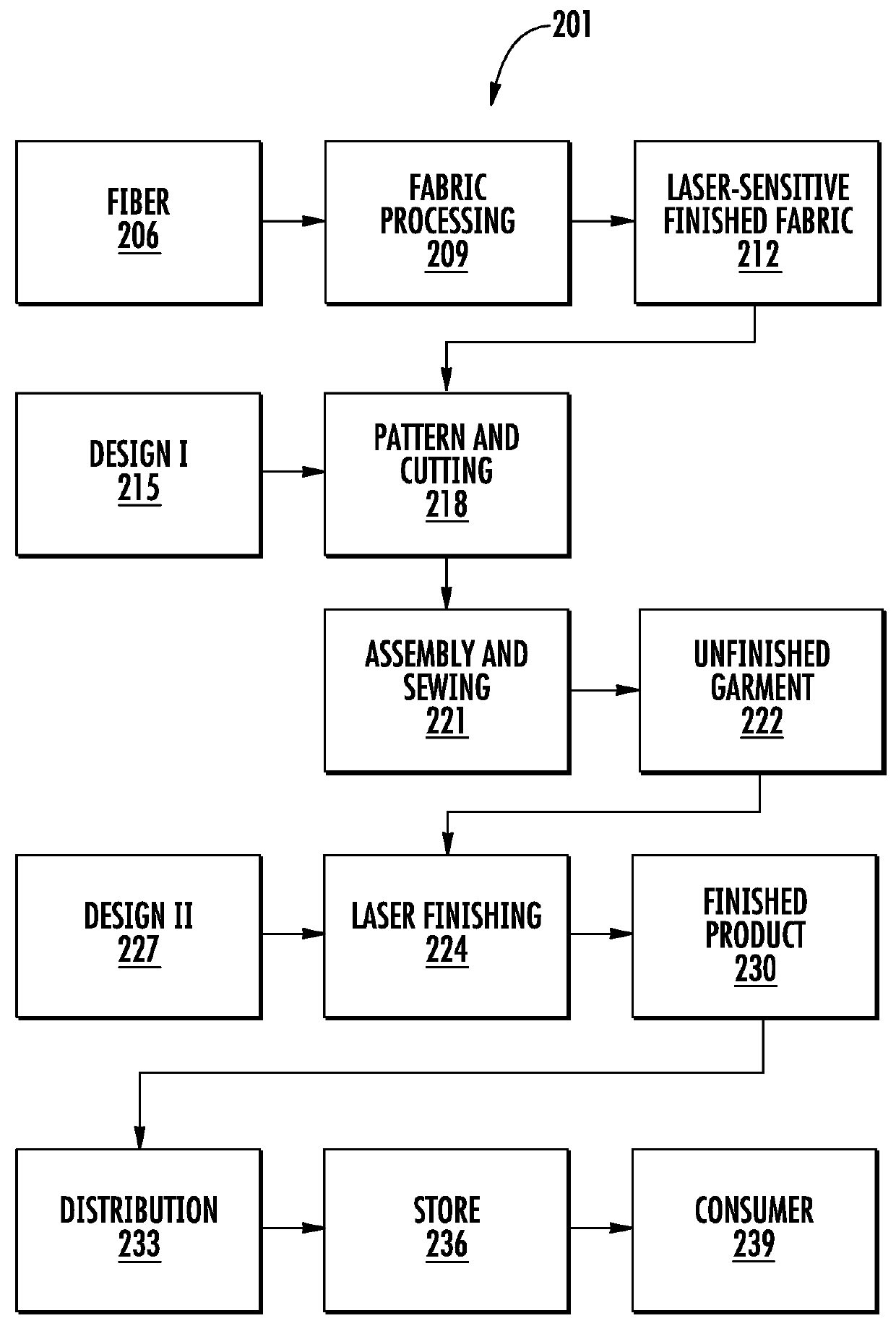

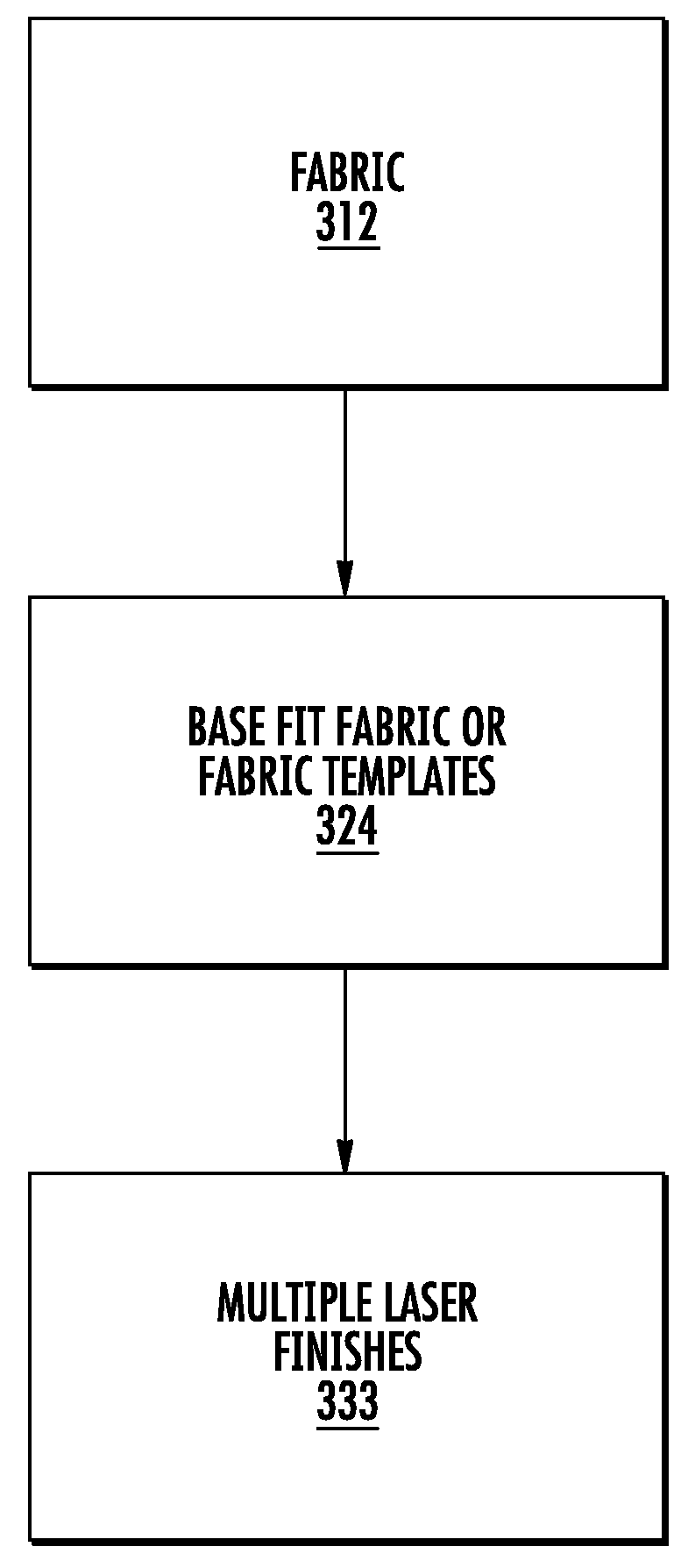

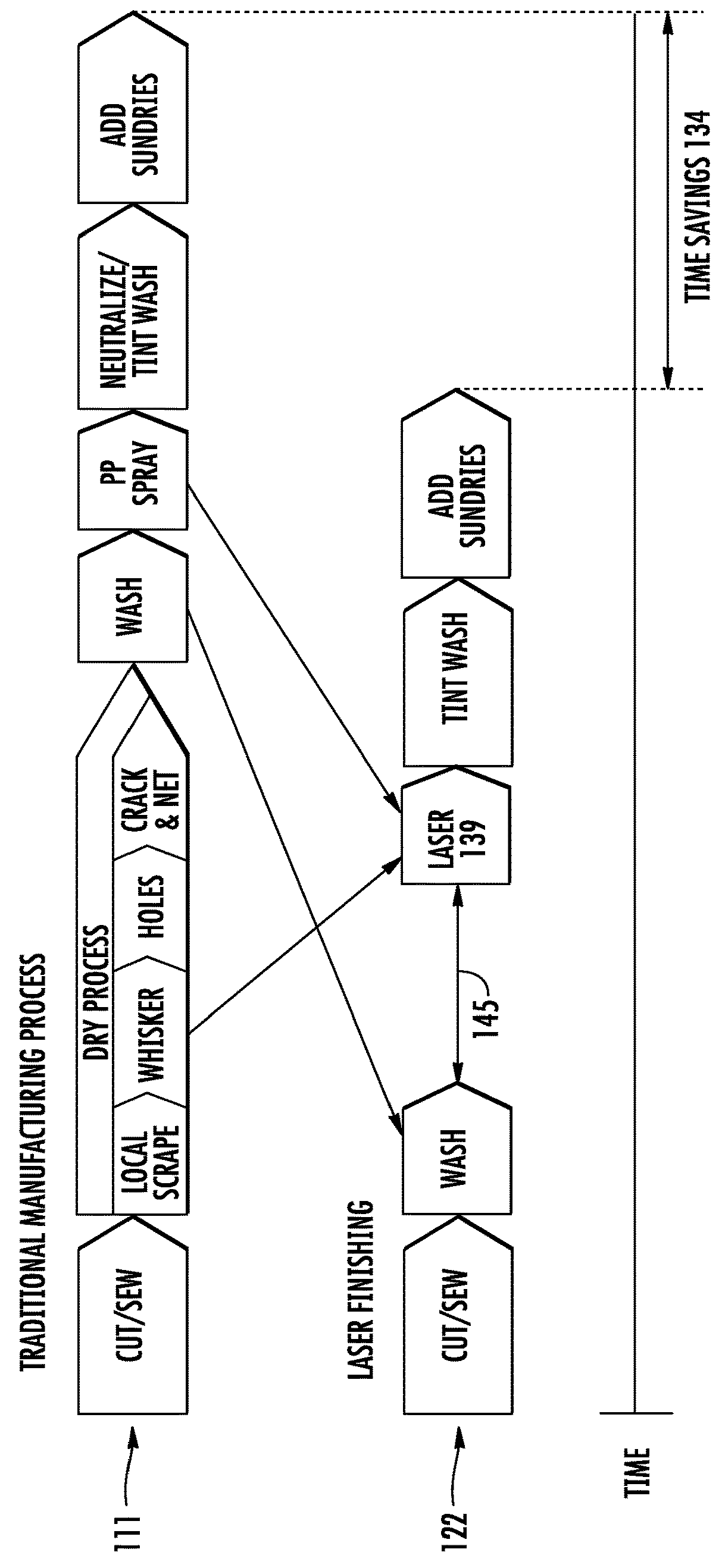

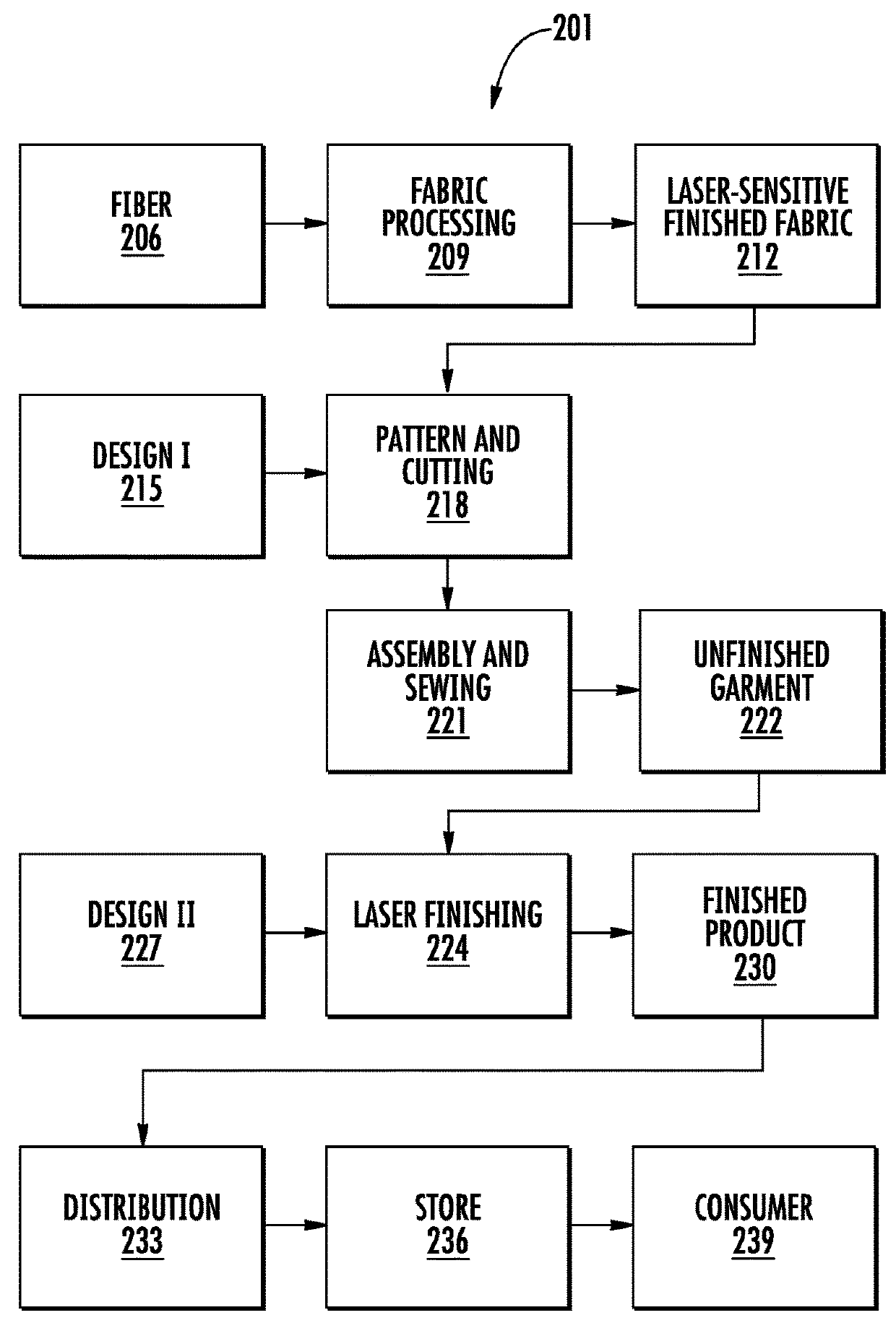

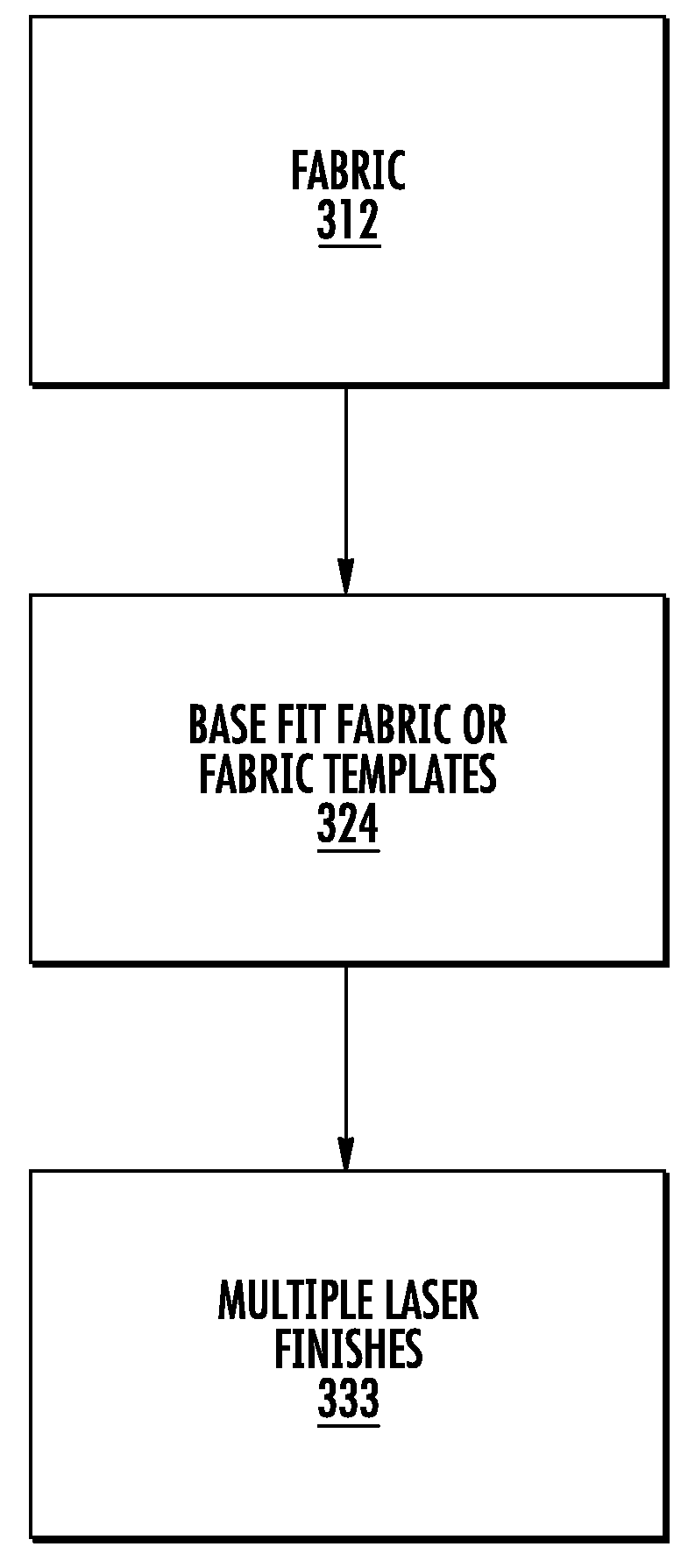

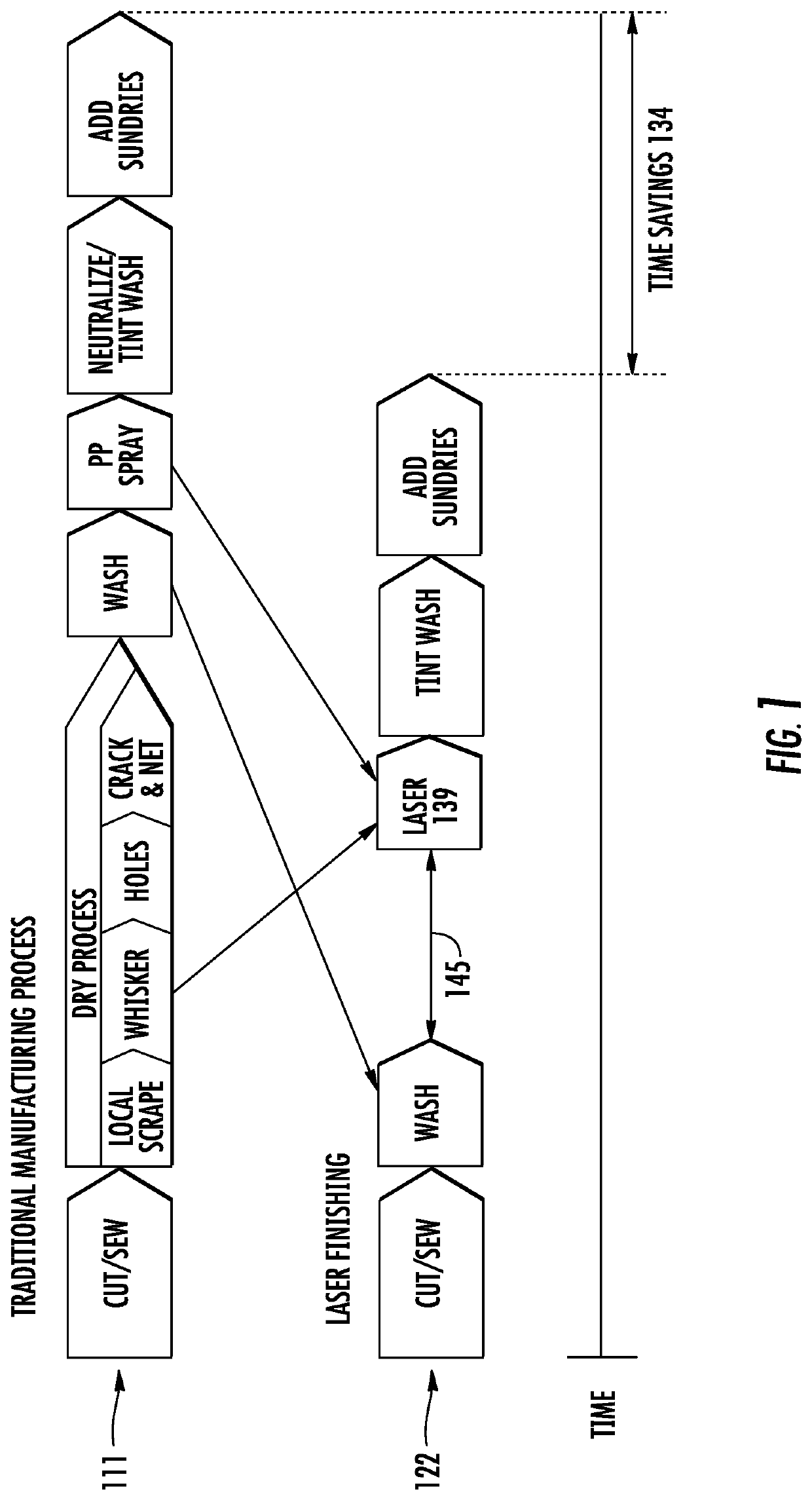

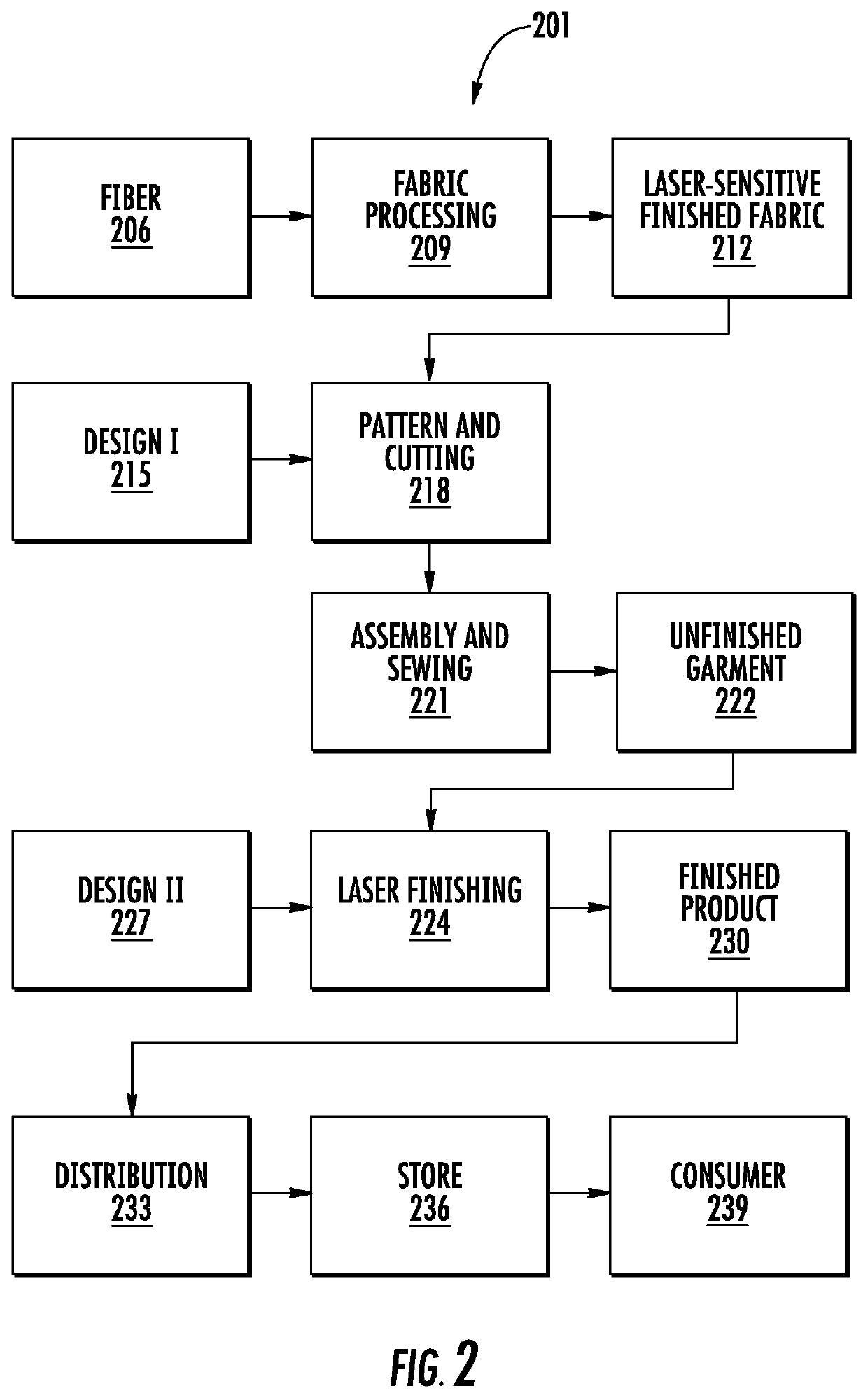

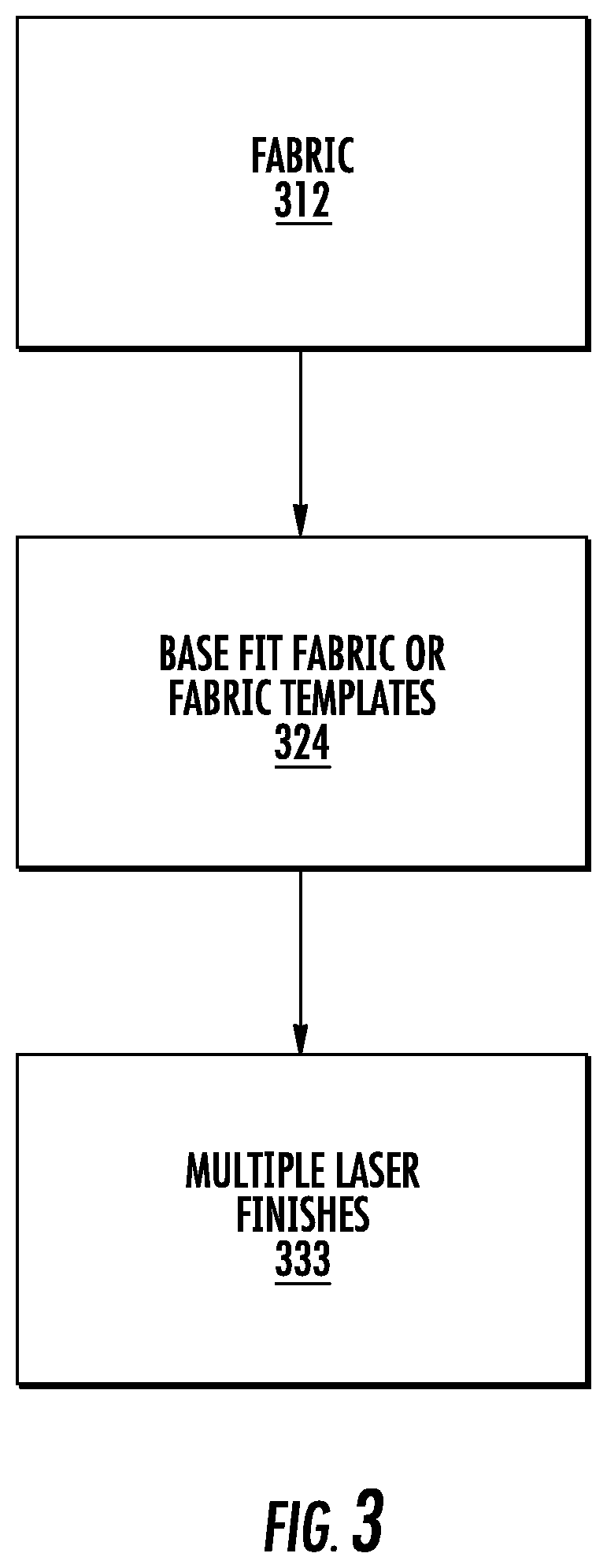

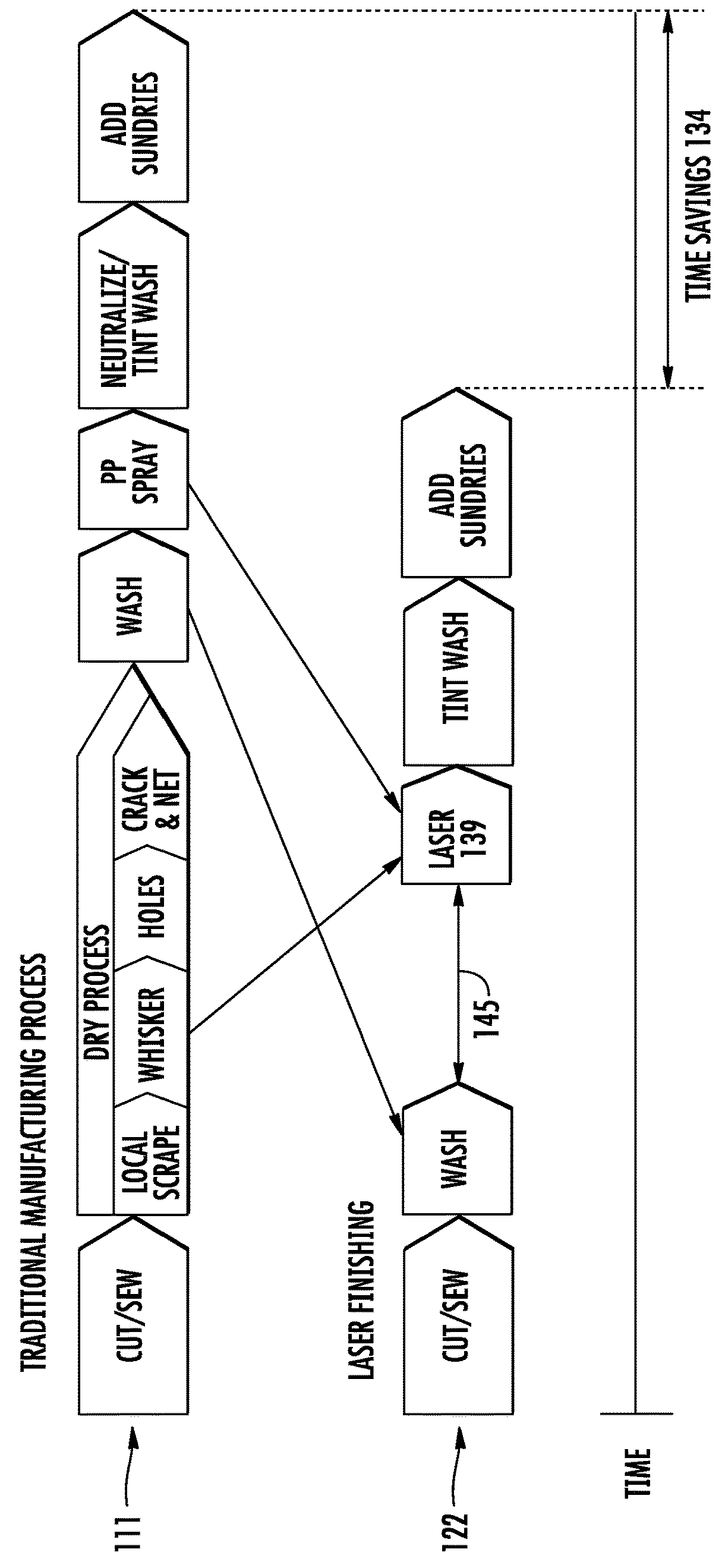

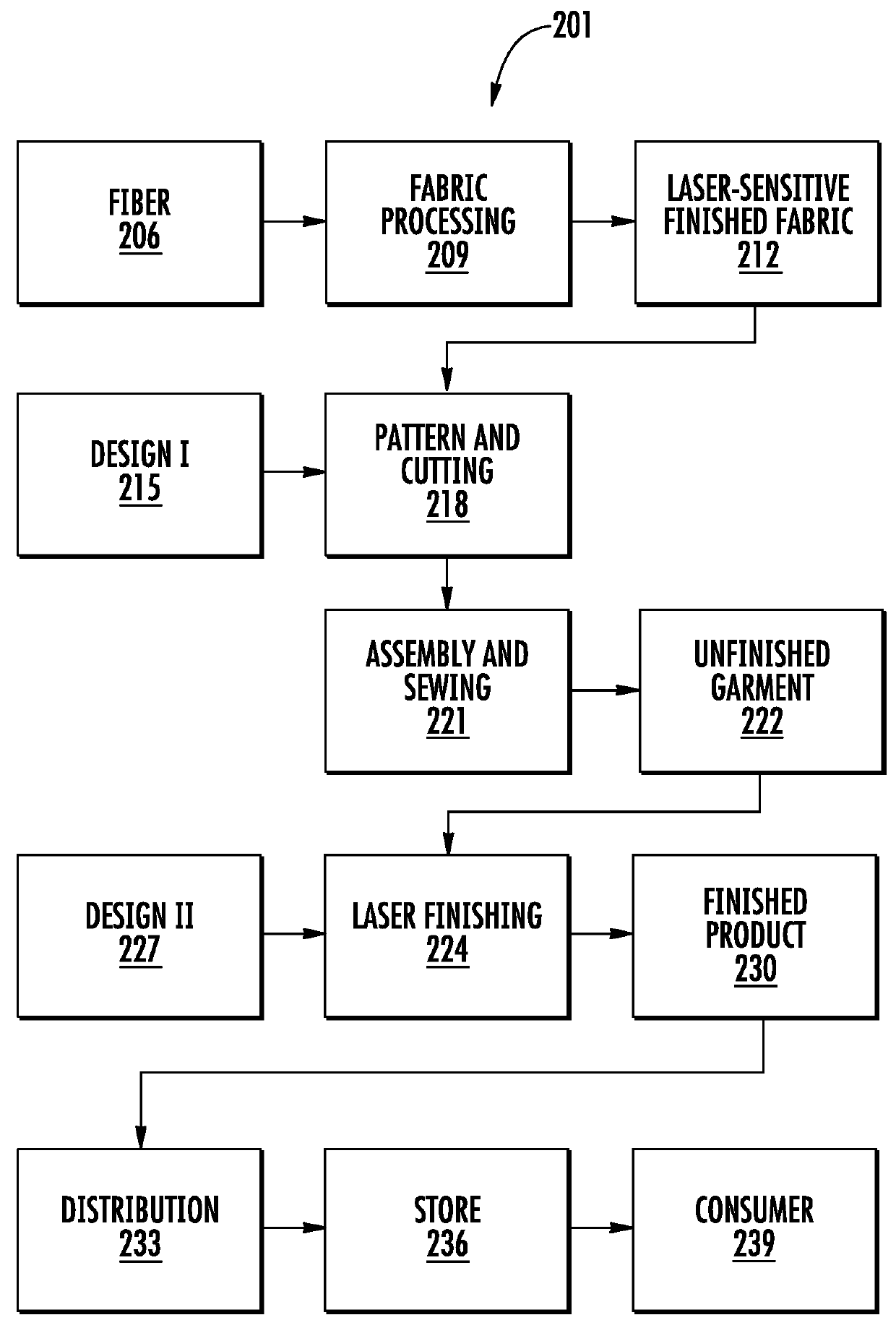

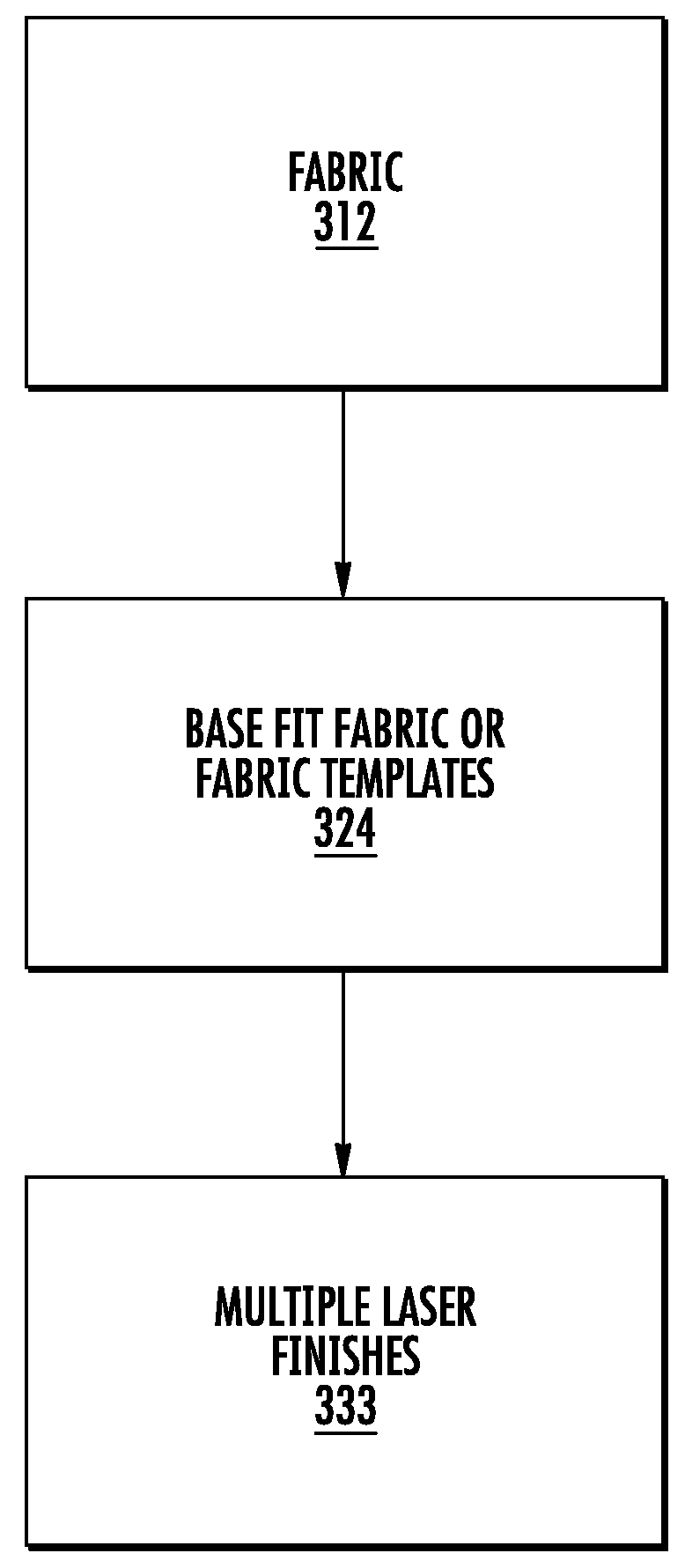

Using Fabric Templates to Obtain Multiple Finishes by Laser Finishing

ActiveUS20180165736A1Reduce finishing costsLow costPattern makingSewing apparatusLost salesTime to market

Laser finishing of apparel products allows an operating model that reduces finishing cost, lowers carrying costs, increases productivity, shortens time to market, be more reactive to trends, reduce product constraints, reduces lost sales and dilution, and more. Improved aspects include design, development, planning, merchandising, selling, making, and delivering. The model uses fabric templates, each of which can be used to produce a multitude of laser finishes. Operational efficiency is improved.

Owner:LEVI STRAUSS & CO

Multiple material golf club head and a method for forming a golf club head

ActiveUS8425349B2Reduce wasteSimilar performanceMetal rolling stand detailsMetal working apparatusEngineeringMetal sheet

A method for forming a golf club head having a volume of approximately 460 cubic centimeters, the method comprising the steps of casting a face component, attaching a bonding flange, stamping a metal sheet of titanium alloy to form a sole component, welding the sole component to the face component to create a golf club head subassembly having a weld line of approximately six inches and polishing the weld line.

