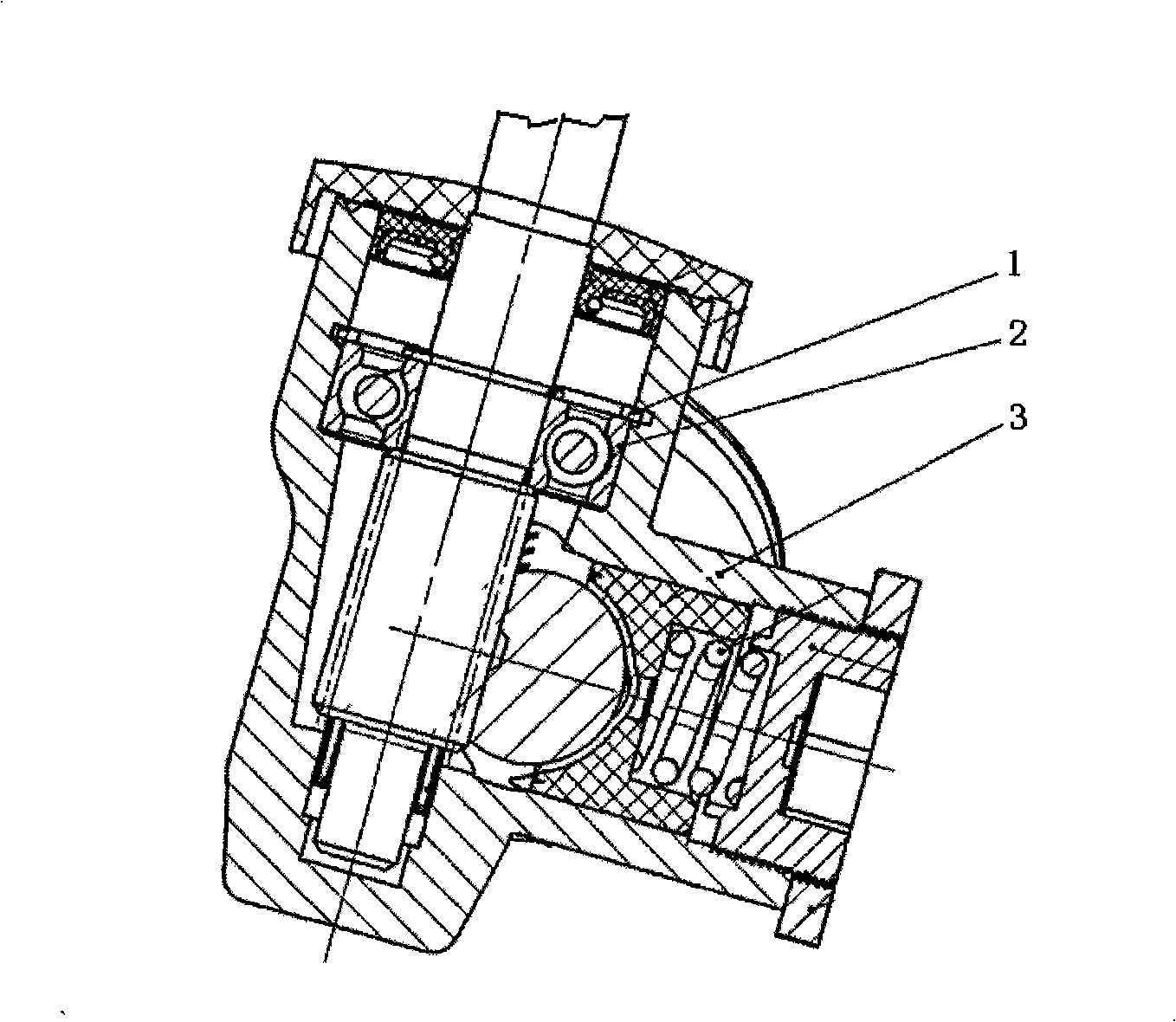

Retainer ring for compensating axial clearance and use thereof

A technology of axial clearance and retaining ring, applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of reducing the meshing stability of the rack and pinion, excessive clearance, and unable to eliminate the fit clearance, etc., to achieve the elimination of axial movement, good meshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

