Patents

Literature

150results about How to "Reduce axial play" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

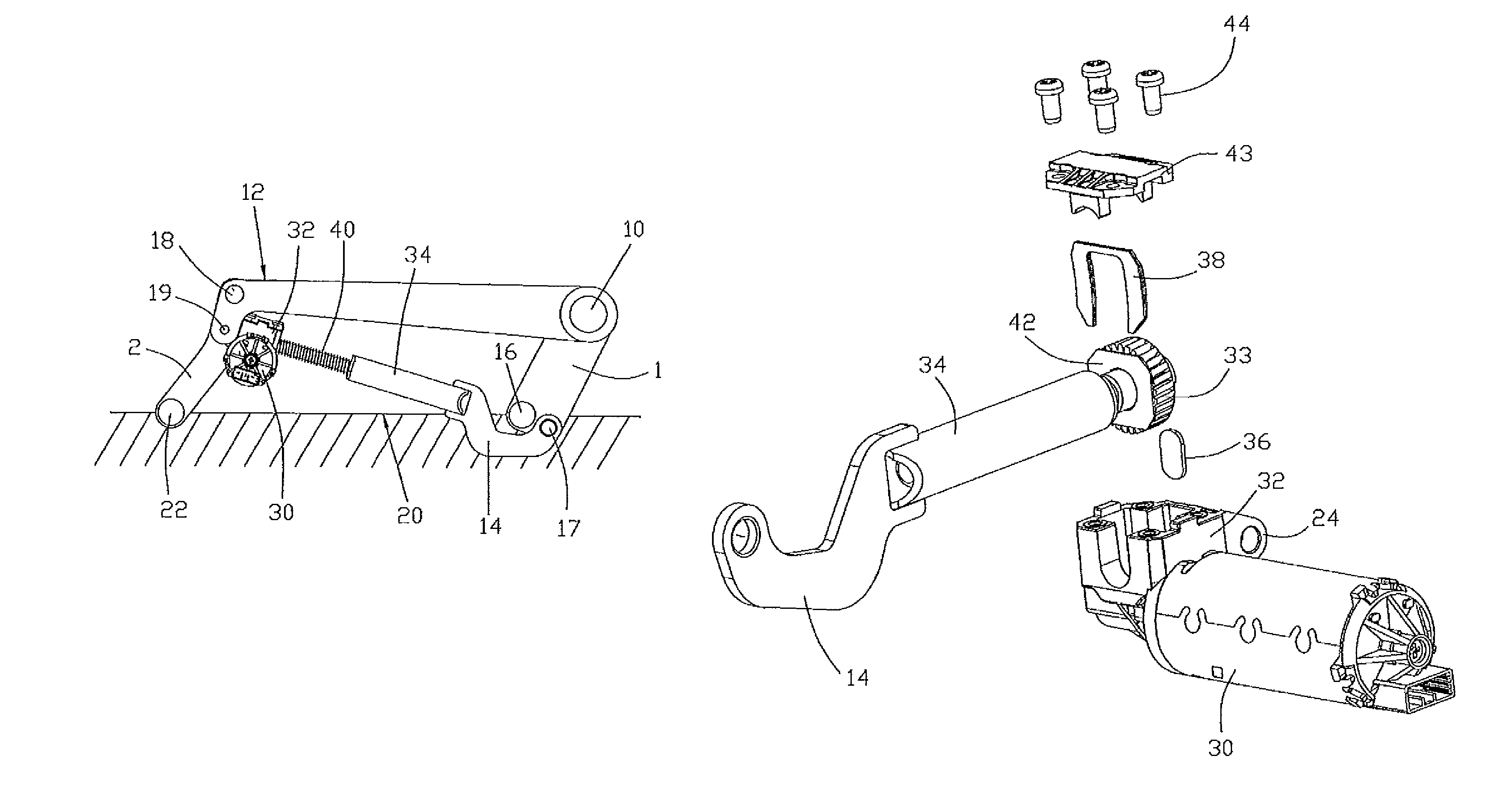

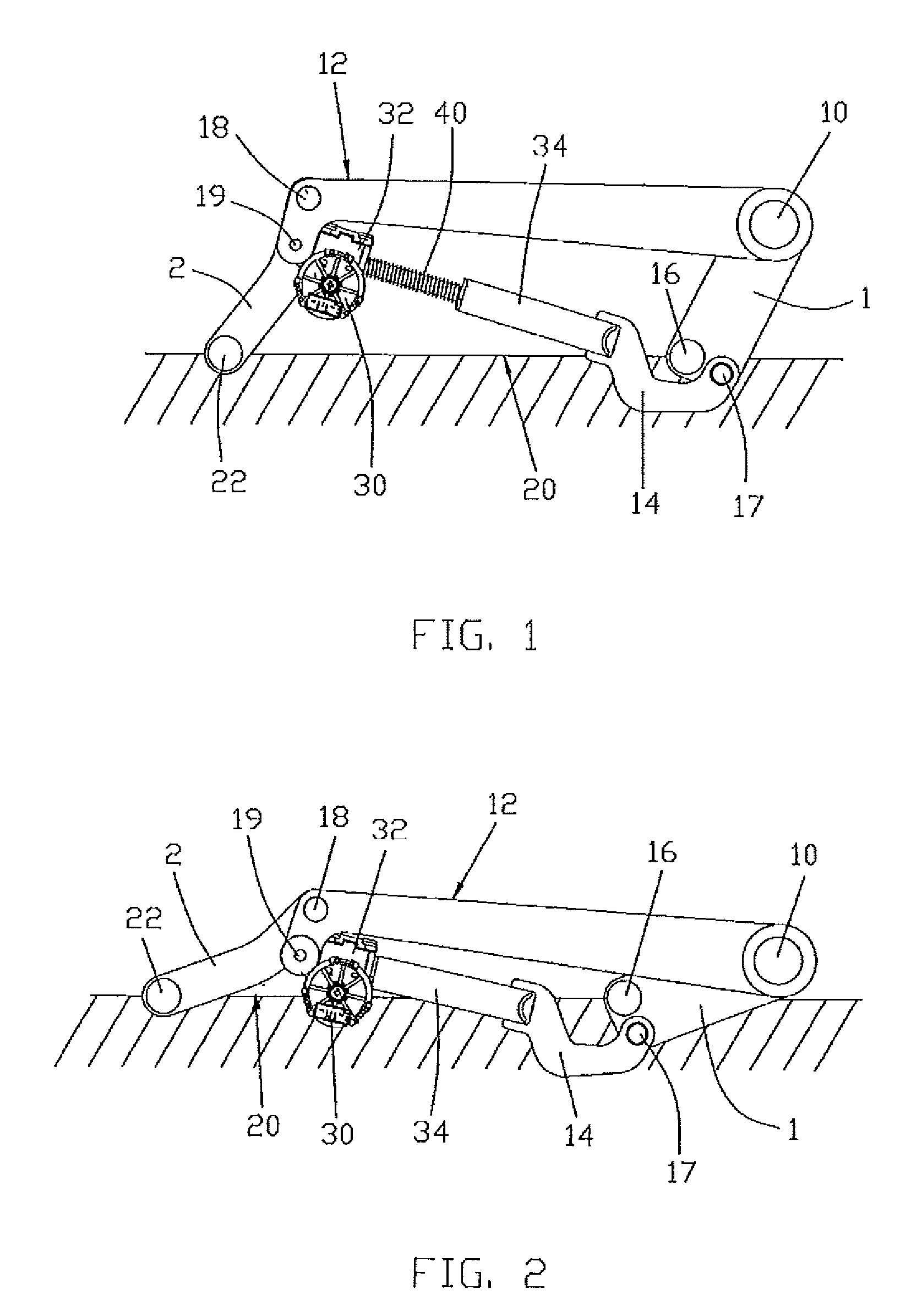

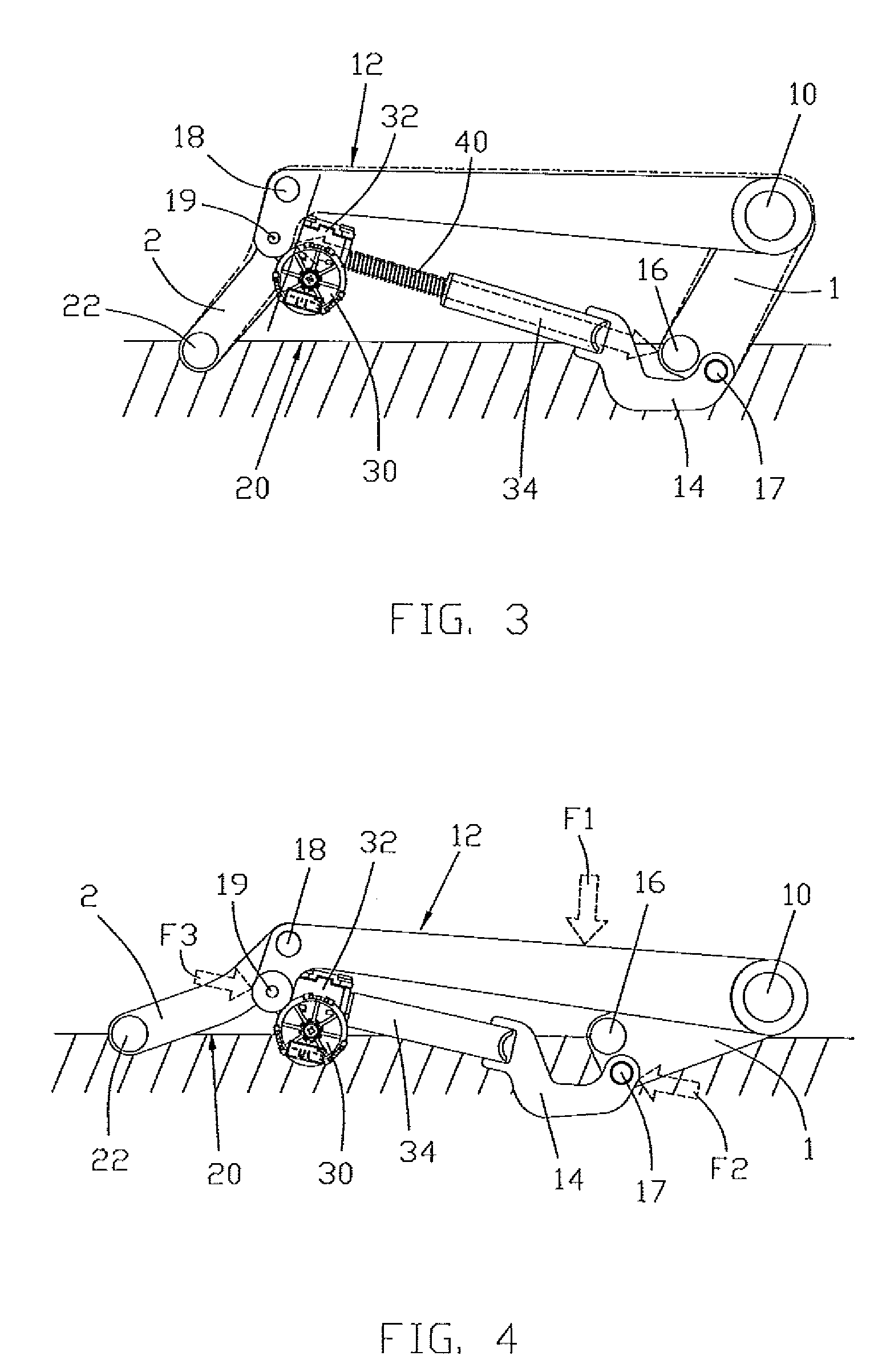

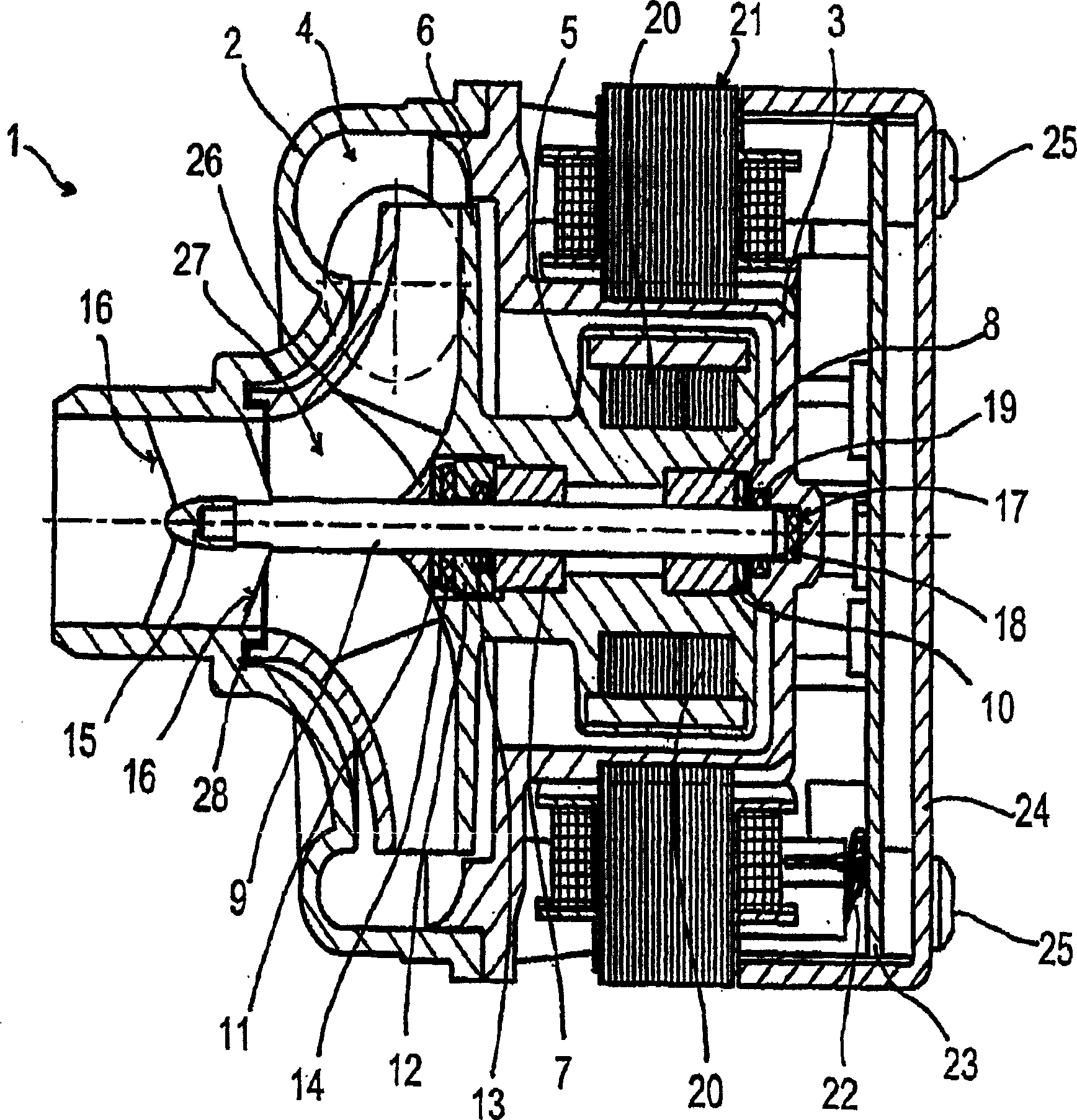

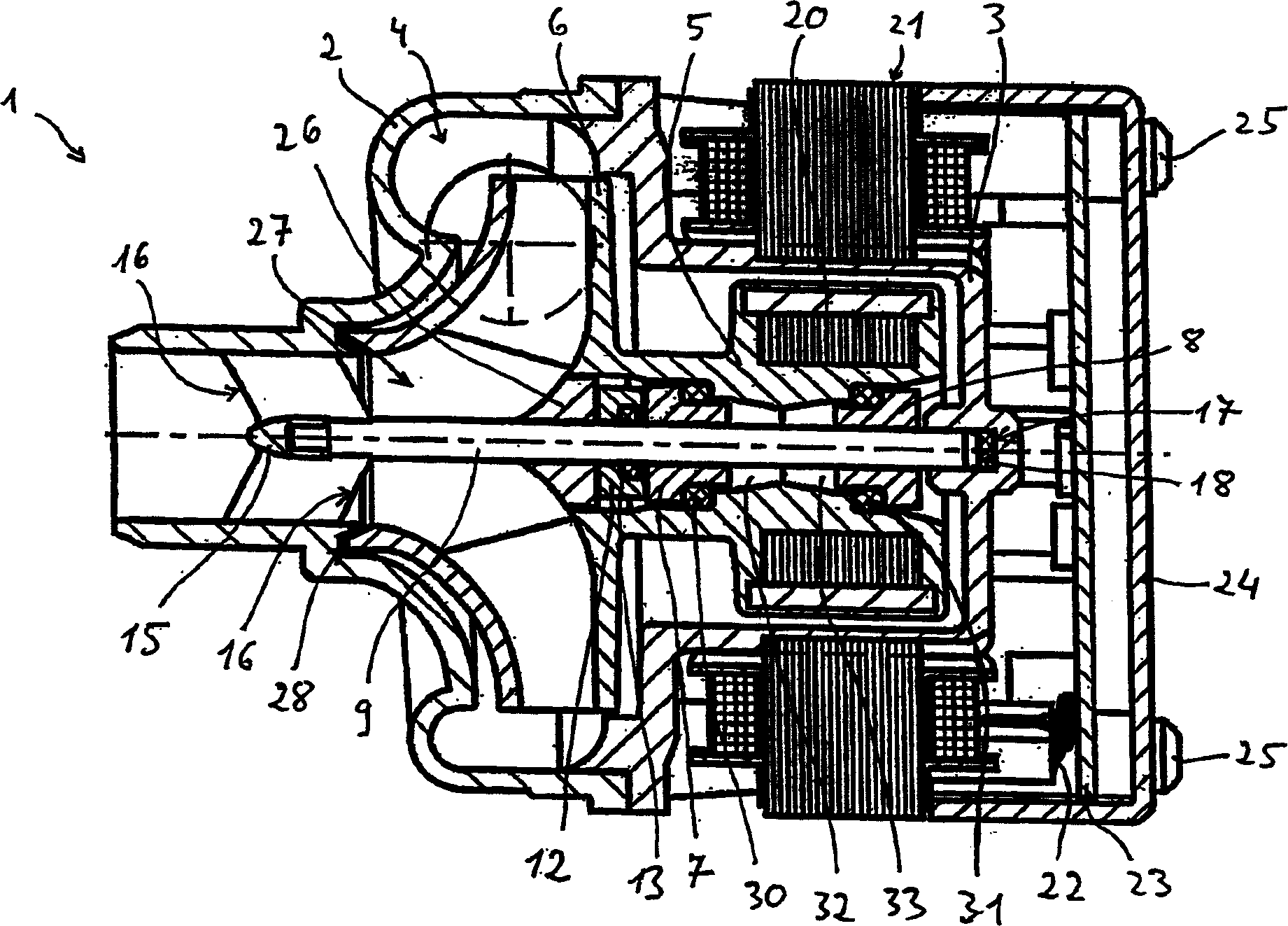

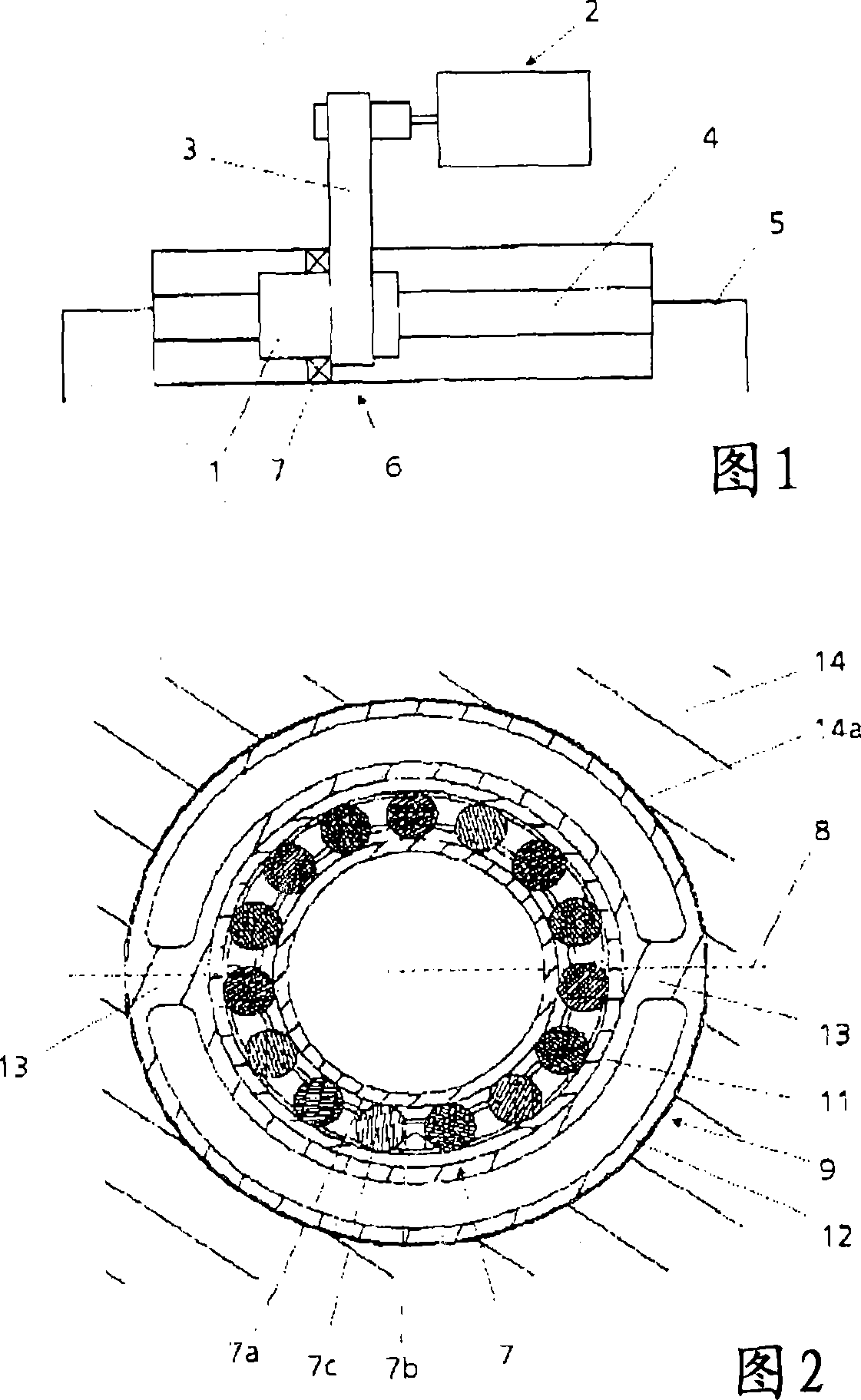

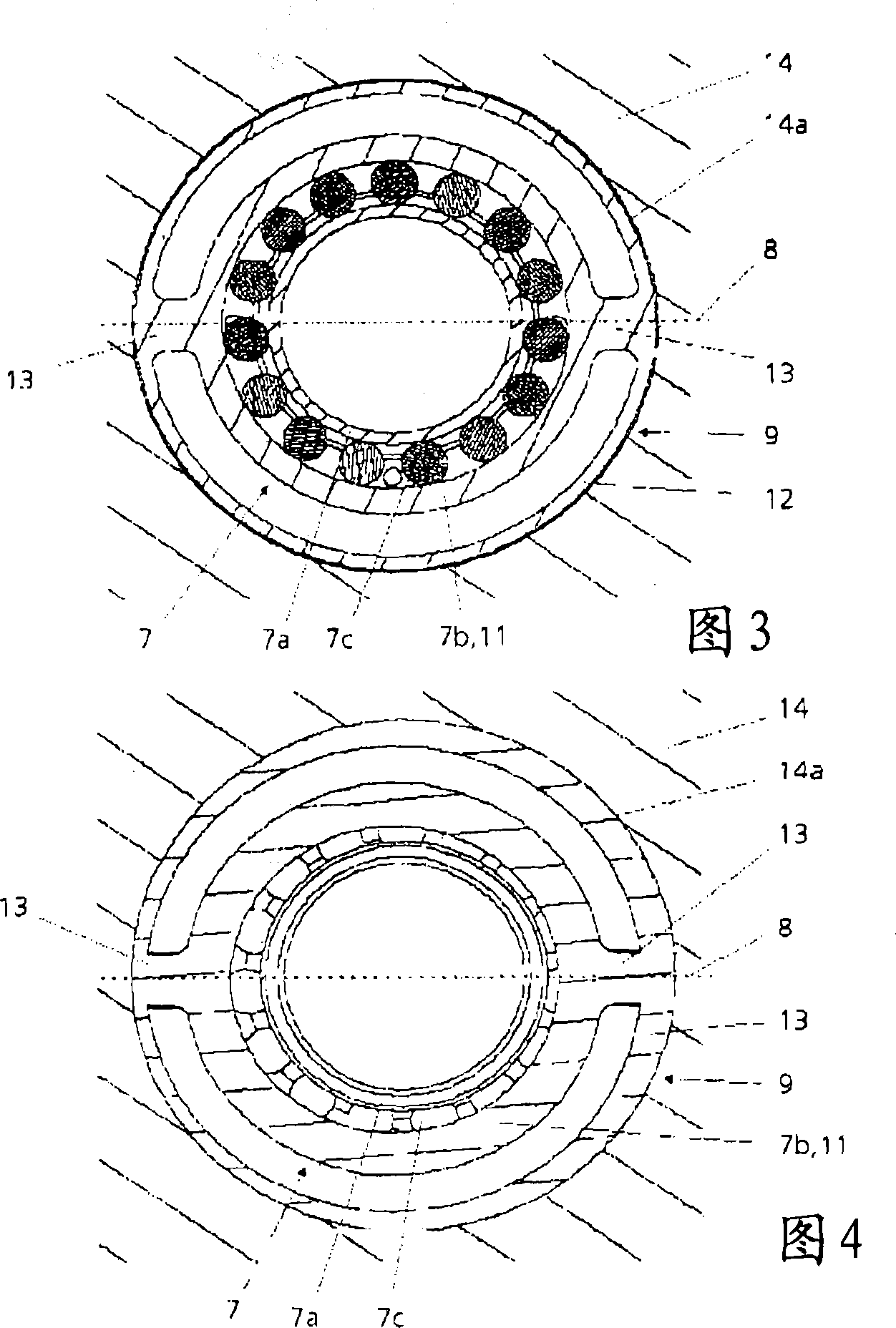

Seat adjuster assembly

A seat adjuster assembly includes an electric motor having an output shaft with a worm gear positioned in a gearbox, a spur gear meshing with the worm gear in the gearbox, a spindle shaft fixed to and driven by the spur gear coacting with a nut contained in a tube, and a linkage system connected to both a vertically movable upper vehicle seat part and a non-vertically movable lower vehicle seat part that positions vertically the upper vehicle seat part responsive to the position of the nut relative to the spindle shaft. At least one washer is provided on the spindle shaft. The spur gear is a plastic spur gear molded over the washer. A pair of leaf springs disposed in the gearbox bears against the spur gear and a wall of the gearbox.