Owner:TOPGOLF CALLAWAY BRANDS CORP

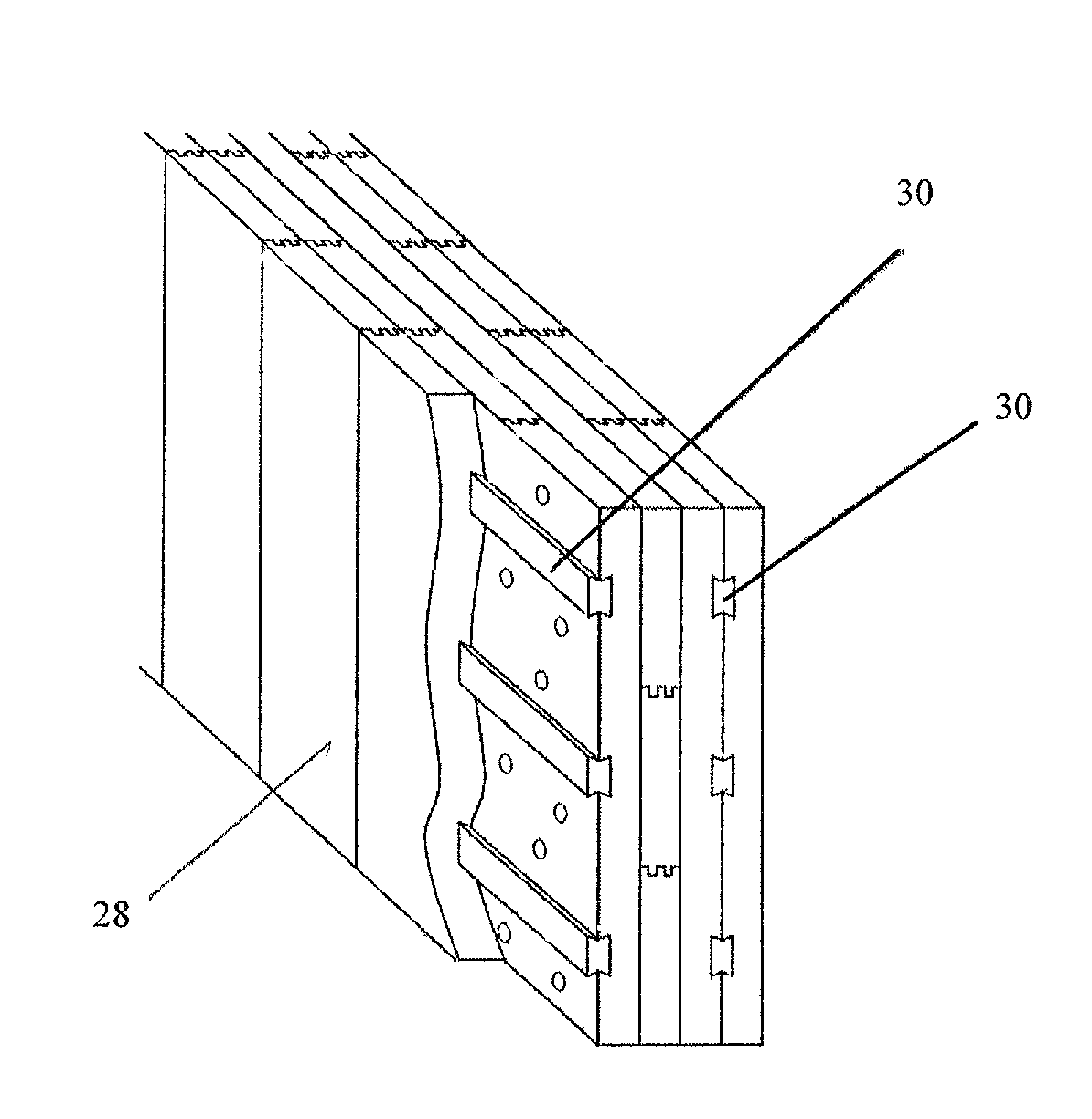

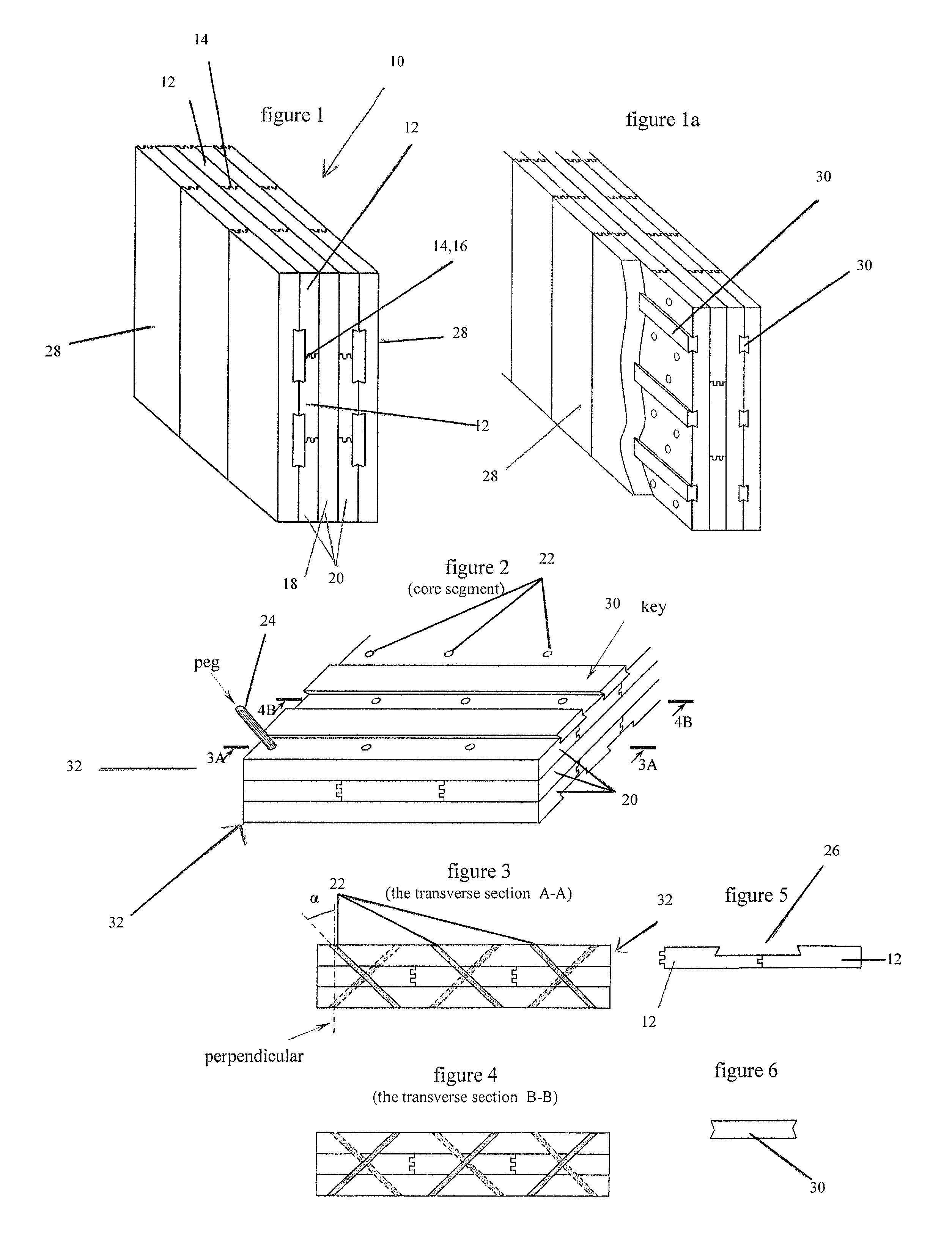

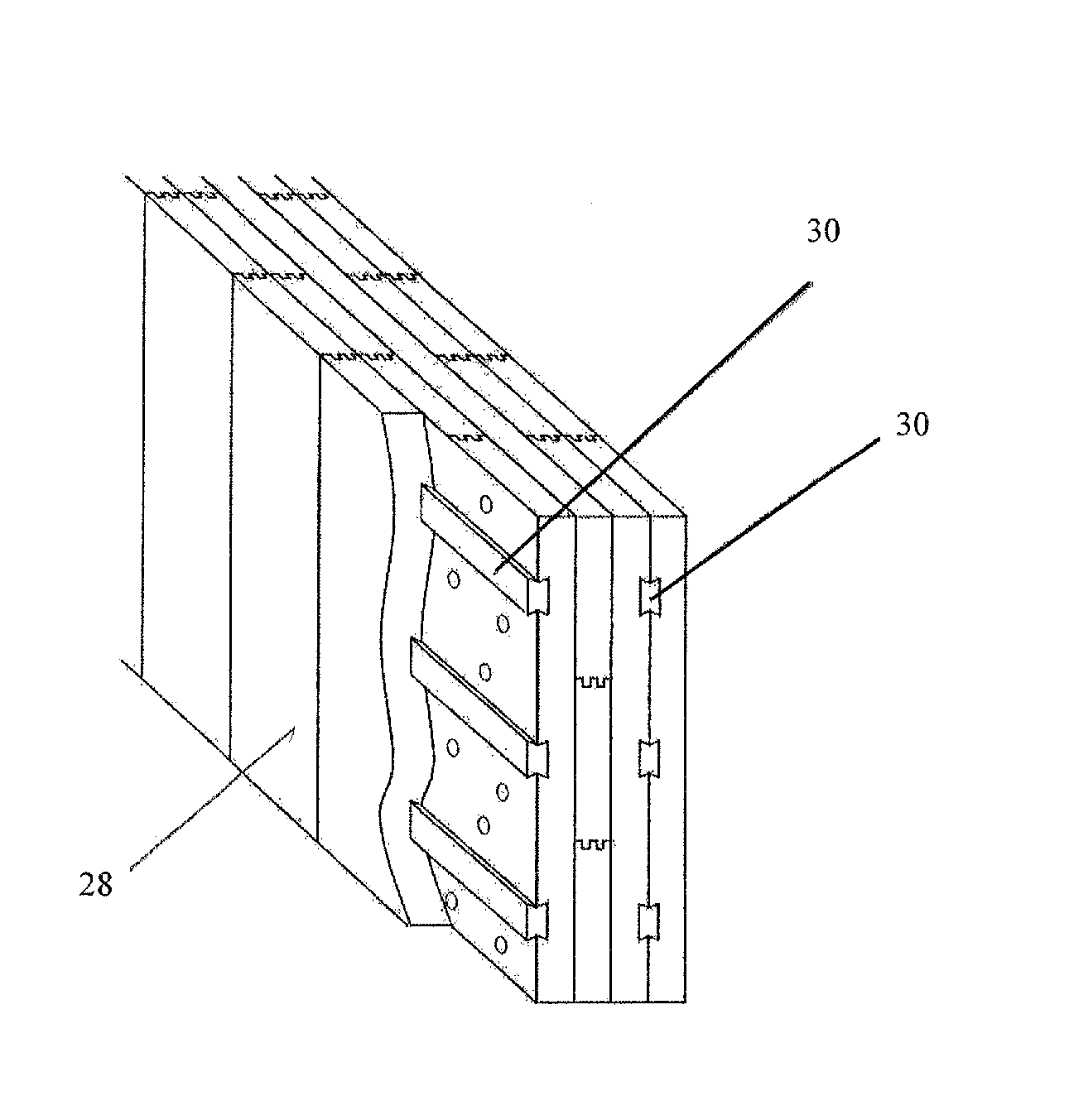

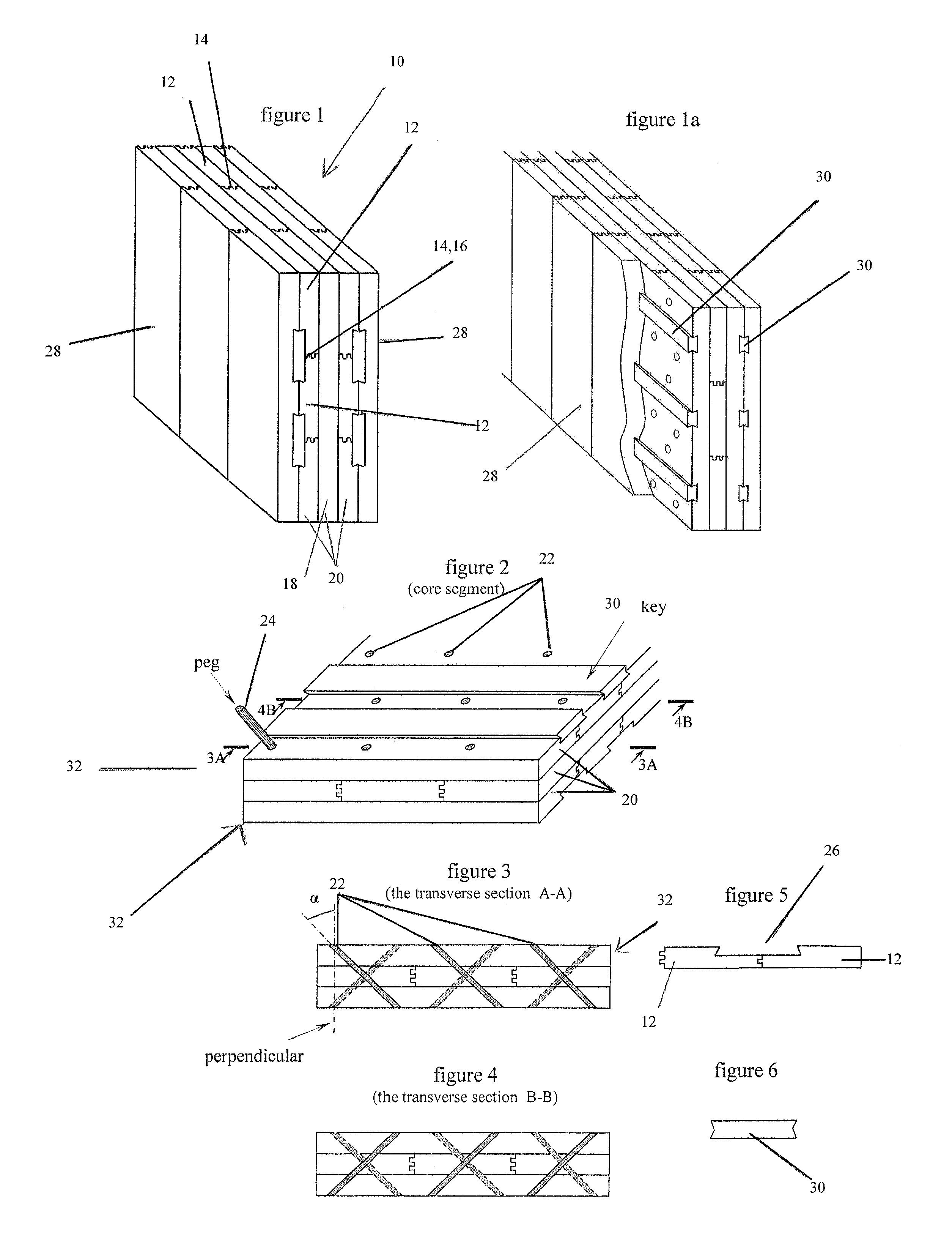

System and method for construction wall panels

InactiveUS8407965B2Low costReduce air permeabilityStapling toolsConstruction materialFiberTongue and groove

Owner:DOROZHKIN SERGEY EVGENYEVICH +1

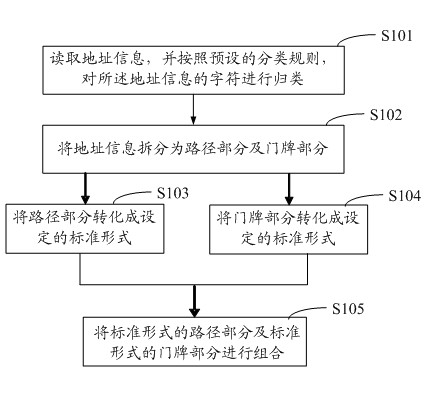

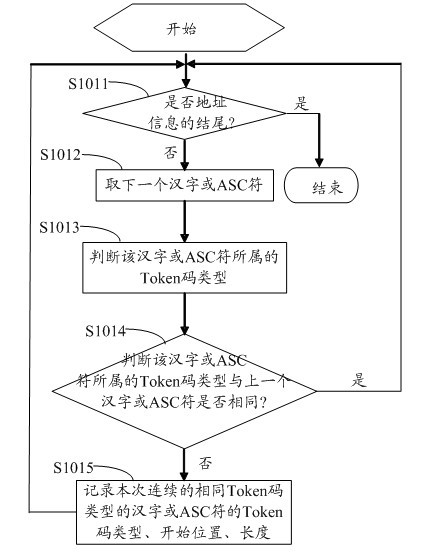

System and method for automatically identifying Chinese address subscribers

InactiveCN102073724AReduce address collation costsImprove finishing efficiencyCharacter and pattern recognitionSpecial data processing applicationsClassification ruleStandardization

The invention is applicable to the postal service field and provides a system and method for automatically identifying Chinese address subscribers. The method comprises the following steps: reading the address information and classifying the characters of the address information according to the preset classification rule; dividing the address information into a path part and a door plate part according to the classification; converting the path part into the set standard form; converting the door plate part into the set standard form; and combining the path part in the standard form with the door plate part in the standard form and outputting the combined parts. In the embodiment of the invention, the address information is classified and the door plate part and the path part are standardized, thus preventing manually classifying the address information which is nonstandard in writing, thereby reducing the address classifying cost and improving the classifying efficiency of the nonstandard address information.

Owner:SHENZHEN ROUTDATA TECH

Method for forming a multiple material golf club head

InactiveUS20100139079A1Additional costWaste of materialMetal rolling stand detailsMetal working apparatusEngineeringGolf club

Owner:CALLAWAY GOLF CO

Custom Apparel Products by Using Fabric Templates and Laser Finishing

ActiveUS20180165737A1Reduce finishing costsLower carrying costPattern makingSewing apparatusOperating modelEngineering

Laser finishing of apparel products allows an operating model that reduces finishing cost, lowers carrying costs, increases productivity, shortens time to market, be more reactive to trends, reduce product constraints, reduces lost sales and dilution, and more. Improved aspects include design, development, planning, merchandising, selling, making, and delivering. The model uses fabric templates, each of which can be used to produce a multitude of laser finishes. Operational efficiency is improved.

