Automobile shock absorber spring dismounting and mounting method

A technology for automobile shock absorbers, disassembly and assembly methods, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of unreasonable layout of shock absorber grab hooks, unreasonable shock absorber force, slippage and deflection and other problems, to achieve the effect of uniform force, not easy to tilt, and prevent overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings.

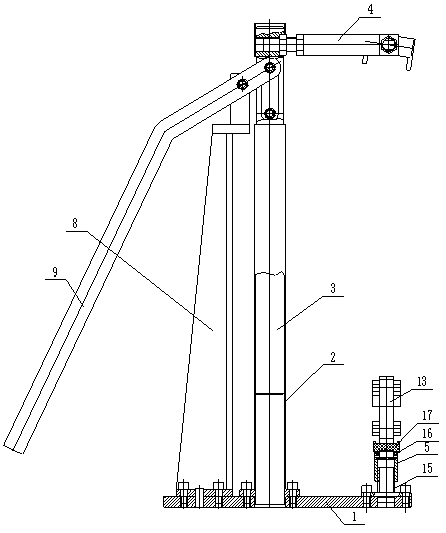

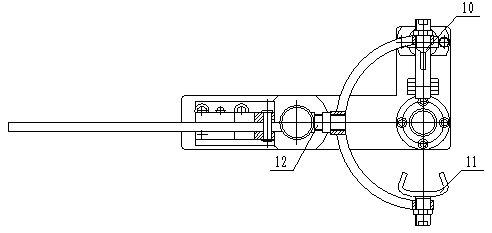

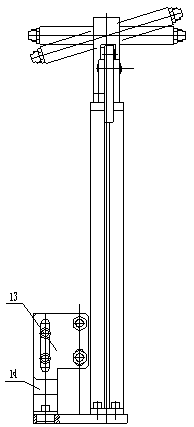

[0048] During specific implementation: if Figure 1 to Figure 9 As shown, a method for disassembling and assembling an automobile shock absorber spring. In this method, the vertical positioning of the shock absorber is realized first, and then the spring is pressed down by a force-applying mechanism above the shock absorber so that the upper end of the spring is separated from the spring seat. Then disassemble the spring seat, which is characterized in that when the shock absorber assembly is positioned vertically, the bottom of the shock absorber is positioned in contact with the force, and at the same time, the pressing member in the force applying mechanism adopts three triangular distributions in the horizontal direction. A point contacts the upper end of the spring to apply downward pressure.

[0049] In this technical solution, the disassembly and asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com