Owner:JOHNSON ELECTRIC SA

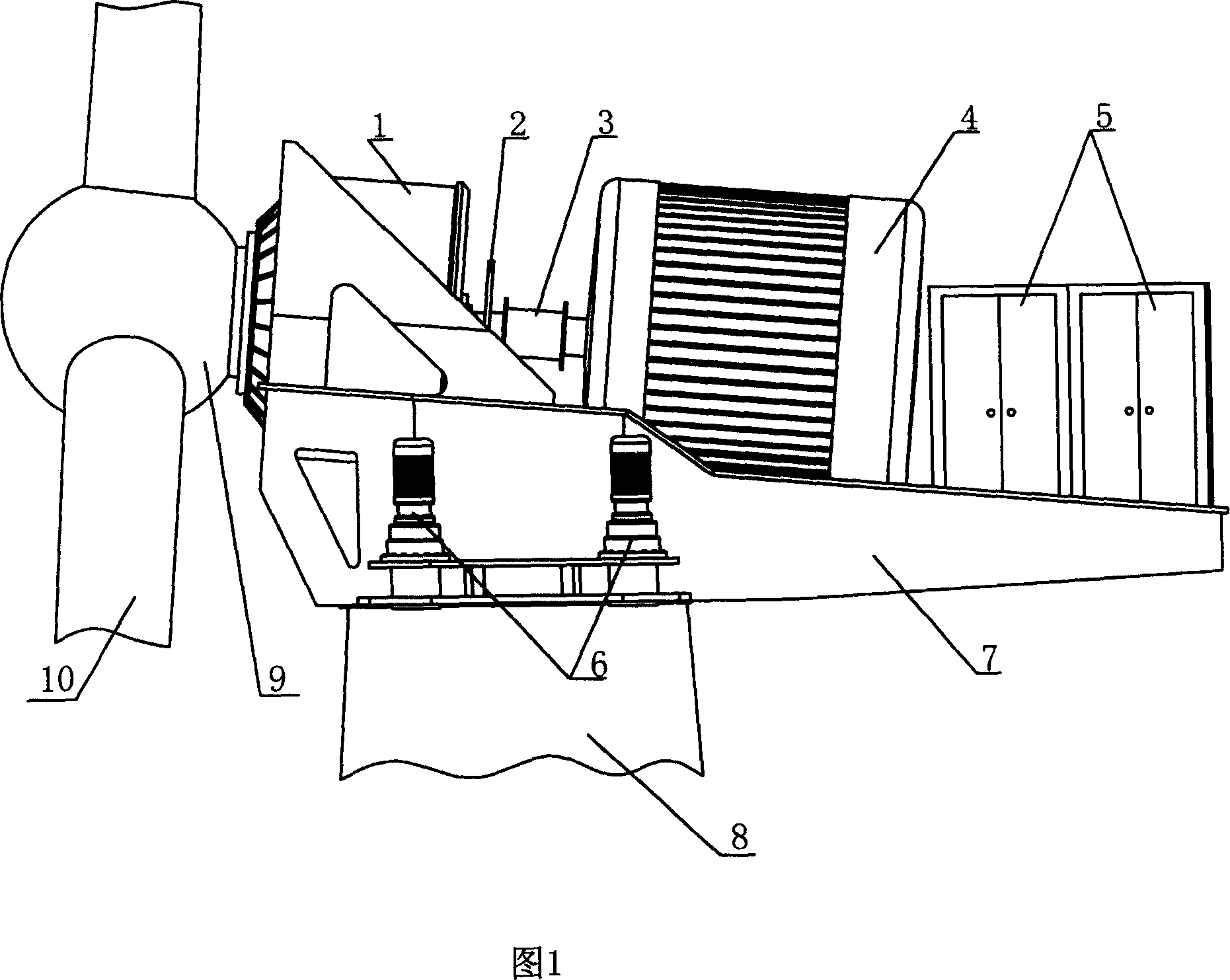

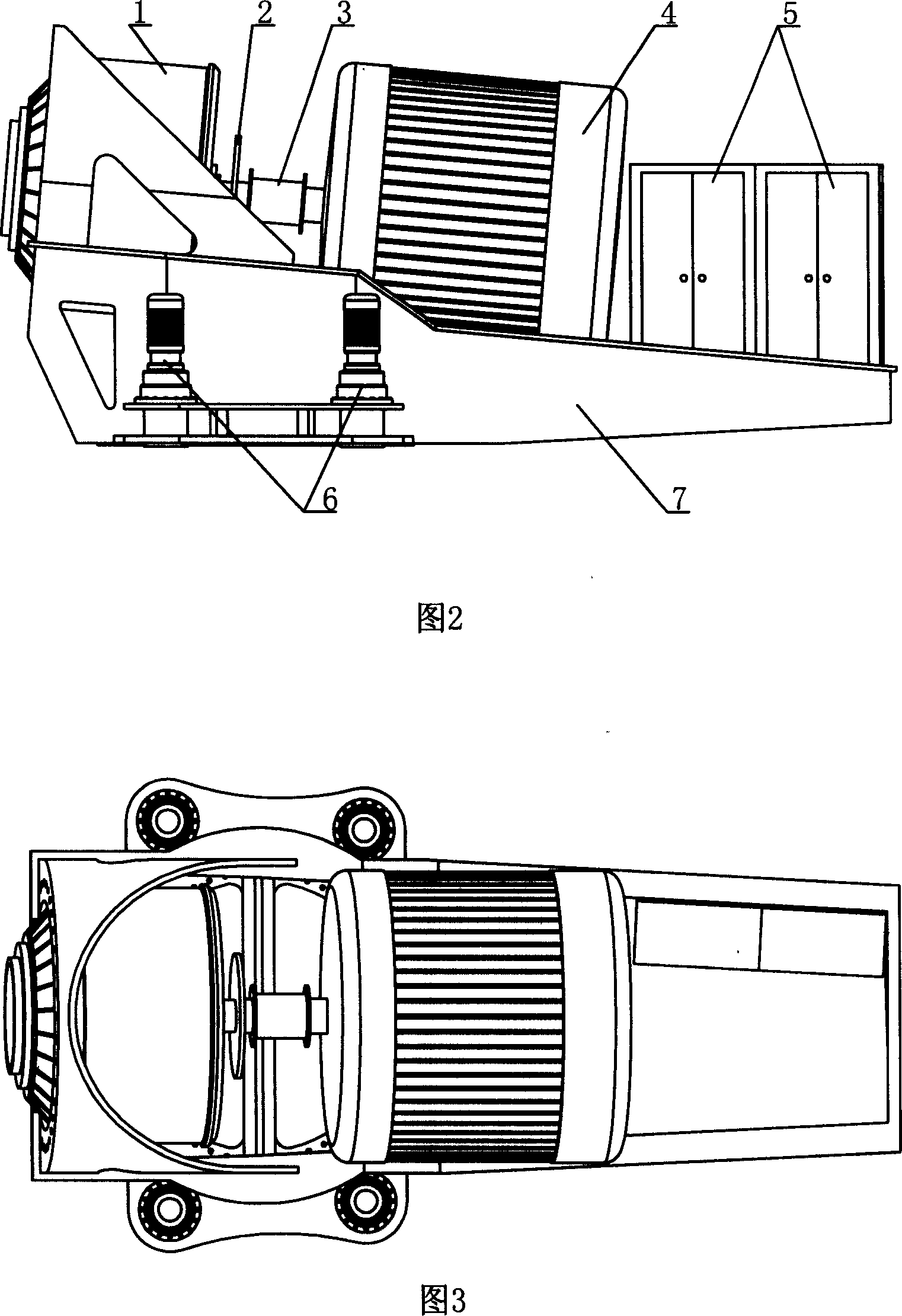

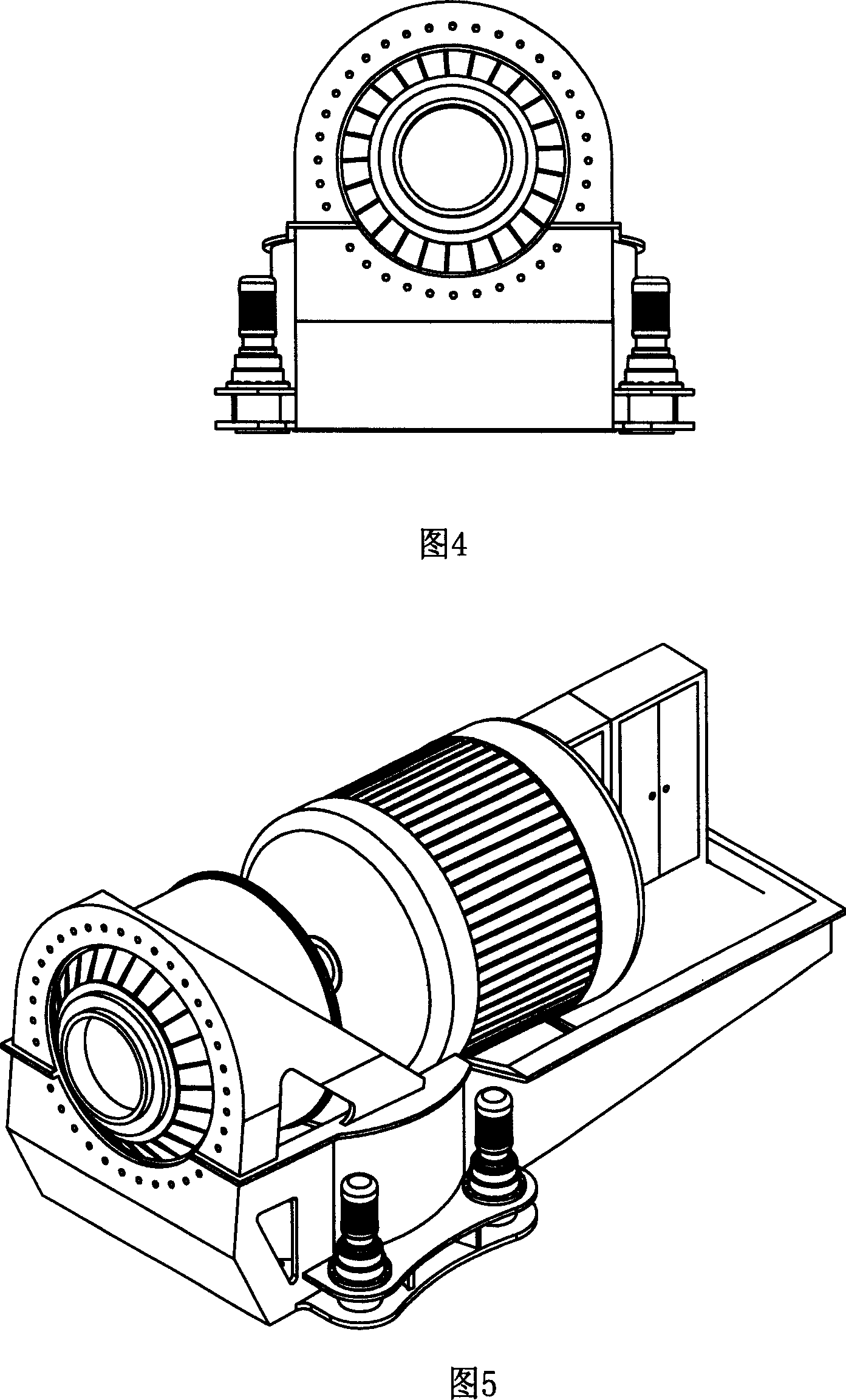

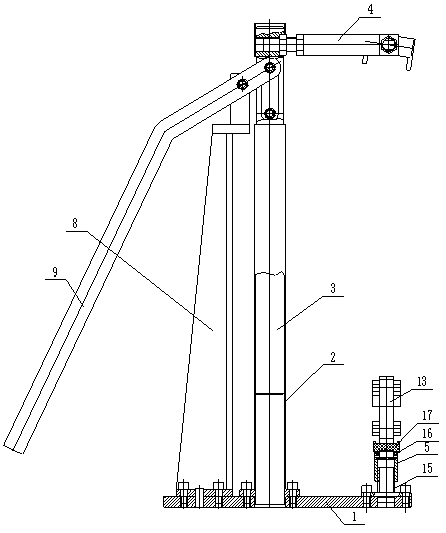

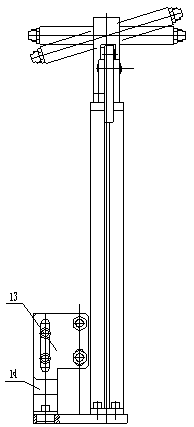

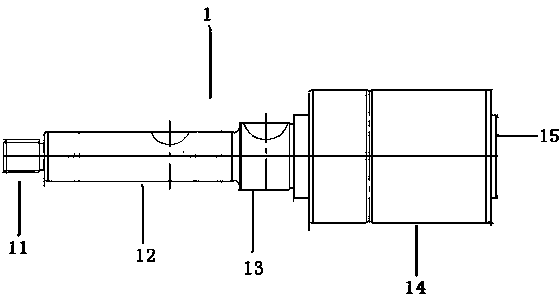

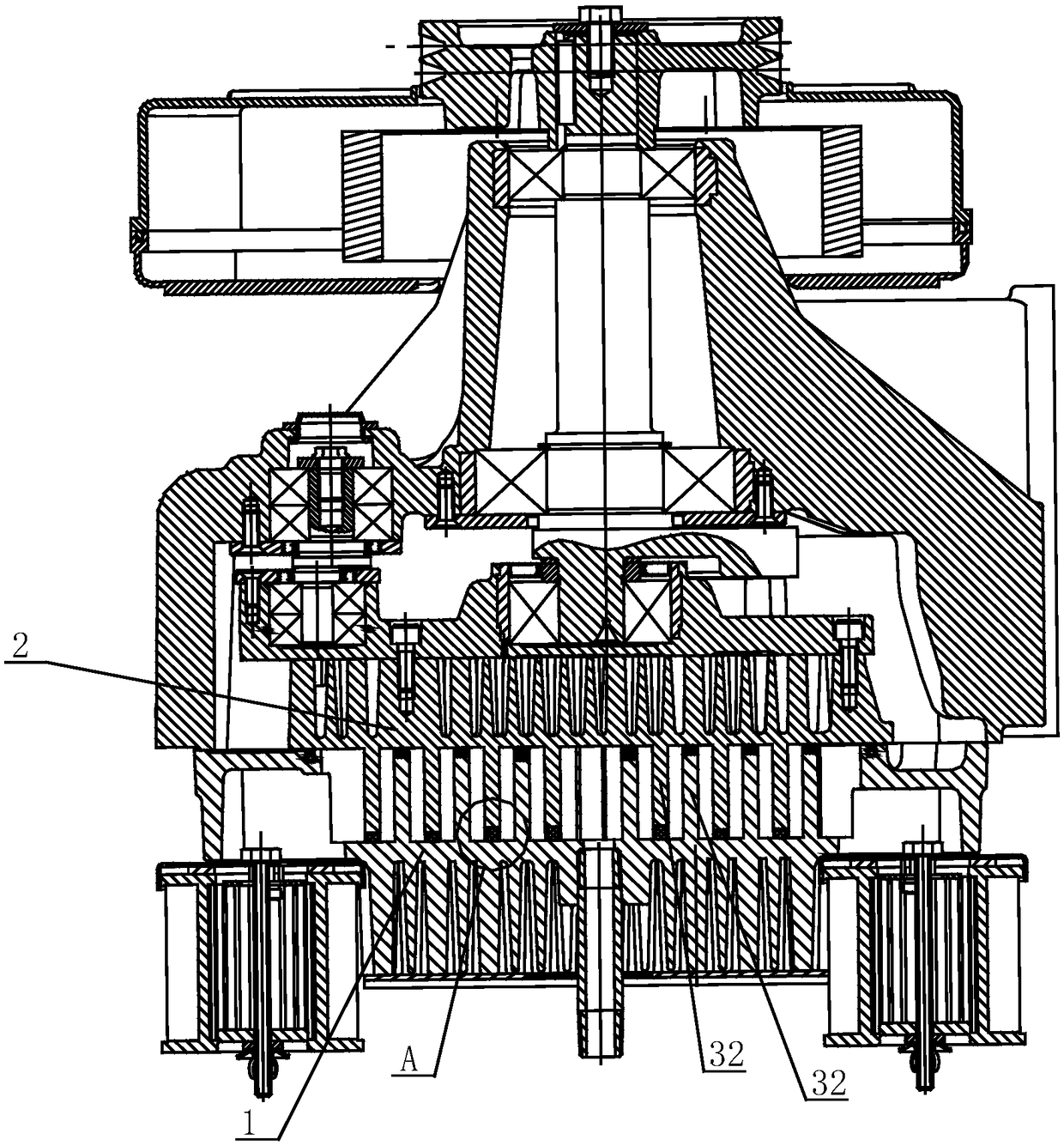

Megawatt semi-direct driving wind-power generator group

InactiveCN101016881AReduce axial playStable structureWind motor controlMachines/enginesNacelleLow speed

A megawatt-level semi-direct driving wind generator comprises a wind wheel, a distance changer, a main axle, a speed accelerating box, a coupler, a generator, a cabin chassis, a bias motor and a control system. The chassis is fixed with the bias motor and the generator, the accelerating box is fixed with the side wall of the chassis, the accelerating box is first-stage planet accelerating gear box, and the motor is low-speed permanent magnetic three-phase synchronous generator. The invention can stabilize the transmission of transmitter, reduce impact, and reduce sealing demand or the like, with adjustable installed height, simple structure, high strength and accurate angle control on distance change as 0.1 degree, to output constant power.

Owner:SHENYANG POLYTECHNIC UNIV

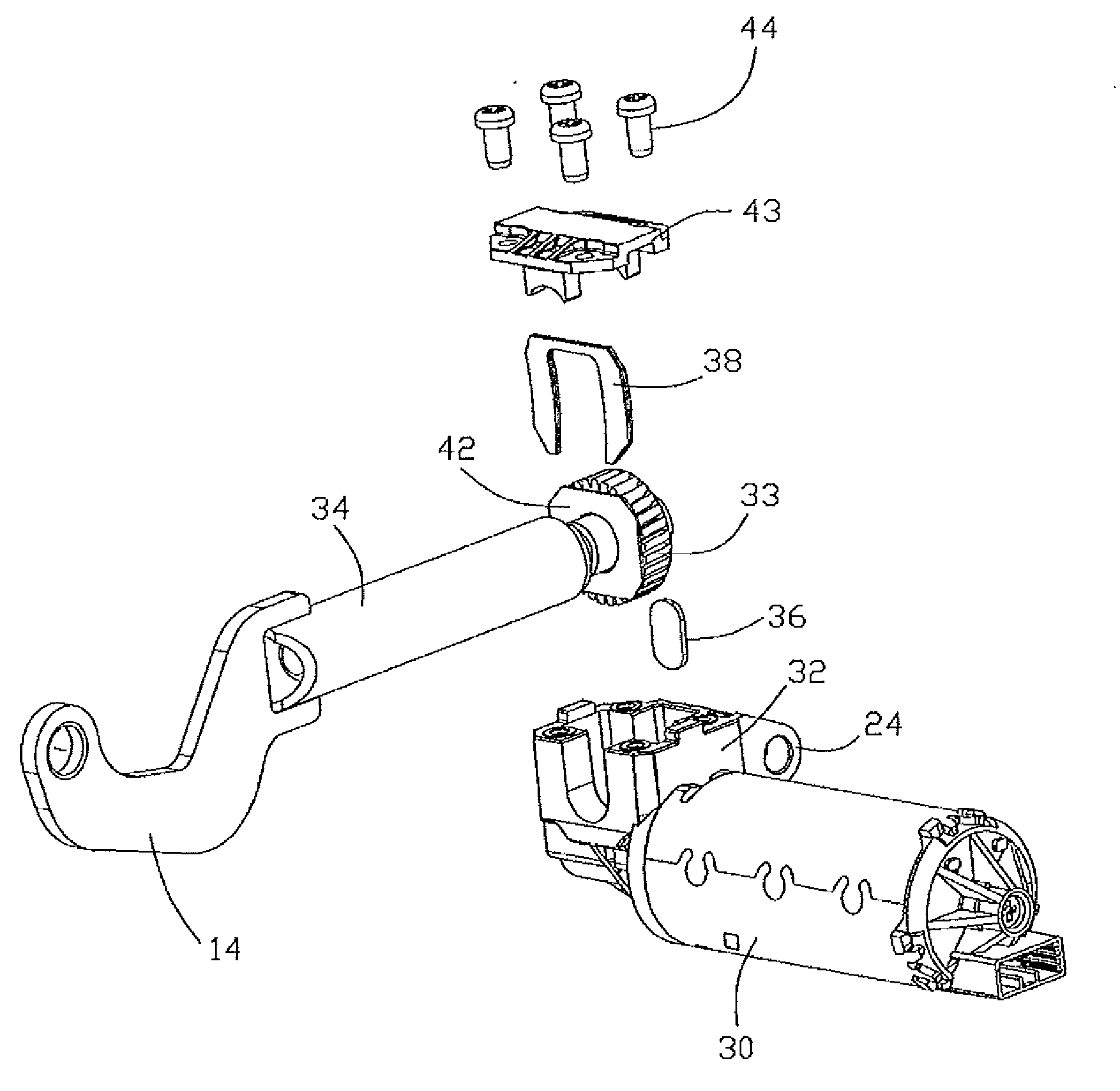

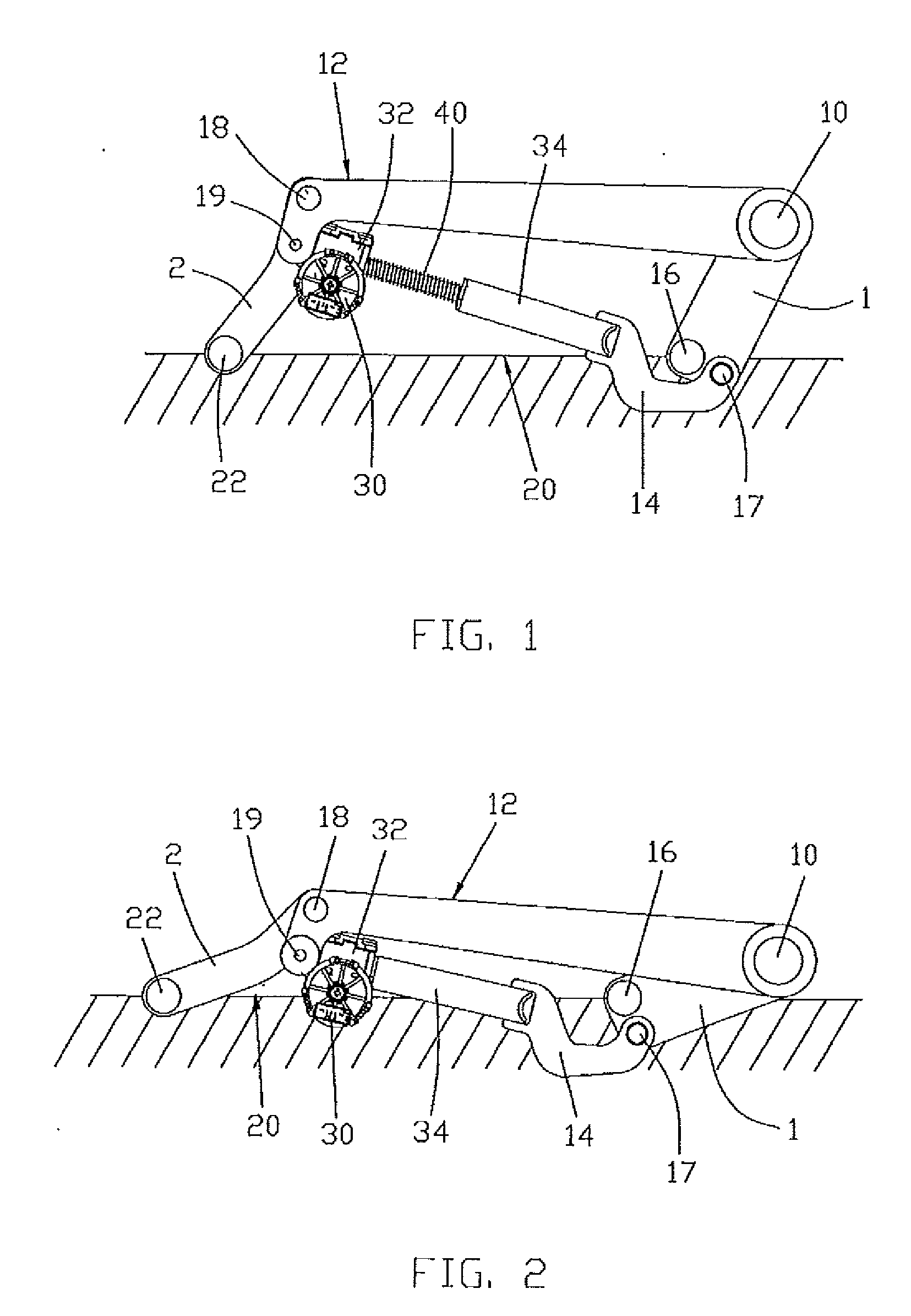

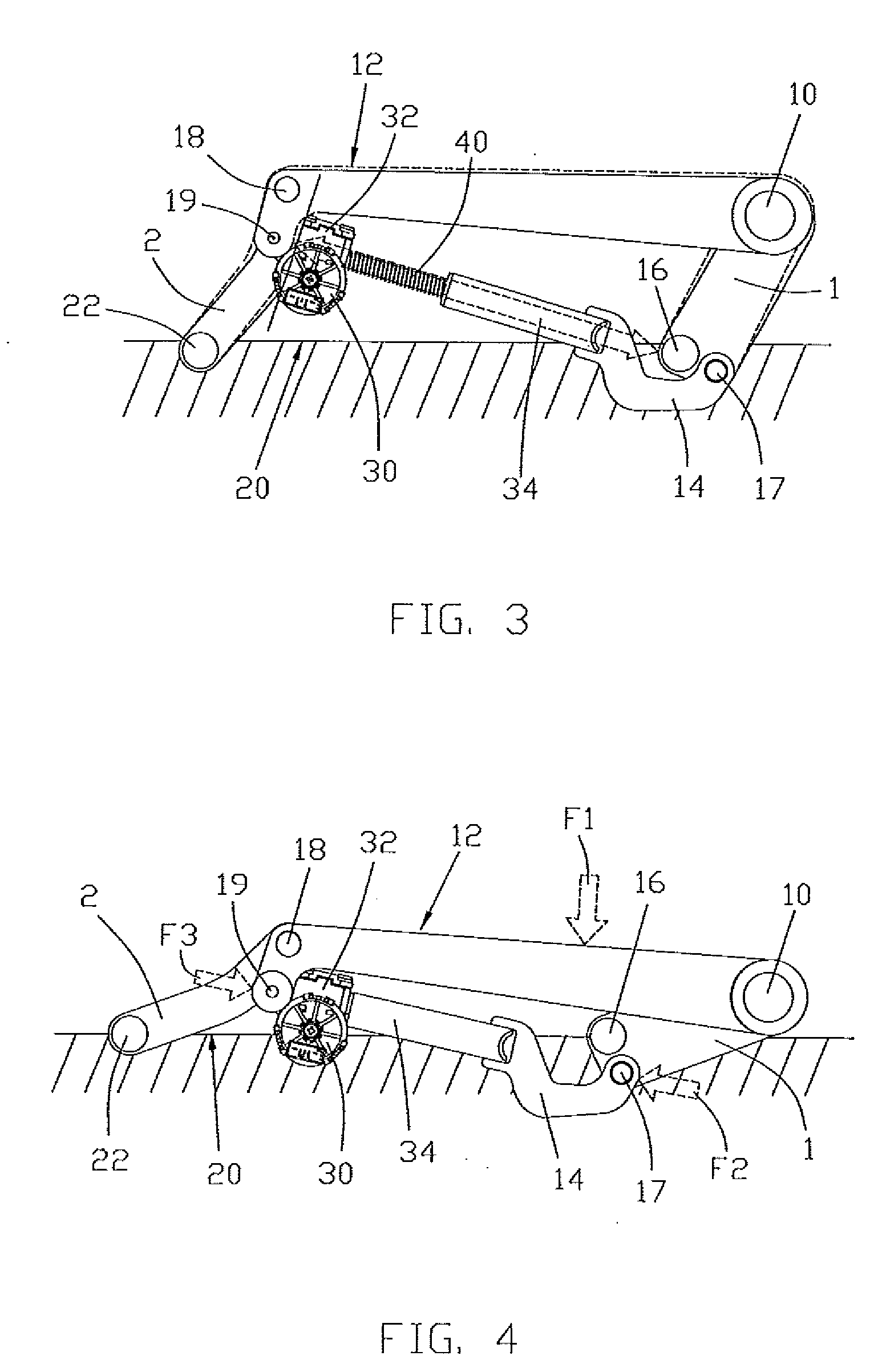

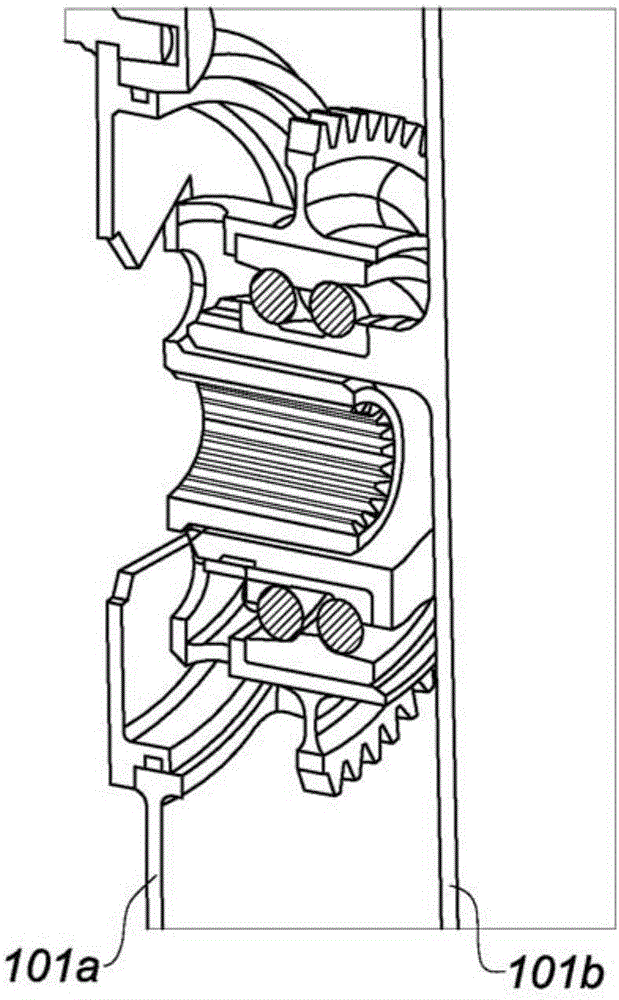

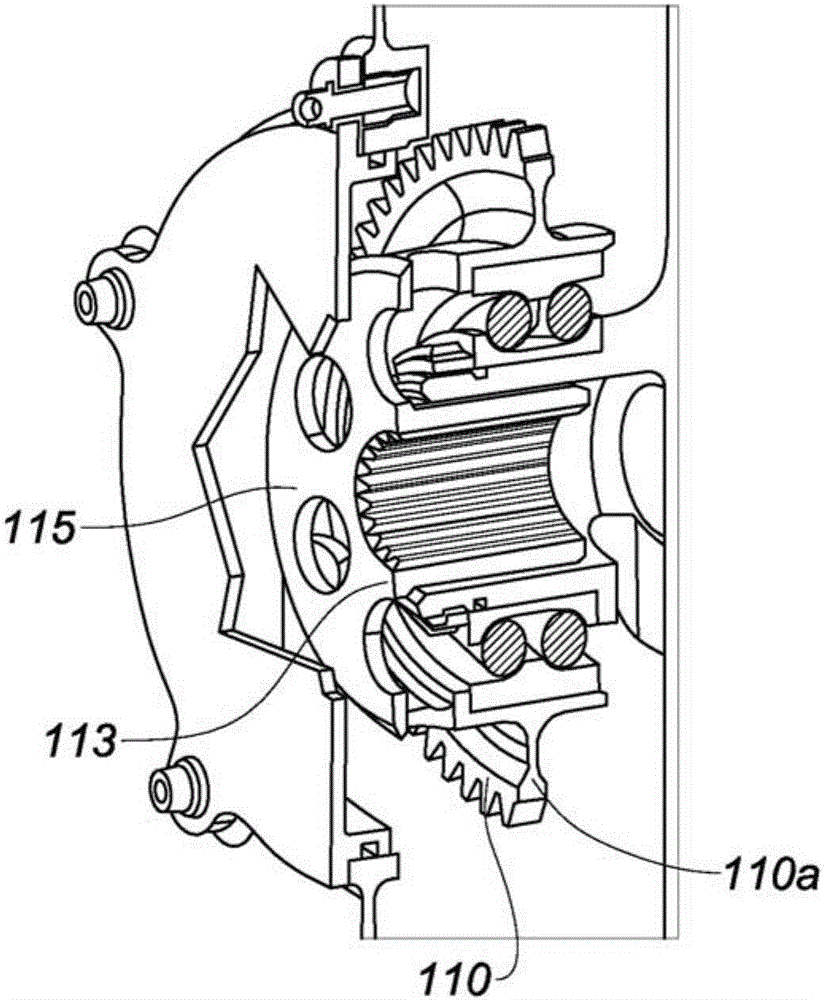

Seat adjuster assembly

ActiveUS20090206644A1Simple designSimple structureGearingMechanical energy handlingEngineeringSpur gear

A seat adjuster assembly includes an electric motor having an output shaft with a worm gear positioned in a gearbox, a spur gear meshing with the worm gear in the gearbox, a spindle shaft fixed to and driven by the spur gear coacting with a nut contained in a tube, and a linkage system connected to both a vertically movable upper vehicle seat part and a non-vertically movable lower vehicle seat part that positions vertically the upper vehicle seat part responsive to the position of the nut relative to the spindle shaft. At least one washer is provided on the spindle shaft. The spur gear is a plastic spur gear molded over the washer. A pair of leaf springs disposed in the gearbox bears against the spur gear and a wall of the gearbox.

