Accessory gearbox for gas turbine engine

A gas turbine and gearbox technology, applied in the field of gas turbine engines and turbine engines, can solve problems such as reducing the thickness of the gearbox

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

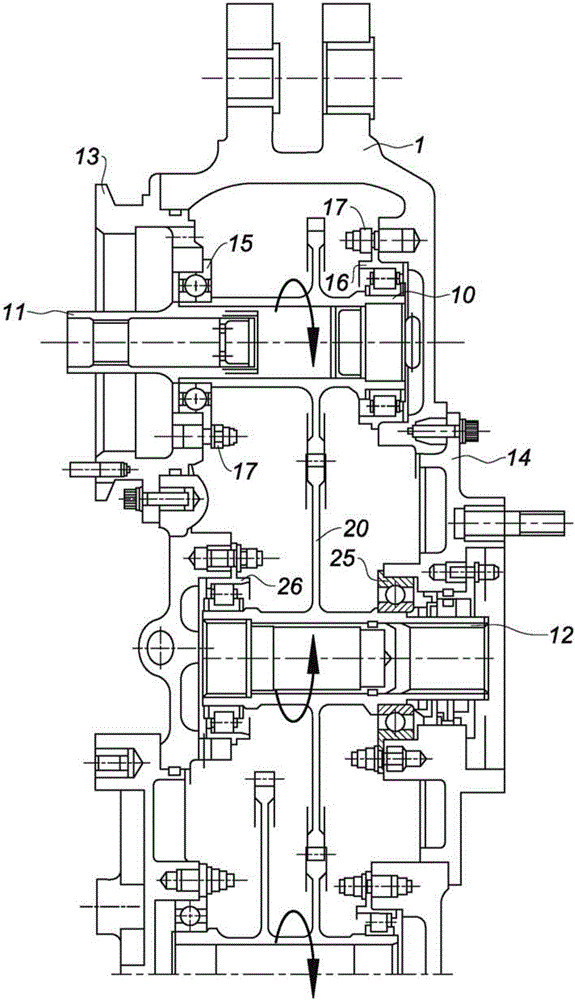

[0017] figure 1 The end of an accessory gearbox of a turbine engine according to the prior art is shown in cross section. It consists of a housing, typically cast and then machined, into which a gear is mounted for receiving a pinion for driving one of the accessories attached to the accessory gearbox. Two pinions are shown in the figure: a first pinion 10 is attached to the input shaft 11 in the AGB and a second pinion 20 includes internal splines 12 for driving the accessory.

[0018] Once the gear is in place in the housing 1 , the opening through which the shaft of the drive accessory passes is closed by a cover in order to ensure that the assembly is fluid tight and that one of the bearings of the gear's shaft is supported. In the case of the first gear 10 , the cover 13 closes the opening on the input shaft 11 side. As far as the pinion 20 is concerned, the cover 14 closes the opening through which the first drive shaft 12 passes. As can be seen from the gears, they a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com