Motor rotor punching sheet finishing machine

A technology for motor rotors and sorting machines, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of scattered and disordered wire slots of punched sheets, affect production efficiency, and time-consuming and laborious sorting process, so as to improve punching sorting efficiency and reduce The Effect of Finishing Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

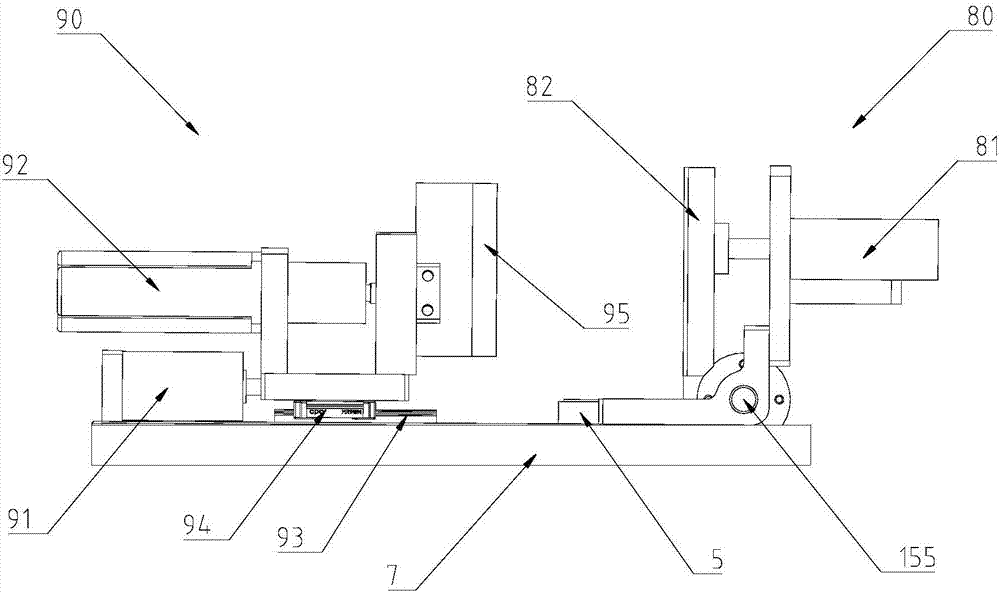

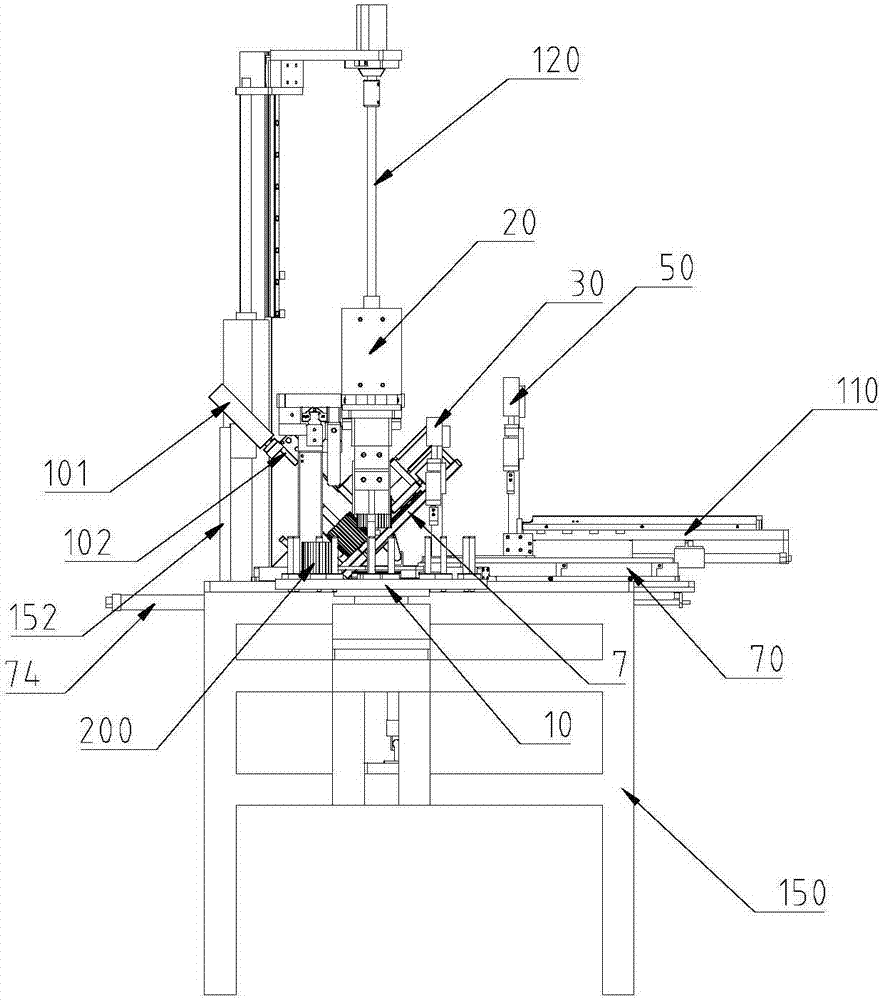

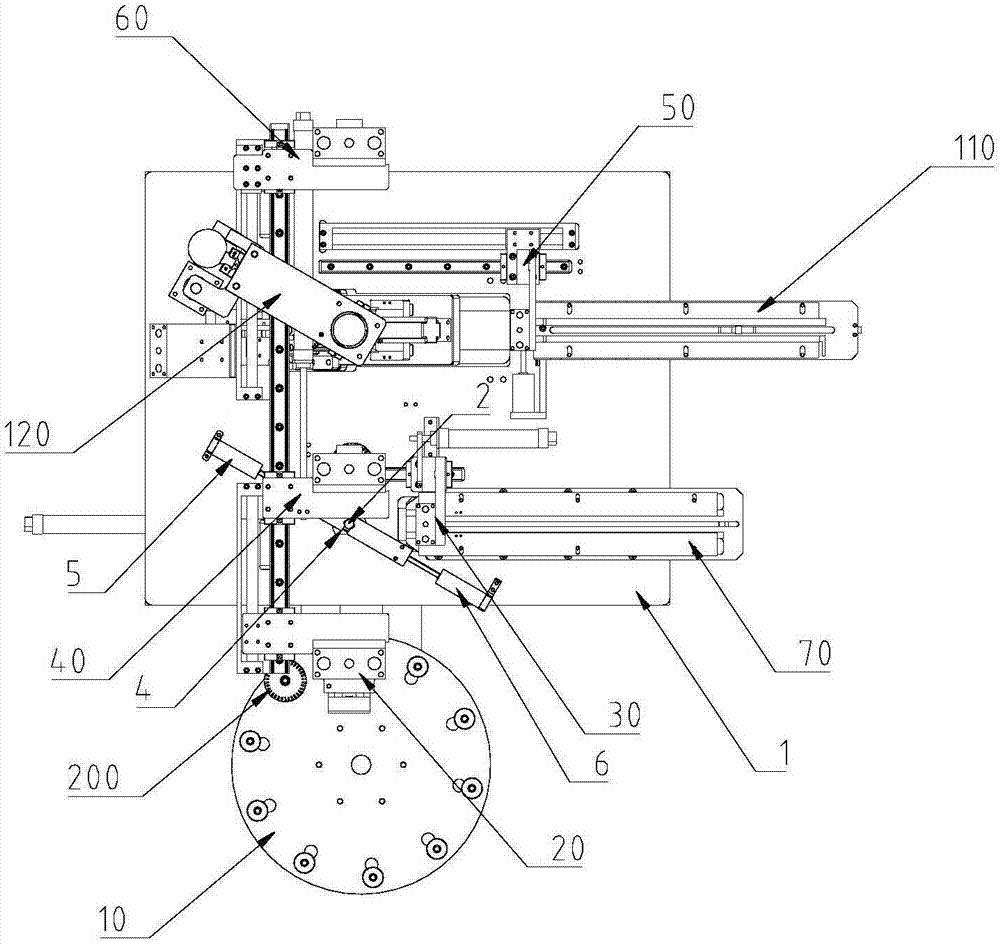

[0032] The structure of the motor rotor punching finishing machine in the embodiment of the present invention is as follows: Figure 1 to Figure 11 As shown, it includes a frame 150 , a punch placement tray, a punch assembly threading screw device, a punch finishing device, a nut tightening device and a fifth manipulator 60 . The frame 150 includes the workbench 1 .

[0033] The punch placement tray 10 includes a tray body 11 , an indexing head 13 and 10 insertion rods 12 , and the ten insertion rods 12 are arranged on the edge of the top of the tray body 11 and distributed evenly along the circumference of the tray body 11 . The disc body 11 is installed above the indexing head 13 and driven by the indexing head 13 , and the indexing head 13 is installed on the frame 150 .

[0034] The punching screw assembly includes a first manipulator 20 , a second manipulator 30 , a screw bin 70 , a screw seat 4 , a first clamping cylinder 5 and a second clamping cylinder 6 .

[0035] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com