Intelligent sealing device for ship tail shaft numerical control magnetic fluid

A sealing device and magnetic fluid technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of complicated installation and maintenance, poor safety and environmental protection, and large leakage, and achieve good sealing effect, long service life, and improved The effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

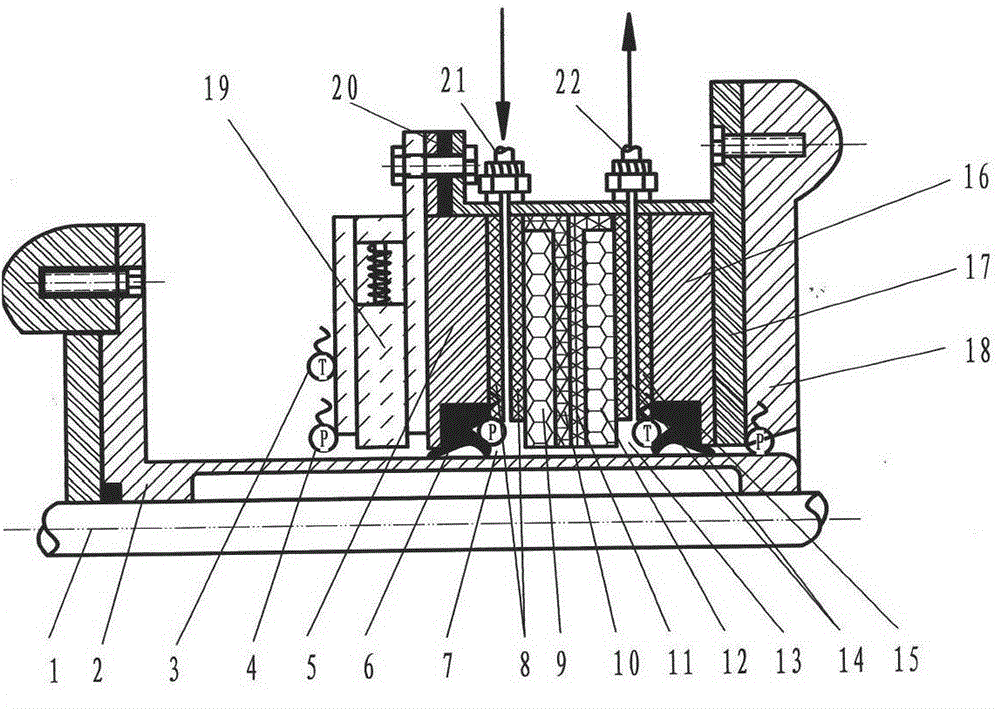

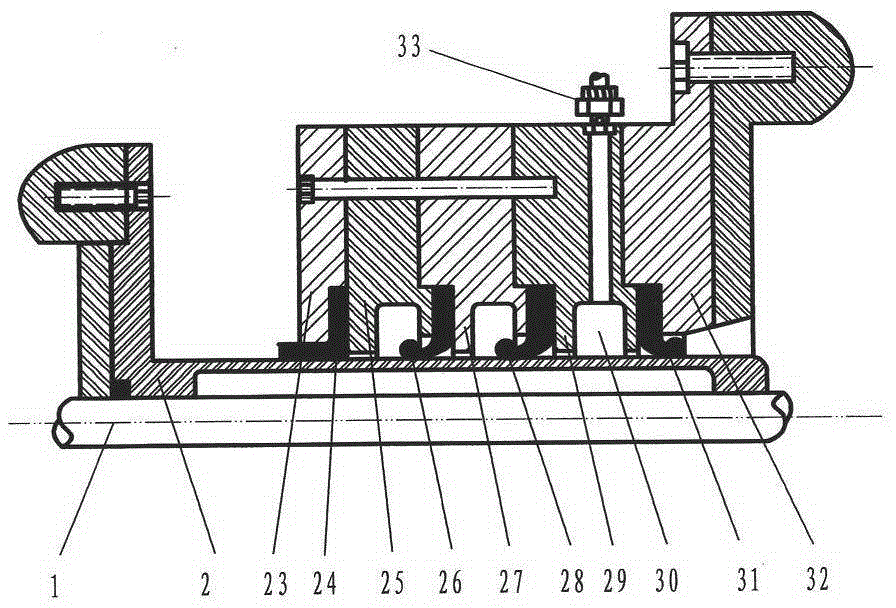

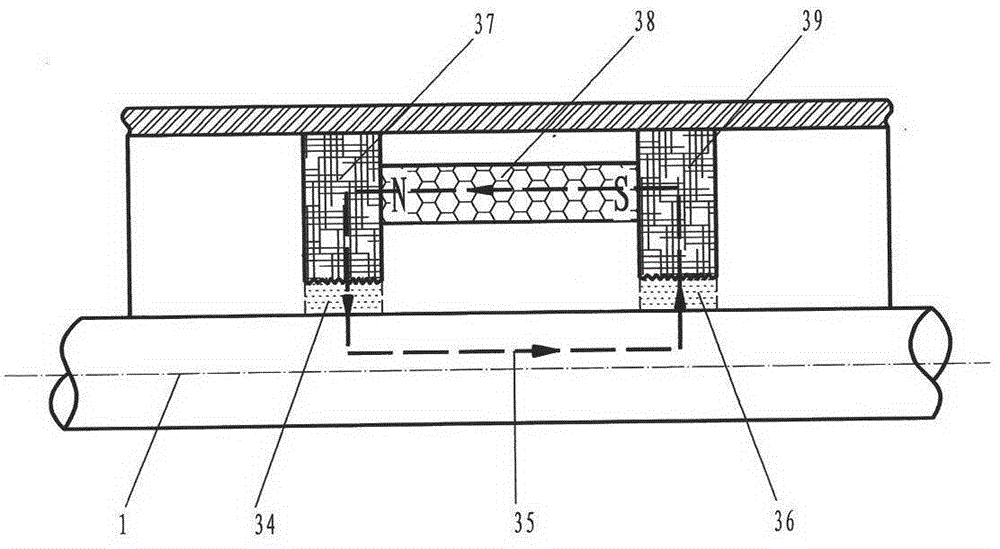

[0073] See attached Figure 1-9, the present invention ship stern shaft numerical control magnetic fluid intelligent sealing device, a stuffing box is arranged at the rear sealing part of the stern shaft, one end of the box is a gland 20, and the other end is connected with the stern post 18 by a flange 17; two layers of parallel devices are arranged in the middle of the box PTFE ring box sleeves 10, 11, nx12 pieces of radially opposed magnetic sector permanent magnets 9, 9" etc. are embedded in each layer of the box sleeve; a magnetic fluid circulation chamber 7, is provided between the magnet-embedded box sleeve and the bushing tube 13. A stainless steel ring 8 and 12 are respectively installed on both sides of the permanent magnet box cover, and 8 magnetic fluid injection or outflow holes are respectively opened in the radial direction; a stainless steel card is respectively installed on the outside of the two stainless steel rings Rings 5 and 14 are used to hold the AH-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com