Owner:LEVI STRAUSS & CO

Multiple material driver-type golf club head

A driver-type golf club head having a composite crown is disclosed herein. The driver-type golf club head includes a subassembly including a cast face component and a stamped sole component, and a compression molded crown component which is bonded to the subassembly. Each of the subassembly and the crown component has a non-overlapping bonding flange that bonds with an interior surface.

Owner:TOPGOLF CALLAWAY BRANDS CORP

System and method for construction wall panels

InactiveUS20110099935A1Reduce air permeabilityReduce the possibilityStapling toolsConstruction materialFiberTongue and groove

A multi-layer wood panel comprises a core segment, made up of a plurality of layers, and two external finishing layers. Each layer is comprised of several boards, joined at the edges with interlocking fingers or tongues and grooves. The layers of the core segment are joined using wood pegs at specified intervals, with the pegs penetrating all the board layers of the core segment at an angle other than perpendicular to the layers. The core segment and the external finishing layers of the panel are joined using key and groove mortise connections, where the key shape corresponds to the shape of the mortise grooves made in the outer surfaces of the boards of the core segment and in the inner surfaces of the outer finishing layer, which are oriented perpendicular or parallel to the direction of the board fibers.

Owner:DOROZHKIN SERGEY EVGENYEVICH +1

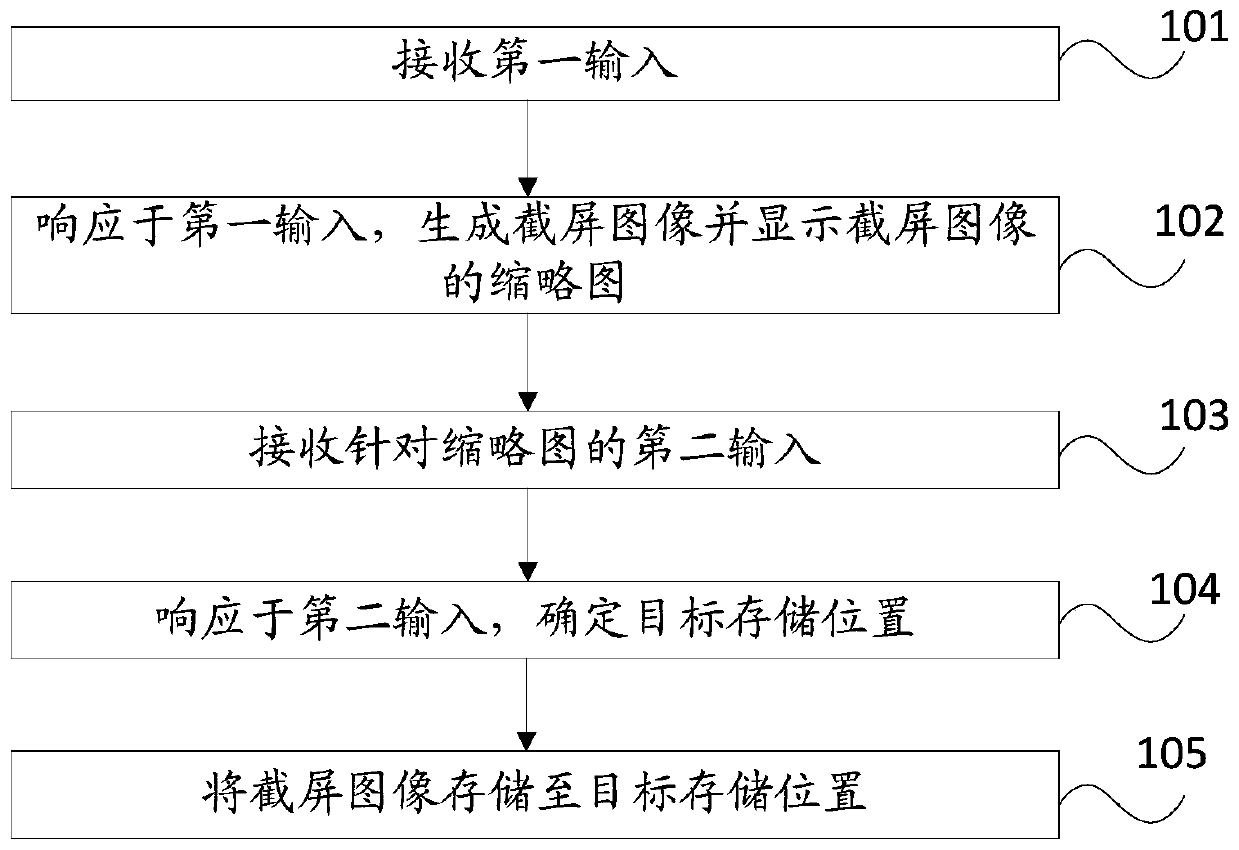

Image storage method and terminal device

ActiveCN109814786AOrderly storageQuick Classification StorageStill image data indexingSpecial data processing applicationsThumbnailTerminal equipment

The invention provides an image storage method and a terminal device. The image storage method comprises the following steps of receiving a first input; in response to the first input, generating a screenshot image and displaying a thumbnail of the screenshot image; receiving a second input for the thumbnail; in response to the second input, determining a target storage position; and storing the screenshot image to a target storage position. According to the image storage method provided by the embodiment of the invention, the function of quickly classifying and storing the screenshot image can be realized, the screenshot image can be orderly stored according to the operation of a user, the arrangement efficiency of the screenshot image is improved, the arrangement cost is saved, and meanwhile, diversified storage modes can be provided for the screenshot image.

