Bearing set with an angular ball bearing and cylinder roller bearing receiving axial forces

A technology of cylindrical roller bearings and angular contact ball bearings, applied in the field of bearing sets, to achieve the effect of improving cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

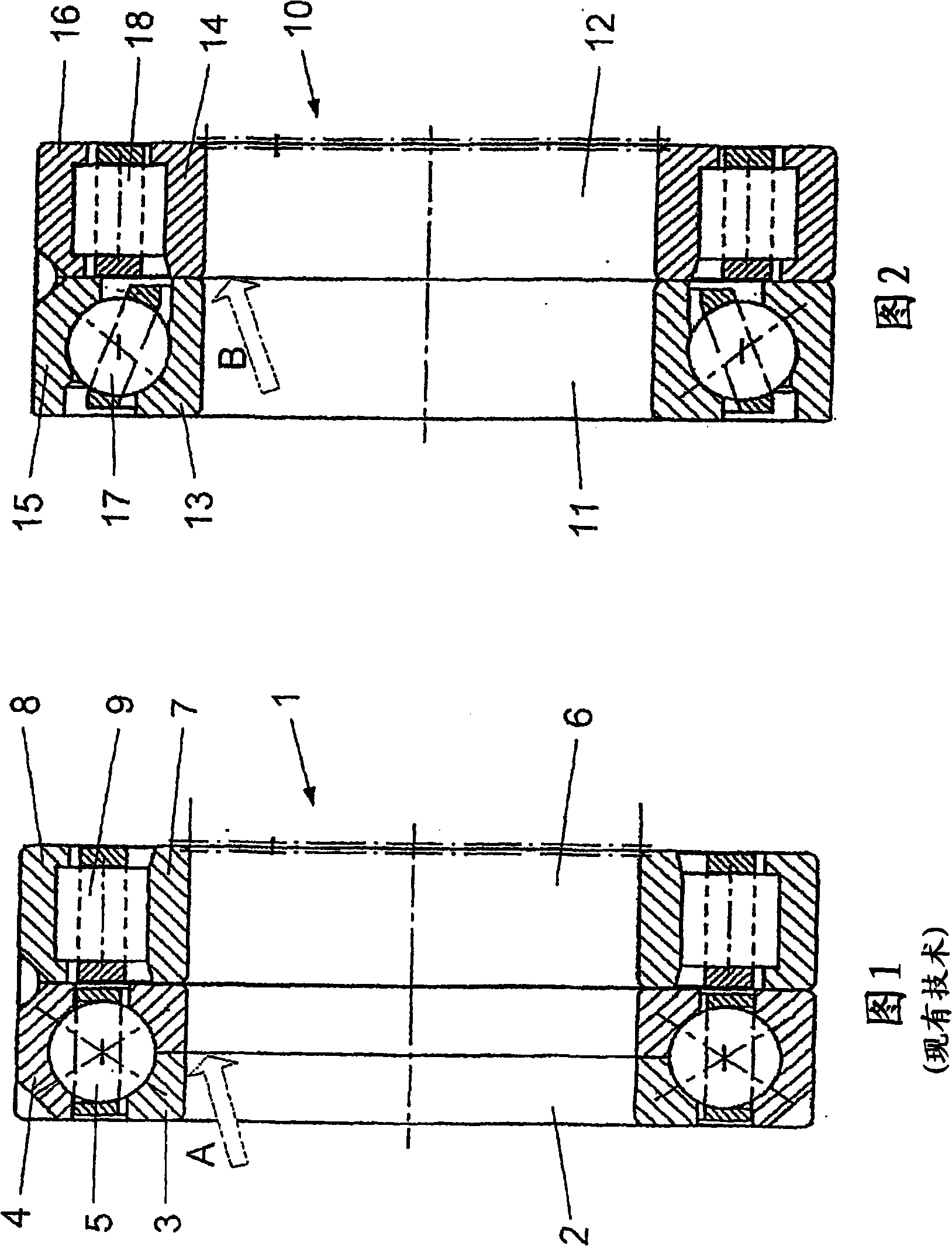

[0019] The bearing set 1 according to the prior art shown in FIG. 1 comprises a QJ bearing 2 designed as a four-point contact ball bearing and an NU axial bearing 6 designed as a bearing with a rib on the outer ring, said OJ bearing having Balls 5 between inner ring 3 and outer ring 4 , said NU axial bearing has cylindrical rollers 9 guided between inner ring 7 and outer ring 8 . Among them, the axial clearance is adjusted according to arrow A in the four-point contact ball bearing.

[0020] According to the invention, the bearing set 10 according to FIG. 2 comprises an angular contact ball bearing 11 and an NJ cylindrical roller bearing 12 designed as a thrust bearing. The two bearings 11 and 12 each have an inner ring 13 and 14 and each an outer ring 15 and 16 , between which balls 17 or cylindrical rollers 18 are accommodated.

[0021] A very small axial clearance according to arrow B is formed between the inner ring 13 of the angular contact ball bearing 11 and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com