Owner:JOHNSON ELECTRIC SA

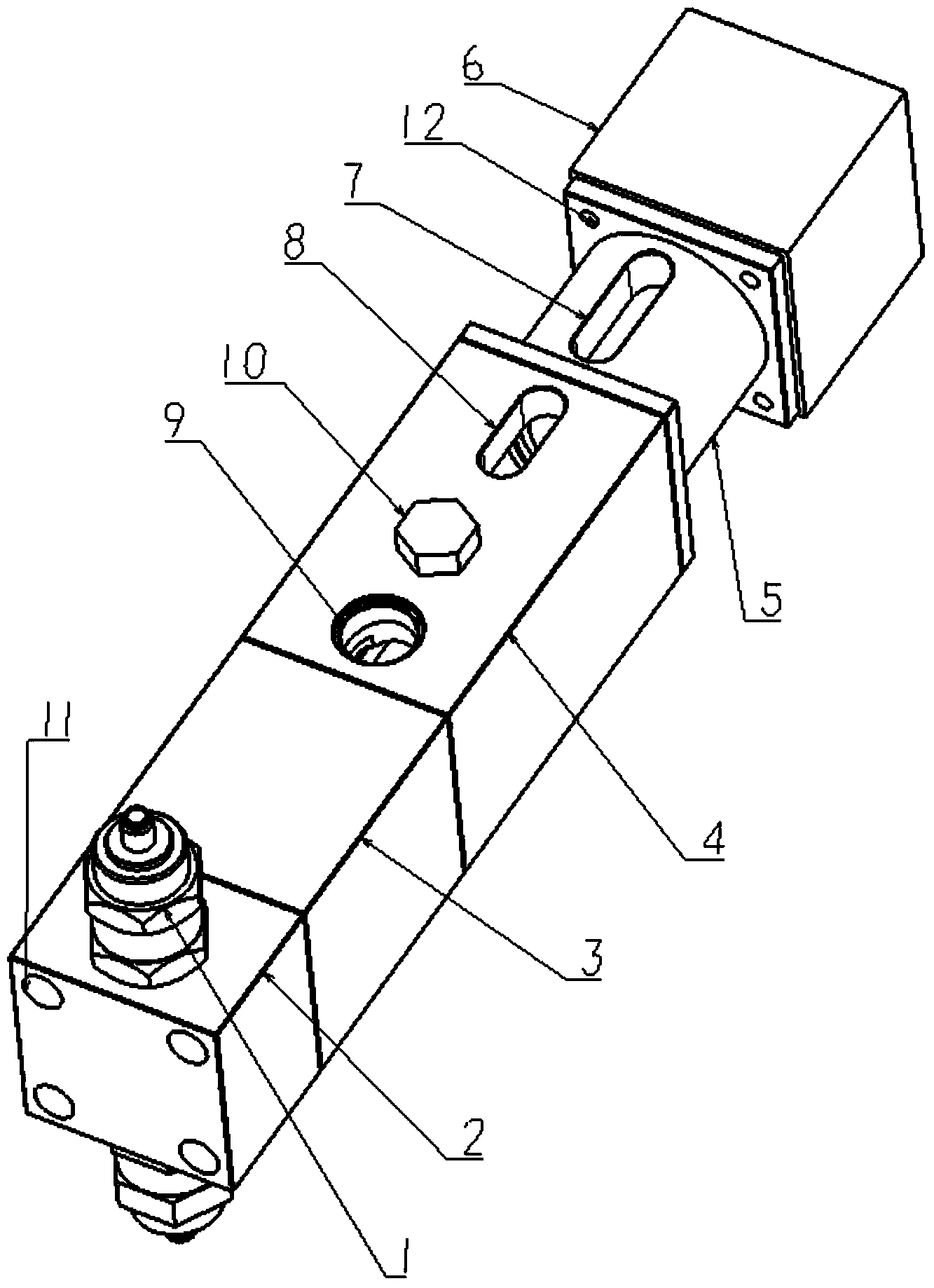

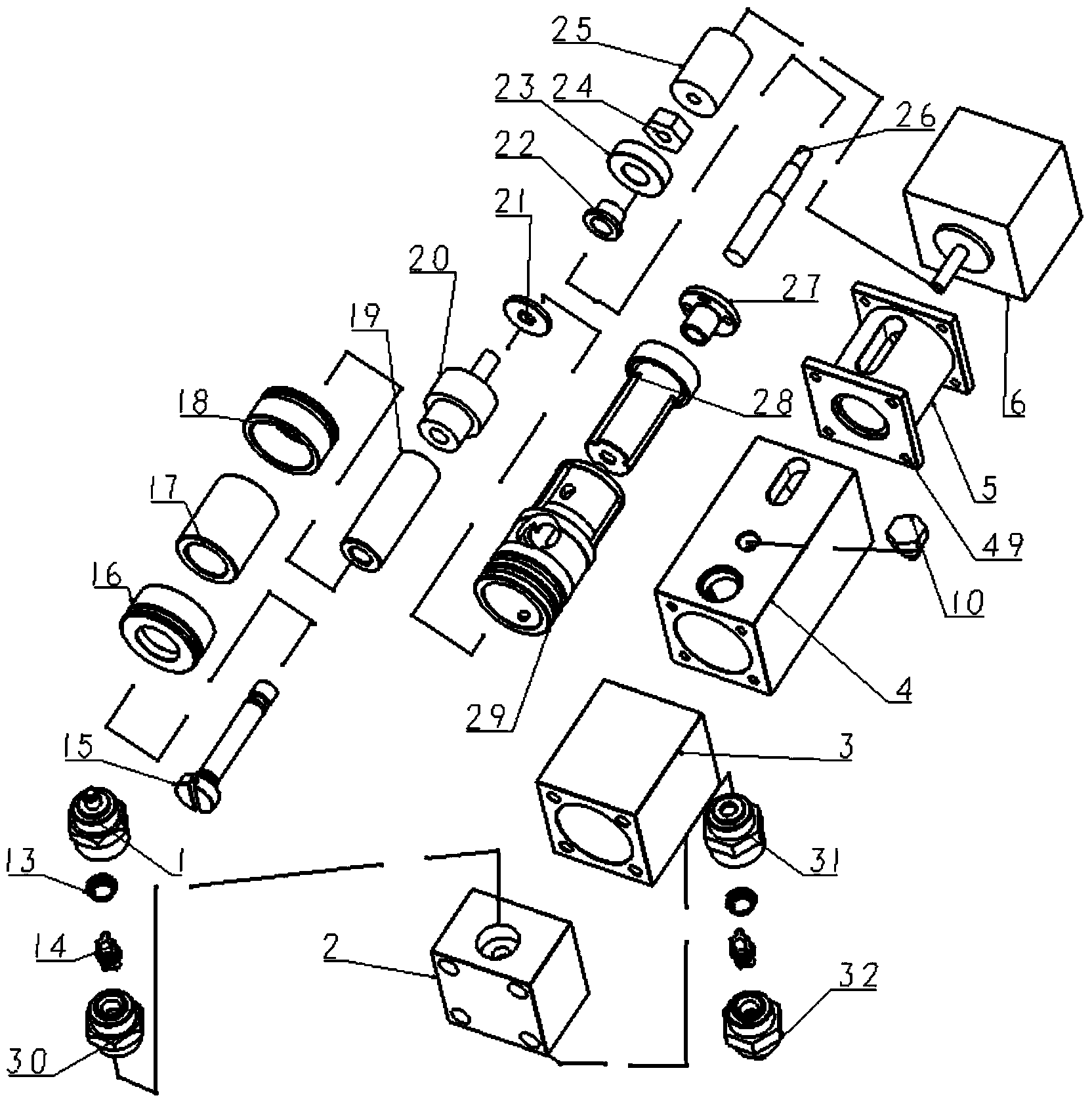

Precision metering ceramic plunger liquid charge pump

ActiveCN103967733AReduce wearAvoid it happening againPositive displacement pump componentsPump controlSurface roughnessDrive motor

The invention discloses a precision metering ceramic plunger liquid charge pump which structurally comprises a pump head, two single-direction valves, a pump body, a driving mechanism and a control driving unit. The singe-direction valves are connected into thread holes in the pump head through threads on upper valve bases and lower valve covers. The pump head penetrates through four through holes through inner hexagonal bolts, and the pump head and a pump body outer shell are fastened on a driving outer shell. A motor base is fastened on the driving outer shell by the fact that inner hexagonal bolts penetrate through four through holes. A driving motor is fastened on the motor base by the fact that inner hexagonal bolts penetrate through four through holes. One end of a plunger core in the pump body is connected with inner threads of a floating connector in the driving mechanism through outer threads. The driving mechanism is connected with the control driving unit. The liquid charge pump has corrosion resistance and abrasion resistance, impurities are not mixed into ceramic, so that the fact that medicine liquid is not contaminated during a liquid-charge process is guaranteed, the roughness of the surface of the ceramic is low, on-line washing is easy, and accuracy and speed are improved.

Owner:山东海燕医用材料制造有限公司

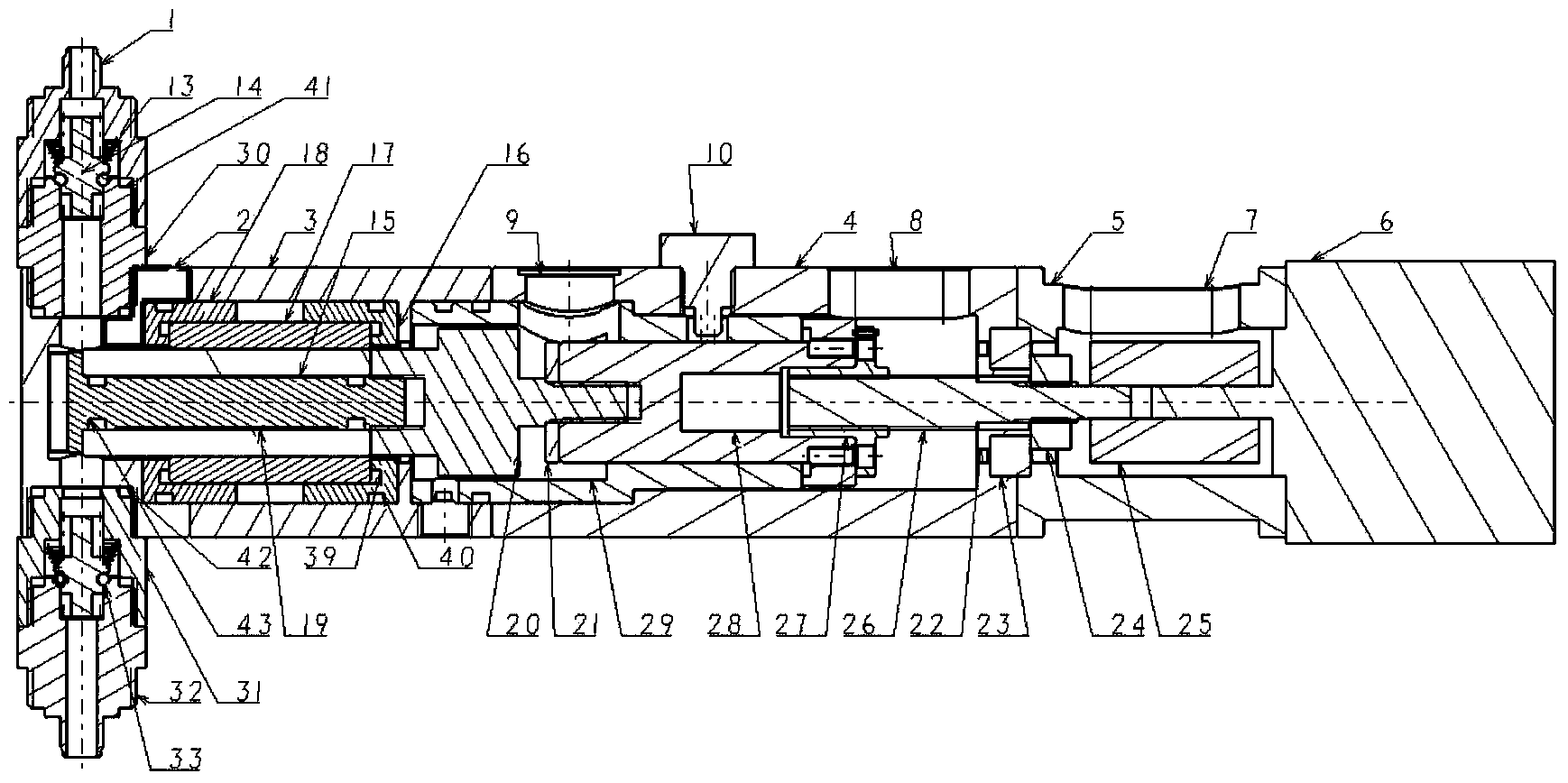

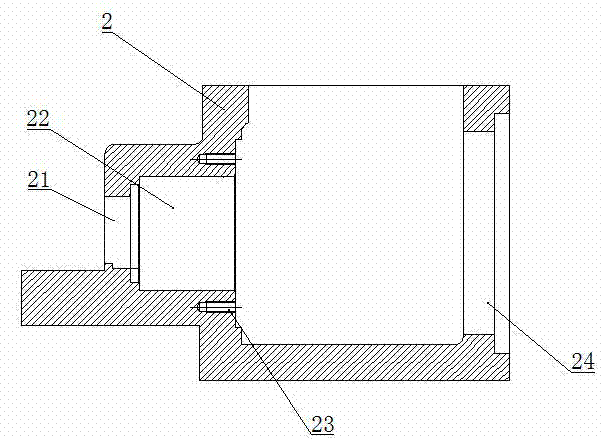

Pump comprising an integrated engine

ActiveCN1826470AImprove utilizationReduced vibration damping requirementsPump componentsPump installationsPhysicsElectric motor

Owner:BOSCH SIEMENS HAUSGERATE GMBH

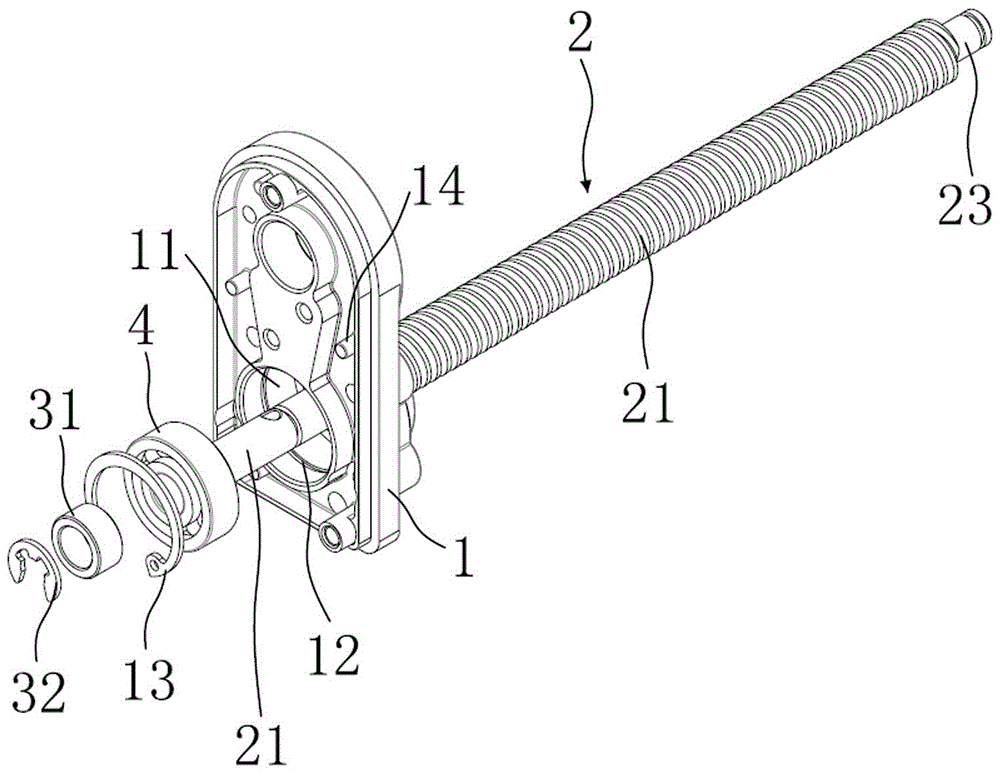

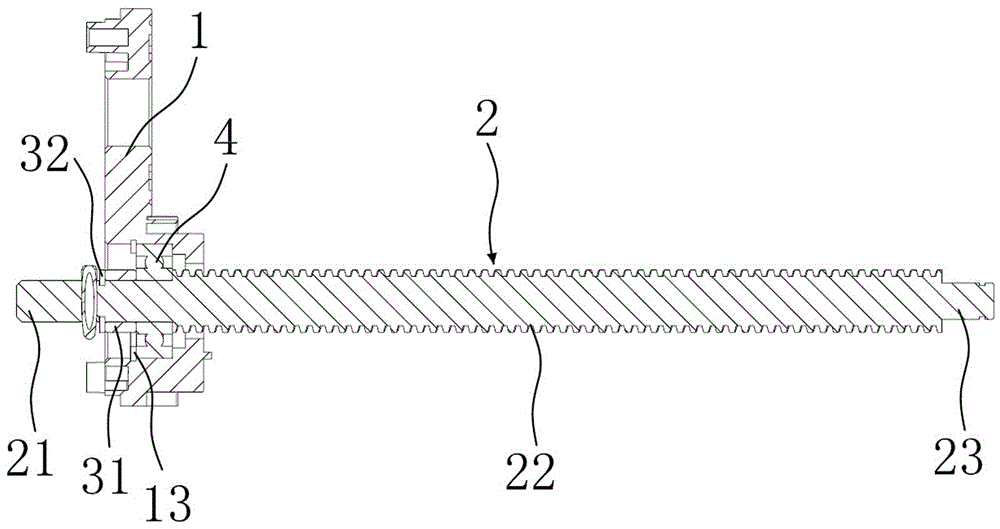

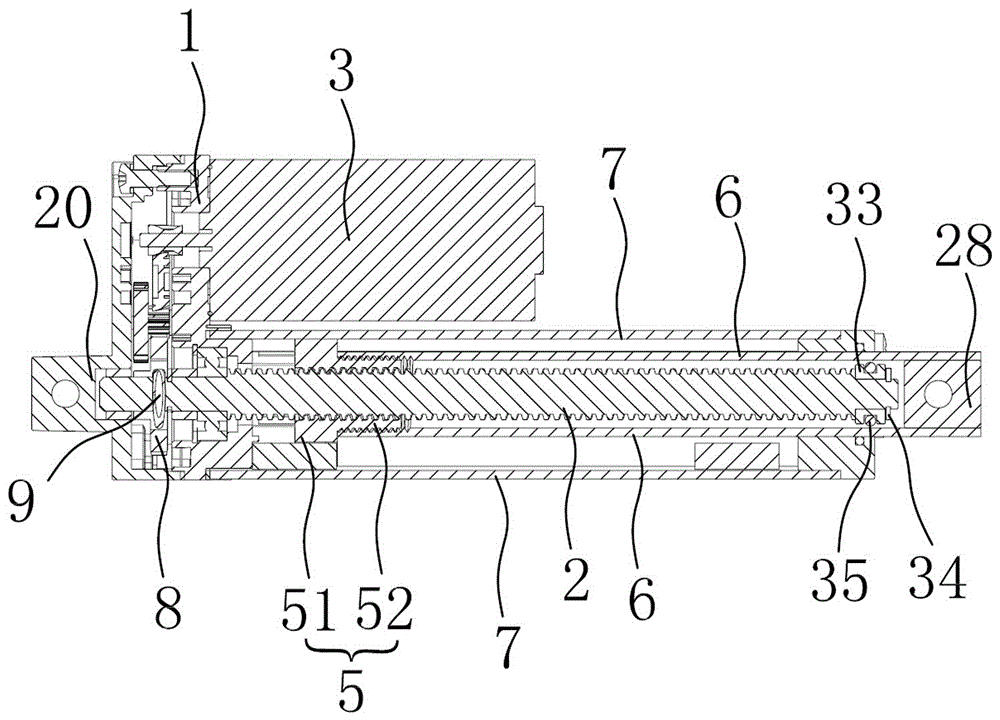

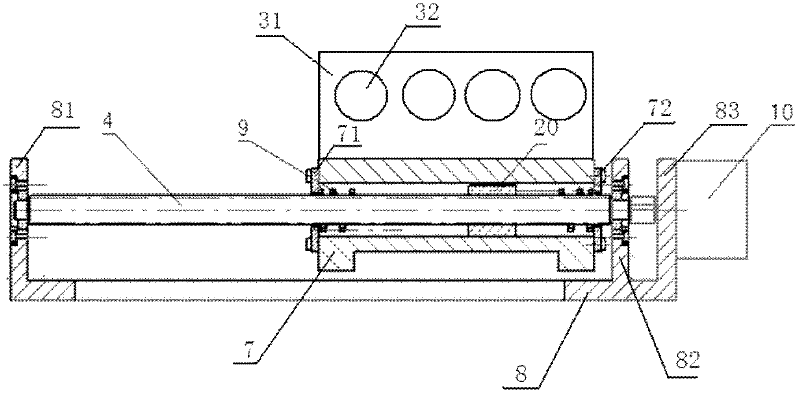

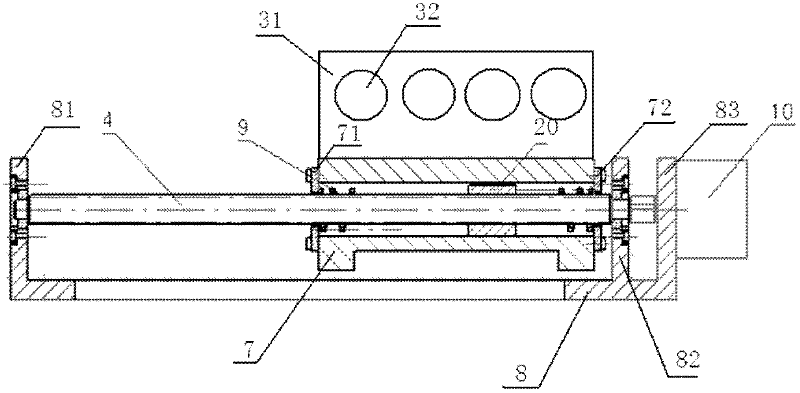

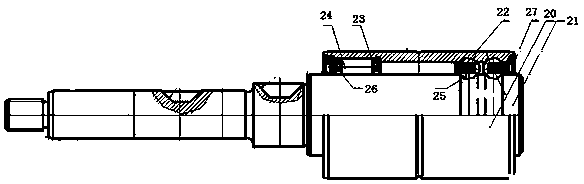

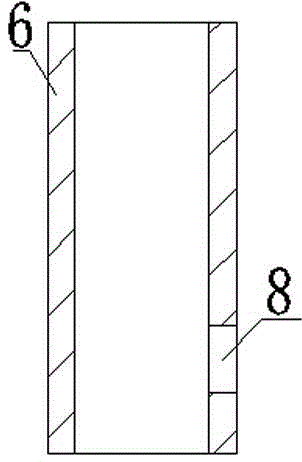

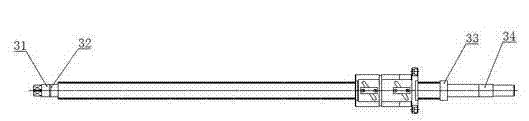

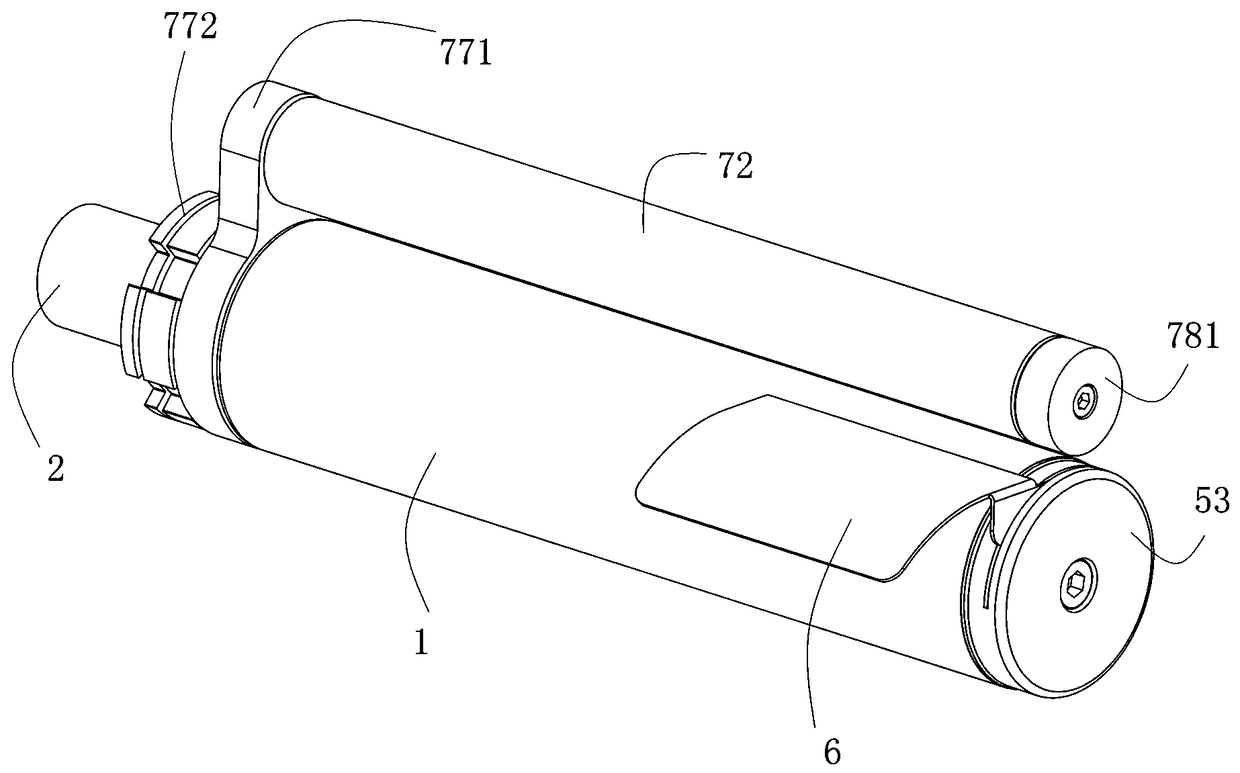

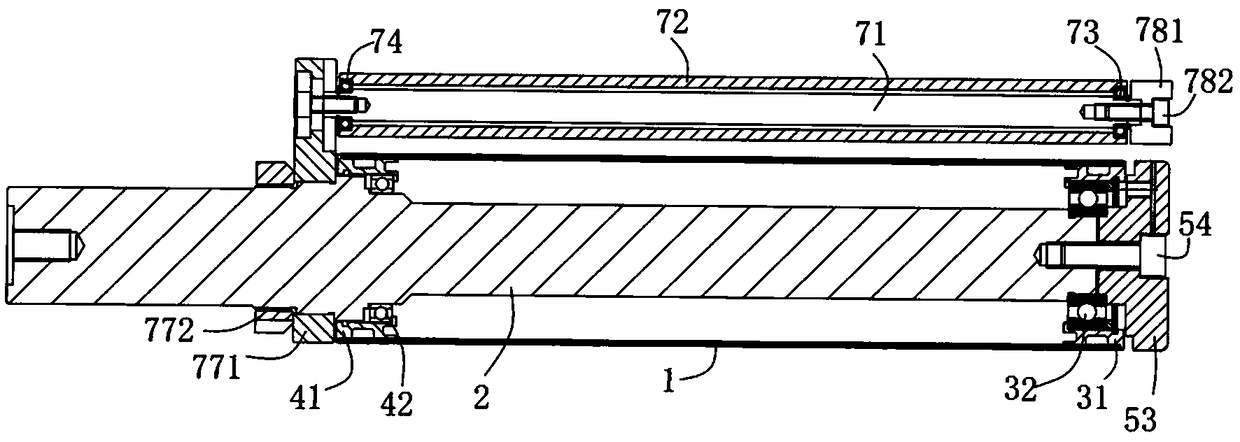

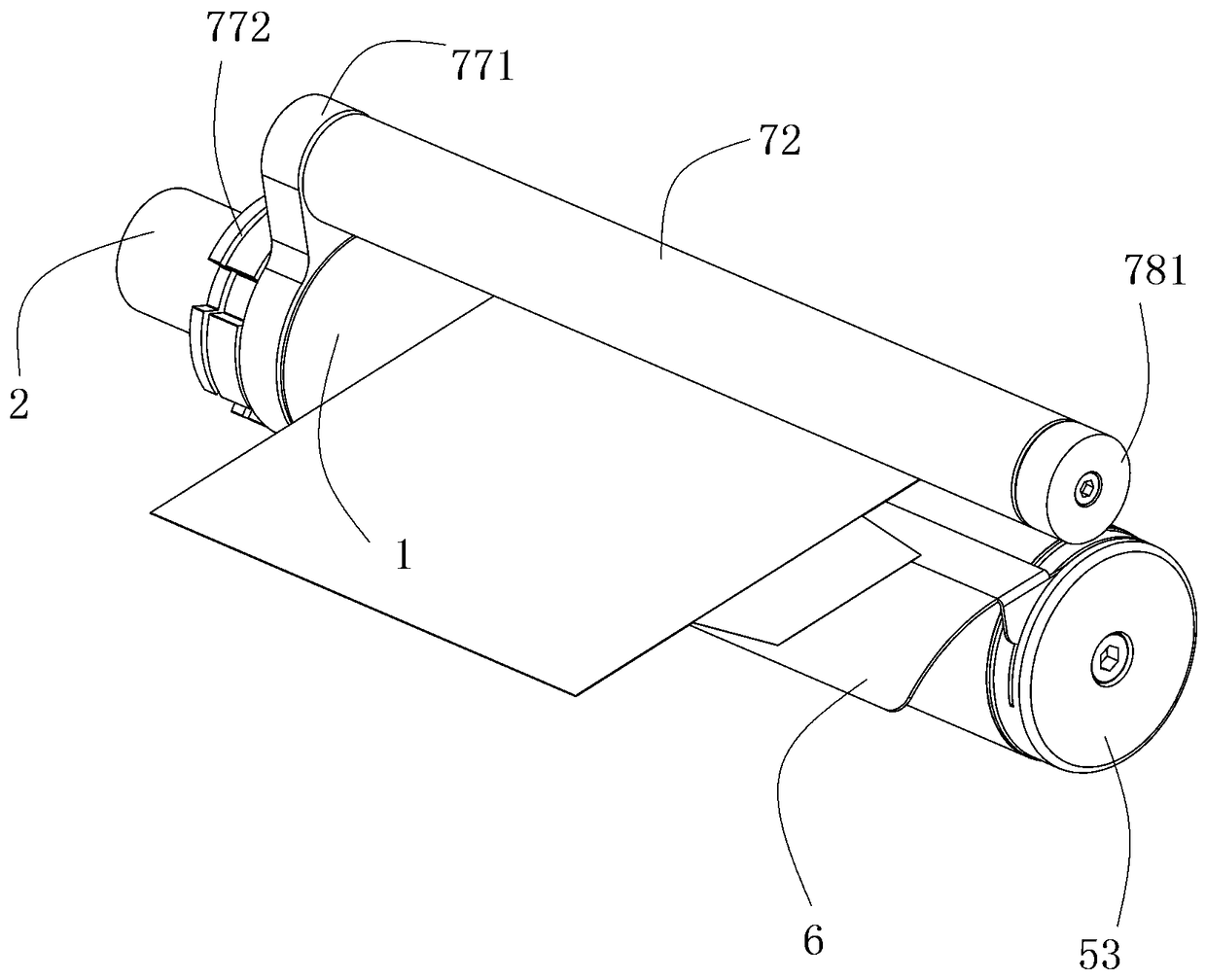

Electric push rod

ActiveCN106253568AReduce axial playAvoid touchingMechanical energy handlingReciprocating motionEngineering

The invention discloses an electric push rod which comprises a casing, a screw rod and a motor. The motor is linked with the screw rod through a speed reduction mechanism. The front end of the screw rod is fixed to the casing. The back end of the screw rod extends to the outer side of the casing. A nut which cooperates with the screw rod is fixed to a top tube which is sleeved by a conduit which is fixed to the casing. The screw rod is rotated such that the top tube makes an axial reciprocating motion relative to the conduit. A bearing room is formed in the casing and a bearing is fixed. The inner ring of the bearing is fixed to the screw rod. A first retaining ring is fixed to the screw rod and is at the front side of the bearing.

