Method for reducing axial drifting of rolling mill rolls

A technology of axial movement and roll movement, which is applied in the field of hot rolling, and can solve the problems of inaccurate judgment of the intersection state between the rolls of the four-high mill, the inability to measure the axial force between the rolls and the axial movement of the rolls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

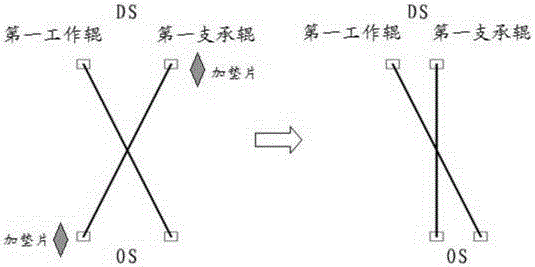

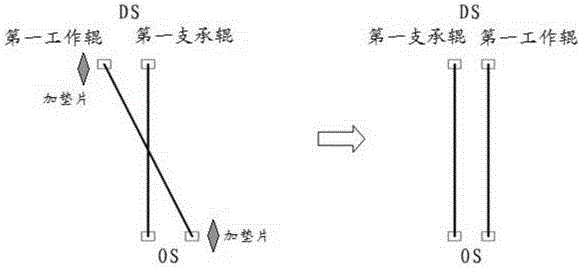

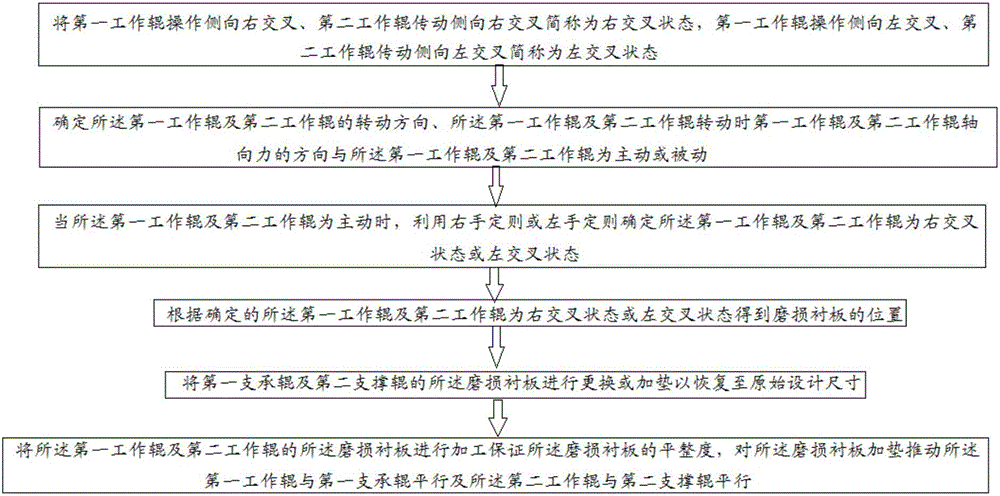

[0023] see Figure 1-7 A method for reducing the axial movement of rolling mill rolls provided by an embodiment of the present invention includes the following steps:

[0024] Step 1, the operation side of the first work roll crossing to the right and the driving side of the second work roll crossing to the right are referred to as the right crossing state, the operating side of the first work roll crossing to the left and the driving side of the second work roll crossing to the left left cross state;

[0025] Step 2, determine the rotation direction of the first work roll and the second work roll, the direction of the axial force of the first work roll and the second work roll when the first work roll and the second work roll rotate, and the direction of the first work roll and the second work roll The first work roll and the second work roll are active or passive.

[0026] Step 3, when the first work roll and the second work roll are active, use the right-hand rule or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com