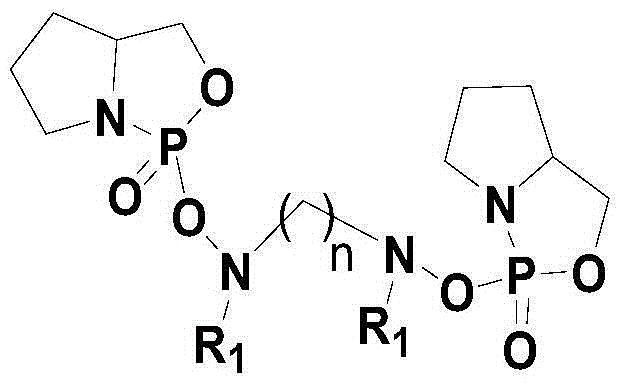

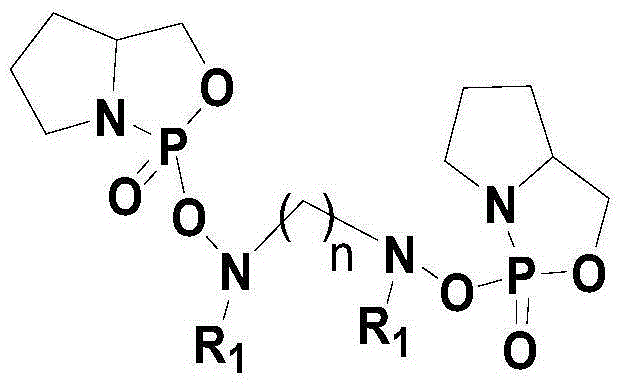

A kind of multifunctional fabric flame retardant and its preparation method and application

A flame retardant, multi-functional technology, applied in the direction of textiles and papermaking, chemical instruments and methods, plant fibers, etc., can solve the problems of high cost, large waste discharge, long time consumption, etc., achieve superior flame retardant effect, reduce finishing cost, emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

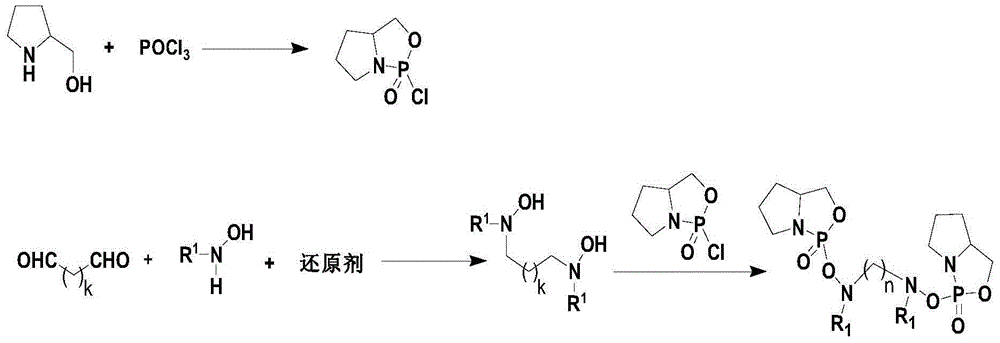

[0038] (1) In a 2-liter four-necked round-bottomed flask equipped with a stirrer, a thermometer and a dropping funnel, add 1 liter of dichloromethane, 101 grams of triethylamine (1mol) and 101 grams of (1mol), slowly add 151.8 grams of POCl at 5-10°C 3 (1mol), after adding, stir at room temperature for 5 hours, and the resulting mixture directly proceeds to the next step without separation and characterization;

[0039] (2) In a 2-liter four-necked round-bottomed flask equipped with a stirrer, a thermometer and a dropping funnel, add 1 liter of methanol, 58 grams of OHCCHO (1mol) and 230 grams of (1mol), after fully stirring evenly, add 38 grams of sodium borohydride (1mol) in batches at a temperature of 5-10°C, react at room temperature for 5-10 hours, then add 1 liter of water to the reaction system, extract the organic phase, the organic phase Then wash twice with 1 liter of saturated brine, dry the organic phase with anhydrous sodium sulfate, filter to remove the desicc...

example 2

[0043] (1) In a 2-liter four-necked round-bottomed flask equipped with a stirrer, a thermometer and a dropping funnel, add 1 liter of dichloromethane, 101 grams of triethylamine (1mol) and 101 grams of (1mol), slowly add 151.8 grams of POCl at 5-10°C 3 (1mol), after adding, stir at room temperature for 5 hours, and the resulting mixture directly proceeds to the next step without separation and characterization;

[0044] (2) In a 2-liter four-neck round-bottomed flask equipped with a stirrer, a thermometer and a dropping funnel, add 1 liter of methanol, 72 grams of (1mol) and 230 grams (1mol), after fully stirring evenly, add 38 grams of sodium borohydride (1mol) in batches at 5-10°C, react at room temperature for 5-10 hours, then add 1 liter of water to the reaction system, extract the organic phase, and then Wash twice with 1 liter of saturated brine, dry the organic phase with anhydrous sodium sulfate, filter out the desiccant, and distill the organic solvent under redu...

example 3

[0048] (1) In a 2-liter four-necked round-bottomed flask equipped with a stirrer, a thermometer and a dropping funnel, add 1 liter of dichloromethane, 101 grams of triethylamine (1mol) and 101 grams of (1mol), slowly add 151.8 grams of POCl at 5-10°C 3 (1mol), and then stirred at room temperature for 5 hours after the addition. The resulting mixture is directly carried out to the next step without separation and characterization;

[0049] (2) In a 2-liter four-necked round-bottomed flask equipped with a stirrer, a thermometer and a dropping funnel, add 1 liter of methanol, 58 grams of OHCCHO (1mol) and 244 grams of (1mol), after fully stirring evenly, add 38 grams of sodium borohydride (1mol) in batches at 5-10°C, react at room temperature for 5-10 hours, then add 1 liter of water to the reaction system, extract the organic phase, and then Wash twice with 1 liter of saturated brine, dry the organic phase with anhydrous sodium sulfate, filter out the desiccant, and distill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com