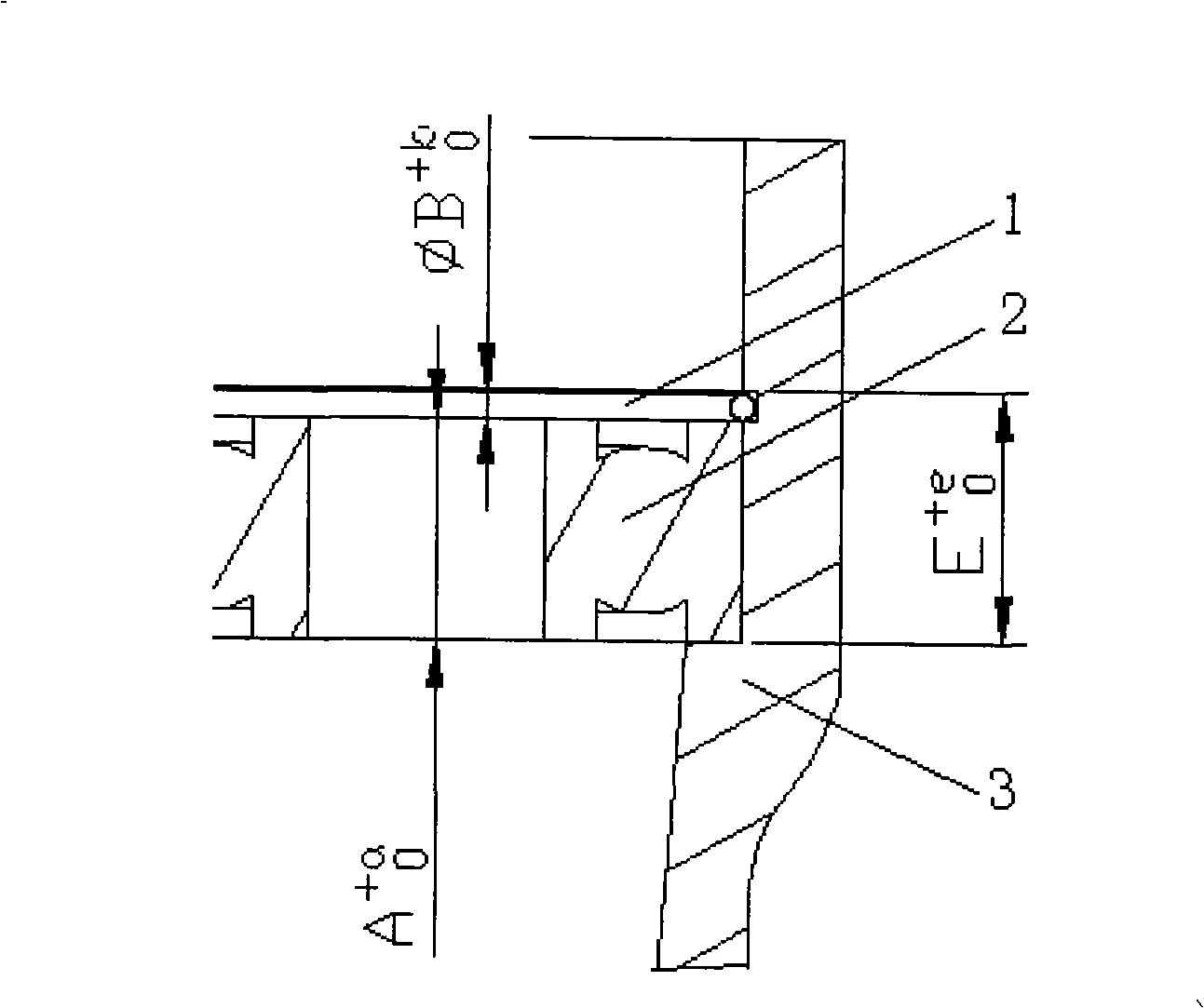

[0035] Taking the above conditions as an example, the machining conditions and the design accuracy target remain unchanged, the size of the retaining ring is A=12.1, B=1.5, and the height of the outer edge of the retaining ring is B 1 = 1.2, the deviation of each size is 0, and the angle between the sliding surface of the retaining ring and the thrust surface β = 15°, then when Δt = e+a+b, that is, the self-adjusting ability of the retaining ring can completely eliminate the interference caused by the fit When there is a gap, the height of the upper side of the inner wall of the tank is set to E 1 :

[0036] E. 1 =A+1.2=13.3

[0037] Δt=e+a+b=2.0

[0038] Depend on

[0039] Δt=(w / cosβ-η)*sinβ

[0040] Get w=1.35

[0041] Then E=E 1 +w*tanβ=13.66mm>A+1.2=13.3

[0042] It can be seen from this that the opening of the outer edge of the groove of this structure is wider, and the outer edge of the retaining ring is narrower, which greatly improves the process performance an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com