Multiple material driver-type golf club head

a golf club head and multiple material technology, applied in golf clubs, golf, sport apparatus, etc., can solve the problem that the finishing process of weld polishing requires expensive polishing belts, and achieve the effect of adding cost and additional cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

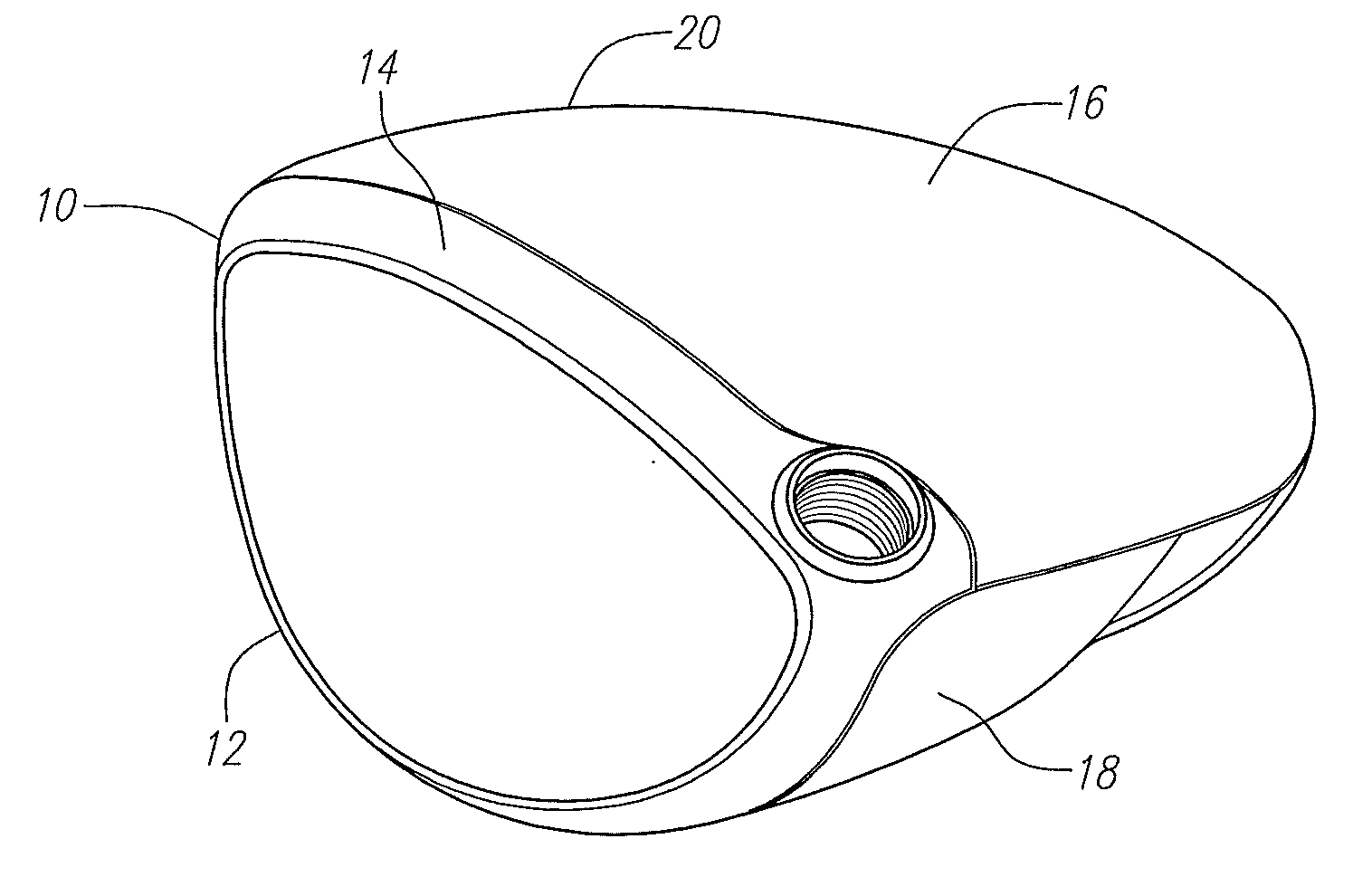

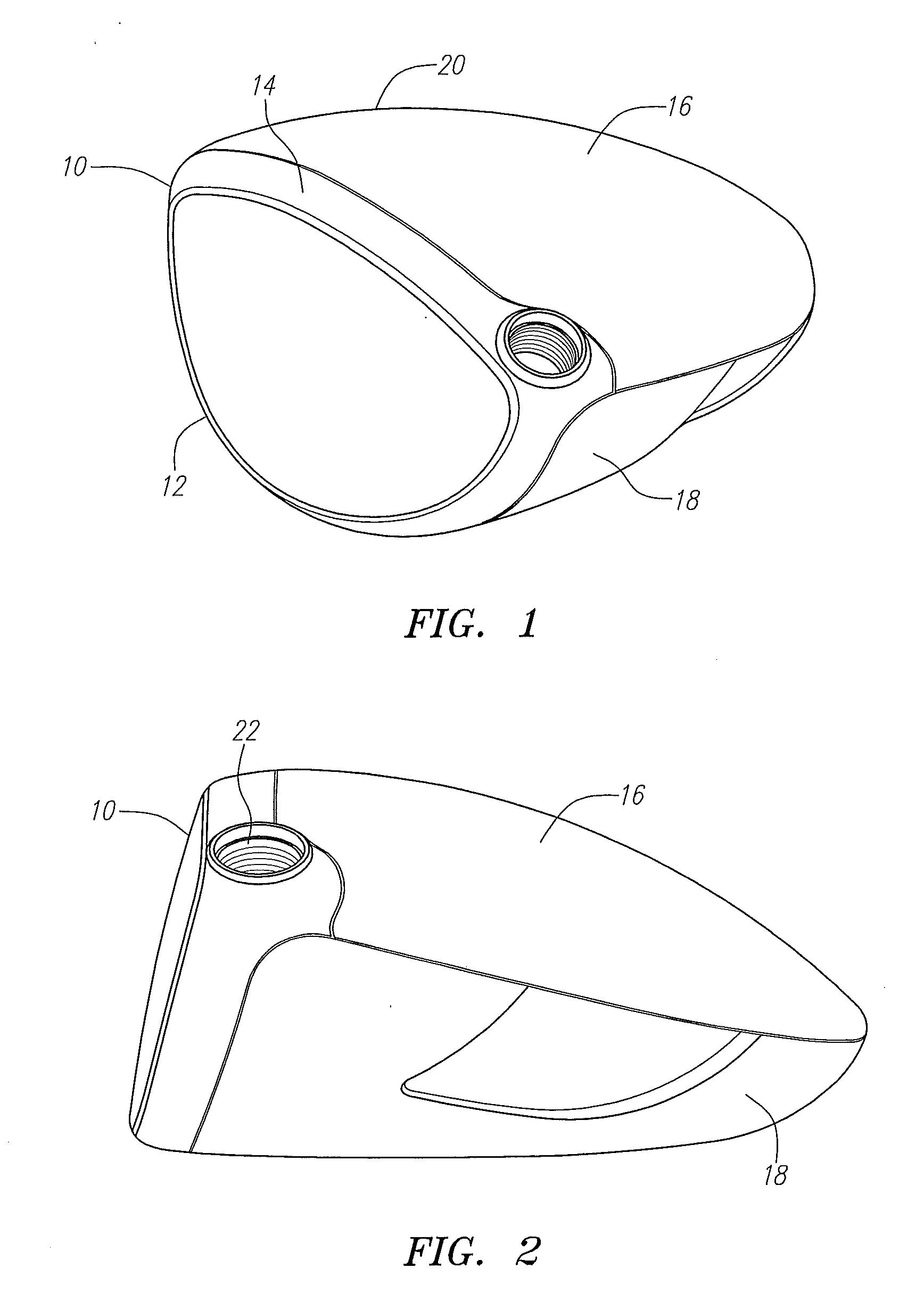

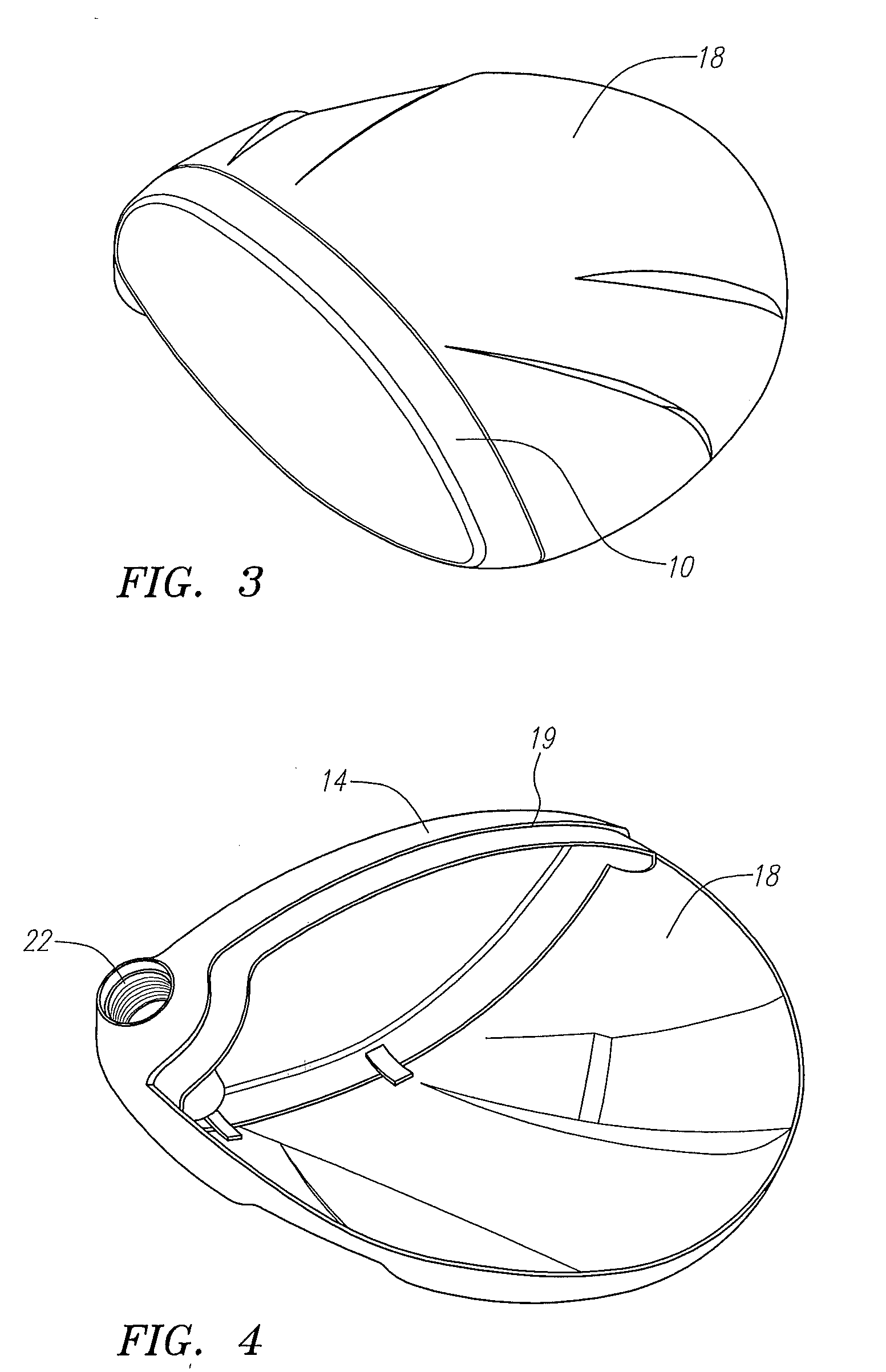

[0030]The driver-type golf club head is formed by a process that preferably includes the manufacture of a cast face component 10 and a stamped metal sole component 18. The face component 10 and the sole component 18 are assembled together in a welding fixture. The welding fixture locates on the inside of the face component 10 and inside of the sole component 18. The welding fixture also locates on some sections of the outside surfaces of the face component 10 and the sole component 18. The crown component 16 is preferably formed from a carbon composite. Once the face component 10 and sole component 18 are welded into a golf club head subassembly, the golf club head subassembly is polished and prepared for adhesive bonding. The composite crown is bonded to the golf club head subassembly using an adhesive. After the adhesive cures, the unfinished golf club head is cleaned and finished (typically painting).

[0031]Preferably the face component 10 is cast from titanium 6-4 alloy. The face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com