Owner:ZHEJIANG LINIX MOTOR

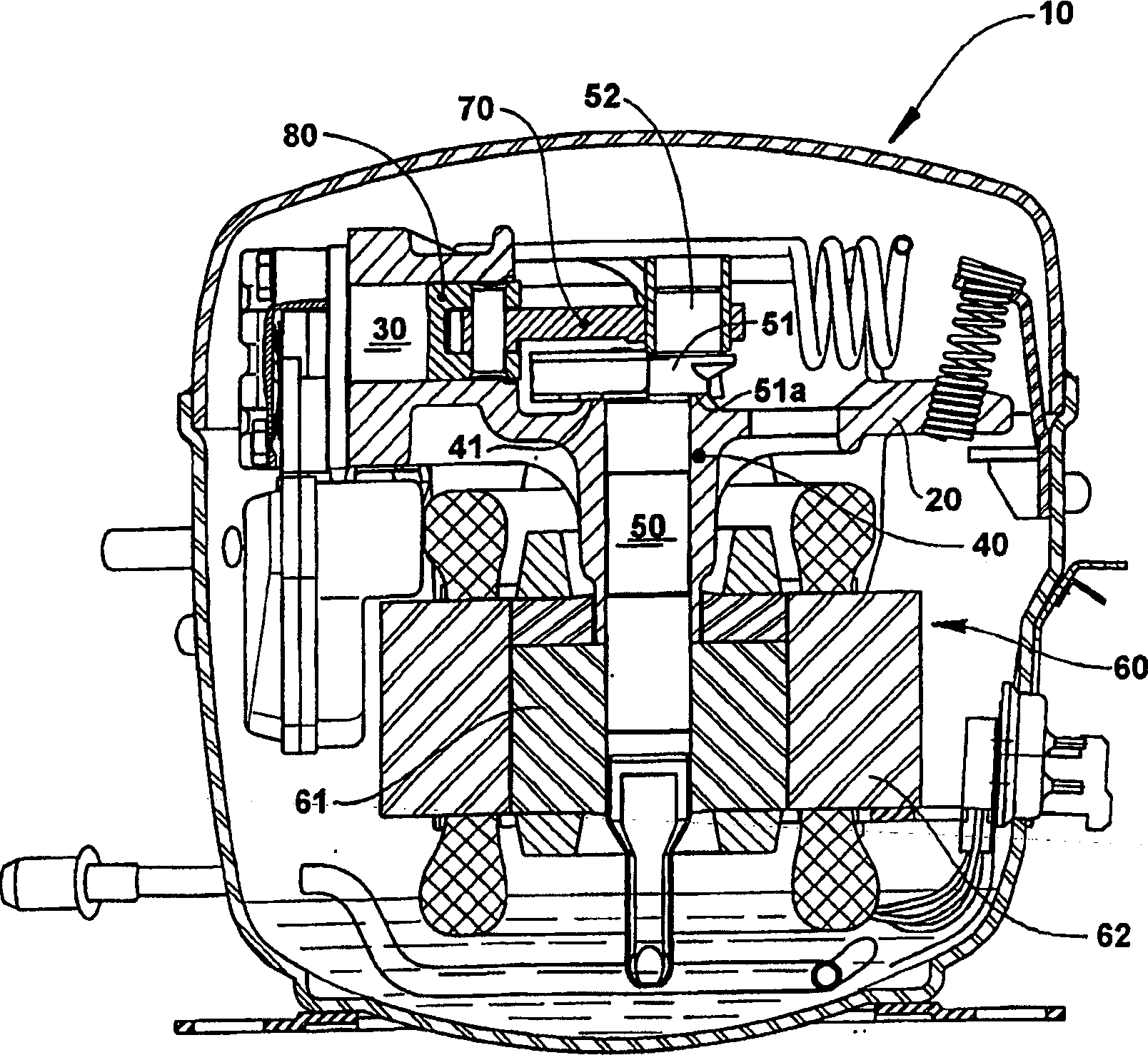

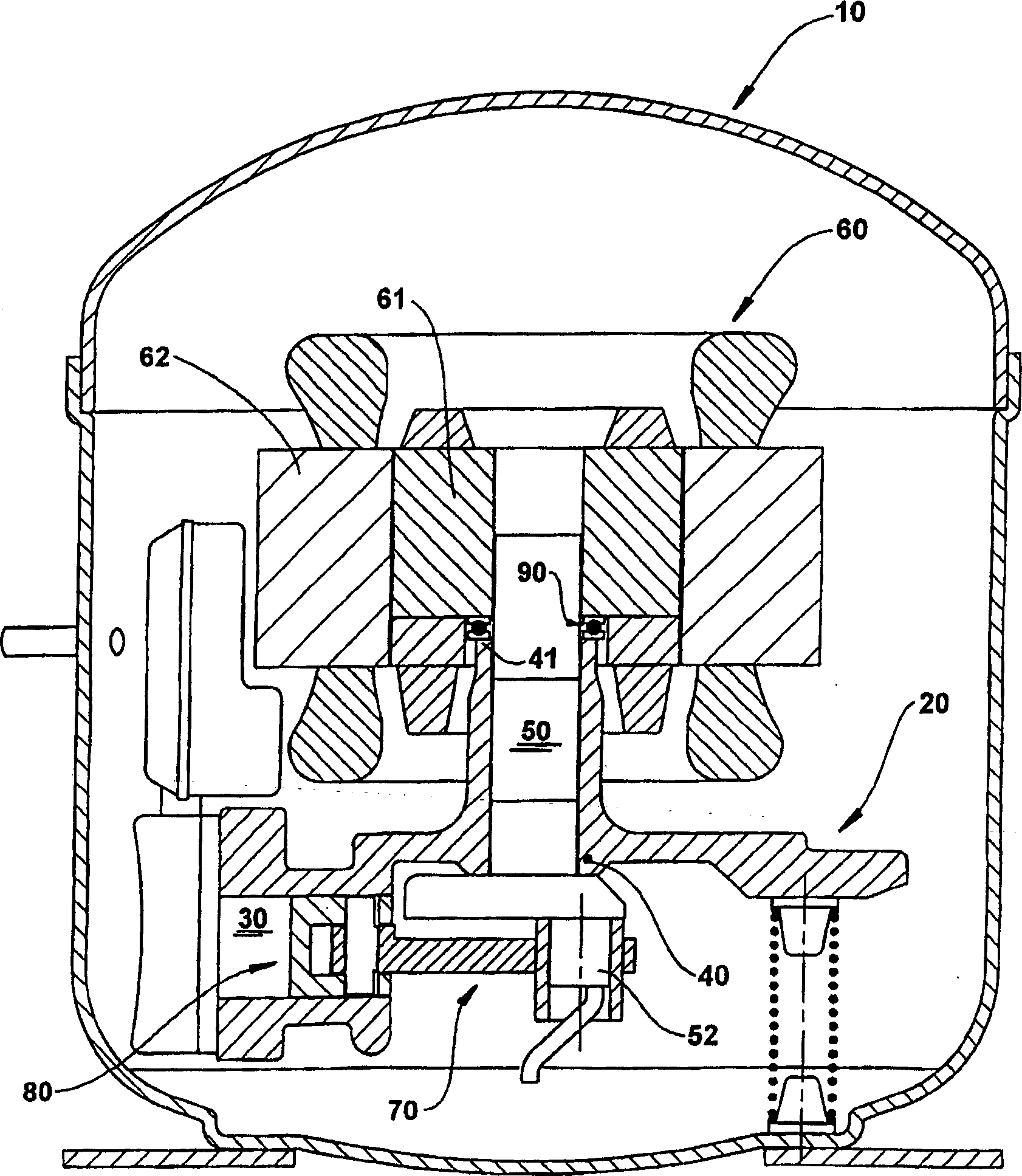

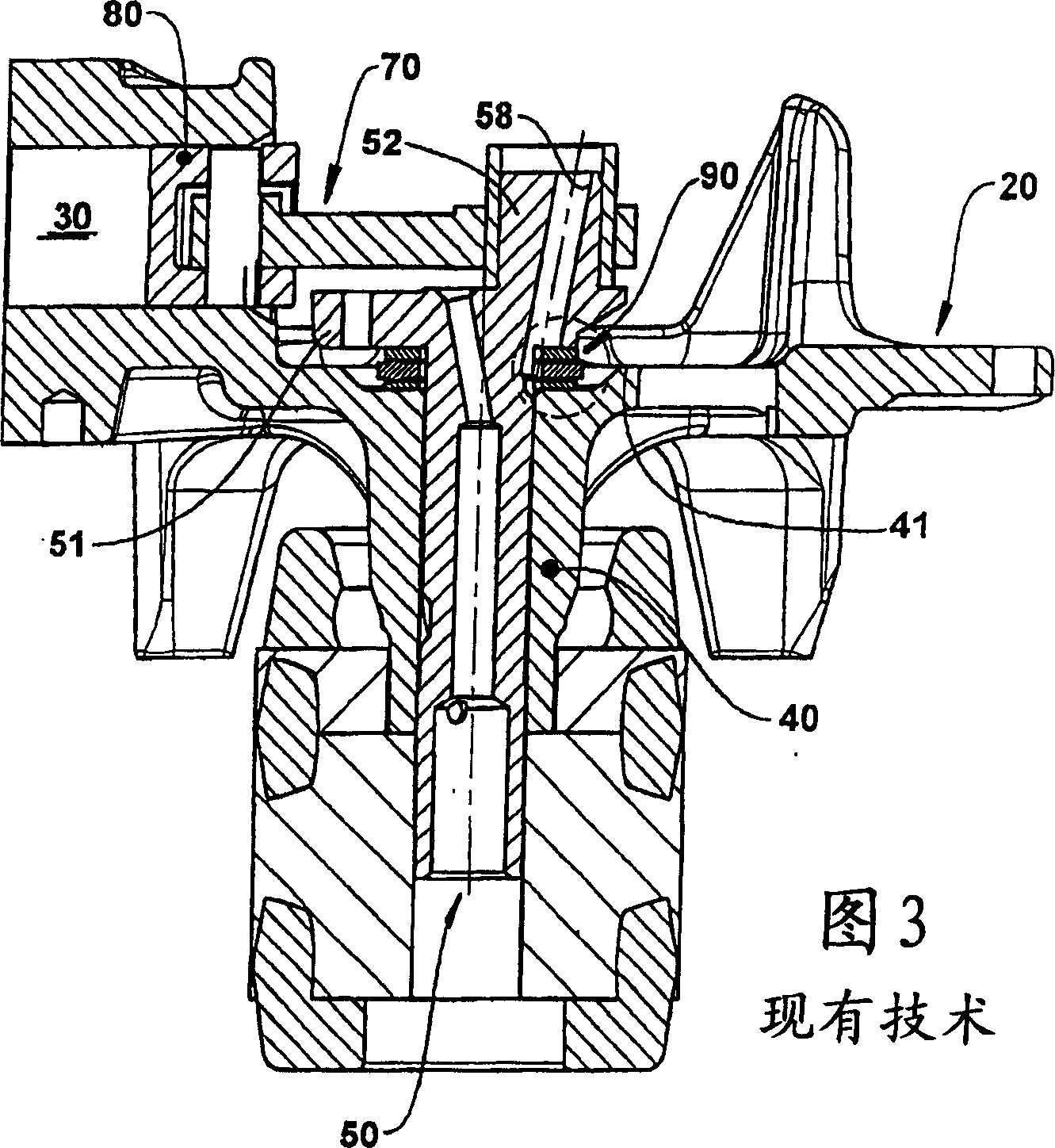

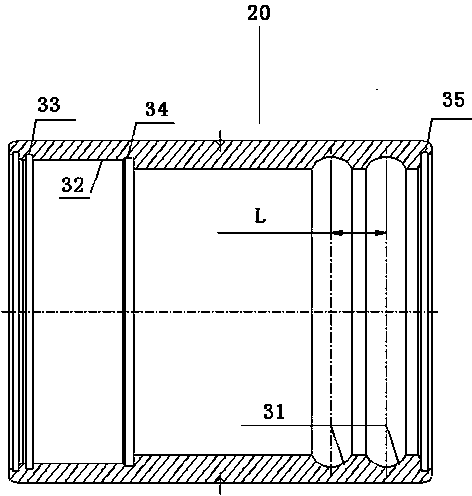

Axial bearing structure for closed compressor

InactiveCN1549898AReduce axial playPositive displacement pump componentsPositive-displacement liquid enginesRolling-element bearingCylinder block

A reciprocating hermetic compressor includes a cylinder block internal to a shell and carrying a cylinder and a radial bearing hub; a crankshaft vertically mounted in the radial bearing hub and carrying, inferiorly, a rotor of an electric motor and, superiorly, a support annular face and an eccentric portion. The radial bearing hub incorporates an upper tubular extension, bearing a corresponding extension of the crankshaft and around which is mounted an axial rolling bearing for supporting the weight of the crankshaft-rotor assembly, as well as the axial stresses produced during compression of the refrigerant gas.

Owner:WHIRPOOL SA

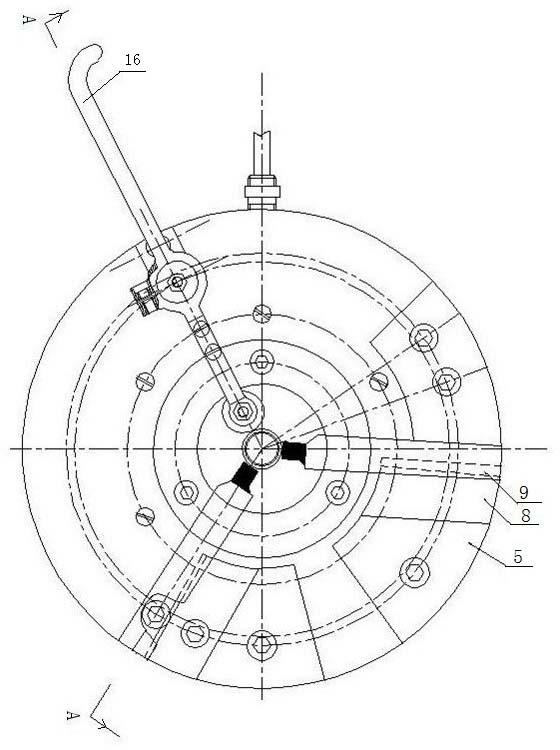

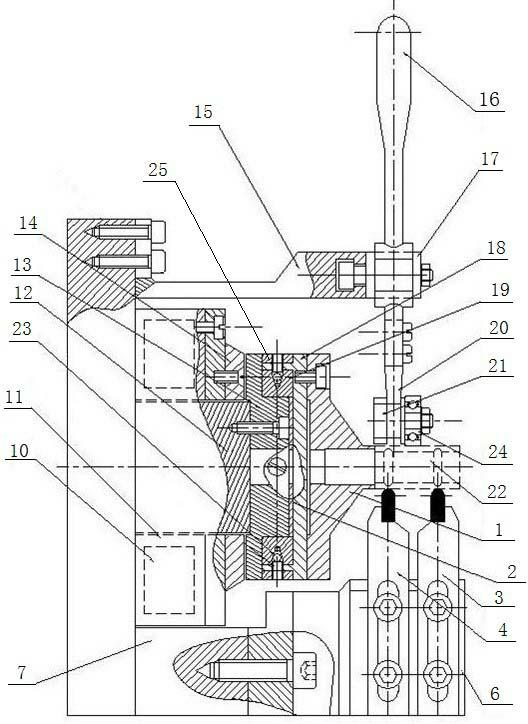

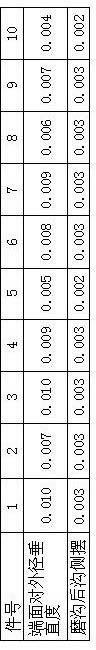

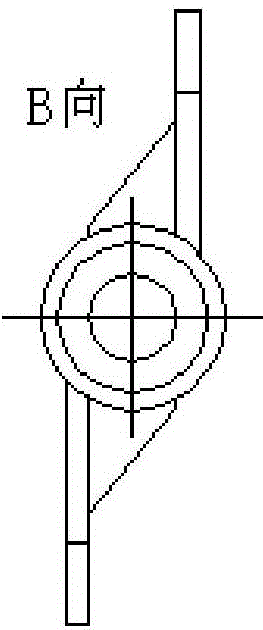

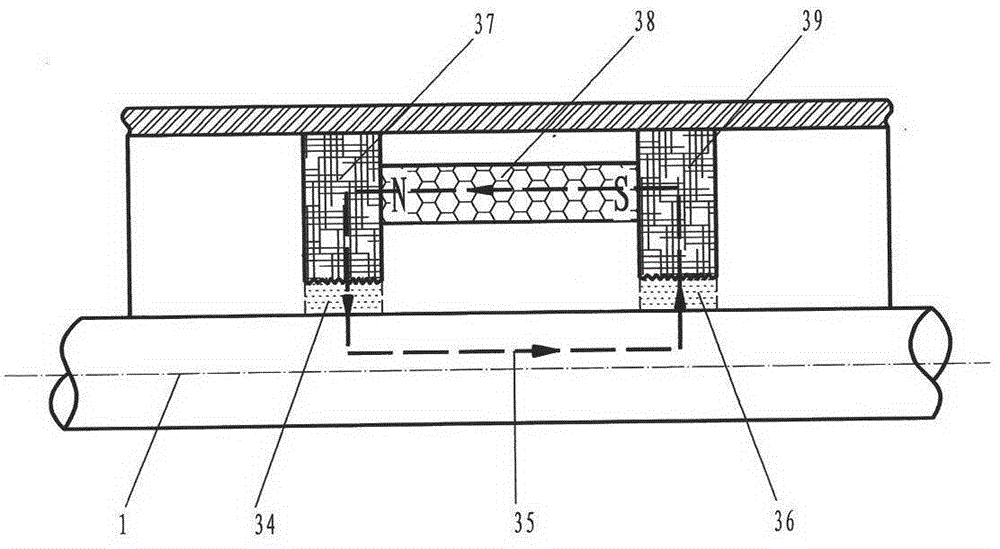

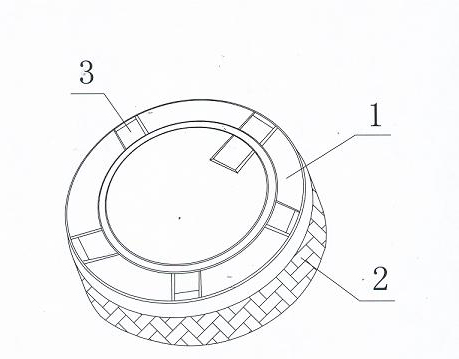

Electromagnetic coreless fixture with locating ring capable of axially floating

ActiveCN102658509AReduce axial playReduce the adverse effects of the vertical difference in the outer diameter of the workpieceRevolution surface grinding machinesGrinding work supportsMarine engineeringMagnetic poles

The invention discloses an electromagnetic coreless fixture with a locating ring capable of axially floating. Above a main shaft are arranged an inner magnetic pole, a magnetic shield ring, an inner floating ring and an outer floating ring, and on the inner floating ring is arranged a conical surface pocket provided with a ceramic ball. The inventive electromagnetic coreless fixture can avoid direct fixation of the locating ring on the main shaft to form rigid connection, which leads to direct influence of main shaft vibration and side swing on stability of the locating ring and a workpiece mounted on the locating ring; and effectively reduce the adverse effects of axial movement of the main shaft and workpiece outer diameter vertical deviation through floating connection formed between the inner and the outer floating ring by pocket connection, improve workpiece machining precision, effectively improve product quality and yield and production efficiency and effectively lower production costs.