Owner:VIVO MOBILE COMM CO LTD

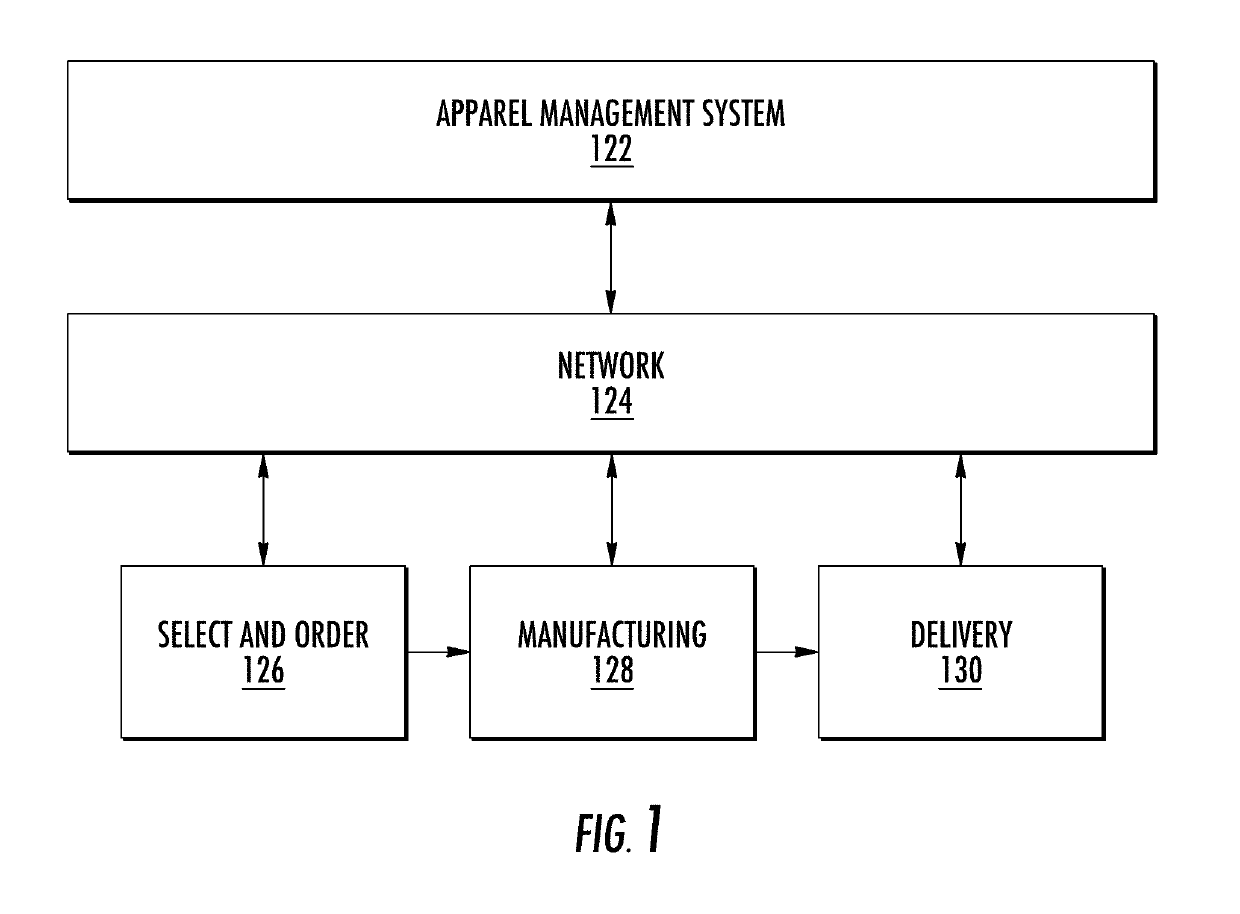

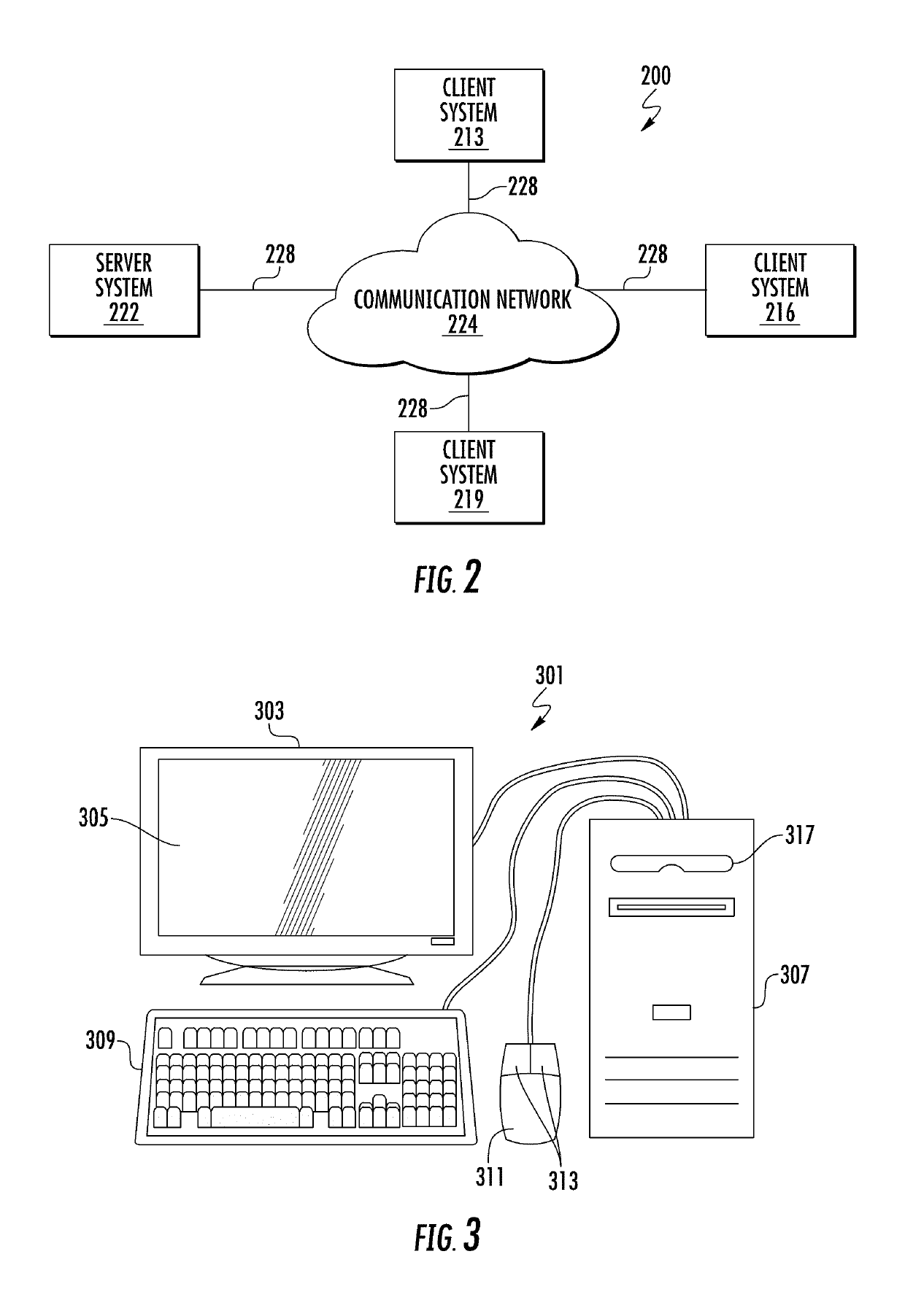

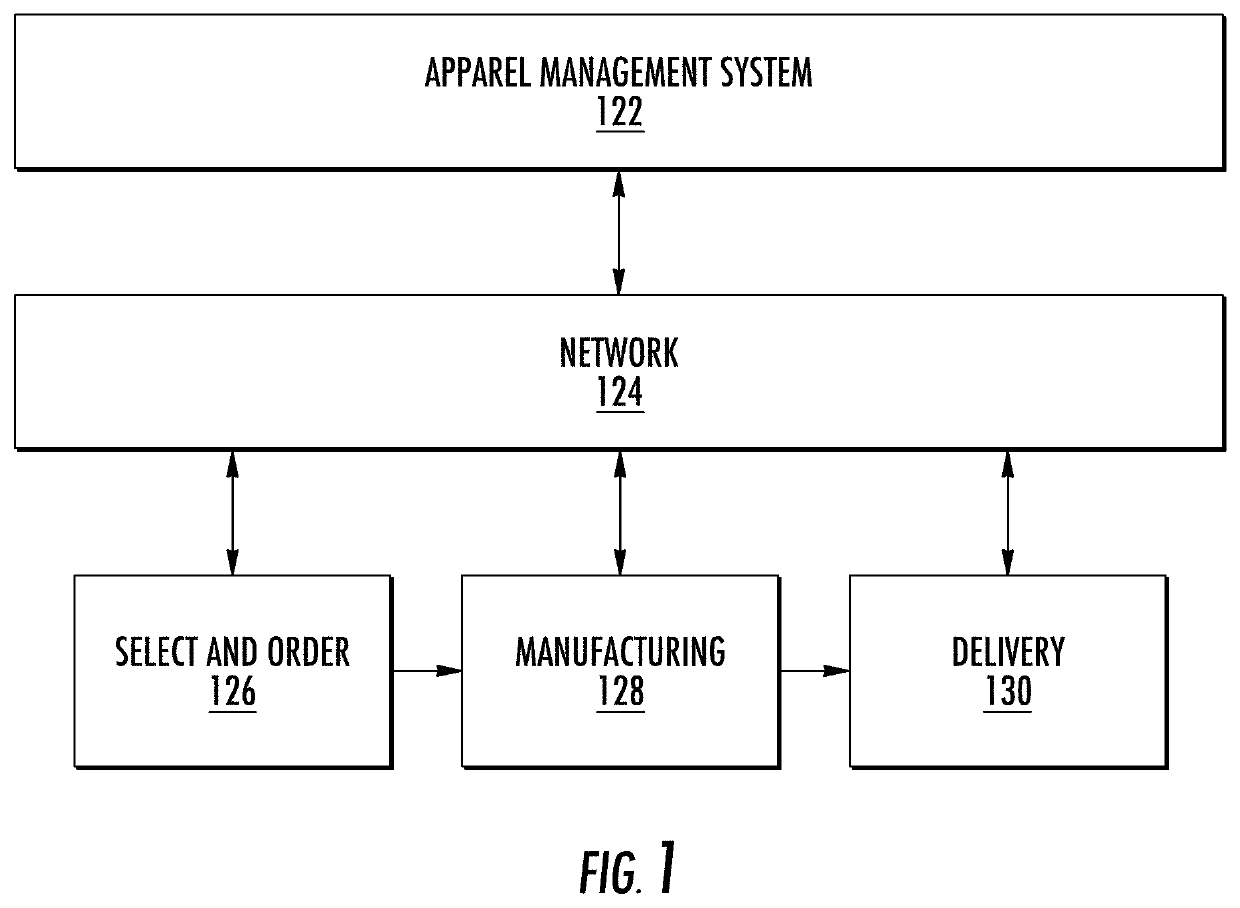

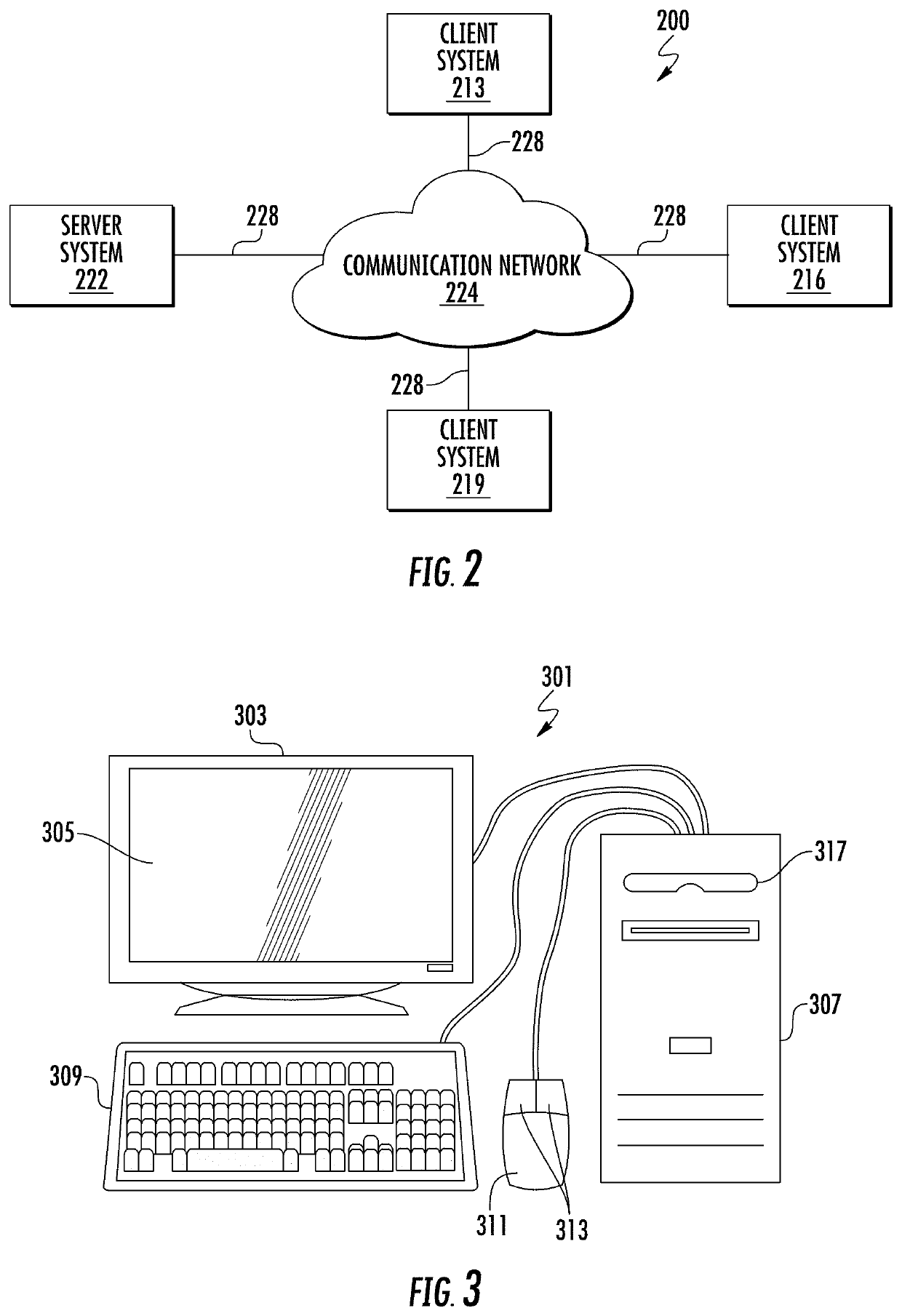

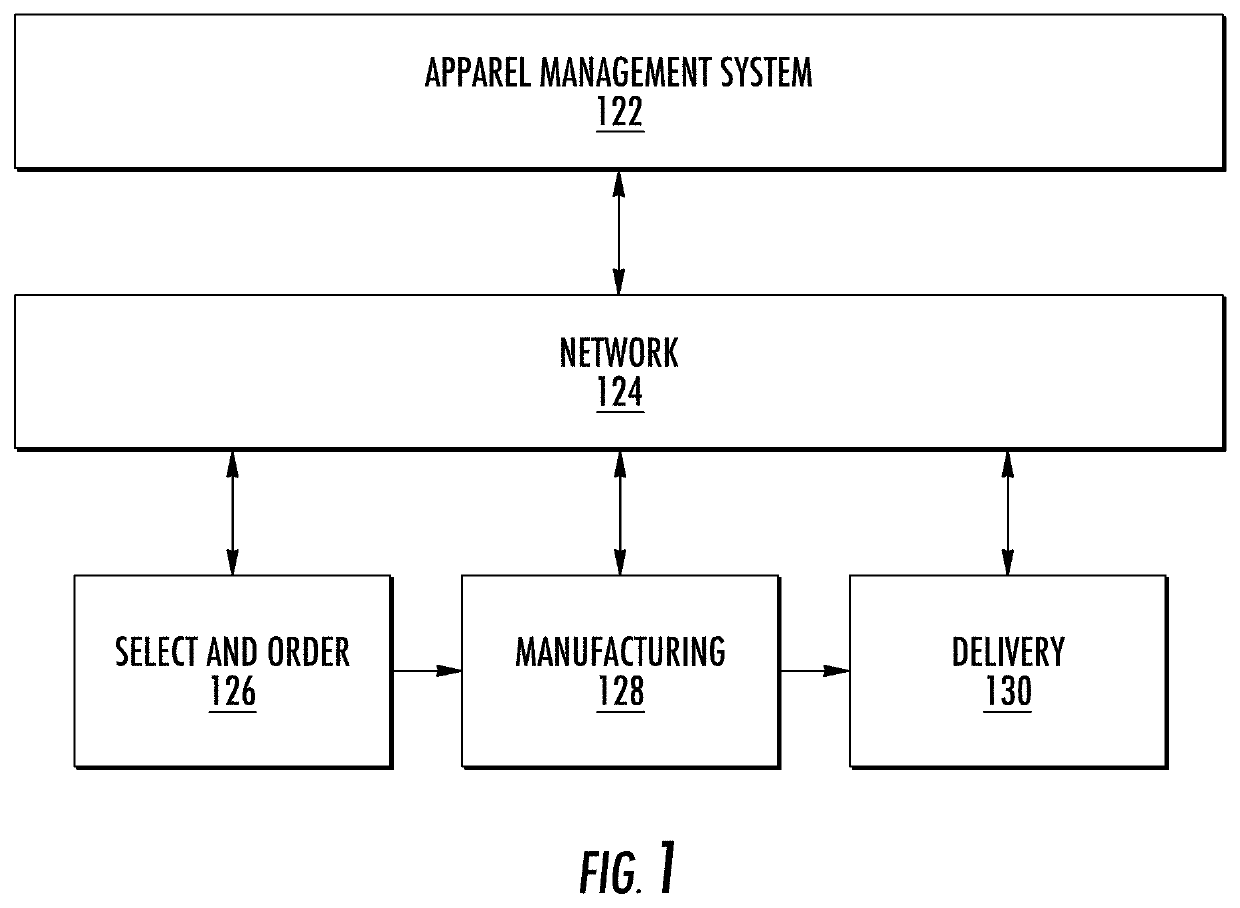

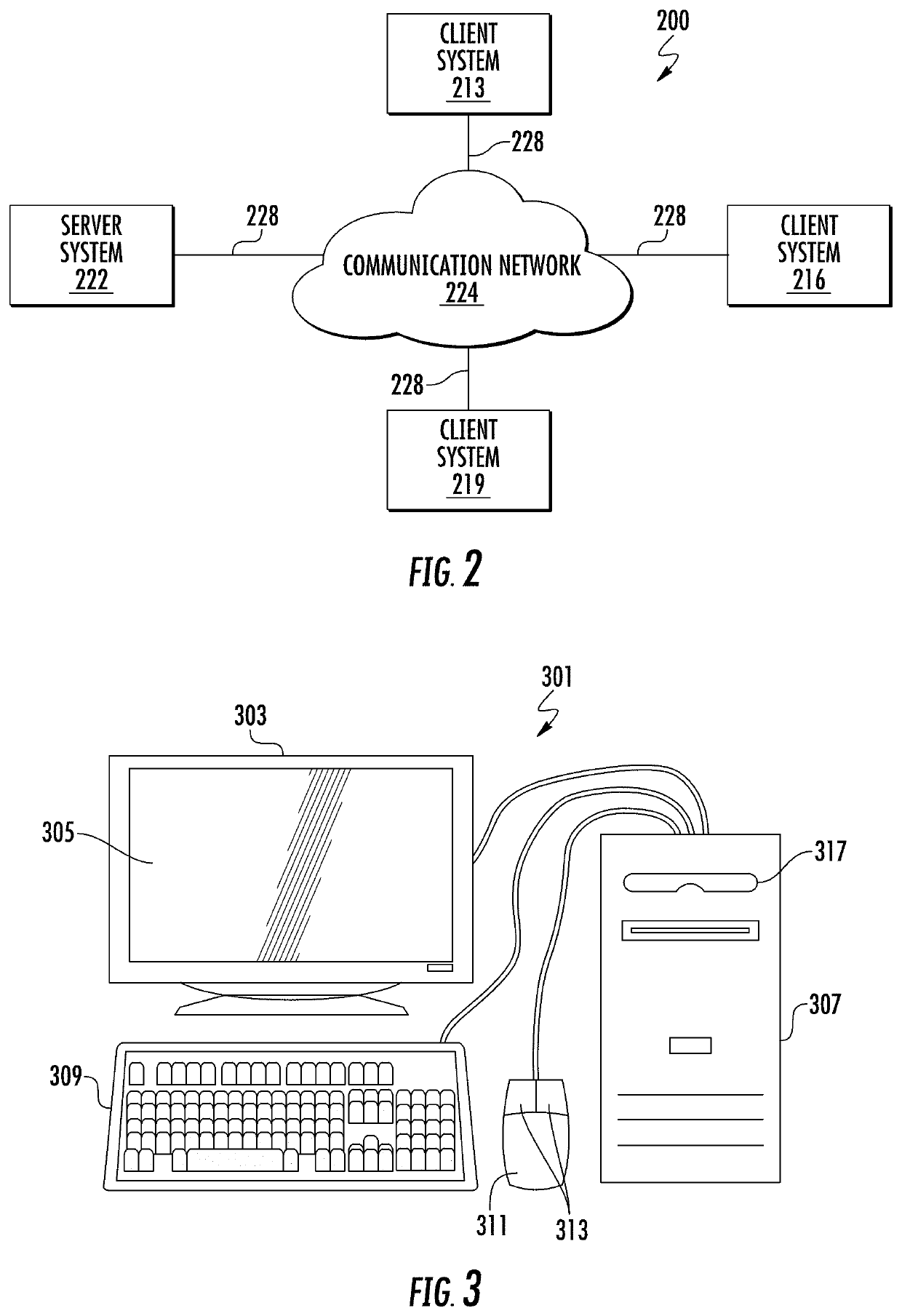

On-Demand Manufacturing of Laser-Finished Apparel

ActiveUS20190264380A1Reduce finishing costsLower carrying costPattern makingLaser beam fibre treatmentLost salesProduction rate

An on-demand manufacturing of apparel system includes online customization and ordering of garments, previewing of the garments, manufacturing including laser finishing of garments, and delivery to the customer. Laser finishing of apparel products reduces finishing cost, lowers carrying costs, increases productivity, shortens time to market, be more reactive to trends, reduces product constraints, reduces lost sales and dilution, and more. Fabric templates can be used to produce a multitude of laser finishes. Operational efficiency is improved.

Owner:LEVI STRAUSS & CO

Custom apparel products by using fabric templates and laser finishing

ActiveUS11241055B2Reduce finishing costsLow costPattern makingSewing apparatusLaser processingProcess engineering

Laser finishing of apparel products allows an operating model that reduces finishing cost, lowers carrying costs, increases productivity, shortens time to market, be more reactive to trends, reduce product constraints, reduces lost sales and dilution, and more. Improved aspects include design, development, planning, merchandising, selling, making, and delivering. The model uses fabric templates, each of which can be used to produce a multitude of laser finishes. Operational efficiency is improved.

Owner:LEVI STRAUSS & CO

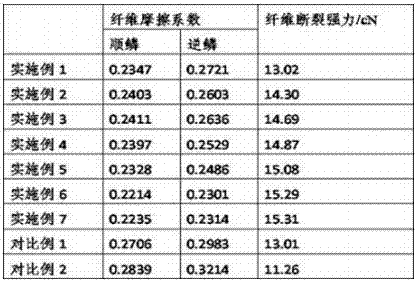

Anti-pilling air layer fabric with wool surface

ActiveCN105544196AReduce directional friction effectImprove smoothnessAbrasion resistant fibresAnimal fibresBiocompatibility TestingEngineering

The invention discloses an anti-pilling air layer fabric with a wool surface. The air layer fabric is formed by sewing or bonding and laminating a wool fabric and air layer auxiliary materials, wherein the wool fabric is subjected to anti-pilling treatment. The anti-pilling treatment comprises the following steps: preparing a first finishing liquid and a second finishing liquid; finishing the first finishing