Patents

Literature

51results about How to "Improve pull-off force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

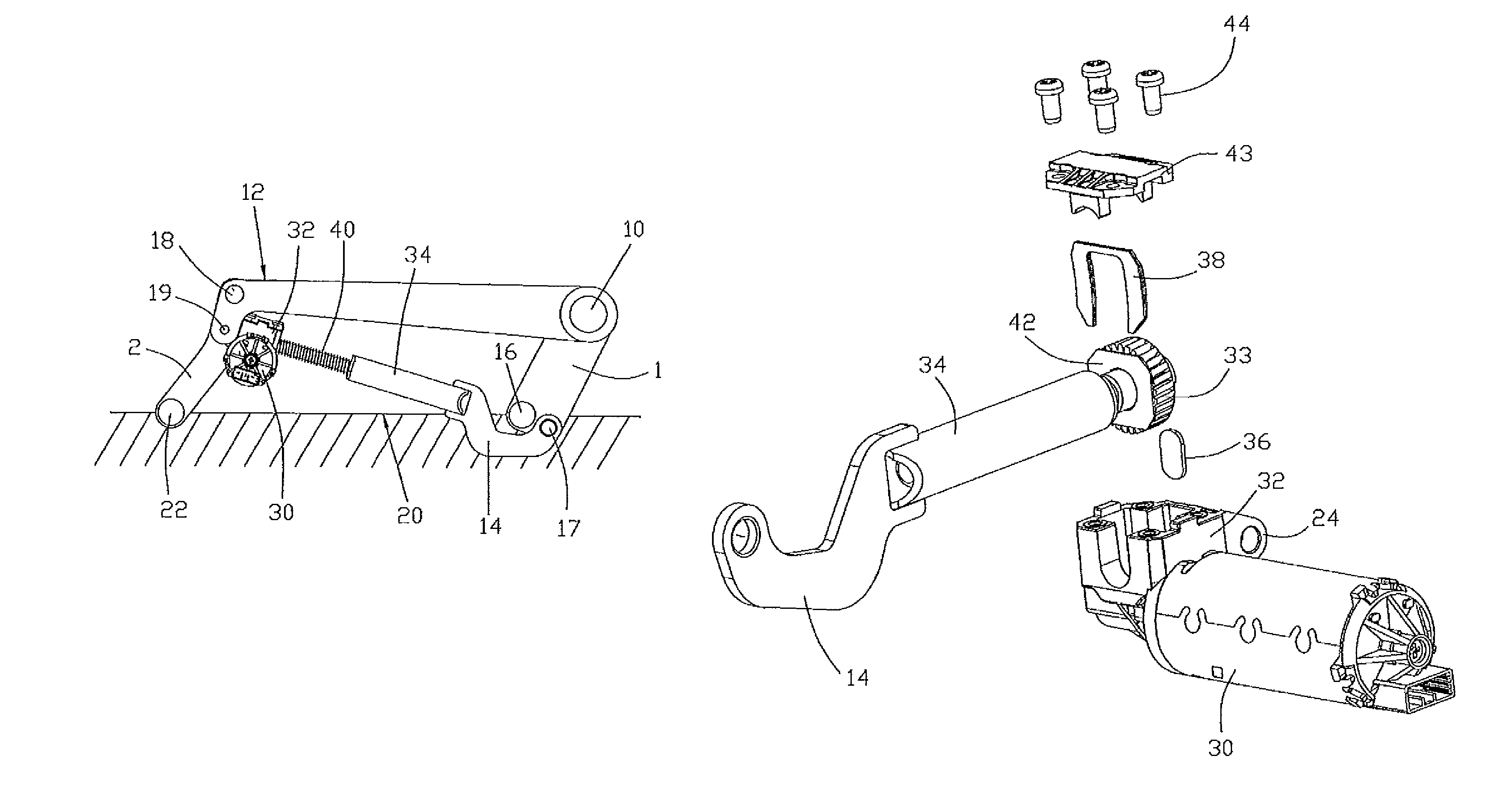