Owner:NINGBO ZHENHAI SILVER BALL BEARING CO LTD

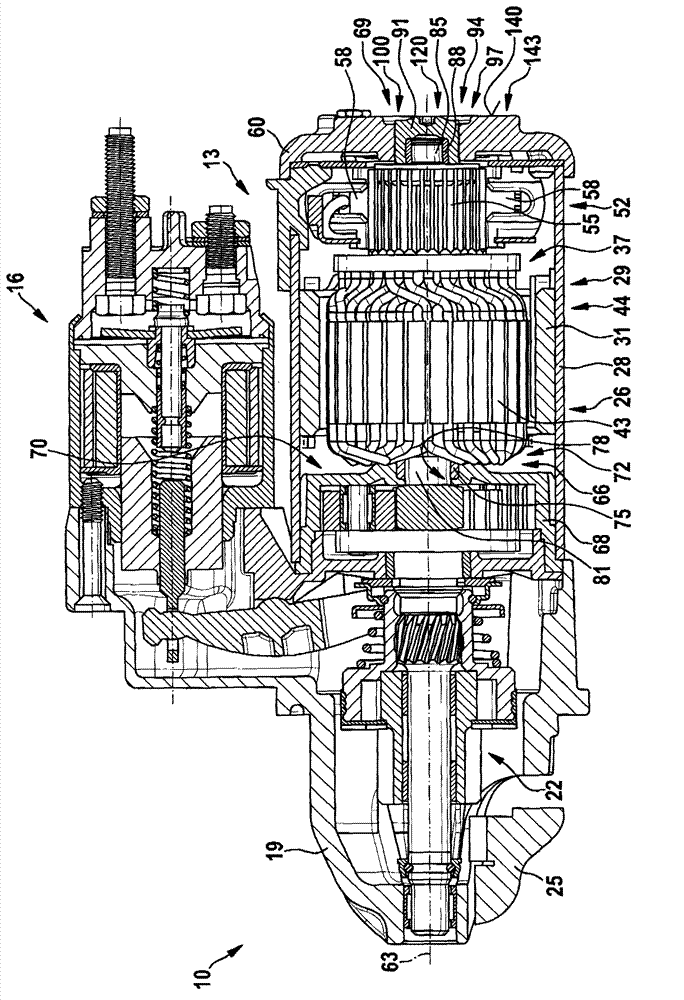

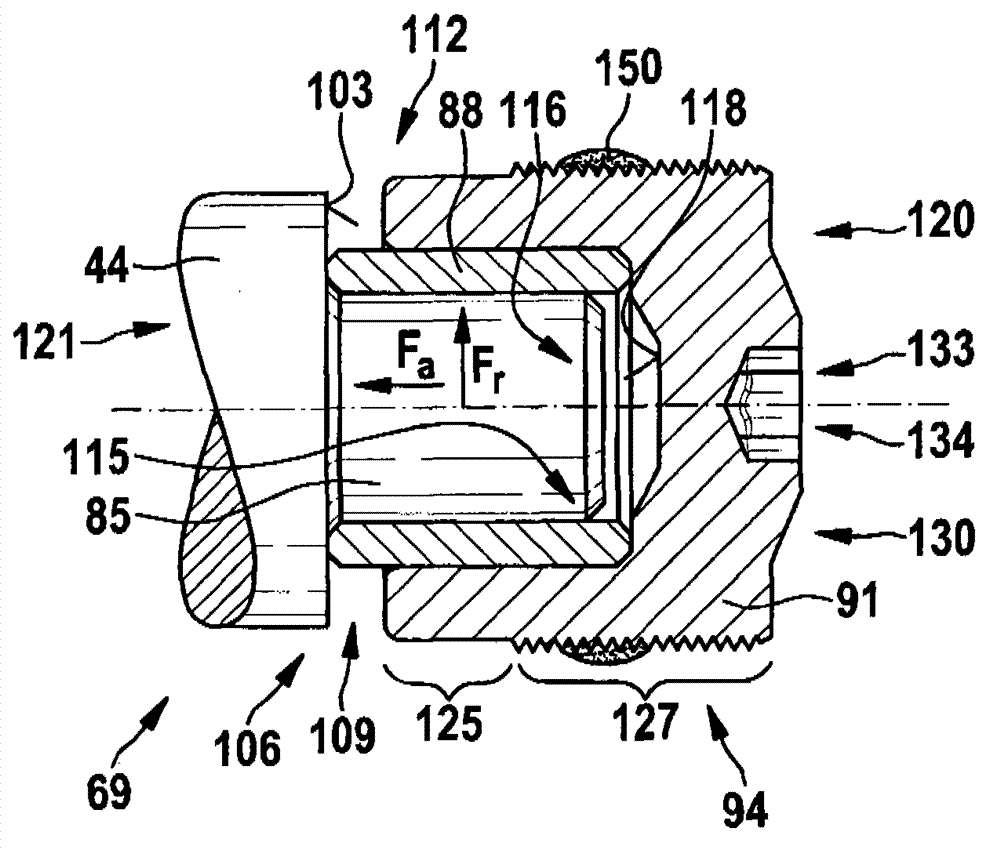

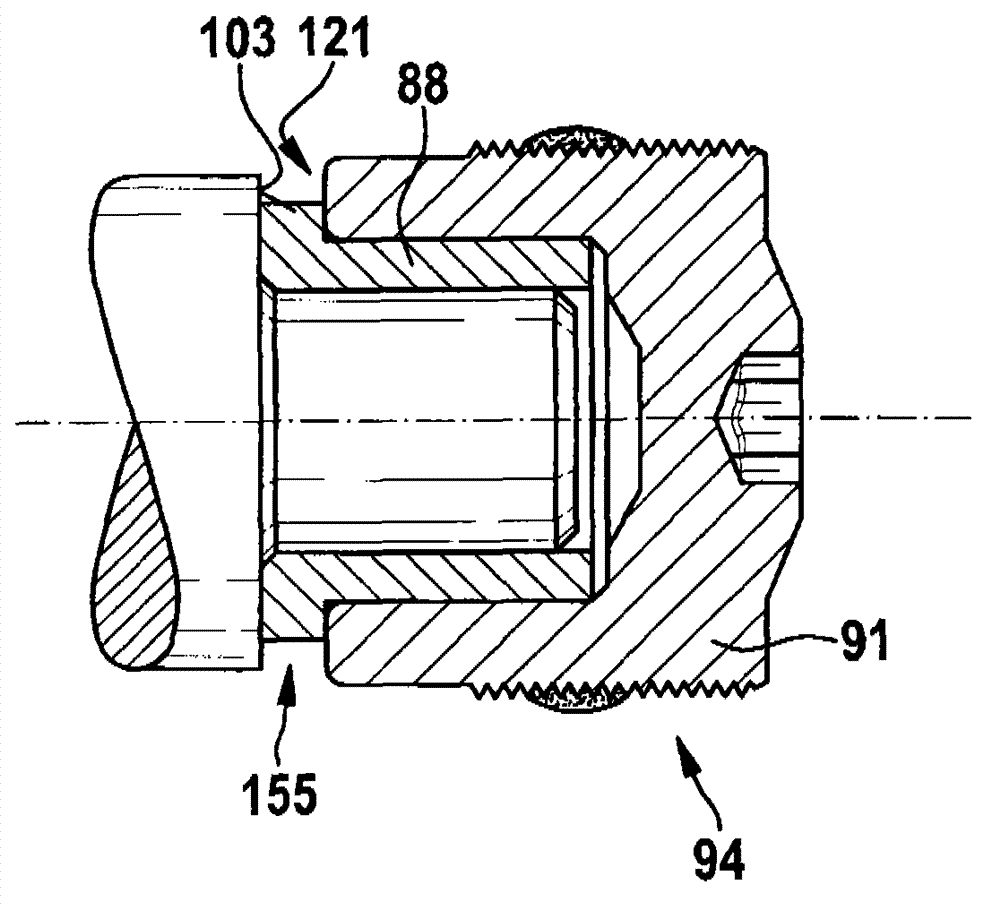

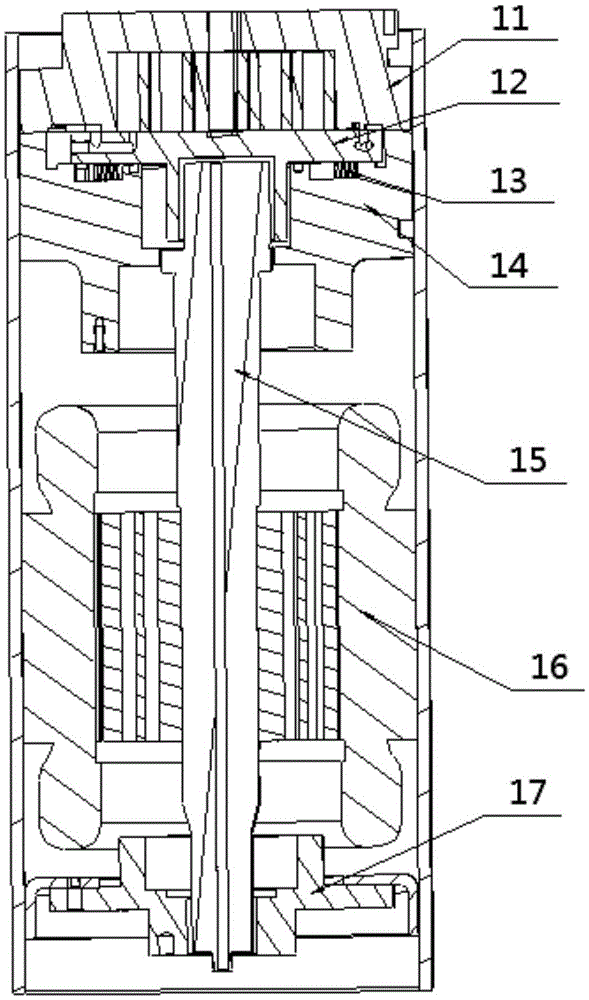

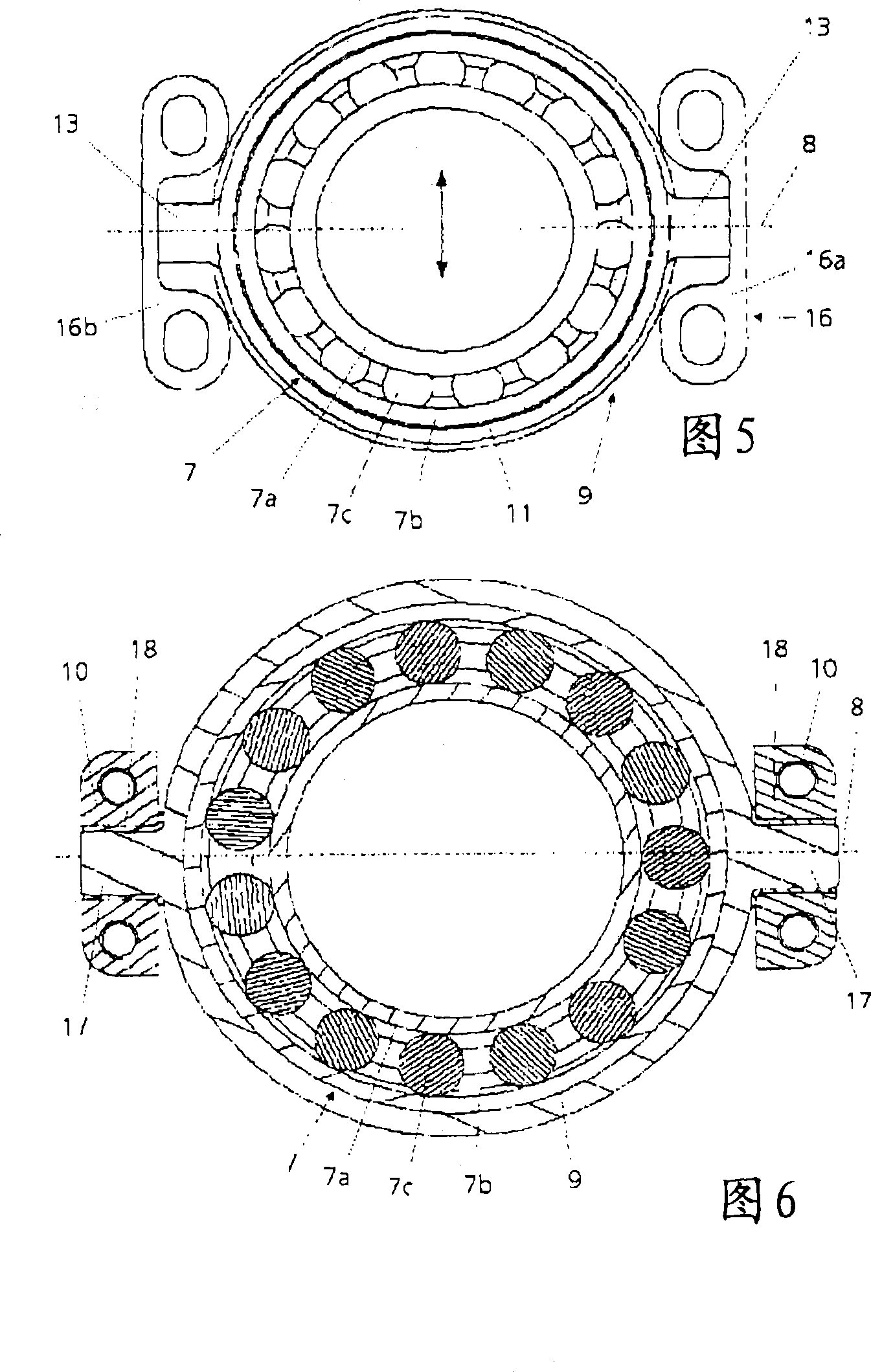

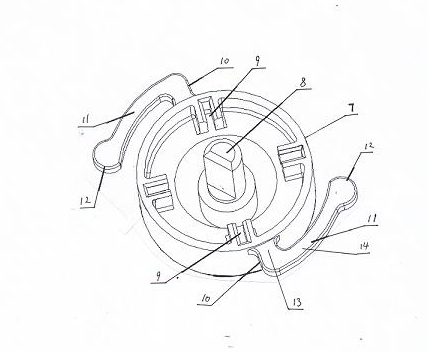

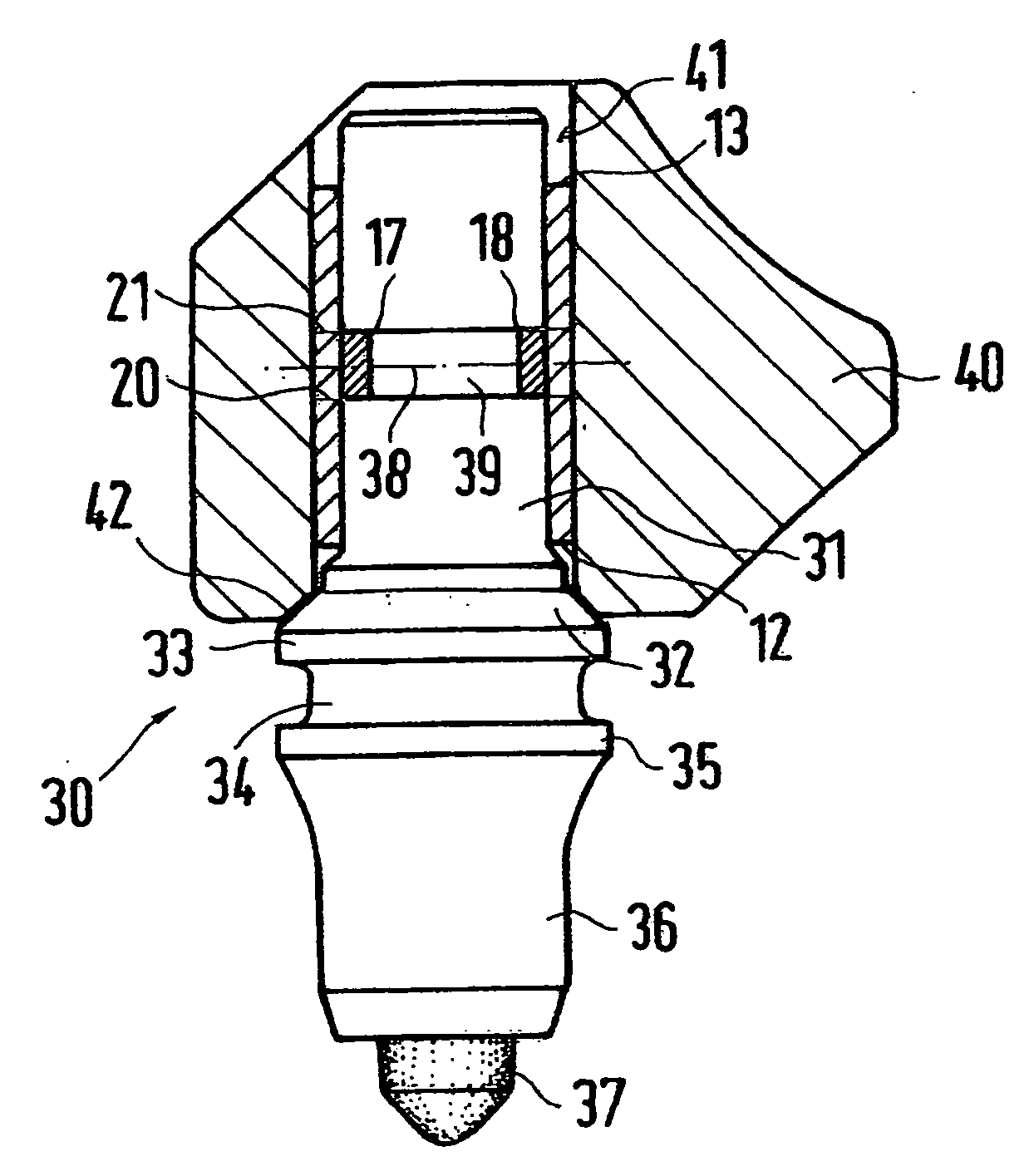

Electric machine, in particular starting device, and method for producing a support bearing assembly of an electric machine

ActiveCN103023189AShort structure lengthClamping statePower operated startersElectric motor startersElectric machineDrive shaft

The invention relates to an electric machine, in particular starting device, and a method for producing a support bearing assembly of an electric machine. The electric machine (10), in particular starting device, has a stator (29), and a rotor (37) which is equipped with a drive shaft and which is arranged radially in an inner side of the stator (29). Support bearing arrangements (66,69) are arranged on a rotating-axial side of the rotor. The arrangement causes bearing forces (Fa, Fr) in radial and rotating-axial direction, and arranged in a bearing cover (60). The arrangement supports a drive shaft (44), and a screw element (91) is held in a retaining thread (94) of the bearing cover by a screw-in thread. The screw element causes radial bearing force and axial bearing force. A cavity i.e. blind hole, is formed in the screw element. An independent claim is also included for a method for manufacturing support bearing arrangement of an electrical machine.

Owner:SEG AUTOMOTIVE GERMANY GMBH

Automobile shock absorber spring dismounting and mounting method

InactiveCN108161417AReduce tiltHigh guiding precisionMetal working apparatusShock absorberEngineering

The invention discloses an automobile shock absorber spring dismounting and mounting method. According to the technical schem, firstly, vertical positioning of a shock absorber is realized, then a force applying mechanism is adopted on the shock absorber to make a spring be pressed downwards to enable the upper end of the spring to be separated and abut against a spring seat, and then the spring seat is disassembled; and the method is characterized in that when the shock absorber assembly is vertically positioned, the bottom contact bearing of the shock absorber is positioned, and at the sametime, a downward pressing component in the force applying mechanism adopts three points which are distributed in a triangular shape in the horizontal direction and a downward pressure in contact withthe upper end of the spring. The method has the advantages that the operation steps are simple, the spring skew amount of the shock absorber is small during dismounting and mounting, the working intensity of the shock absorber during dismounting and mounting can be reduced, and the dismounting and mounting efficiency is high.

Owner:力帆科技(集团)股份有限公司

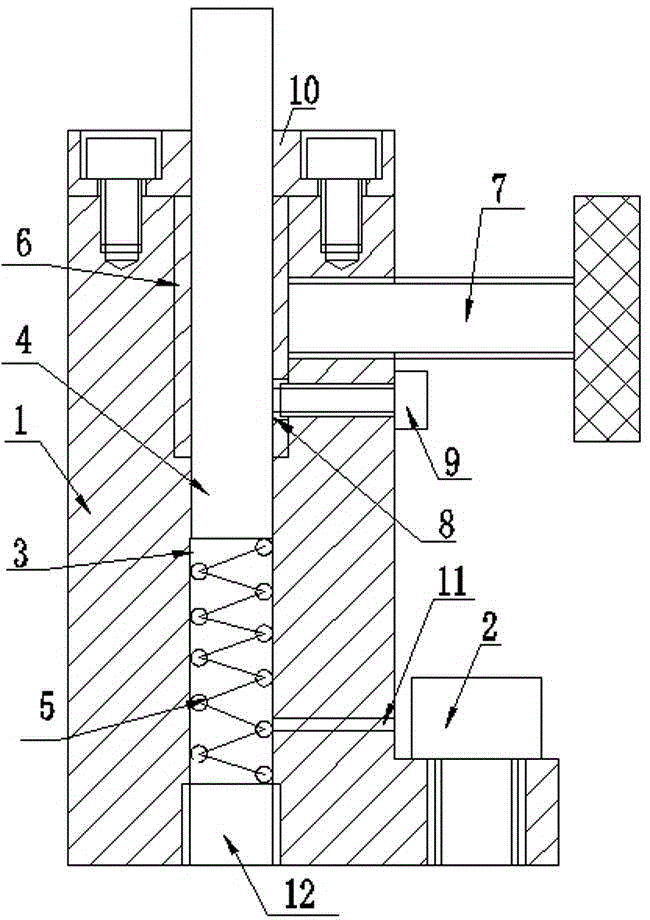

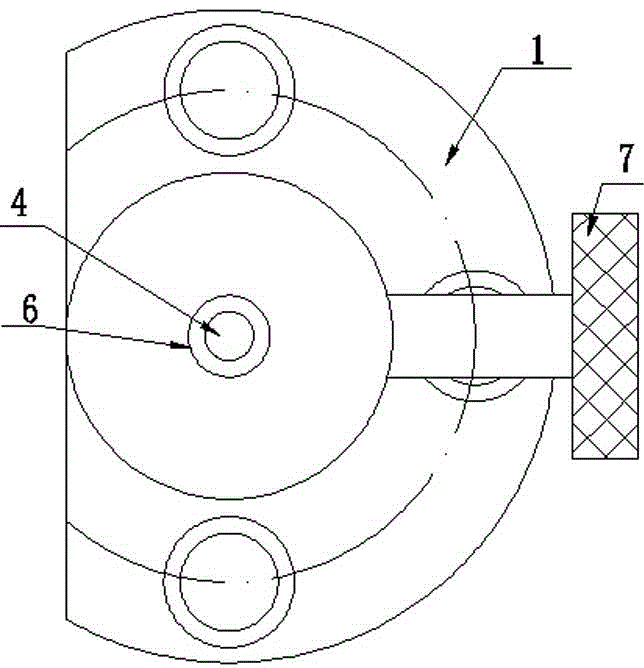

Method for machining low-roughness high-peak textured roller

ActiveCN105290547ALow running costSurface Morphology of Excellent Disordered Cold RollPeak valueColor difference

The invention provided with a method for machining a low-roughness high-peak textured roller. The low-roughness high-peak textured roller is machined through the steps of adjusting equipment operation accuracy, changing the roller grinding travel, reducing transverse texturing color difference, avoiding surface arcing of the textured roller, reducing the defects of bright spots and scratches on the surface of the textured roller and changing a textured roller driver structure. Compared with the prior art, the method has the beneficial effects that on the condition of not changing the performance such as the high efficiency and low operation cost of an electric spark texturing device and the excellent disordered cold roller surface topography, the lowest roughness value of the electric spark textured cold roller is reduced to 1.2 microns, and the peak value of the textured cold roller is increased to more than 130 per square centimeter, the spraying and stamping performance of a cold-rolled automobile sheet can be obviously improved, and the method has wide application prospects in production of high-end cold-rolled automobile sheets.

Owner:ANGANG STEEL CO LTD

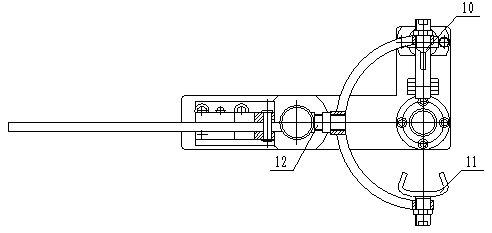

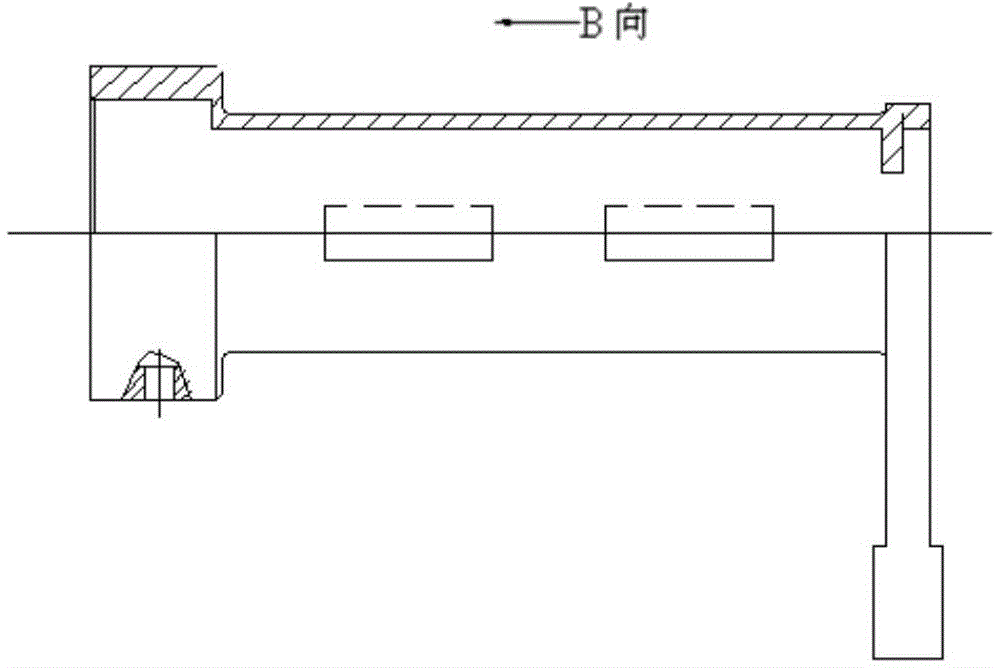

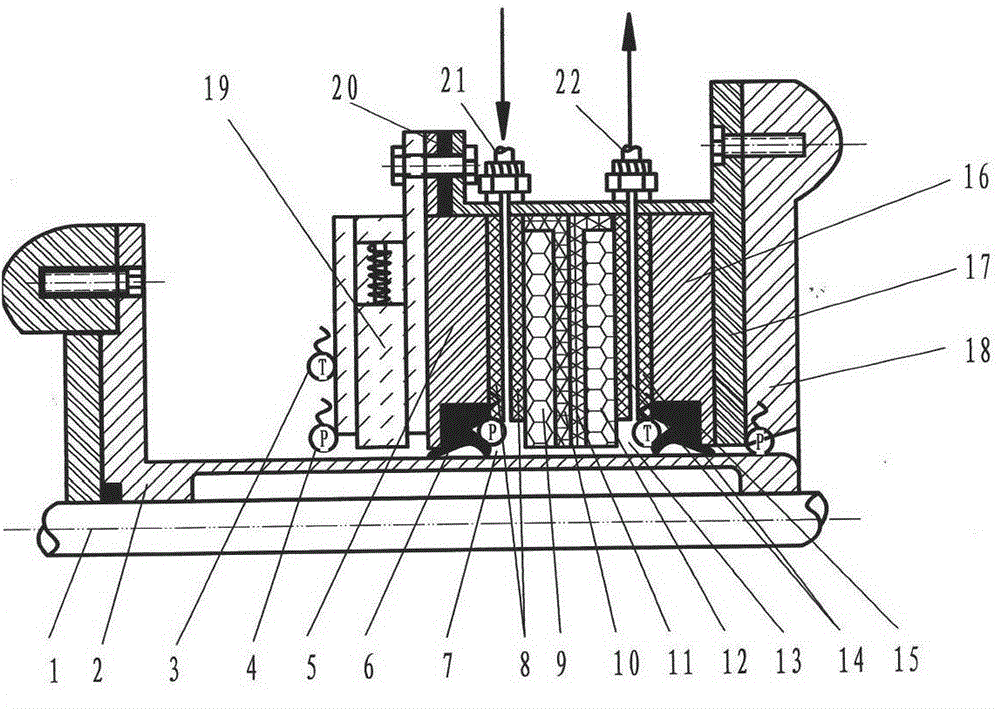

Linear light modulation switching mechanism of television measurement system of large-caliber equipment

InactiveCN102523476AMeet the design requirementsReduced Profile Height DimensionsTelevision systemsMountingsUltrasound attenuationEngineering

The invention relates to a linear light modulation switching mechanism of a television measurement system of a large-caliber equipment. An optical filer support and an attenuation slice support of the mechanism are respectively fixed on platforms of two linear switching mechanisms. A first guide rail of the switching mechanism penetrates a platform by a through hole of the platform; a second guide rail is embedded into a groove; and two ends of the first guide rail and two ends of the second guide rail are respectively and fixedly connected with a first vertical plate and a second vertical plate. One end of a screw rod is movably connected with the first vertical plate and the other end of the screw rod passes through a through hole on the second vertical plate and is cooperated with the through hole. A motor is fixed on a third vertical plate of a pedestal and a rotating shaft penetrates the third vertical plate and is fixedly connected with the screw rod. And a nut is threadedly connected with the screw rod and is connected with the platform by a key; and a first spring and a second spring are sleevedly installed on the screw rod and are respectively at two sides of the nut. According to the invention, the provided mechanism has advantages of simple structure, accurate localization, high light modulation precision, low transmission noise, and dimensions of the appearance and the height are small; and moreover, air space between an optical filer and an attenuation slice is small.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Intelligent sealing device for ship tail shaft numerical control magnetic fluid

The invention discloses an intelligent sealing device for ship tail shaft numerical control magnetic fluid. According to the main structure of the intelligent sealing device, a stuffing box is arranged at the sealed part of a tail shaft, one end of the box is provided with a gland, and the other end of the box is connected with a sternpost through a flange. Two layers of PTFE ring box sleeves are arranged in the middle of the box in parallel, and nx twelve radial hedging magnetic sector permanent magnets are embedded in each layer of box sleeve. Magnetic fluid circulating cavities are formed between the box sleeves in which the magnets are embedded and a shaft tube. The two sides of each permanent magnet box sleeve are each provided with a stainless steel circular ring and provided with eight magnetic fluid injecting or discharging holes, wherein the outer sides of the two stainless steel circular rings are each provided with a stainless steel clamping ring. An AH type metal framework teflon sealing ring is clamped on a tail shaft tube. An MCU is arranged, a magnetic fluid input pump and an electromagnetic overflow valve are controlled according to the pressure and temperature sensor information, the pressure in the magnetic fluid circulating cavities and the pressure at the draft of a warship and a submarine can be randomly the same, sealing, lubricating and cooling functions are achieved on the tail shaft tube through circulation of pressurized cold and hot magnetic fluid, and an electromagnetic sealing brake is arranged for strengthening static sealing of the tail shaft tube during downtime.

Owner:宝嘉智能科技(南通)有限公司

Integral shaft-connect type fan clutch bearing

The invention discloses an integral shaft-connect type fan clutch bearing. The bearing adopts a row of rollers and double-row steel balls, the double-row steel balls adopt an angular contact structure in a geometric form, the bearing comprises a bearing outer ring, a mandrel, a steel ball holder, a roller holder and a seal ring, wherein channels and a raceway are machined on the bearing outer ring and used for bearing the rolling elements and guiding the rotation of rolling elements, the rolling elements comprise the steel balls and the cylindrical rollers, the mandrel is inserted into the bearing outer ring in the axial direction, inner channels are machined on the outer diameter of the mandrel and used for bearing the steel balls and guiding the rotation of the steel balls, an inner raceway is further machined on the outer diameter of the mandrel and used for bearing the cylindrical rollers, the steel ball holder is arranged between the bearing outer ring and the mandrel and makes the steel balls distributed in the channels at equal intervals, the roller holder adopts a design of a cylinder-shaped structure and a spring collar structure, a spring collar is assembled on the bearing outer ring in a matched mode to prevent the cylindrical rollers from springing out in the axial direction, and the sealing ring is installed in a seal groove formed in the end of the bearing outer ring in a pressed mode and remains still with the bearing outer ring.

Owner:长沙优力电驱动系统有限公司

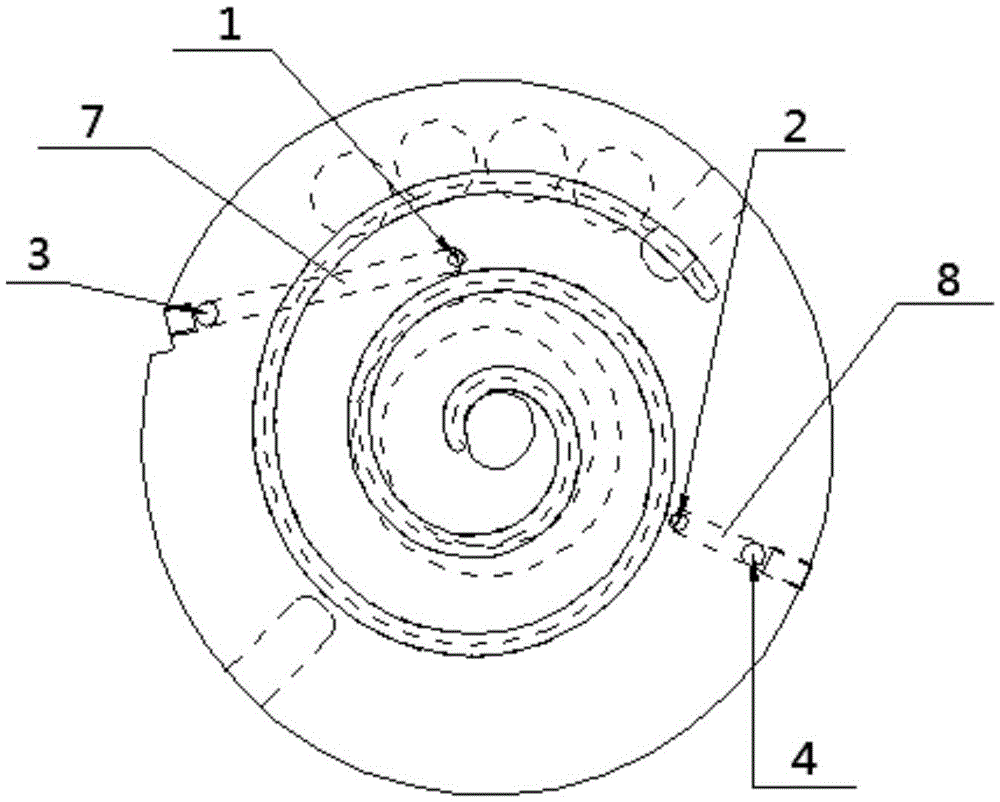

Asymmetric scroll compressor and air conditioner

ActiveCN105545734AReduce the impactReduce axial playRotary piston pumpsRotary piston liquid enginesAirflowEngineering

The invention relates to an asymmetric scroll compressor and an air conditioner. The compressor comprises a static scroll plate and a dynamic scroll plate, wherein the dynamic scroll plate is opposite to the static scroll plate, is rotatable relative to the static scroll plate and is provided with a back-pressure hole channel and a first hole channel; a compression cavity and a back-pressure chamber of the compressor can be communicated through the back-pressure hole channel; the first hole channel can be communicated with a pressurized air cavity in the compressor; a first airflow outlet of the first hole channel is symmetric to a second airflow outlet of the back-pressure hole channel relative to a rotating center of the dynamic scroll plate; the first hole channel can be communicated with the pressurized air cavity in the compressor, so that the direction of moment formed by pressurized airflow, passing the first hole channel, on the dynamic scroll plate is opposite to that of moment of pressurized airflow passing the back-pressure hole channel, influence of overturning moment on the dynamic scroll plate is reduced, and the stability of the asymmetric scroll compressor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Power steering with an elastically mounted recirculating ball spindle gear

InactiveCN101160233ASimple structureReduce axial playRolling contact bearingsGearingRecirculating ballEngineering

A power steering system with a circulating ball spindle mechanism, an extending element of the circulating ball spindle mechanism being support rotatably over a bearing and the bearing of the element making possible a swiveling motion corresponding to the direction of action of interfering forces.