liquid; finishing the second finishing liquid; cleaning and drying the finishing liquids; and the like. Sulfydryl in a keratin molecule is combined with the sulfydryl on the wool surface; the bulges of scales are filled; and a finished protective film is formed on the surfaces of wool fibers through finishing of an ethanediamine-modified polylactic acid in the second finishing liquid, so that the friction coefficients of the fiber surfaces are reduced, and the strength of the wool fibers can also be increased. The film-forming materials of the first finishing liquid and the second finishing liquid are good in biocompatibility; the anti-pilling effect of the fabric prepared by lamination of the wool fabric reaches the second level; the warming effect can be increased when the fabric is combined to the air layer fabric; and the fabric is high in vertical sense and relatively excellent in wearing comfort.

Owner:阜南华翔羊毛衫有限公司

On-demand manufacturing of laser-finished apparel

ActiveUS11313072B2Reduce finishing costsLow costPattern makingLaser beam fibre treatmentLaser processingManufacturing systems

Owner:LEVI STRAUSS & CO

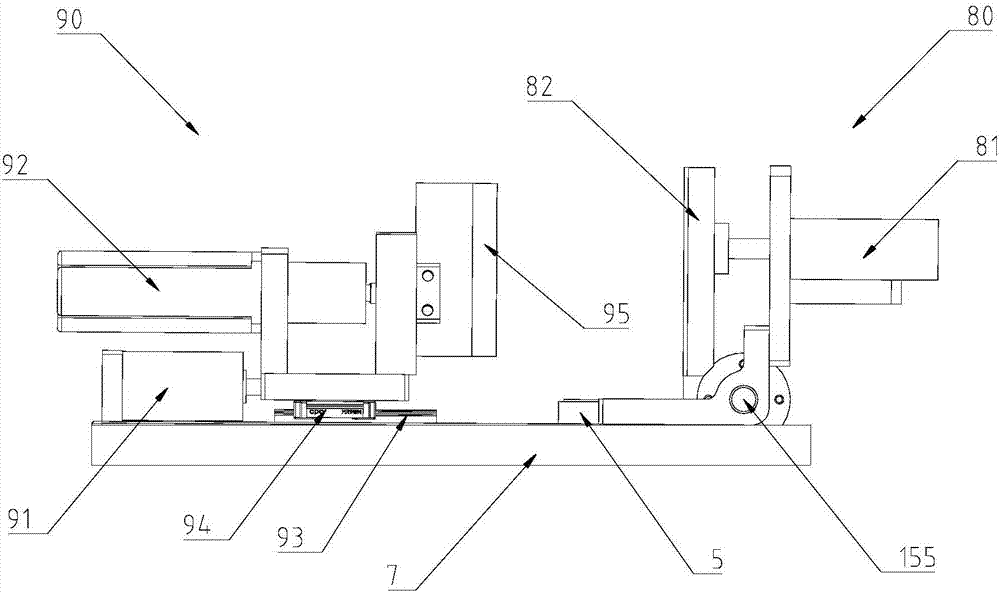

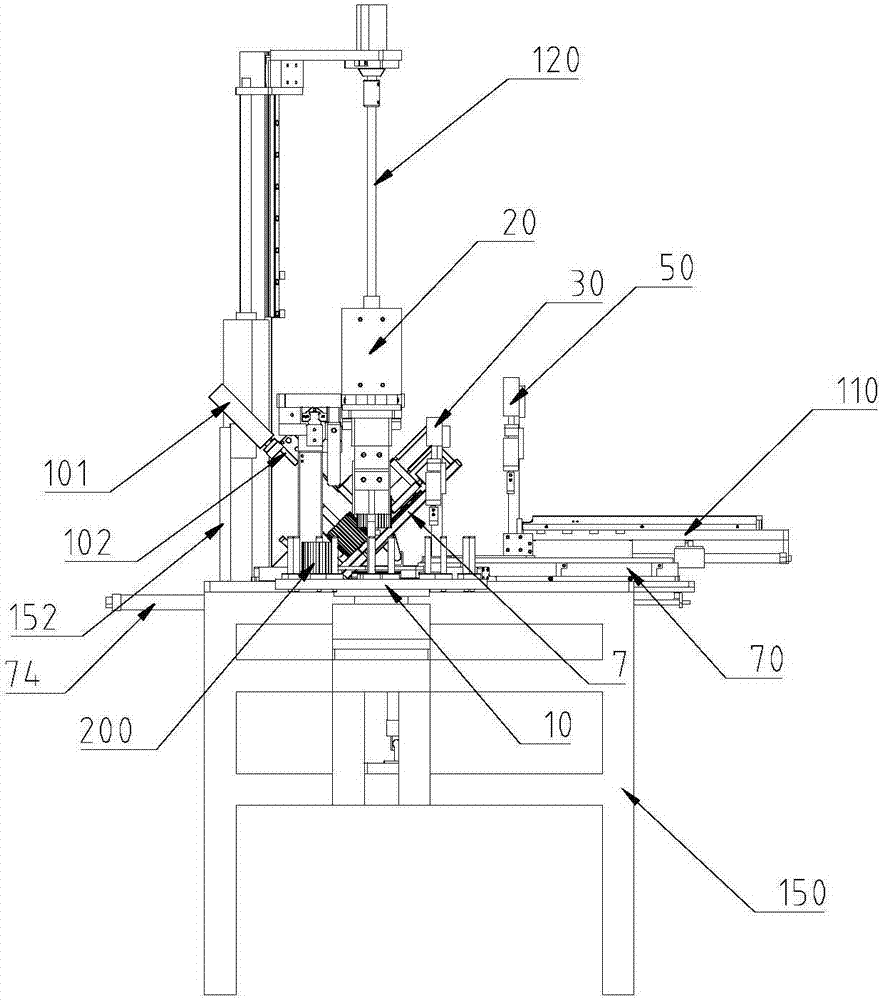

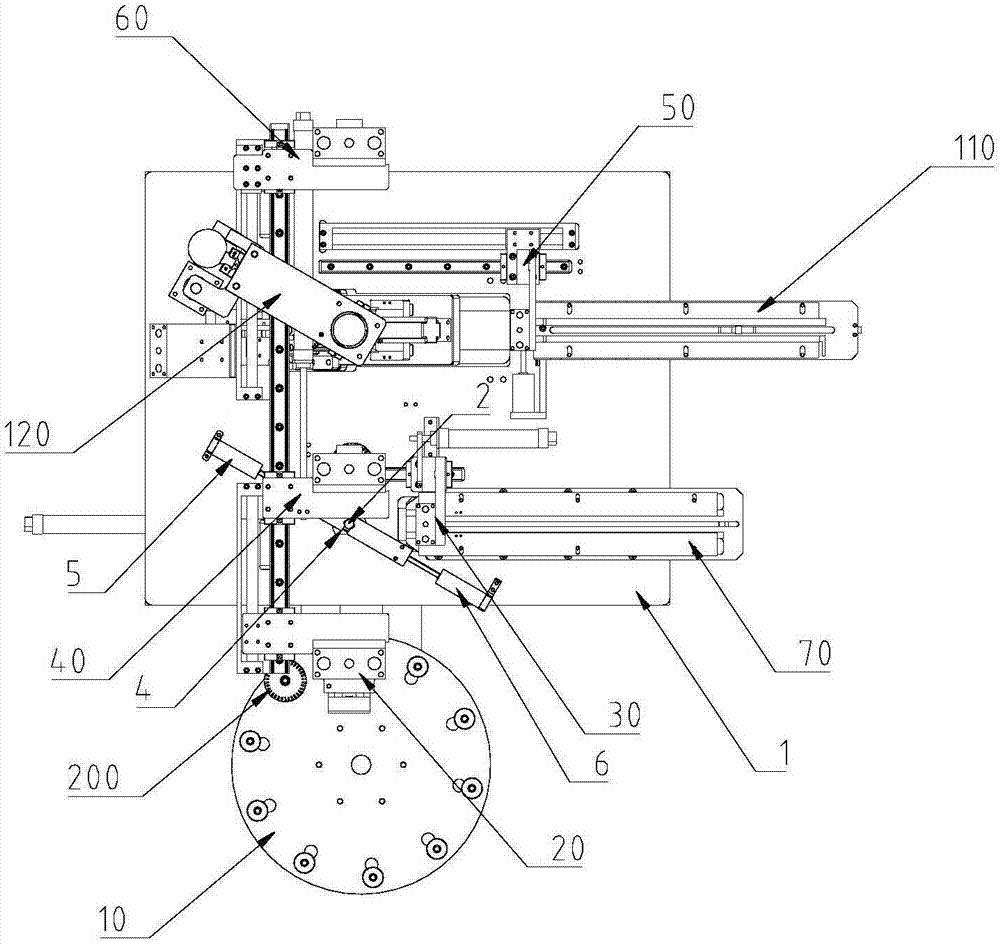

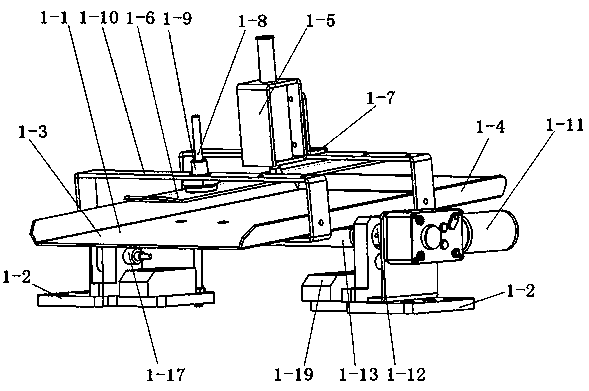

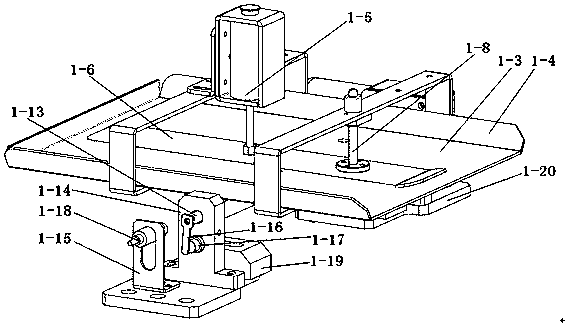

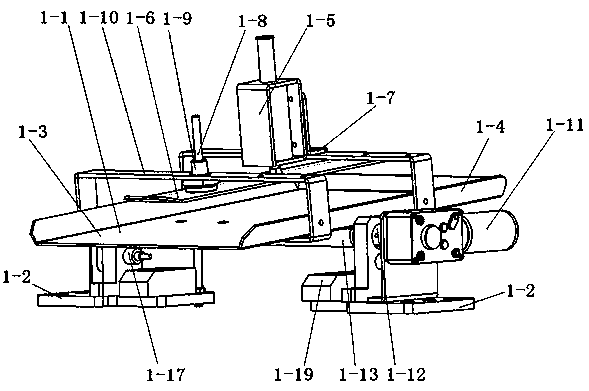

Motor rotor punching sheet finishing machine

InactiveCN107017739AImprove finishing efficiencyReduce finishing costsManufacturing stator/rotor bodiesPunchingEngineering

The invention discloses a motor rotor punching sheet finishing machine, which comprises a rack, a punching sheet placement disk, a punching sheet group sleeving screw device, a punching sheet finishing device and a nut screwing device, and is characterized in that the punching sheet group sleeving screw device sleeves a well laminated punching sheet group on the punching sheet placement disk on a screw, the punching sheet finishing device aligns wire slots of all punching sheets sleeved on the screw so as to form a groove for aluminum casting, the nut screwing device sleeves a nut on the screw and screws up. The motor rotor punching sheet finishing machine can automatically align the wire slots of the motor core punching sheet group, and can improve the finishing efficiency and reduce the finishing cost of the punching sheets.

