Multi-shaft drive two-way rotating fan turbine and fan compressor with inserts

A two-way rotation, compressor technology, applied in the direction of engine components, engine functions, machines/engines, etc., can solve the problems of low compressor working efficiency, increase the working resistance of the fan, hinder the air engine, etc., to reduce the amount of force deformation, The effect of reducing weight and reducing root structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

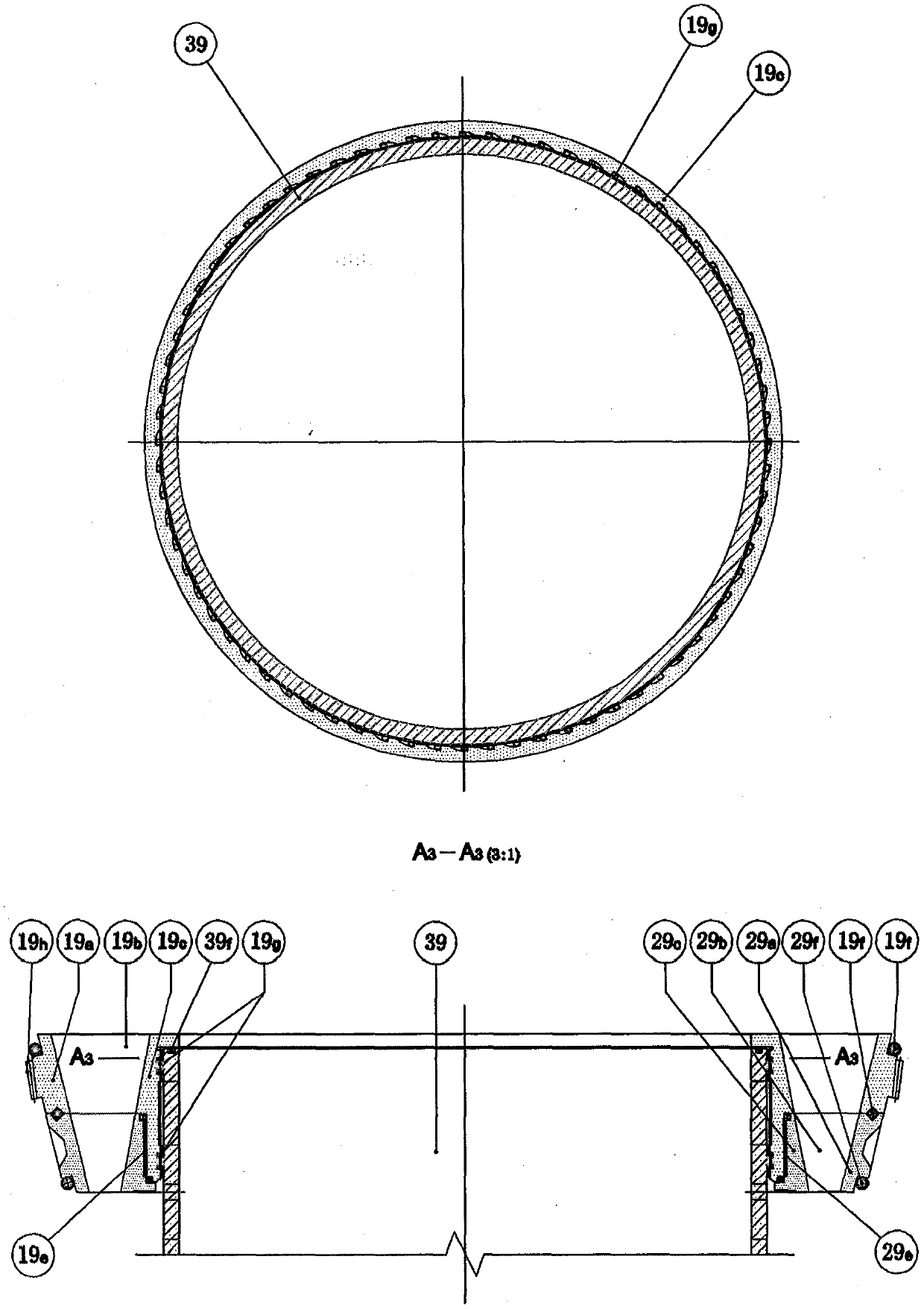