Owner:ZF LENKSYSTEME GMBH

Accessory gearbox for gas turbine engine

ActiveCN106460551AImprove operationOptimize space requirementsEngine fuctionsShaftsGear wheelFlight vehicle

The invention relates to an accessory gearbox capable of driving the accessory devices of a gas turbine engine, such as an aircraft engine. Said accessory gearbox includes a housing and a plurality of gear wheels having axes that are parallel to one another inside the housing. The housing includes a means for attaching the accessory devices to the wall of the housing and driving them, via the gear wheels, through openings in the wall of the housing. The gear wheels are supported in the housing by rolling-element bearings. Each rolling element includes a first ring that is stationary relative to the housing, and a movable ring, secured to the gear wheel, wherein at least one (110) of said gear wheels is supported by a single rolling element (120).

Owner:HISPANO

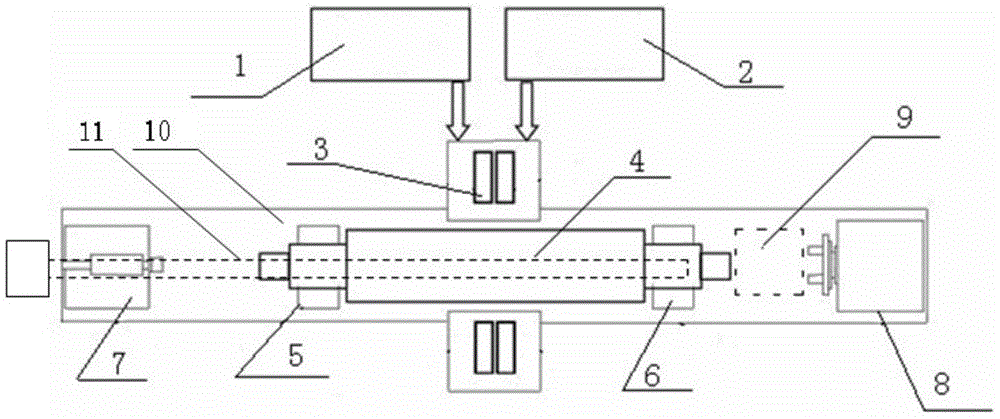

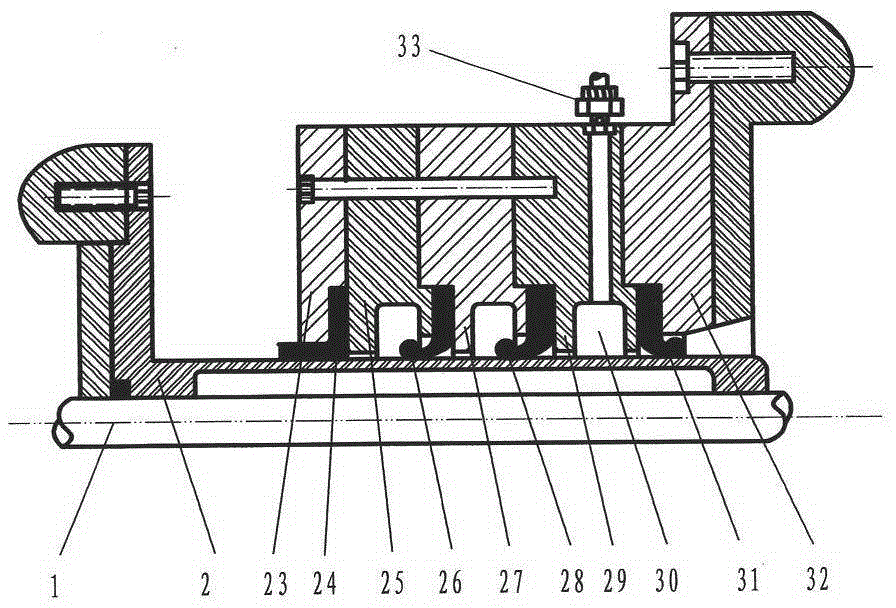

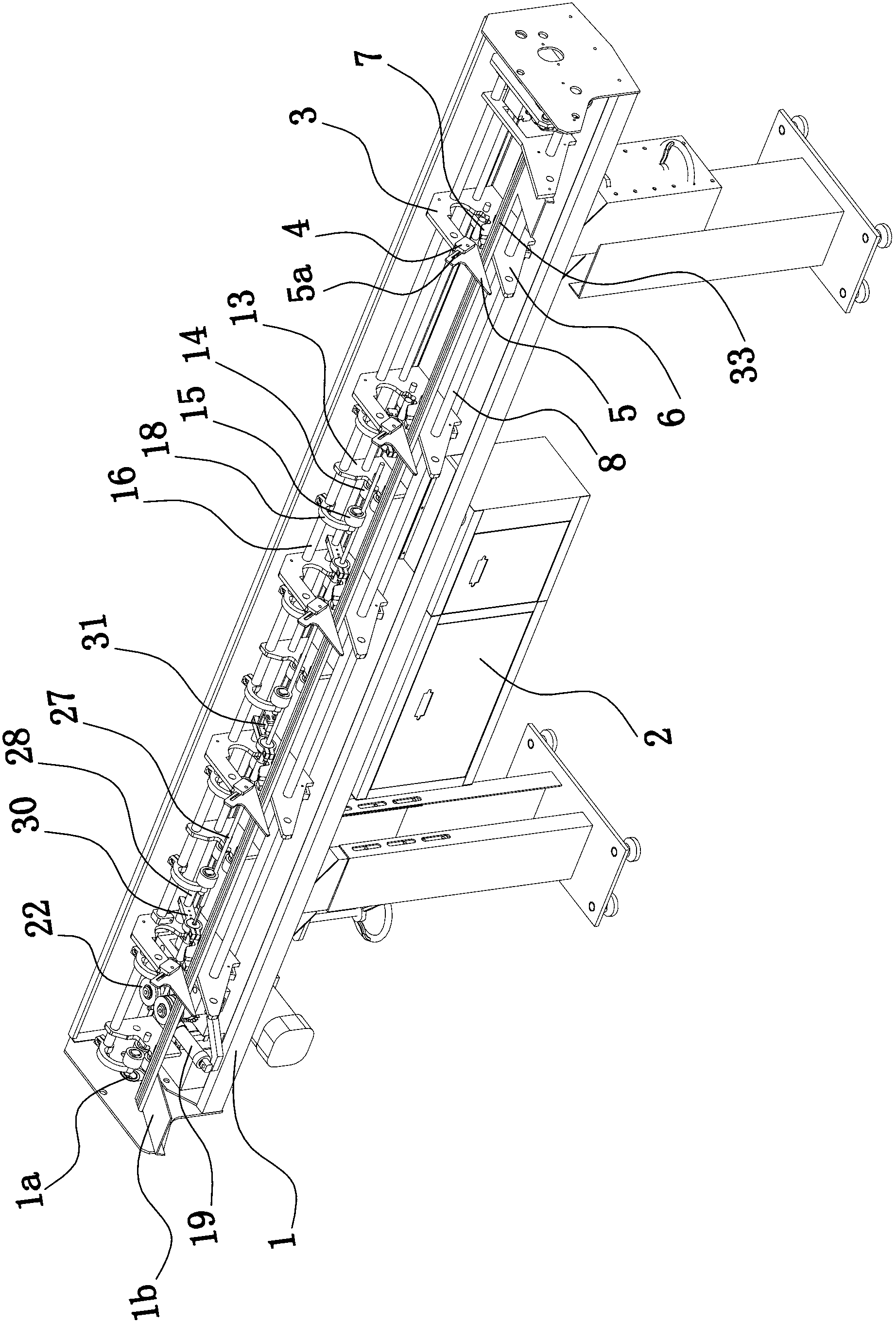

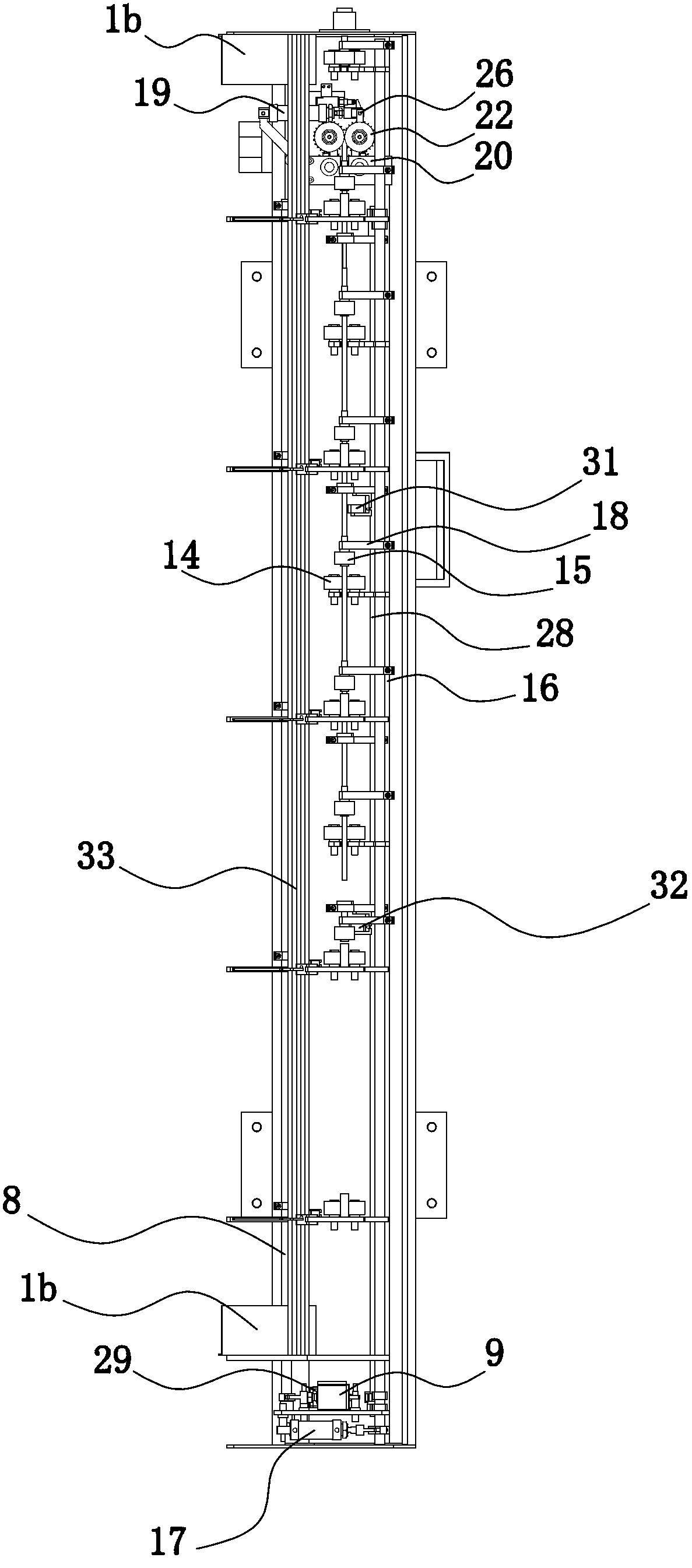

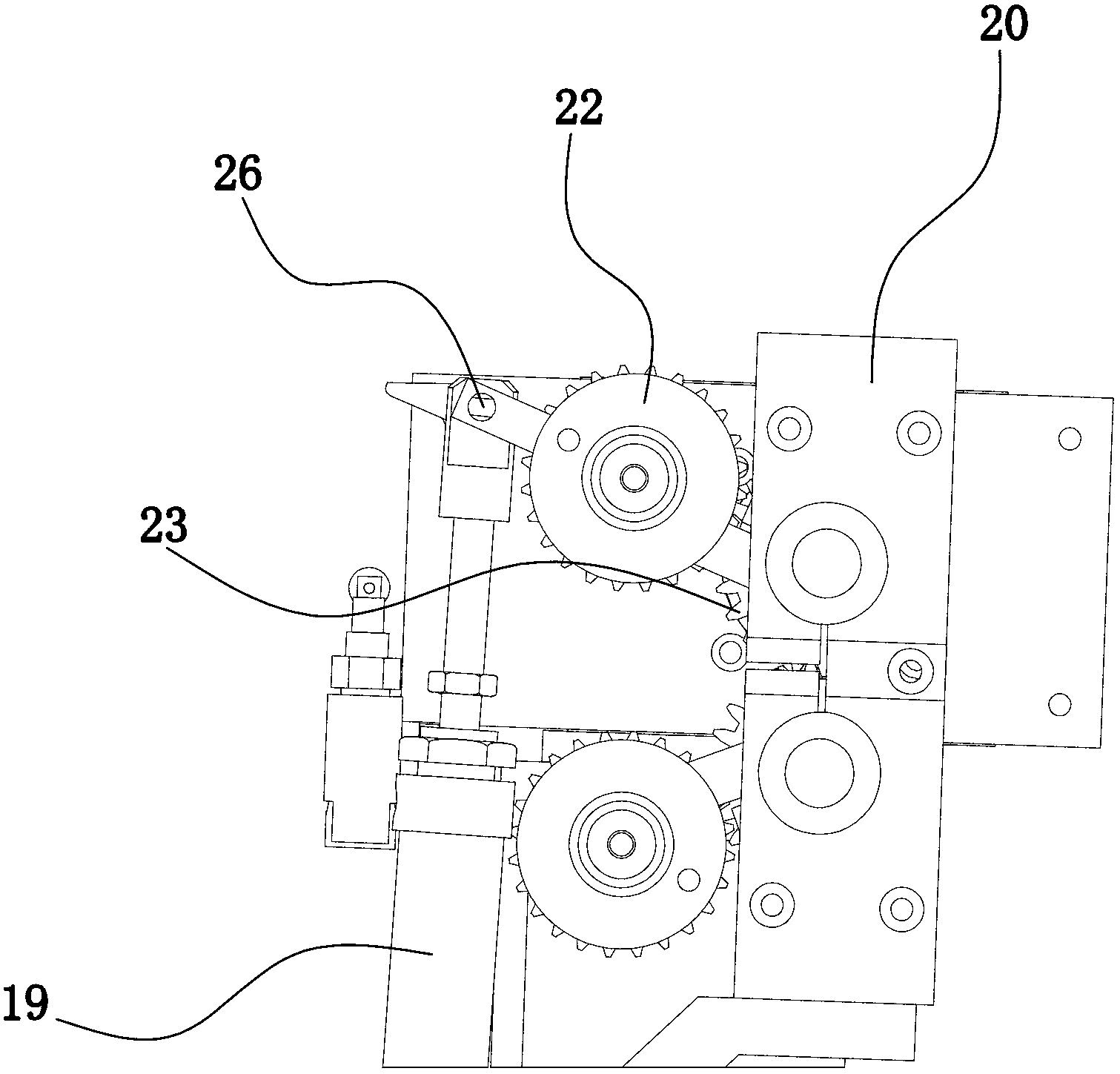

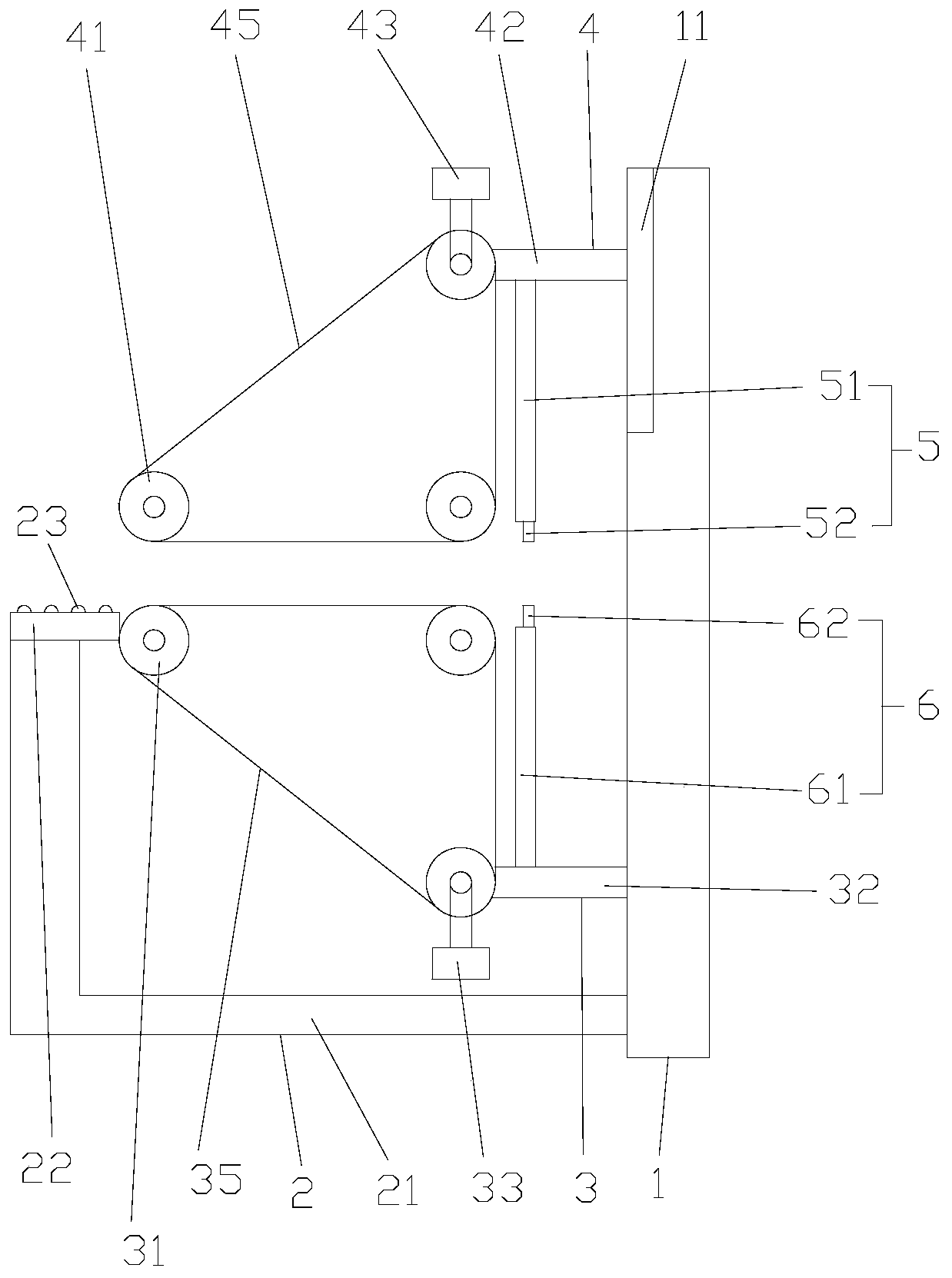

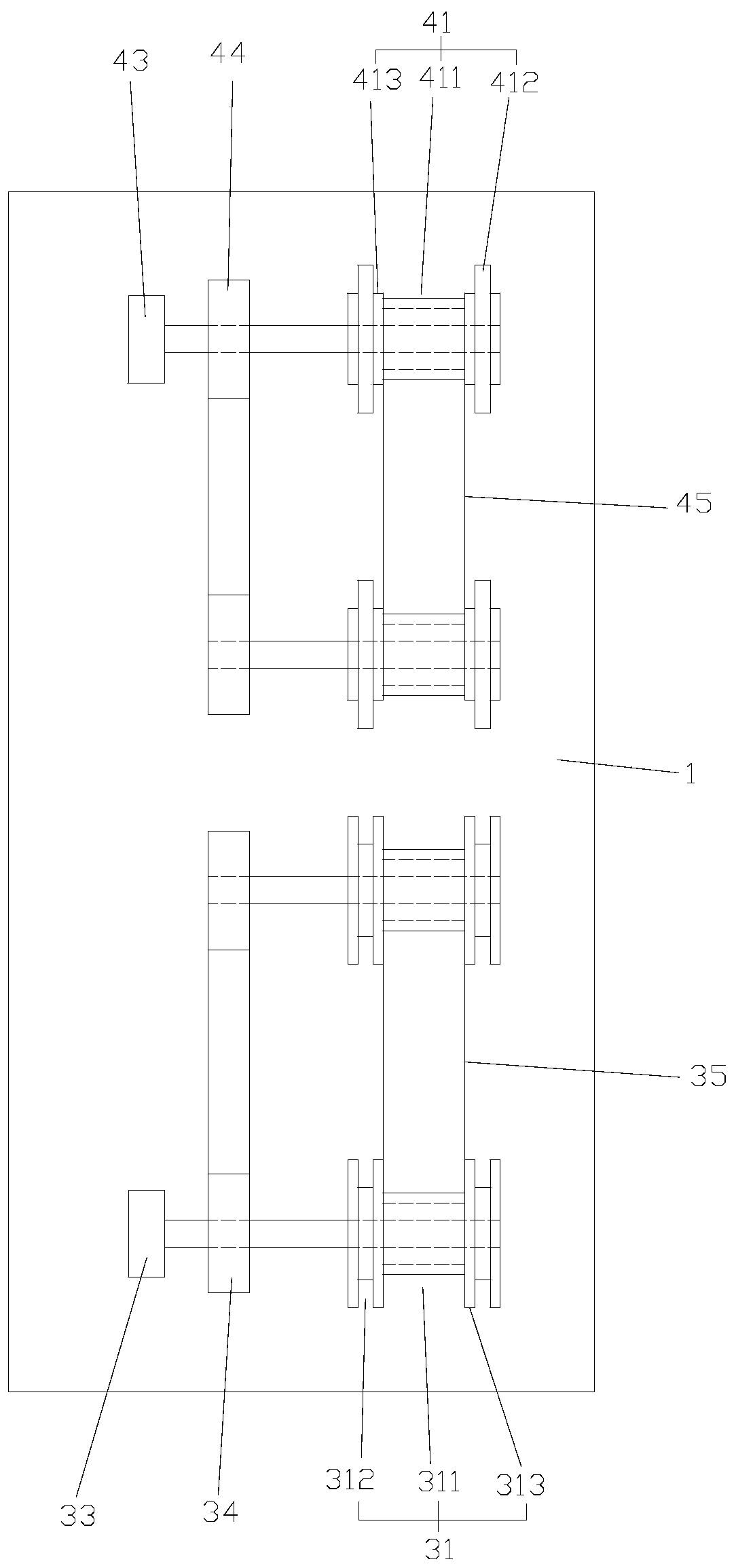

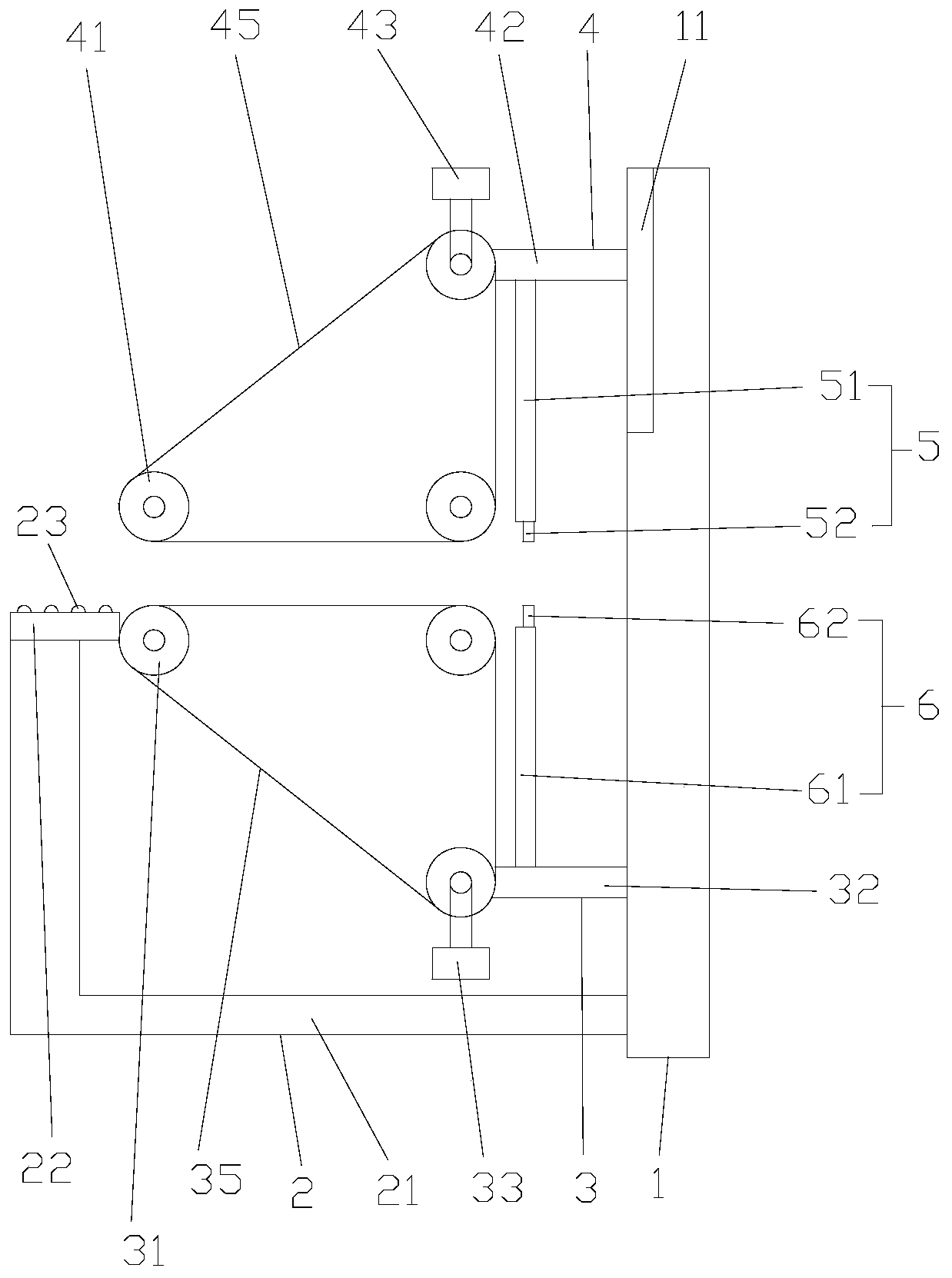

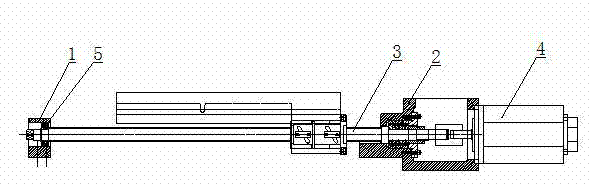

Feeder

ActiveCN102699352AReduce axial playReduce noiseMetal-working apparatusProgrammable logic controllerElectricity

The invention provides a feeder and belongs to the technical field of numerically-controlled machine tools. The problem that the conventional feeder is low in feeding efficiency and low in stability is solved. The feeder comprises a frame with a discharging hole, a feeding mechanism, a clamping mechanism, a programmable logic controller (PLC)-based control cabinet which is fixedly arranged on the frame, and a primary conveying mechanism and a secondary conveying mechanism which are used for feeding long bars positioned on the clamping mechanism, wherein the feeding mechanism is used for conveying the long bars to the clamping mechanism one by one; the clamping mechanism is used for fixedly clamping the long bars; and the feeding mechanism, the clamping mechanism, the primary conveying mechanism and the secondary conveying mechanism are arranged on the frame and are electrically connected with the control cabinet. The feeder has the advantages of simple structure, high efficiency and high stability.