Owner:SHENZHEN UNIV

Multiple Apparel Products by Using Fabric Templates and Laser Finishing

ActiveUS20180160757A1Reduce finishing costsLow costPattern makingSewing apparatusTime to marketLost sales

Laser finishing of apparel products allows an operating model that reduces finishing cost, lowers carrying costs, increases productivity, shortens time to market, be more reactive to trends, reduce product constraints, reduces lost sales and dilution, and more. Improved aspects include design, development, planning, merchandising, selling, making, and delivering. The model uses fabric templates, each of which can be used to produce a multitude of laser finishes. Operational efficiency is improved.

Owner:LEVI STRAUSS & CO

Sulfuric acid dew point corrosion resisting steel capable of avoiding surface cracks and rolling technology of sulfuric acid dew point corrosion resisting steel capable of avoiding surface cracks

ActiveCN110983206ASimplify the finishing processReduce consumptionTemperature control deviceWork treatment devicesCrazingHeating furnace

The invention provides a sulfuric acid dew point corrosion resisting steel capable of avoiding surface cracks and a rolling technology of the sulfuric acid dew point corrosion resisting steel capableof avoiding the surface cracks. Compared with the prior art, according to the steel and the rolling technology thereof, a steel billet is heated in a heating furnace, and the heating furnace is divided into a preheating section, a first heating section, a second heating section, a first soaking section and a second soaking section in the length direction of the furnace; in the furnace, the temperature of the preheating section is lower than or equal to 750 DEG C, the temperature of the first heating section is 600-900 DEG C, the temperature of the second heating section is 850-1000 DEG C, thetemperature of the first soaking section is 1120-1160 DEG C, and the temperature of the second soaking section is 1100-1140 DEG C; and the quick temperature increasing heating time of the preheating section and the first heating section is 55-65 min, the heating time of the second heating section is 25-35 min, and the heat preservation time of the first soaking section and the second soaking section is 90-120 min. Formation of the surface cracks of the steel billet in the heating process is controlled by reasonably optimizing the heating temperature and the heat preservation time, and thus mesh cracks on the surface of rolled materials are avoided.

Owner:WUHU XINXING DUCTILE IRON PIPES

Casting process for casting motorcycle engine cylinder block

InactiveCN106583649ALow costReduce finishing costsFoundry mouldsFoundry coresPressure systemPlastic film

The invention discloses a casting process for casting a motorcycle engine cylinder block. The evaporative pattern casting process is adopted for casting the motorcycle engine cylinder block, so that the traditional sand shakeout and decoring procedures are omitted thoroughly, treatment cost is lowered, mold cost is lowered, high-precision castings are produced repeatedly one hundred percent, and the wall thickness error is controlled within + / - 0.5 mm. The casting process includes the following specific steps that a foam plastic gasifiable pattern is manufactured; the motorcycle engine cylinder block pattern is subjected to foam plastic gasification, and then the foam plastic gasifiable pattern is combined and dried; fireproof paint is brushed or sprayed on the surface of the foam plastic gasifiable pattern, and then the foam plastic gasifiable pattern is dried again; a special sand box for containing the motorcycle engine cylinder block is placed on a three-dimensional vibration compacting table and filled with bottom sand, and then vibration compacting and strike-off are carried out; the dried foam plastic gasifiable pattern is placed on the bottom sand, layer-by-layer sand filling is carried out according to process requirements, and strike-off is carried out on the opening of the box after automatic vibration compacting; and the opening of the sand box is covered with a plastic thin film, a sprue cup is placed, and an evaporative pattern is obtained and connected with a negative pressure system.

Owner:重庆市合川区银窝铸造厂

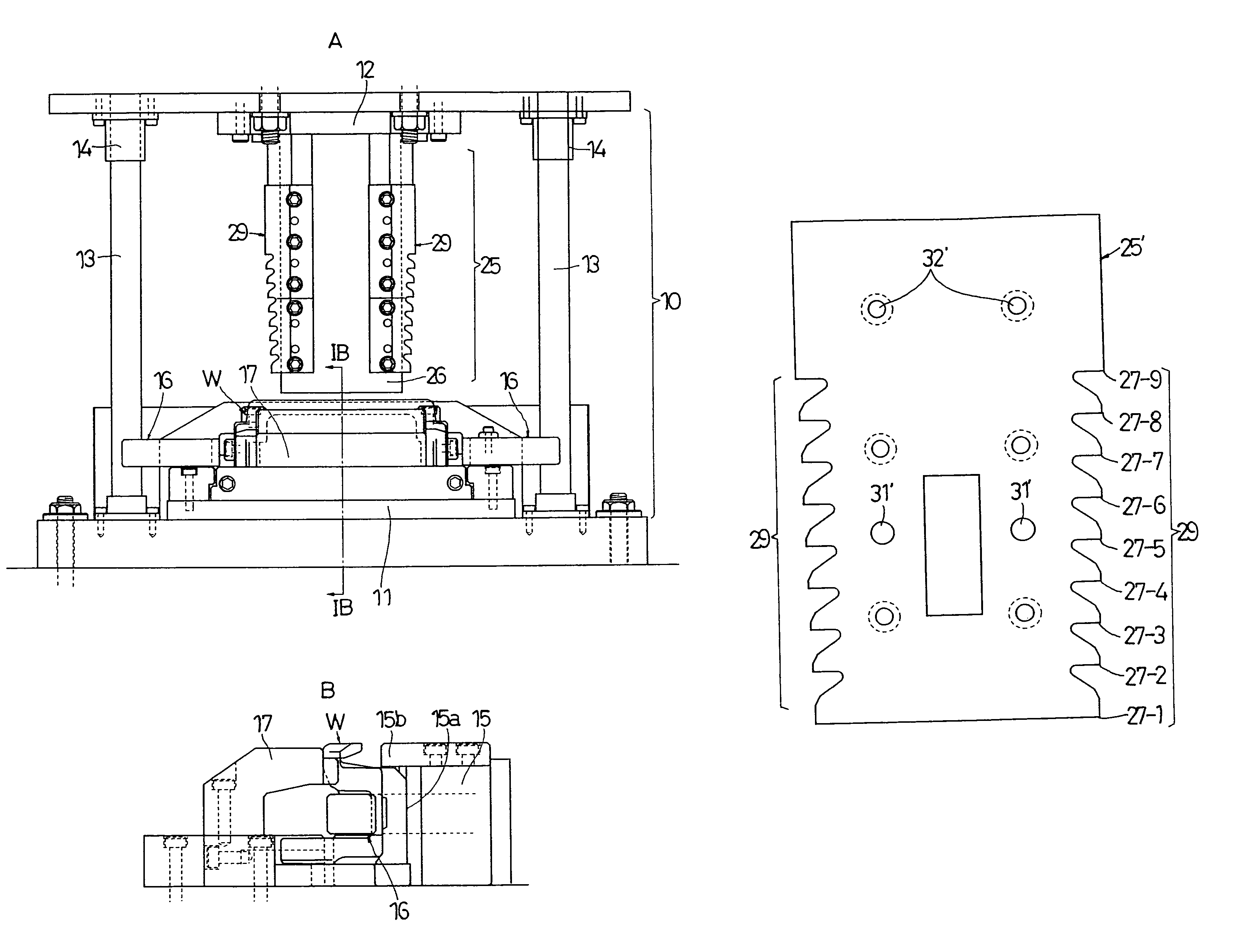

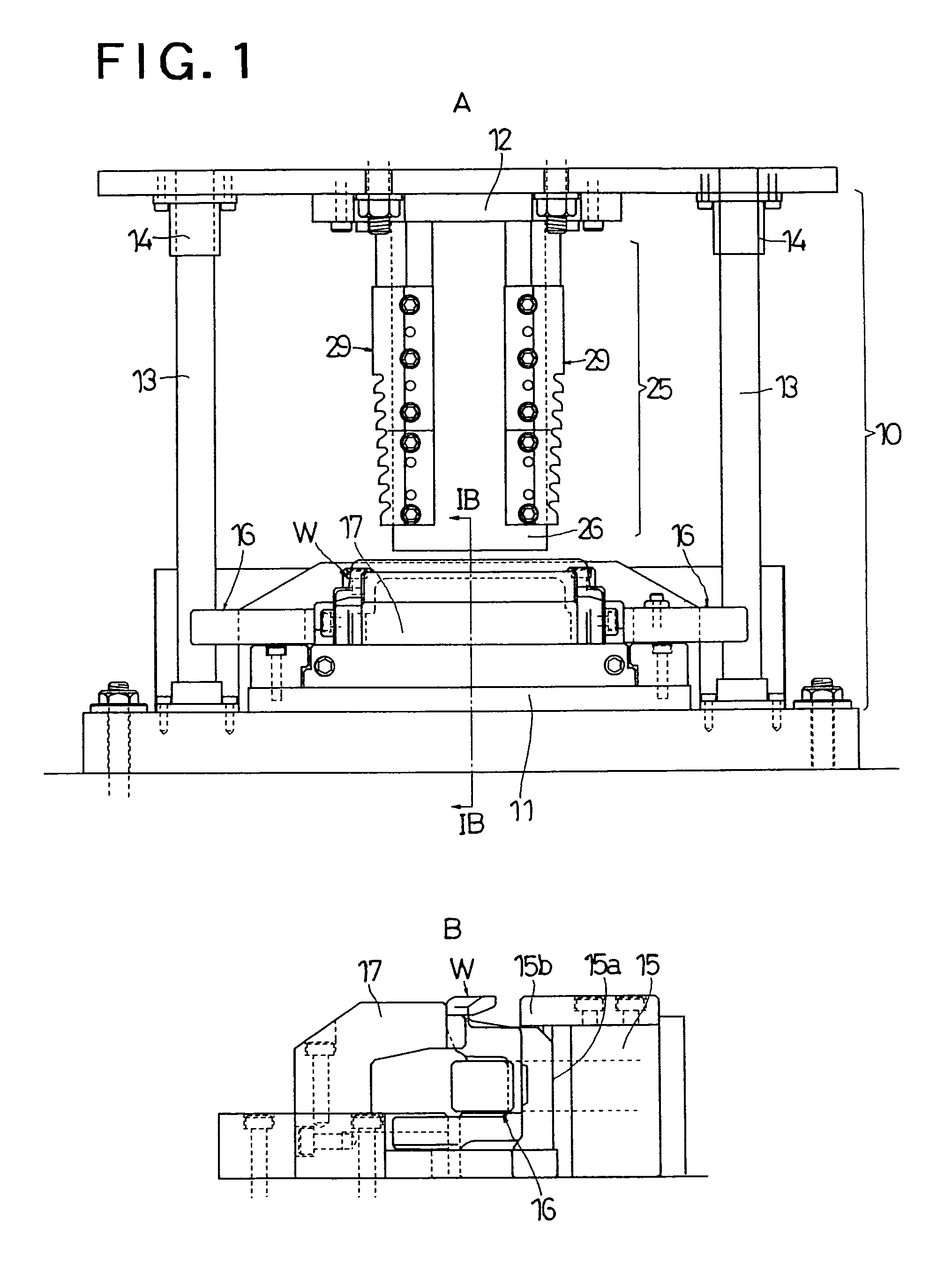

Method of removing excess metal from casting with press, and cutter used therefore

A set of dies are composed in order to remove excess metal from a casting with a press. A method of removing the excess metal from the casting includes the steps of: attaching a cutter to one of the stationary die side or the movable die side; setting a work on the other side; and punching excess metal of the work into a recess shape by one punching motion of the movable die with a plurality of blades from the first blade, which is smaller, to the final blade, which is larger and protruded, when the excess metal of the work is removed by a punching motion of the movable die conducted on the stationary die.

Owner:MOHKA MFG

A kind of sizing agent for after-finishing needle-punched filter felt and preparation method thereof

The invention discloses an impregnating compound for the post treatment of needled filtering felt and a preparation method thereof, and belongs to the technical field of auxiliary agents for filtering felt. The impregnating compound is prepared from the following raw materials in parts by weight: 4 to 6 parts of polytetrafluoroethylene solution with a solid content of 60%, 8 to 10 parts of acrylic resin emulsion with a solid content of 30%, 1.2 to 1.3 parts of polyvinyl alcohol water solution with a solid content of 20%, 2.5 to 3 parts of methyl phenyl silicone oil emulsion with an oil content of 30%, 2.5 to 3 parts of dispersion liquid of coupling agent, and 75 to 85 parts of water. The provided impregnating compound has a low fluorine content and air permeability; thus the cost of post treatment of needled filtering felt is reduced, and the filtering precision of processed needled filtering felt is improved.

Owner:淄博玖壹商贸有限公司

Impregnating compound for post treatment of needled filtering felt and preparation method thereof

The invention discloses an impregnating compound for the post treatment of needled filtering felt and a preparation method thereof, and belongs to the technical field of auxiliary agents for filtering felt. The impregnating compound is prepared from the following raw materials in parts by weight: 4 to 6 parts of polytetrafluoroethylene solution with a solid content of 60%, 8 to 10 parts of acrylic resin emulsion with a solid content of 30%, 1.2 to 1.3 parts of polyvinyl alcohol water solution with a solid content of 20%, 2.5 to 3 parts of methyl phenyl silicone oil emulsion with an oil content of 30%, 2.5 to 3 parts of dispersion liquid of coupling agent, and 75 to 85 parts of water. The provided impregnating compound has a low fluorine content and air permeability; thus the cost of post treatment of needled filtering felt is reduced, and the filtering precision of processed needled filtering felt is improved.

