Method for machining low-roughness high-peak textured roller

A technology with low roughness and processing method, applied in the field of EDM texturing, can solve the problem of grinding defect coverage, surface roughness uniformity, surface chromatic aberration control, surface scratch control, which is difficult to achieve, has little practical application significance, and rolls. Few applications, etc., to achieve the effects of excellent disordered cold roll surface morphology, improved spraying and stamping performance, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

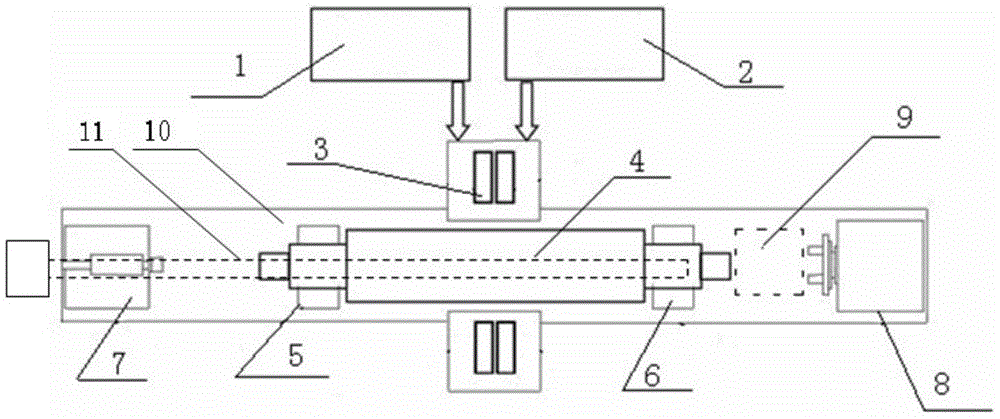

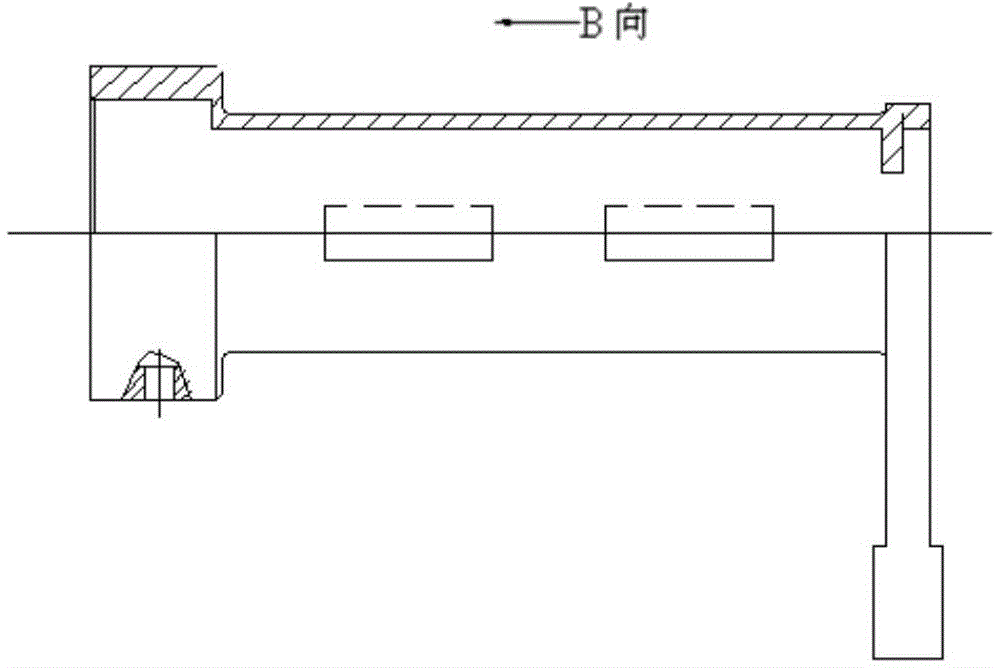

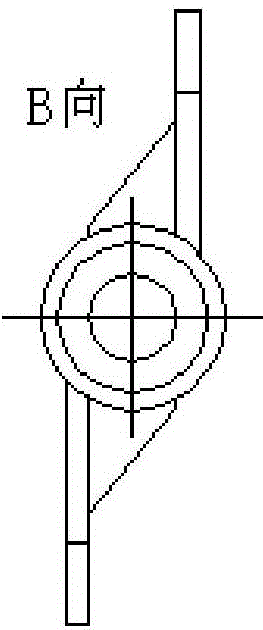

[0029] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

[0030] A processing method for low-roughness and high-peak-number textured rolls, by changing the drive structure, changing the roll grinding stroke, reducing the texturing lateral color difference, avoiding the surface arcing of the textured roll, and improving the two points and scratches on the textured roll surface Defective steps, to realize the processing of roughness and high peak number textured rolls, the specific operation steps are as follows:

[0031] 1) Change the grinding stroke of the roll: in the initial grinding, add two grinding strokes to eliminate the horizontal printing defects; in the middle grinding, reduce the speed of the middle grinding from 35r / min to 30r / min, Z The shaft speed is controlled at 2400-2600mm / min, the X-axis feed rate is controlled below 0.3mm / min, and the number of intermediate grinding is increased by 1 to 2 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com