Owner:宁波宫铁智能科技有限公司

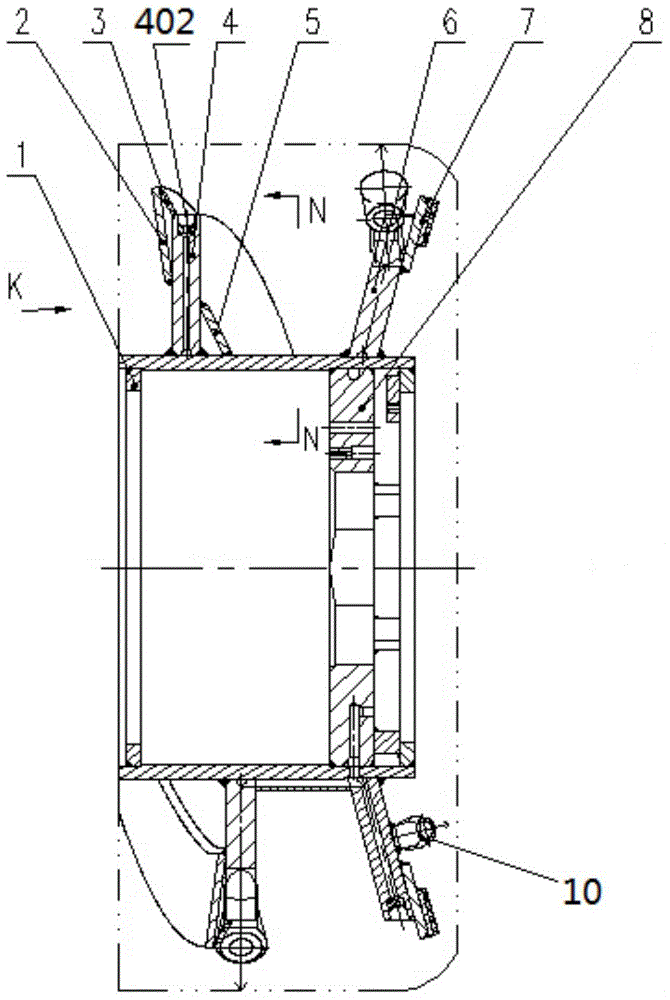

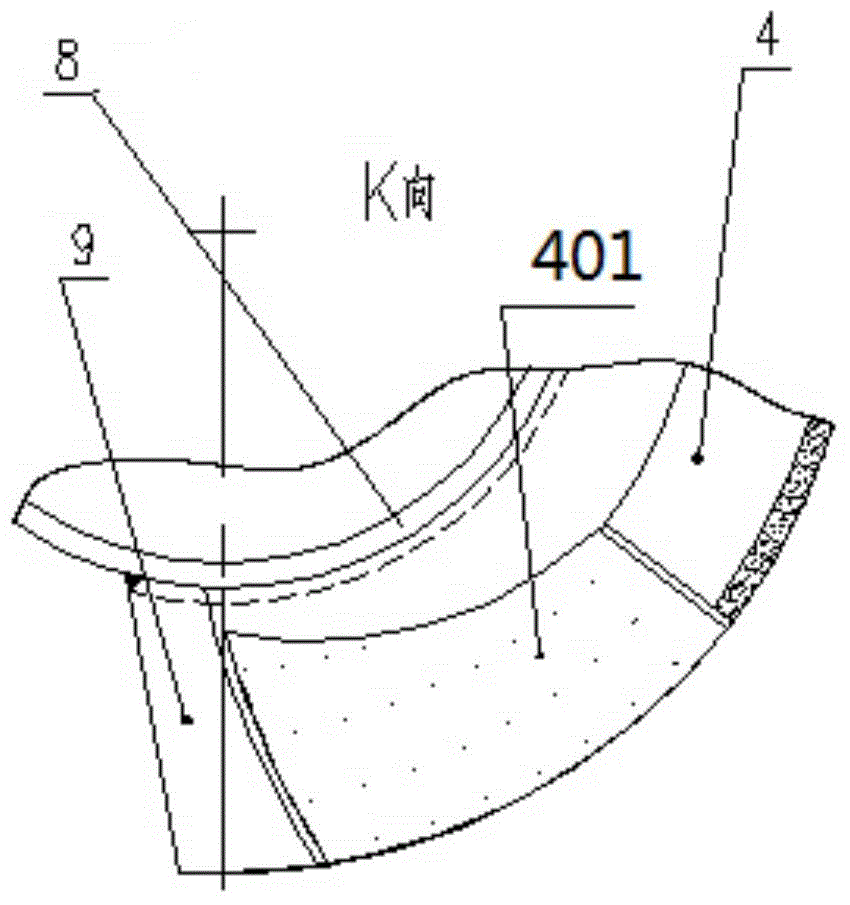

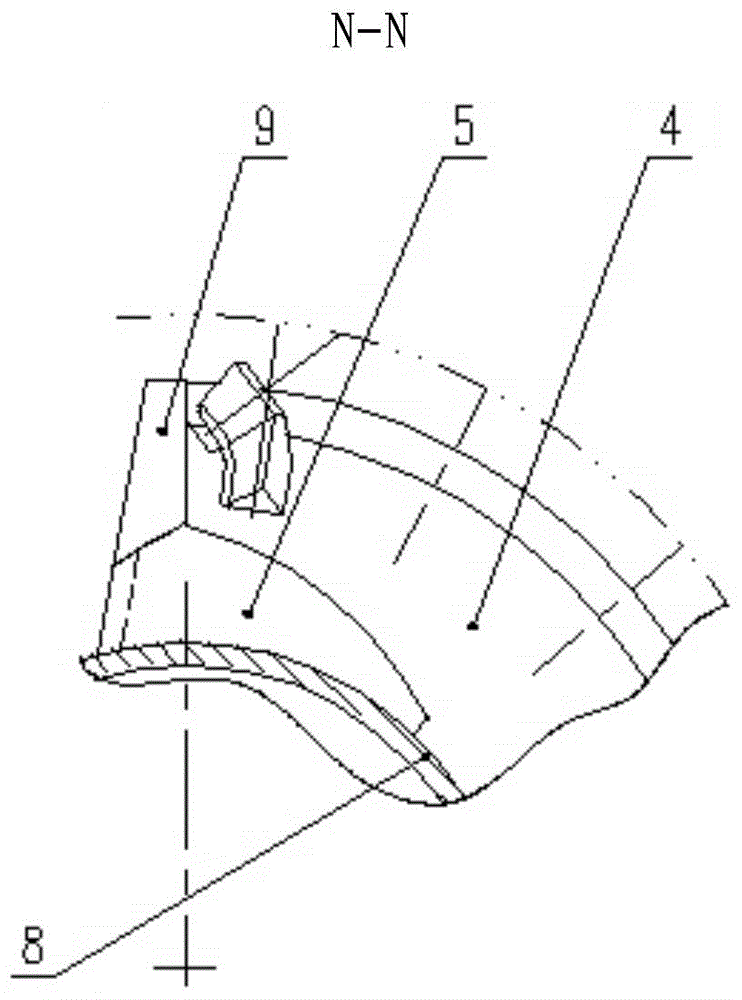

Powerful drum of coal cutter

The invention relates to a powerful drum of a coal cutter. The powerful drum comprises a drum body (8), a combined main blade (4) and an end disc (6), wherein small blades (9) are arranged at the tail part of the combined main blade (4); the bottoms of the small blades (9) are fixedly welded with the drum body (8); a water inlet channel (402) is formed inside the combined main blade (4); a group of spray holes (401) is formed in the side face of the tail part; the spray holes (401) are communicated with the water inlet channel (402); the spraying direction moves along the axial direction of the drum body; auxiliary blades (2) are arranged on the combined main blade (4); a sealing plate (3) is arranged between the auxiliary blades (2) and the combined main blade (4); a rib plate (5) is fixedly arranged between the combined main blade (4) and the drum body (8); the end disc (6) is welded on the drum body (8); and a wear-resistant plate (7) and small end disc cutting teeth (10) are arranged on the outer side of the end disc (6) along the axial direction of the drum body. According to the powerful drum of the coal cutter disclosed by the invention, the strength and wear resistance of the coal cutter drum are enhanced, and the service life of the drum is prolonged.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +1

Double-face abrasive belt polishing machine for machining single-layer welding material H309LNB

PendingCN110000669AReasonable structureExtend your lifeBelt grinding machinesGrinding feedersEngineeringWelding

The invention provides a double-face abrasive belt polishing machine for machining a single-layer welding material H309LNB. The double-face abrasive belt polishing machine comprises a machine base, anauxiliary conveying device, a lower polishing device, an upper polishing device, an upper blowing device and a lower blowing device. The auxiliary conveying device is connected to the machine base. The lower polishing device is connected to the machine base. The upper polishing device is connected to the machine base. The upper polishing device is installed above the lower polishing device. The upper blowing device is installed on the upper polishing device, and the lower polishing device is connected with the lower blowing device. The polishing efficiency is high.

Owner:HAIYAN ZHONGDA METAL ELECTRONIC MATERIAL CO LTD

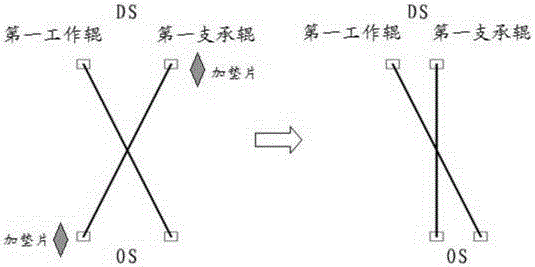

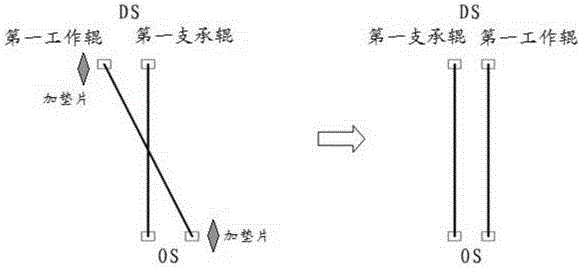

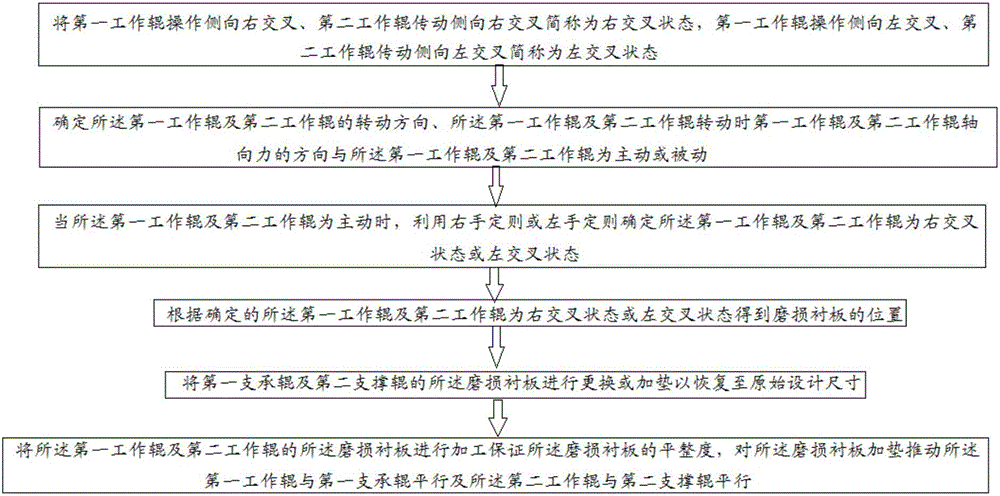

Method for reducing axial drifting of rolling mill rolls

ActiveCN106623437AReduce axial playReduce playRolling equipment maintainenceMetal rolling arrangementsEngineeringRight-hand rule

The invention discloses a method for reducing axial drifting of rolling mill rolls, and belongs to the technical field of hot rolling. The method for reducing axial drifting of the rolling mill rolls comprises the following steps that the rotating direction of the first working roll and the rotating direction of the second working roll are determined, and the axial force direction of the first working roll and the axial force direction of the second working roll and whether the first working roll and the second working roll are active or passive during rotation of the first working roll and the second working roll are determined; whether the first working roll and the second working roll are in a right cross state or a left cross state is determined according to the right-hand rule or the left-hand rule; a worn lining plate of the first supporting roll and a worn lining plate of the second supporting roll are replaced or padded so as to restore the original design size; the worn lining plates are padded to push the first working roll to be parallel to the first supporting roll and push the second working roll to be parallel to the second supporting roll. According to the method for reducing axial drifting of the rolling mill rolls, harmful crossing and drifting of a four-high rolling mill roll system can be quickly and accurately inhibited.

Owner:BEIJING SHOUGANG CO LTD

Manual auxiliary support

InactiveCN105234688AAct as a floating supportAchieve surface contactPositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:东实汽车动力零部件(湖北)有限公司

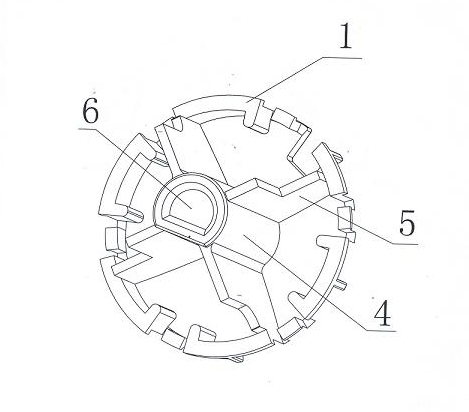

Knob-type gating switch balancing device for automobile electrical appliances

The invention discloses a knob-type gating switch balancing device for automobile electrical appliances. The device comprises a switch upper cover and a switch lower cover, and is characterized in that: the switch upper cover is arranged on a gating switch balancing body by an upper positioning column and a lower positioning column, and is fixed in an upper cover fixing groove by an upper cover fixing clip; the gating switch balancing body is arranged in the switch lower cover; and limit structures are formed between the upper cover fixing clip of the switch upper cover and the upper cover fixing groove of the gating switch balancing body, between the limit groove of the gating switch balancing body and the internal limit column of the switch lower cover, and between the stop position of an elastic arm and the external limit column of the switch lower cover. The plurality of structures of a traditional knob switch are integrated together, so that the knob-type gating switch balancing device is high in integration level and reliable in performance, and a mould is simple and easy to realize. The knob-type gating switch balancing device has the advantages that: shaking quantity is greatly reduced and operating force is uniform in the operating process in circular motion; and the knob-type gating switch balancing device has clear gears, a high integration level, good hand feel, high practicality, low cost and high performance, and is easy to machine, quick in installation, simple and reliable.

Owner:JIANGLING HLDG

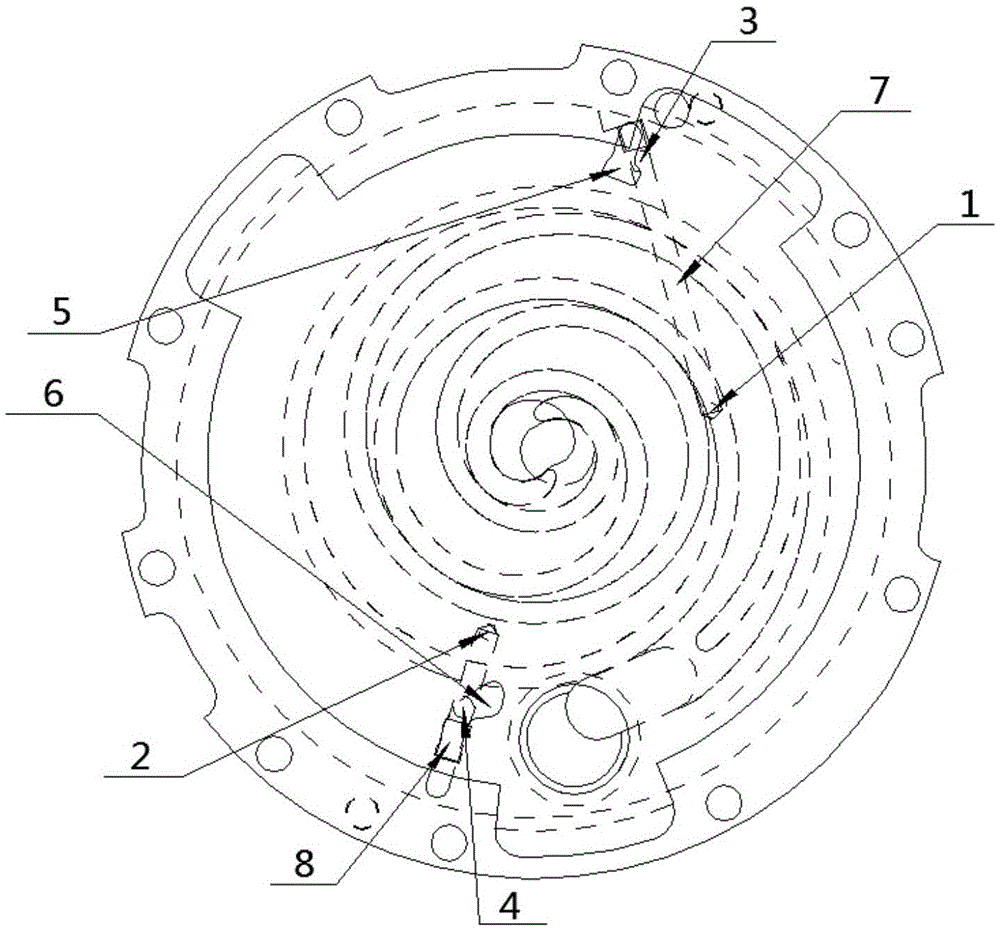

Floating type axial sealing structure

PendingCN109058111AReduce axial playExtended service lifeSealing arrangement for pumpsRotary piston pumpsEngineeringHigh pressure

The invention belongs to the technical field of compressors, and particularly relates to a floating type axial sealing structure. The technical scheme is as follows the floating type axial sealing structure comprises a static scroll plate and a dynamic scroll plate are correspondingly provided with a vortex tooth, a sealing groove is formed in the tooth surface of the vortex tooth, and a sealing structure is arranged in the groove; the shape of the sealing structure corresponds to the shape of the vortex tooth, the sealing structure is composed of a wear-resisting sheet, a sealing strip and asealing lining from outside to inside in sequence through glue; the sealing structure is divided into three sections from the outer ring to the inside in sequence along the rotation direction of the vortex tooth by the partition plates which are arranged in the sealing groove: a low -pressure sealing section, a medium-pressure sealing section and a high-pressure sealing section; in terms of length, the low-pressure sealing section is larger than the medium-pressure sealing section, the medium-pressure sealing section is larger than the high-pressure sealing section; the partition plates playsan air-sealing role on the sealing groove. The vortex tooth and the sealing structure are designed according to different pressures of the vortex tooth, the gas flow in the tooth grooves is reasonablyplanned, the sealing effect of the sealing structure is improved, and radial leakage is effectively controlled.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

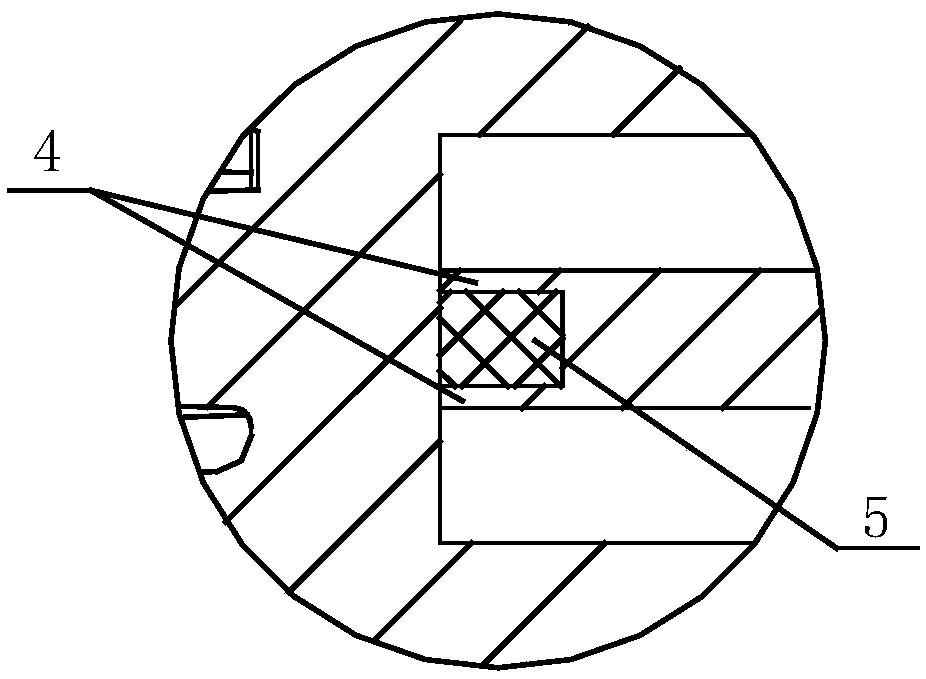

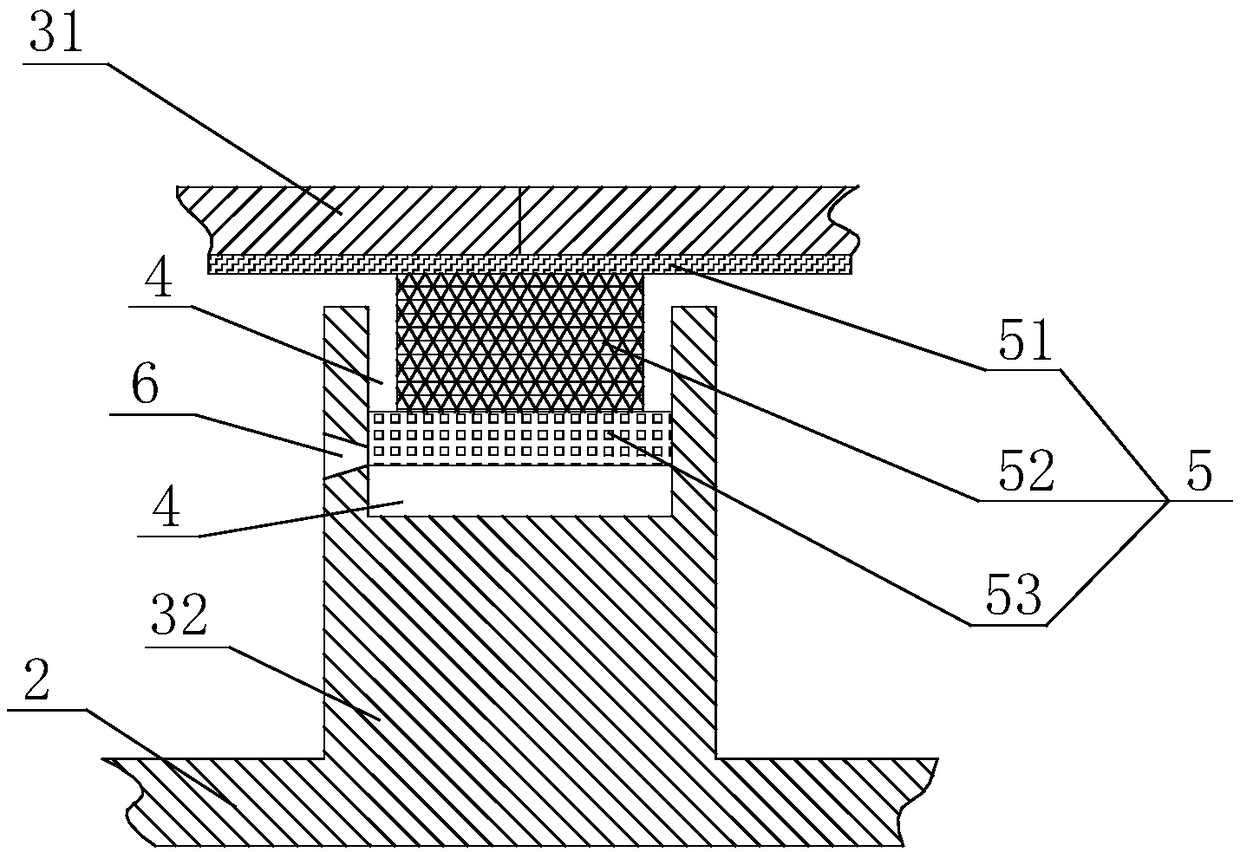

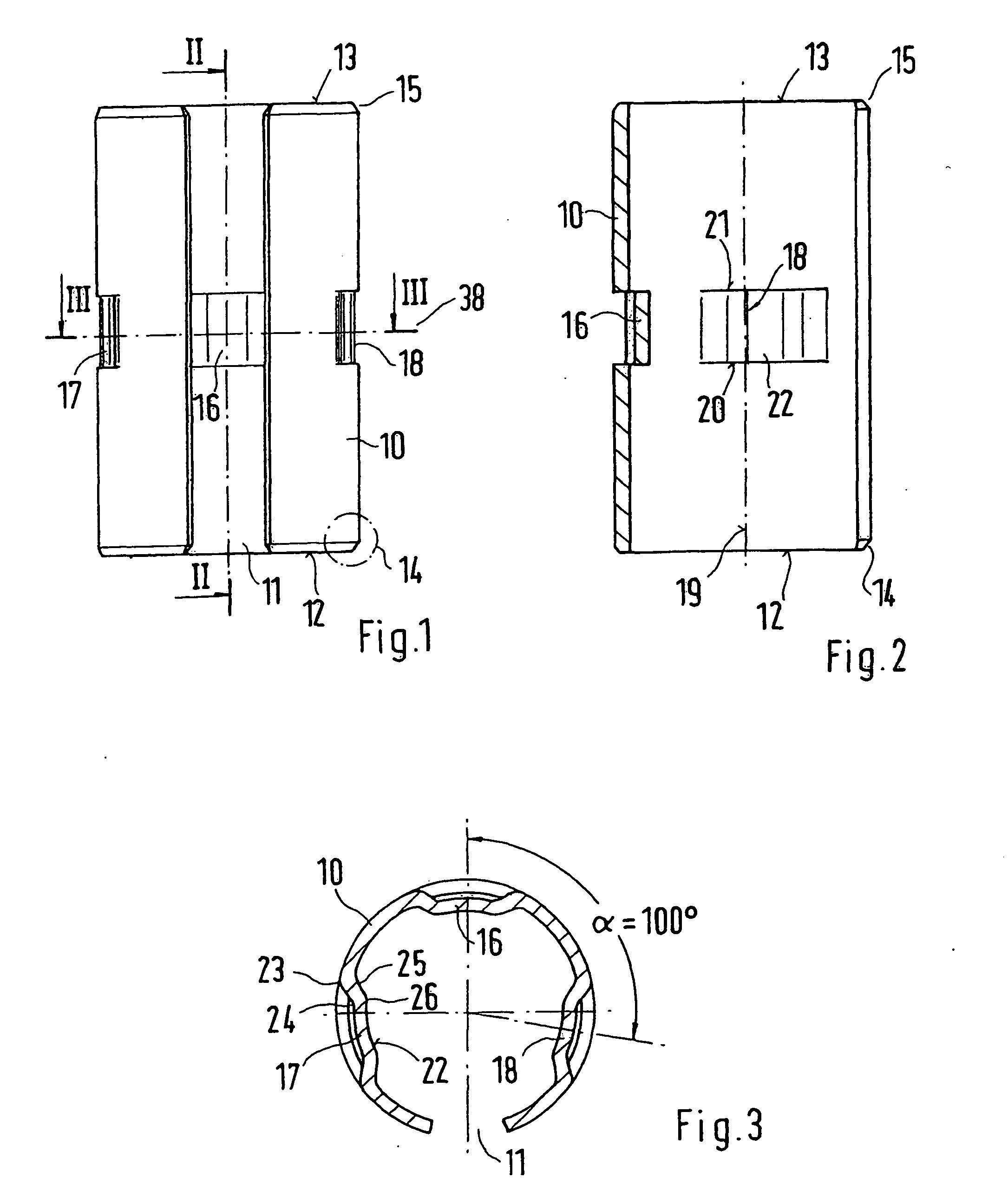

Circular-Shank Tool Comprising a Tool Holder

A circular-shank tool including a tool holder for improving the centering of the shank of the circular-shank tool in the locking sleeve by a configuration of the retaining elements and to improve an ability of the shank to rotate in the sleeve. To achieve this, the retaining elements are distributed between two stamped edges that lie transversely with respect to a longitudinal axis of the locking sleeve and are stamped inwards or indented, the stamped edges extend over part of the circumference of the locking sleeve and are interspaced at a distance that corresponds to the width of the peripheral groove in the shank of the circular-shank tool and the retaining elements form a coaxial concave centering section facing the convex groove base of the peripheral groove.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