Owner:淄博玖壹商贸有限公司

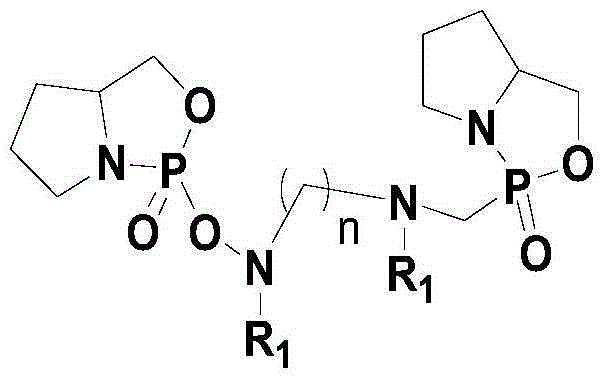

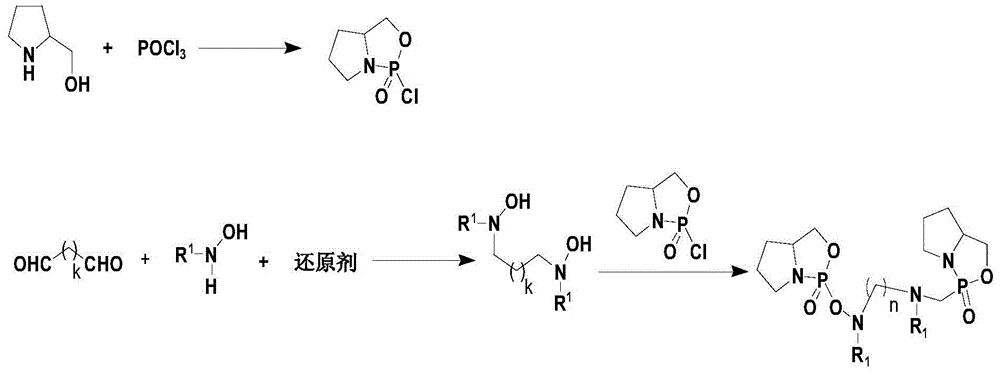

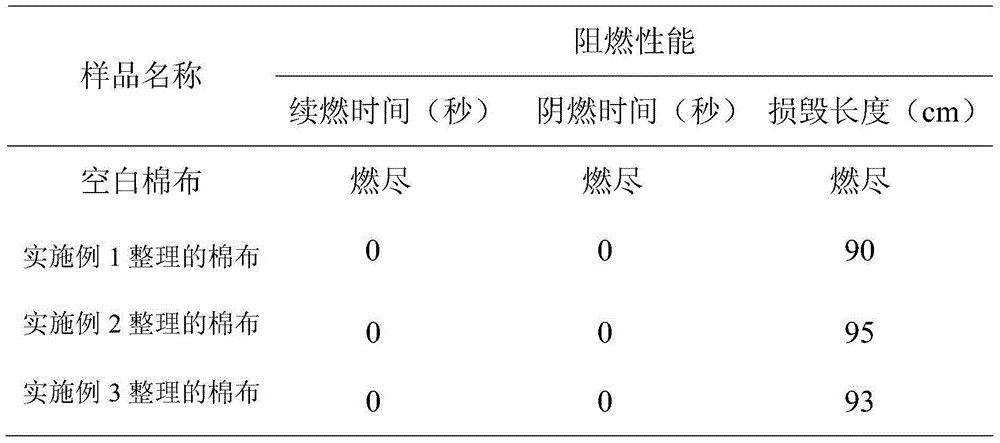

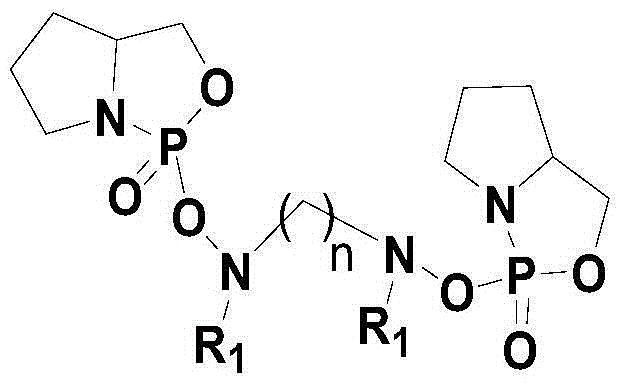

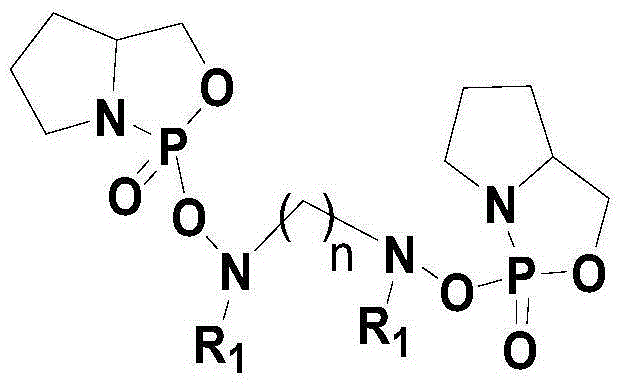

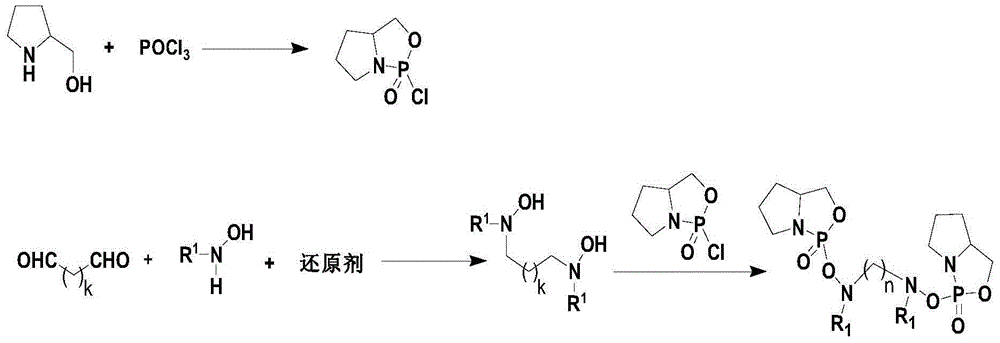

Multifunctional fabric fire retardant as well as preparation method and application of fabric fire retardant

ActiveCN103981704AImprove flame retardant performanceReduce finishing costsGroup 5/15 element organic compoundsVegetal fibresAliphatic hydrocarbonNitrogen

The invention discloses a multifunctional fabric fire retardant as well as a preparation method and application of the fabric fire retardant. The structural formula of the fire retardant is as shown in the specification, wherein in the structural formula, the n is great than or equal to 2 and less than or equal to 10; R<1> is one of H, C(1-6) saturated aliphatic hydrocarbon, C(2-6) unsaturated alkyl and a compound with the structural formula shown in the specification; in the compound, the m is great than or equal to 1 and less than or equal to 10; the R<2> is one of H and C(1-6) saturated aliphatic hydrocarbon; the R<3> is one of H and C(1-6) saturated aliphatic hydrocarbon; R<4> is one of H and C(1-6) saturated aliphatic hydrocarbon. The fire retardant disclosed by the invention belongs to an intumescent fire retardant containing two fire-retardant elements, namely nitrogen and phosphorus and is excellent in fire-retardant effect; N-O bonds and quaternary ammonium ions are contained in molecules and the fire retardant has the functions of low yellowing and sterilization, so that multistep finishing can be realized in one time, the finishing cost of fabrics is greatly reduced and the pollutant discharge amount of printing and dyeing industry can be greatly reduced.

Owner:约克夏染料(中山)有限公司

A kind of multifunctional fabric flame retardant and its preparation method and application

ActiveCN103981704BImprove flame retardant performanceReduce finishing costsGroup 5/15 element organic compoundsVegetal fibresAliphatic hydrocarbonNitrogen

Owner:约克夏染料(中山)有限公司

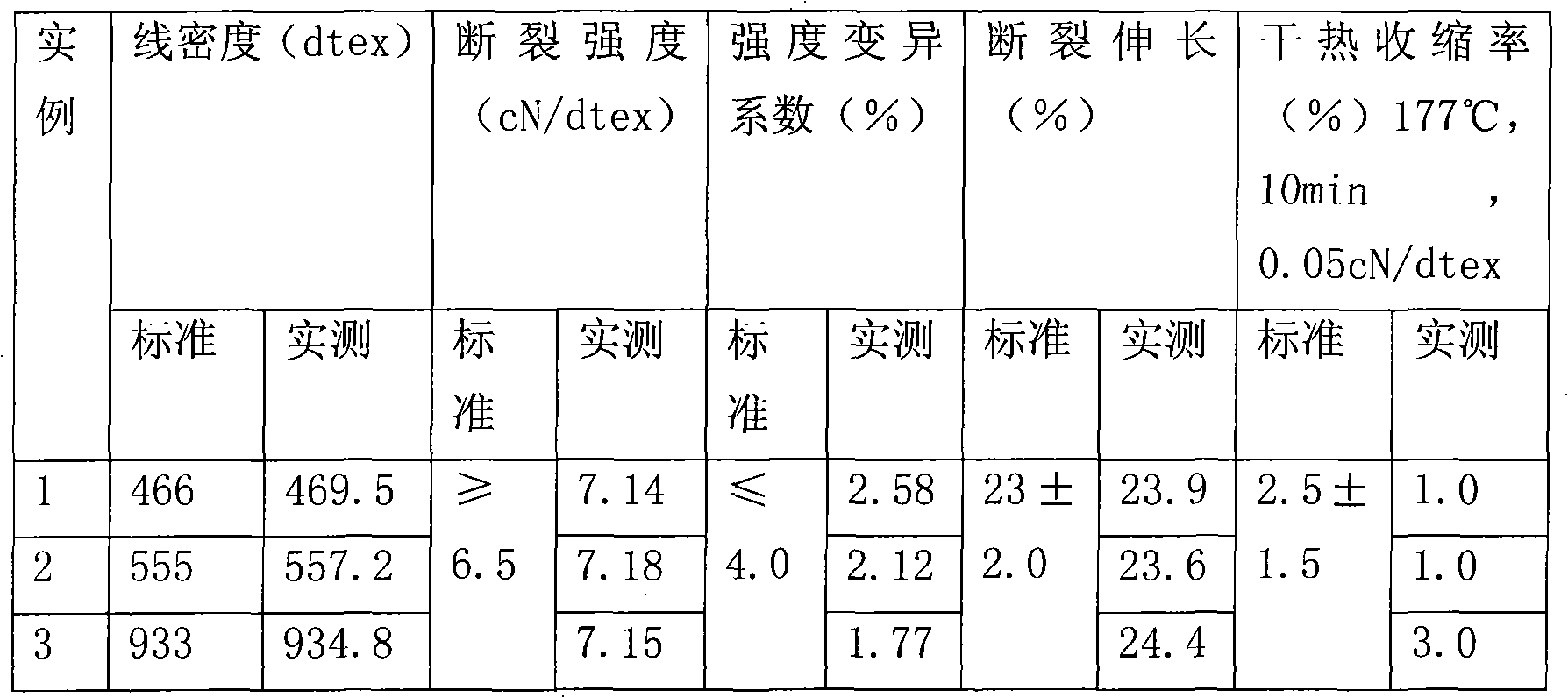

Process for producing polyester industrial fiber for processing safe air bag of automobile

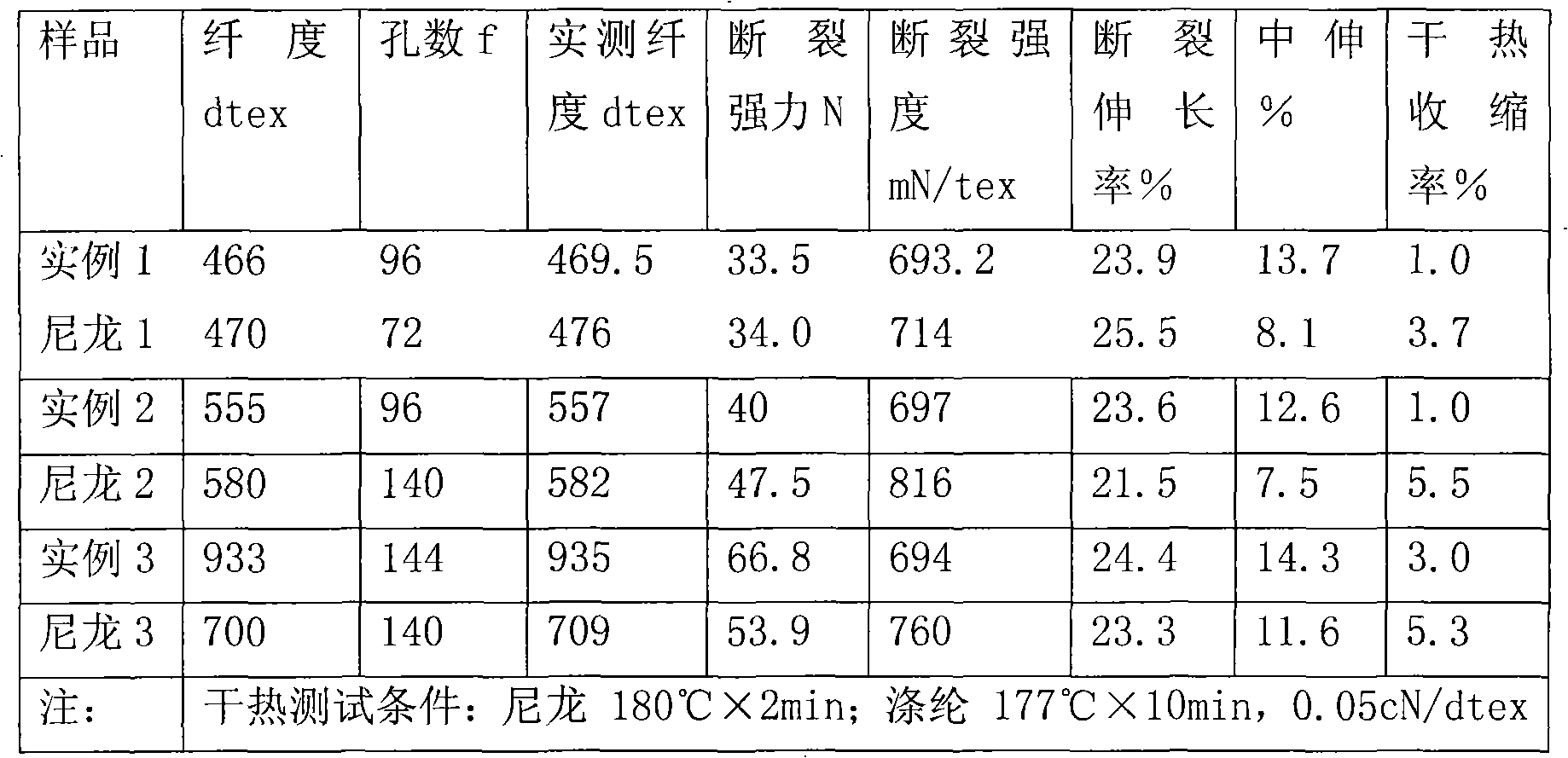

ActiveCN101634052BHeat resistantHigh strengthArtificial filament heat treatmentMelt spinning methodsPolyesterNylon 66

The invention relates to a process for producing a polyester industrial long fiber for processing a safe air bag of an automobile, which sequentially comprises the following steps: A. processing a polyester slice with high viscosity: enabling the viscosity of the polyester slice to reach 1.0-1.1dl / g; B. melting and spinning: transmitting the polyester slice after solid phase polymerization to a spinning screw rod extruder, melting in a spinning screw rod, entering a spinning assembly by a metering pump and extruding from a fiber spray plate with a diameter of 190 mm to 220 mm to spin fusant, , then heating by a slow cooling heater, carrying out cooling for molding by a side-molding blowing device and then entering a spinning passage; C. stretching and winding: oiling the surface of a fiber and carrying out second-grade high-speed stretching with the total stretching multiple being 5.0 to 5.8, carrying out high-temperature loosing thermoforming at 230 DEG C-250 DEG C and carrying out winding for molding in the range of the winding process speed of 2,500-3,000 m / min to prepare a finished product. The fiber for the safe air bag, which is produced by the process, can completely replace a nylon 66 fiber, is used for spinning terylene safe air bag fabrics and greatly reduces the processing cost.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

Bill sorting and placing device

PendingCN110002059AIngenious structural designReduce finishing costsPackaging automatic controlEngineeringMechanical engineering

The invention relates to a bill sorting and placing device, and belongs to the technical field of bill sorting and placing devices. The bill sorting and placing device comprises a tray body for holding bills; a bill pressing mechanism capable of lifting up and down is mounted above the tray body; an overturning mechanism for driving the tray body to rotate is mounted below the tray body; two mounting brackets used for mounting the tray body onto a machine body are mounted on the two sides in the width direction of the tray body; the mounting brackets are provided with sensing mechanisms for monitoring the tilt angle of the tray body; and the overturning mechanism and the sensing mechanisms are in communication connection with a controller. The bill sorting and placing device is ingenious in structure design and high in work efficiency, and scanned irregular bills and bills with deep folds can be uniformly stacked and compacted and automatically put into package bags uniformly.

Owner:烟台拓伟智能科技股份有限公司

On-demand manufacturing of apparel by laser finishing fabric rolls

ActiveUS11352738B2Reduce finishing costsLow costPattern makingLaser beam fibre treatmentLaser processingProcess engineering

An on-demand manufacturing of apparel system includes online customization and ordering of garments, previewing of the garments, manufacturing including laser finishing of garments, and delivery to the customer. Laser finishing of apparel products reduces finishing cost, lowers carrying costs, increases productivity, shortens time to market, be more reactive to trends, reduces product constraints, reduces lost sales and dilution, and more. Fabric templates can be used to produce a multitude of laser finishes. Operational efficiency is improved.

Owner:LEVI STRAUSS & CO

Method for improving condition of Sophora buds from golden Sophora japonica

ActiveCN107714762AThe configuration and completion process is simpleEasy to operatePlant ingredientsBudCell budding

The invention discloses a method for improving condition of Sophora buds from golden Sophora japonica. The method comprises the following steps: (1) water is added into an enzyme deactivating apparatus, alkali lye is added, and heating is carried out; (2) water and alkali lye are added into the enzyme deactivating apparatus every two hours in the heating process of the step (1), in order to guarantee alkali lye in a pot is kept at a certain concentration, heating is carried out till water is boiled, Sophora buds are added into the enzyme deactivating apparatus for carrying out enzyme deactivation, boiling state is kept and enzyme deactivation is carried out for 12-15 minutes, and the product is obtained. The method has obvious effects, processed Sophora buds from golden Sophora japonica have golden yellow color, good condition, and high price.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

A kind of anti-pilling wool surface air layer fabric

ActiveCN105544196BReduce directional friction effectImprove smoothnessAbrasion resistant fibresAnimal fibresBiocompatibility TestingEngineering

Owner:阜南华翔羊毛衫有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com