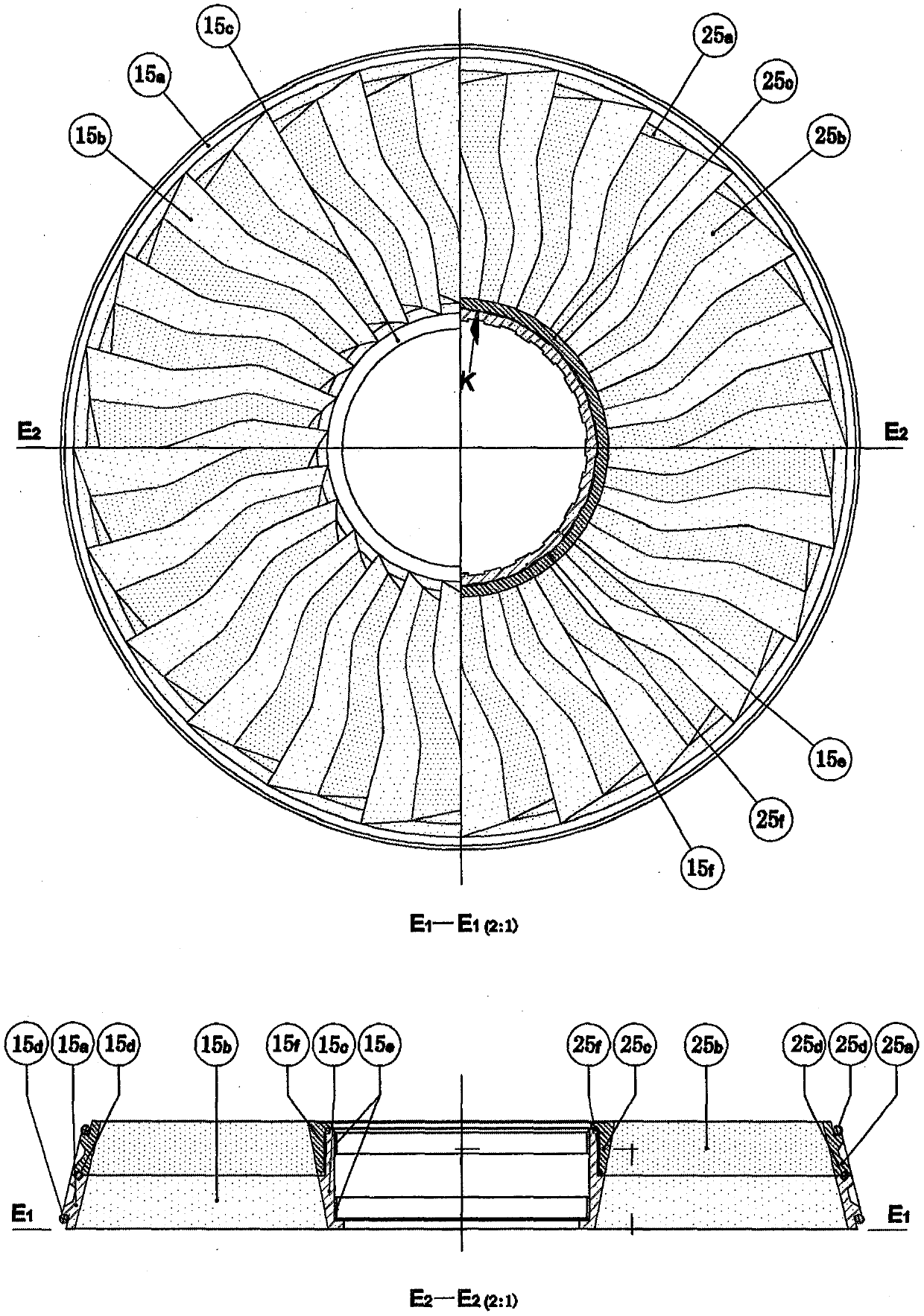

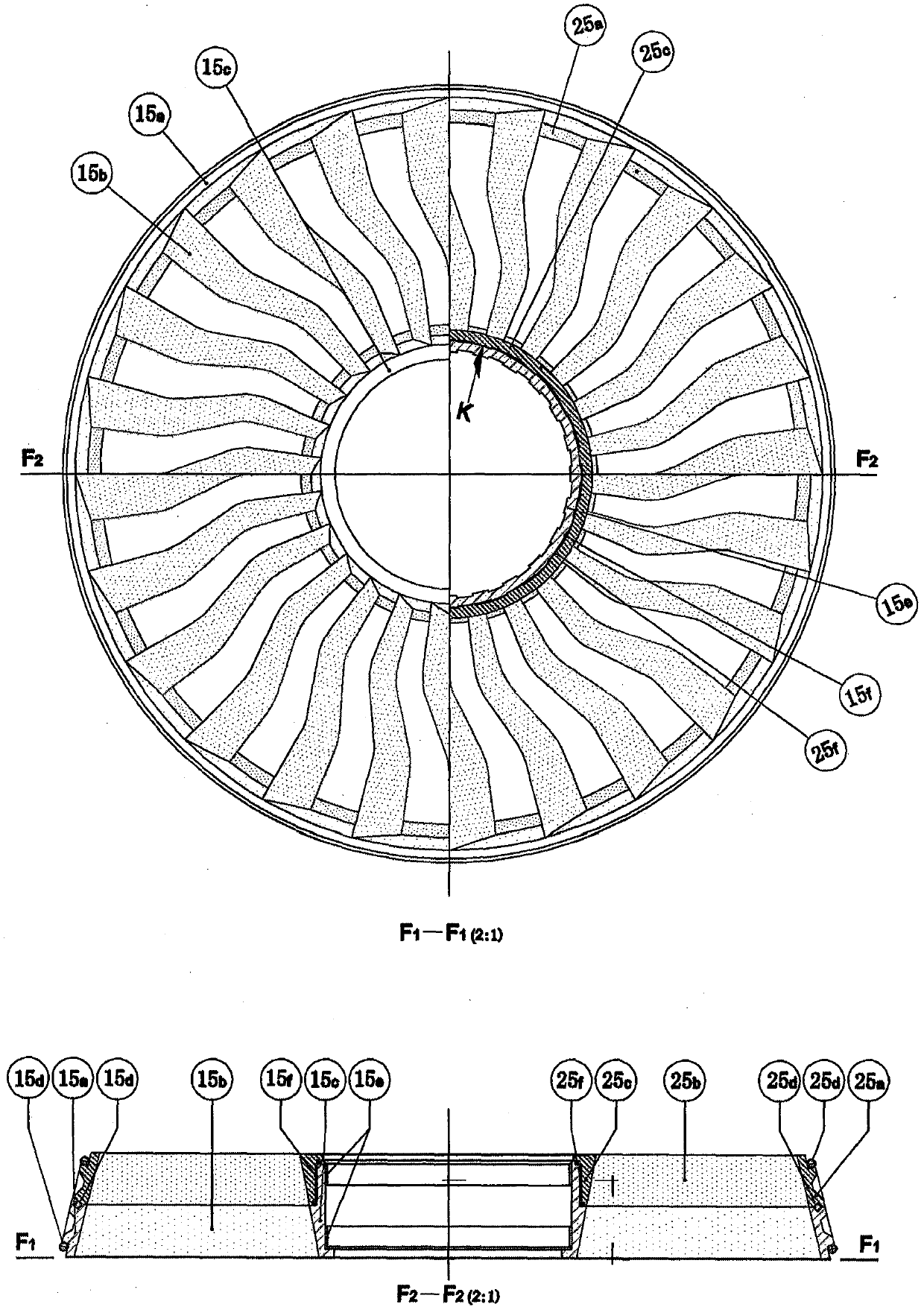

[0018] In order to understand more clearly the technical means adopted by the present invention to the improvement of existing turbojet engine (core machine) in work and transmission mode, structural configuration form, working cooling mode, starting mode, and in order to allow the above-mentioned features of the present invention and The advantages can be more obvious and easy to understand. The following is accompanied by the accompanying drawings, and the detailed description is as follows:

[0019] 1. The multi-shaft sleeve transmission two-way rotating wheel fan turbine and the embedded fan compressor have the following working and transmission modes: a turbine fan drives a corresponding compressor fan to rotate through a transmission sleeve , its working speed and steering are the same and opposite to the rotation direction of the corresponding wheel fan of the adjacent scroll pressure, and the speed of each wheel fan can be different; except for the first wheel fan of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com