Ball screw driving structure for numerically-controlled machine tool

A ball screw and drive structure technology, applied in metal processing mechanical parts, metal processing equipment, feeding devices, etc., can solve the problem of not finding the ball screw drive structure of CNC machine tools, and achieve high transmission positioning accuracy and reduce shaft size. The effect of the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

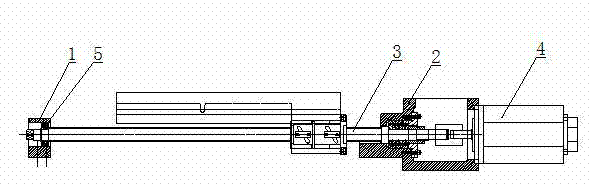

[0010] Such as figure 1 As shown, it includes a bearing seat 1, a transmission box 2, a ball screw 3 and a motor 4.

[0011] The bearing seat 1 is fixed on one end of the machine tool base, and the transmission box 2 is fixed on the other end of the machine tool base.

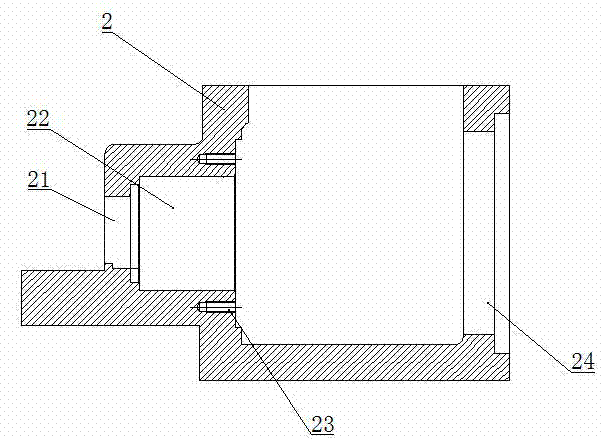

[0012] Such as figure 2 As shown, one side wall of the transmission box 2 is provided with a through hole horizontally passing through the side wall of the transmission box 2. The through hole is stepped and consists of a shaft hole 21 and a bearing hole 22 that are coaxially arranged. The inner diameter is smaller than the inner diameter of the bearing hole 22, and the bearing hole 22 is located on the inner side of the side wall, and a number of circularly distributed threaded holes 23 are drilled on the inner wall of the transmission case at the end of the bearing hole; the other side of the transmission case is provided with a motor installation 孔24.

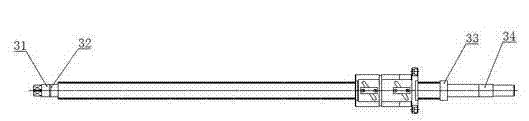

[0013] Such as image 3 As shown, the left end of the ball sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com