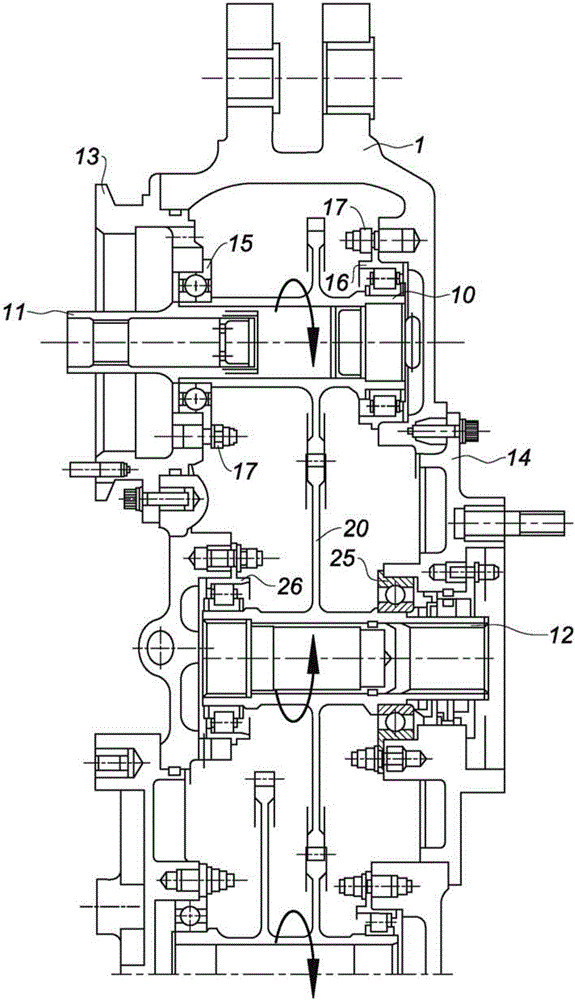

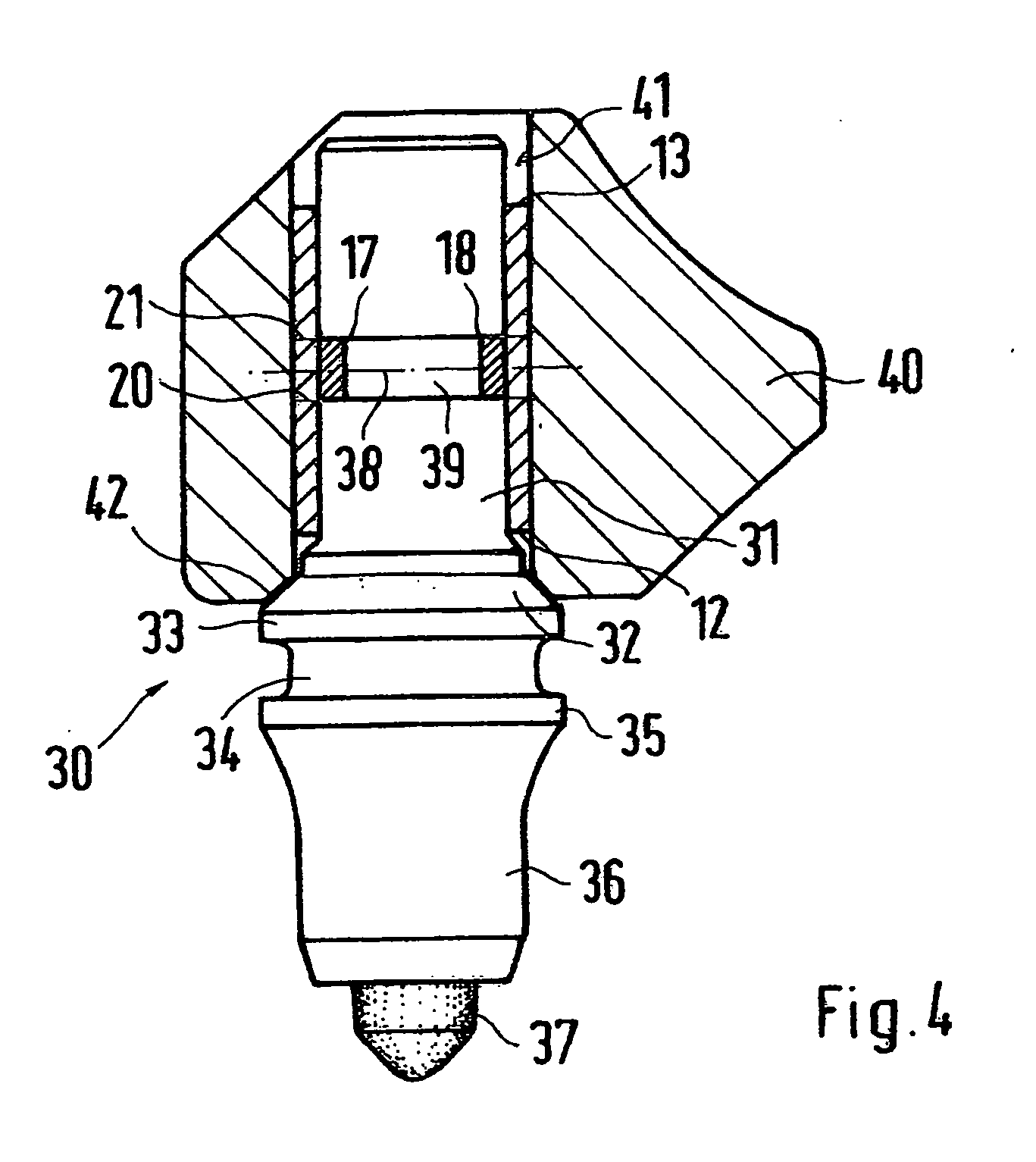

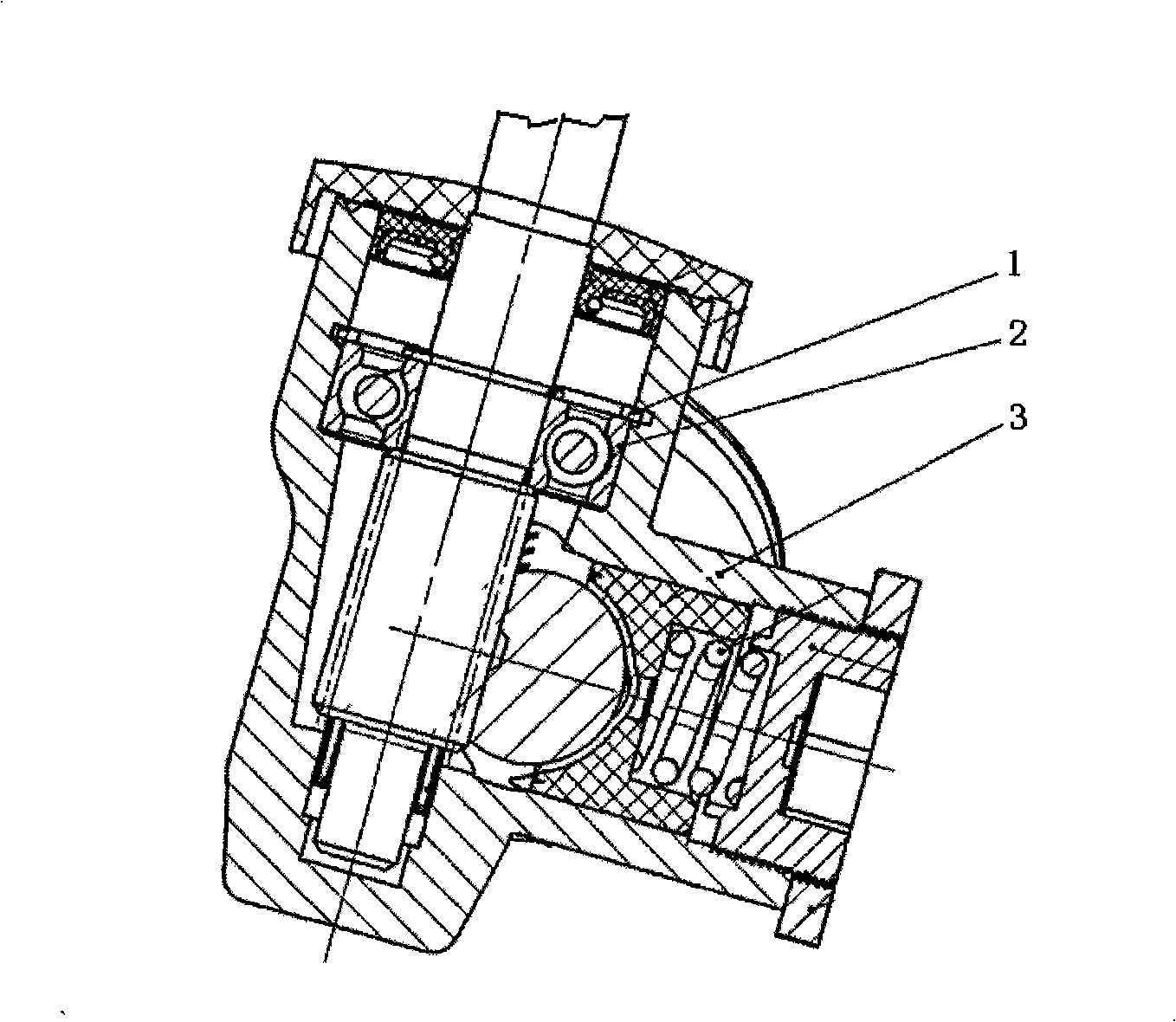

Bearing set with an angular ball bearing and cylinder roller bearing receiving axial forces

InactiveCN101310118AReduce axial playOrientation is accurateRoller bearingsBall bearingsAxial forceEngineering

The invention relates to a bearing set (10) for a shaft to be guided in an axially restricted and exact manner, a running wheel or the like for machine units. The aim of the invention is to devise less expensive bearings for receiving comparatively low axial back pressure forces. The bearing set (10) consists of a ball bearing (11), especially an angular ball bearing, receiving axial back pressure forces due to operation, and a ring slide bearing receiving axial back pressure forces or a cylinder roller bearing configured as a support bearing and receiving axial back pressure forces.

Owner:SCHAEFFLER TECH AG & CO KG

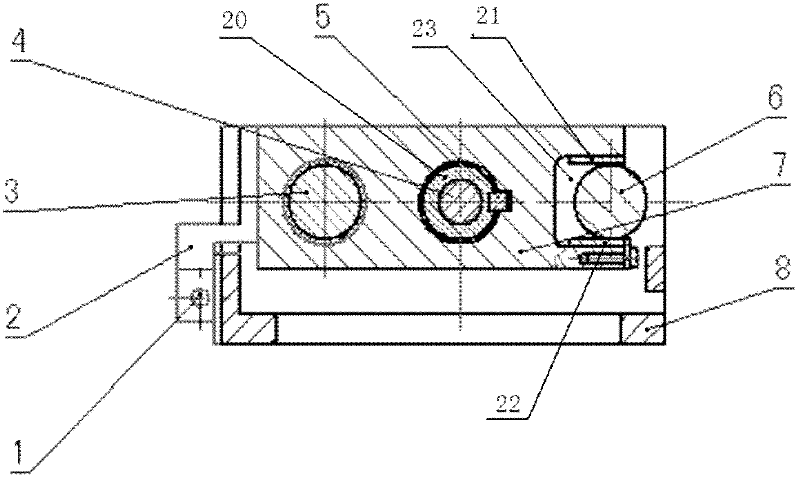

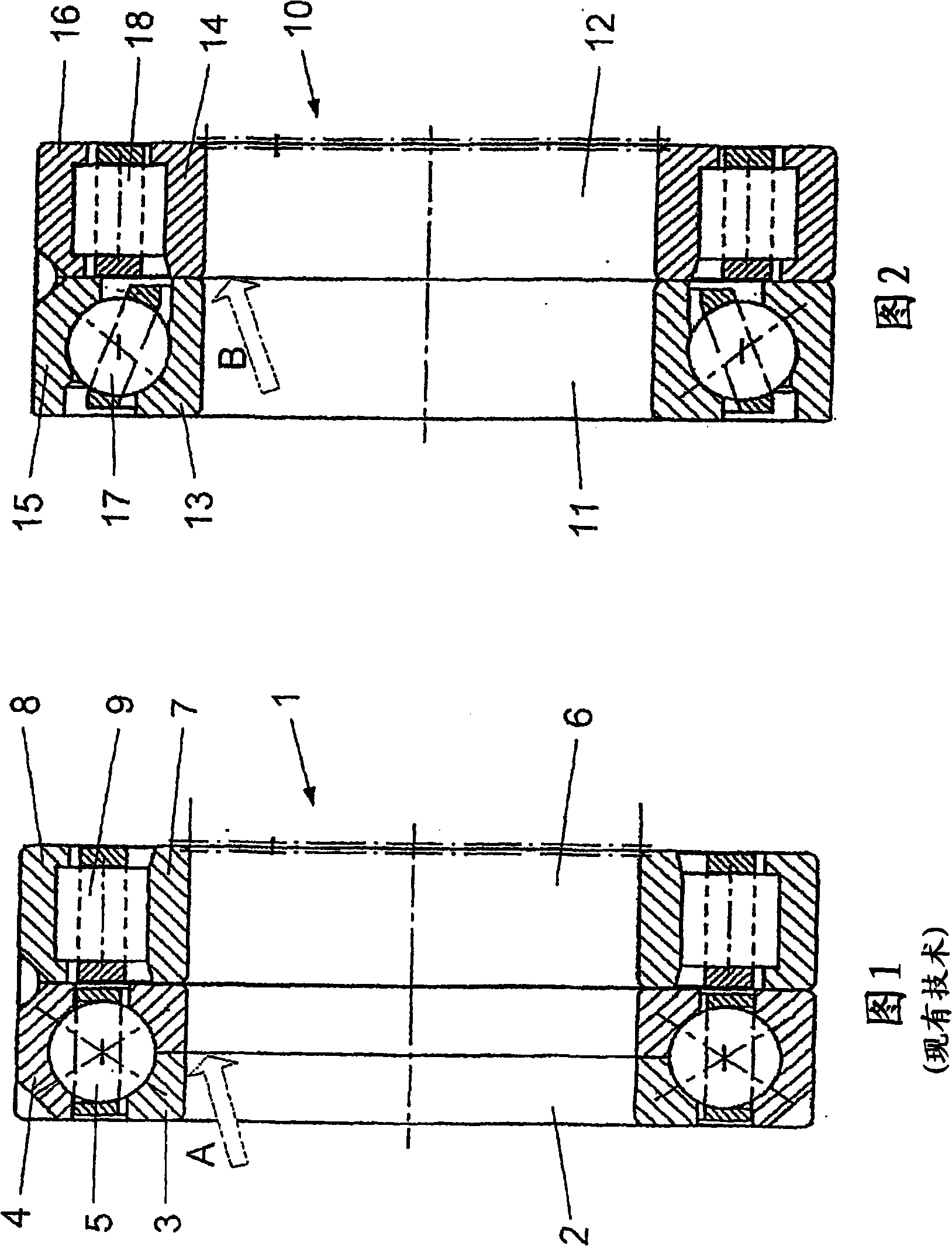

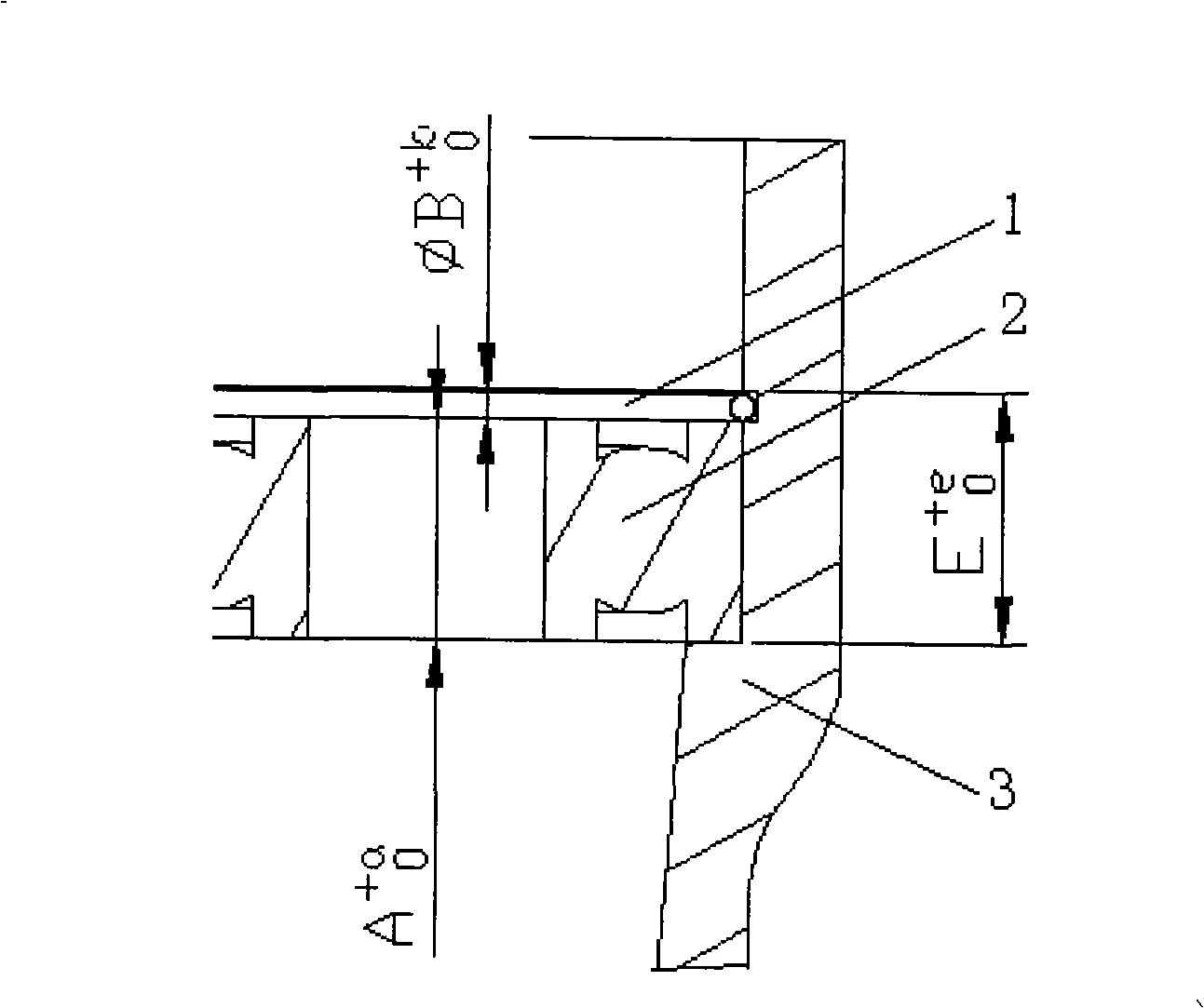

Ball screw driving structure for numerically-controlled machine tool

InactiveCN102862085AHigh transmission positioning accuracyReduce axial playFeeding apparatusLocknutBall screw

The invention relates to a ball screw driving structure for a numerically-controlled machine tool. The ball screw driving structure for the numerically-controlled machine tool is innovatively characterized by comprising a bearing seat, a transmission case, a ball screw and a motor, the bearing seat is fixed at one end of a machine tool base, the transmission case is fixed at the other end of the machine tool base, the left end of the ball screw is supported in the bearing seat through a bearing pack A, the right end of the ball screw is supported in the transmission case through a bearing pack B, the motor is mounted on a motor mounting hole of the transmission case, and an output shaft of the motor is connected with the right end of the ball screw through a coupler. The ball screw driving structure for the numerically-controlled machine tool has the advantages that the ball screw driving structure is applicable to medium-speed rotating and high-precision use conditions as one end of the ball screw is fixed while the other end of the ball screw is movable; and the bearing pack B is axially limited by the aid of a pressing ring, an inner ring lock nut, an inner ring limit step of the ball screw and the transmission case step face, axial clearance is reduced beneficially, and transmission and positioning precision is high.

Owner:JIANGSU HUANYANG COMBINATION MACHINE

Retainer ring for compensating axial clearance and use thereof

The invention discloses a retaining ring which can compensate axial space; the retaining ring is an open-typed retaining ring, and comprises a thrust face and an outer ring surface; the retaining ring is characterized in that: the retaining ring also has a sliding surface, the shape of the cross section of which is wedge-shaped. The preferable value of the included angle between the sliding surface and the thrust face is 5-25 degrees. Suitable included angle slope is determined according to the axial force and the friction coefficient of the sliding surface of the retaining ring. Simultaneously, the shape of an installation groove of the retaining ring is modified correspondingly and changed into an inclined place with the same inclined angle by coordinating with the sliding surface, so the retaining ring which adapts to the installation groove of the retaining ring can slide and regulate the space automatically. The application of a retaining ring which can compensate axial space is used axially and fixedly by the steering input gear shaft of a gear rack type machinery redirector which is widely used in micro cars or light cars. The test and the actual operation prove that the retaining ring has good axial space compensation function, reduces the axial coordinating space and the axial movement value of the gear when in work, removes the abnormal meshing sound, and improves the working performance and reliability of the redirector.

Owner:CHERY AUTOMOBILE CO LTD

A pole plate passing roller structure

PendingCN108987797AReduce frictionSmall moment of inertiaElectrode manufacturing processesFinal product manufactureAxial pressureEngineering

A pole piece passing roller structure is disclosed, It comprises a first passing roller, a first central shaft and a first fixing assembly, wherein one end of the first passing roller inner wall is provided with a first rolling assembly, the other end of the first passing roller inner wall is provided with a second rolling assembly, the first passing roller is connected with the first central shaft through the first rolling assembly and the second rolling assembly, the second rolling assembly is connected with the first central shaft, and the first fixing assembly is connected with one end ofthe first central shaft. The pole piece passing roller structure realizes that the first bearing is not subjected to axial pressure and ensures that the first bearing is in a zero clearance state, sothat the first passing roller is subjected to less frictional force when rotated, the inertia of the first passing roller is small, avoiding the broken belt or wrinkling caused by excessive moment ofinertia of the pole piece, The axial movement of the first passing roller is reduced, a gap is arranged between the second bearingand the second step of the first central shaft, and the axial pressuregenerated by squeezing the second bearing is avoided, so that the second bearing is only used for supporting the first passing roller, so that the resistance of the first passing roller is smaller, and the quality and the yield of the lithium battery cell production are greatly improved.

Owner:GUANGDONG JITI SMART EQUIP CO LTD

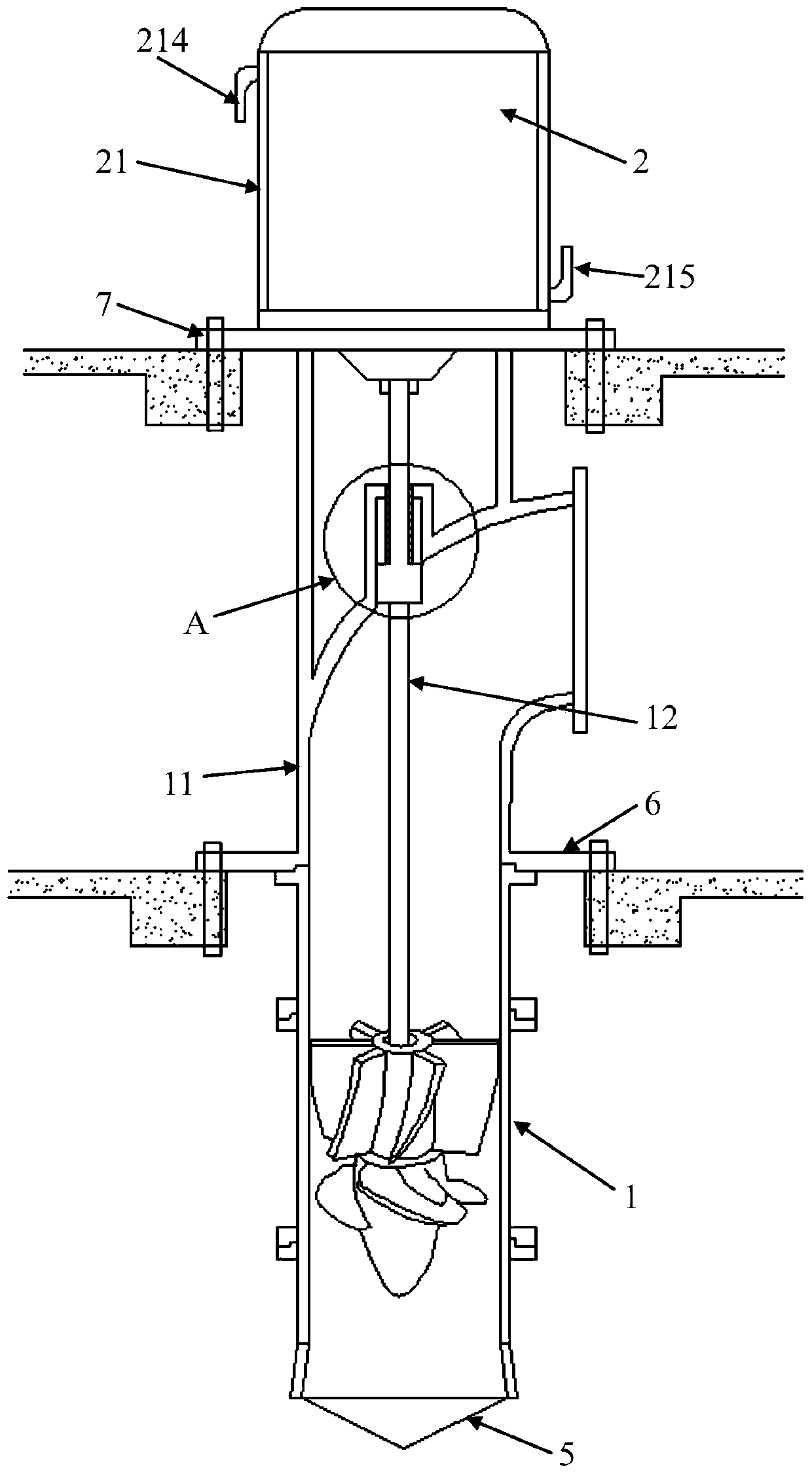

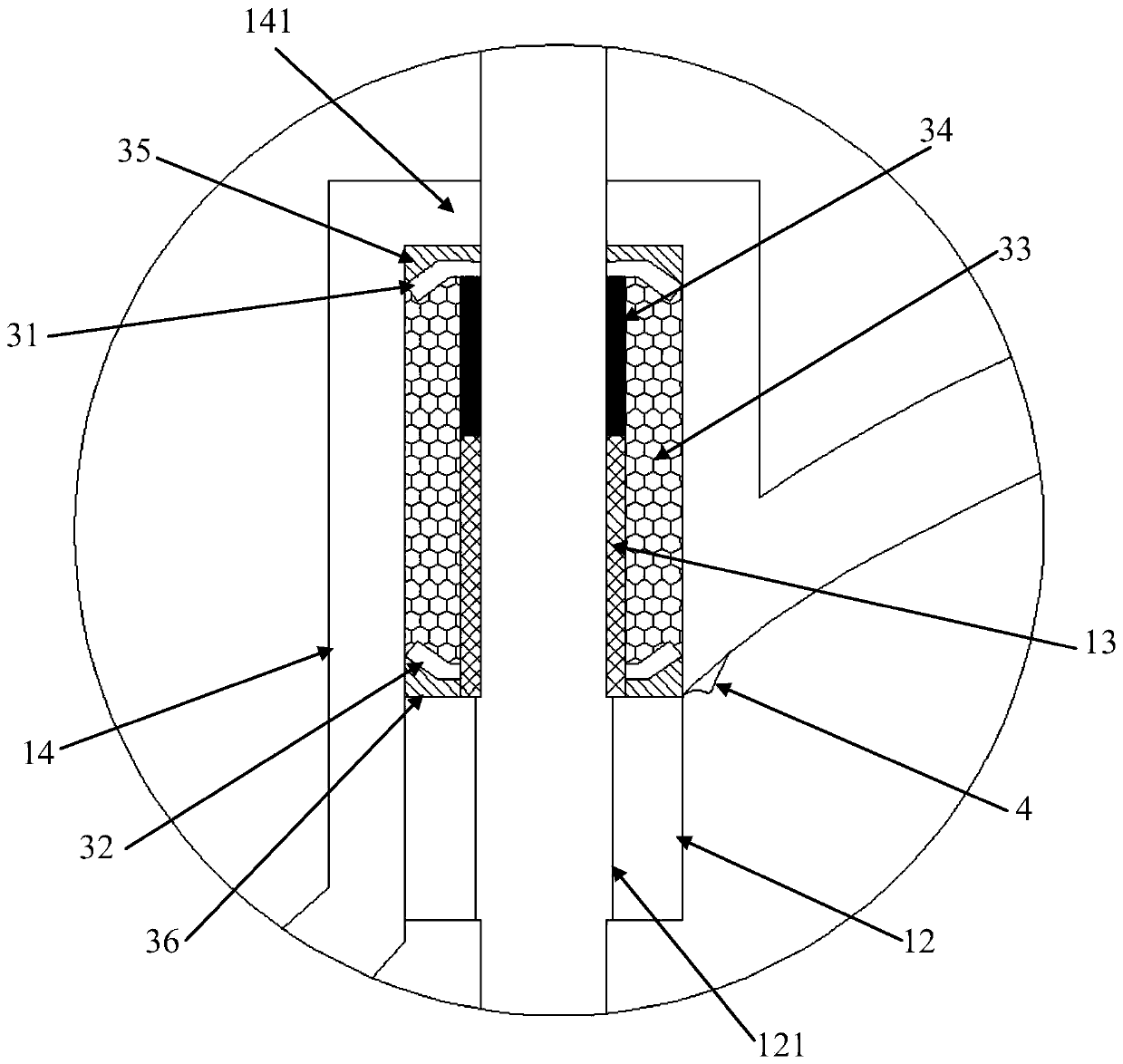

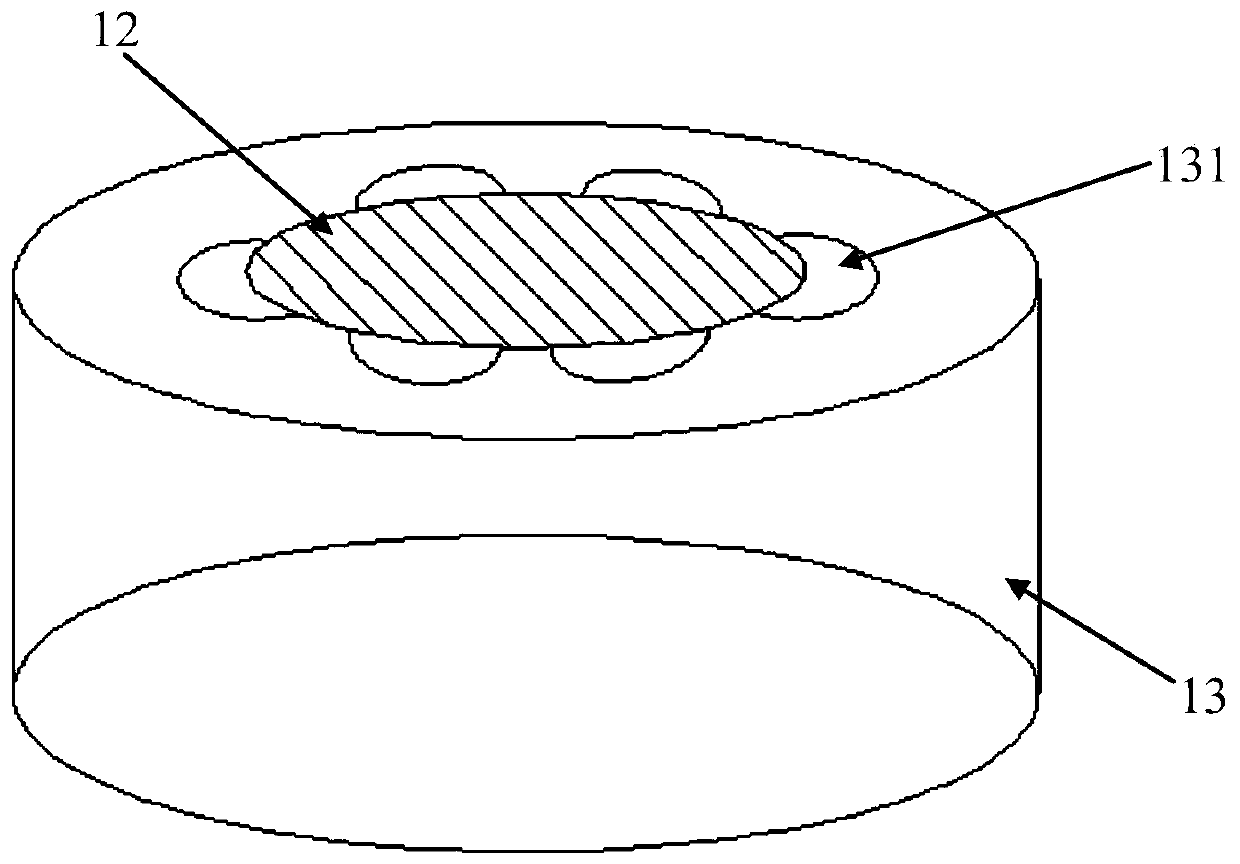

Novel axial flow pump

PendingCN110043477ARealize self-lubricationAchieve cooling and lubricationPump componentsPump installationsAxial-flow pumpCooling effect

The invention provides a novel axial flow pump. The novel axial flow pump comprises an axial flow pump body and a seal assembly, wherein the axial flow pump body comprises a shell and a pump shaft; aguide pipe communicating with the interior of the shell is arranged on the top of the shell; an annular supporting part is arranged on the inner wall of the top end of the guide pipe; a rubber bearingmatched with the pump shaft is arranged in the guide pipe; the pump shaft comprises a shaft shoulder supported against the bottom end of the rubber bearing; the seal assembly comprises a first elastic adjusting part and a second elastic adjusting part; the first elastic adjusting part is arranged on the pump shaft in a sleeving manner and is located between the supporting part and the rubber bearing; the second elastic adjusting part is arranged on the rubber bearing in a sleeving manner and is located below the first elastic adjusting part; a buffer layer which is arranged on the rubber bearing in a sleeving and sealing manner is arranged between the first elastic adjusting part and the second elastic adjusting part; a containing cavity for placing filler is formed by the first elastic adjusting part, the buffer layer, the rubber bearing and the pump shaft in a surrounding manner; and wedge-shaped sealing rings are pressed between the first elastic adjusting part and the supporting part and between the second elastic adjusting part and the shaft shoulder. The novel axial flow pump has relatively good sealing property and cooling effect.

Owner:GAOYOU HUAN LIU PUMP IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com