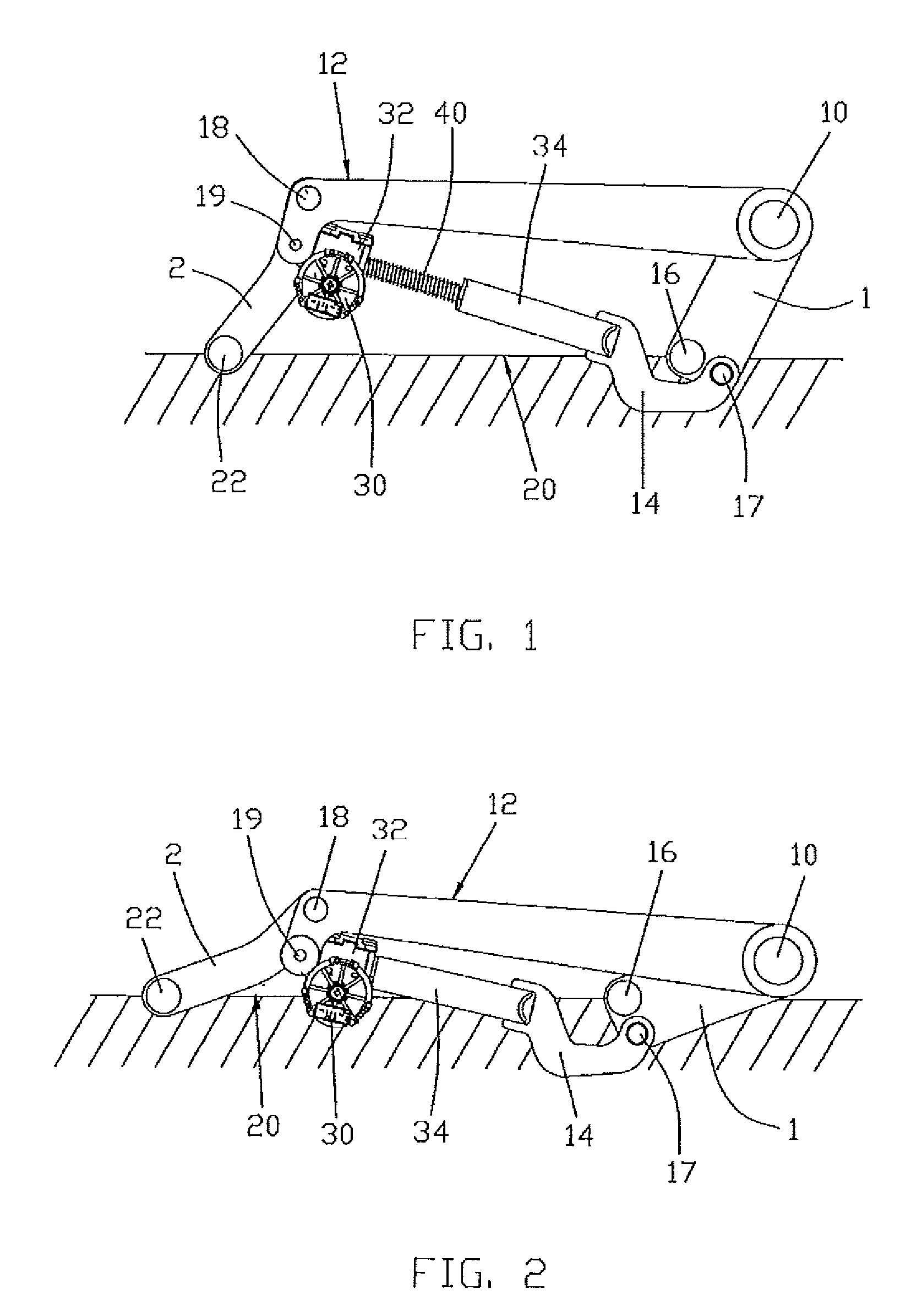

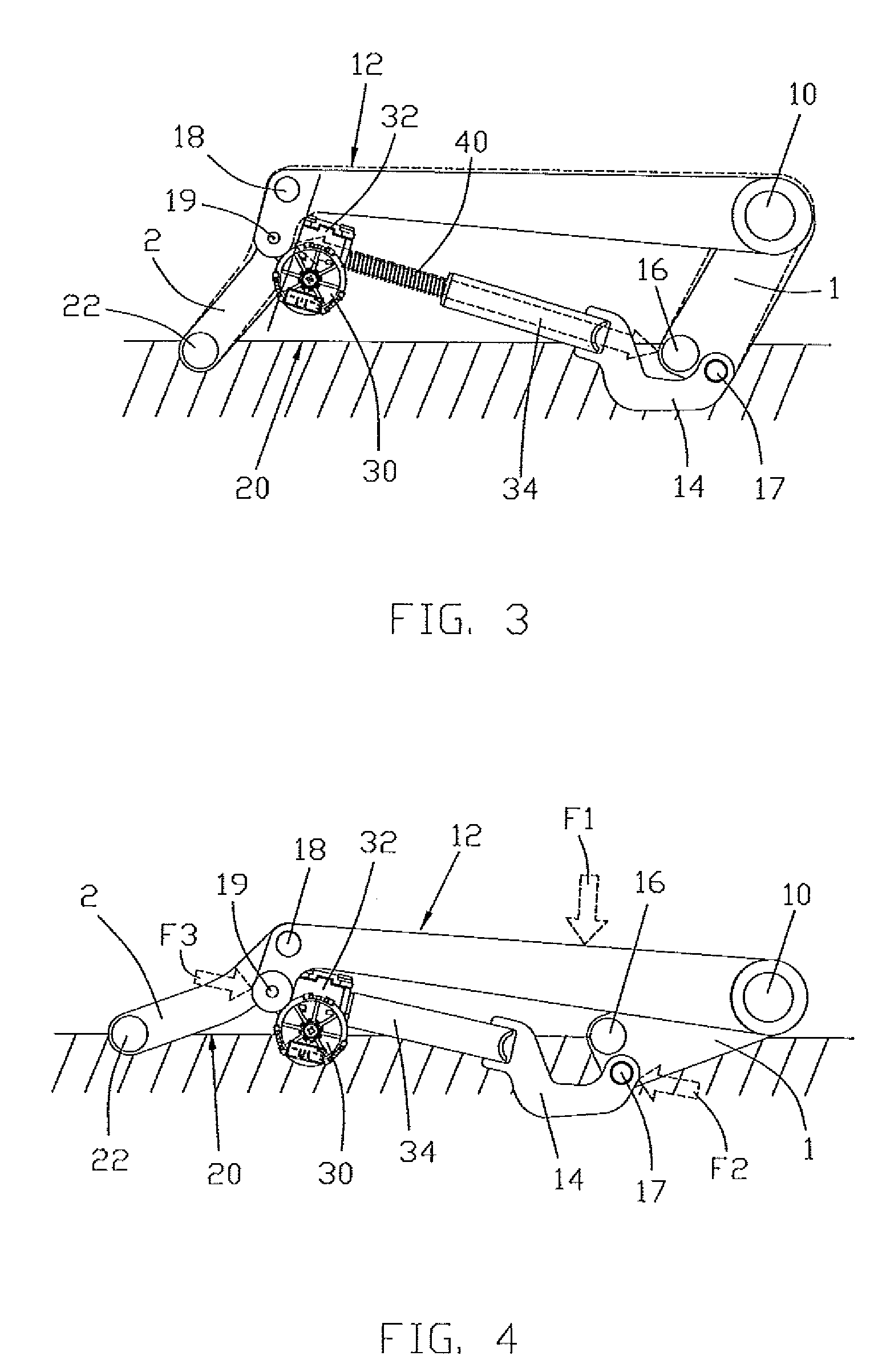

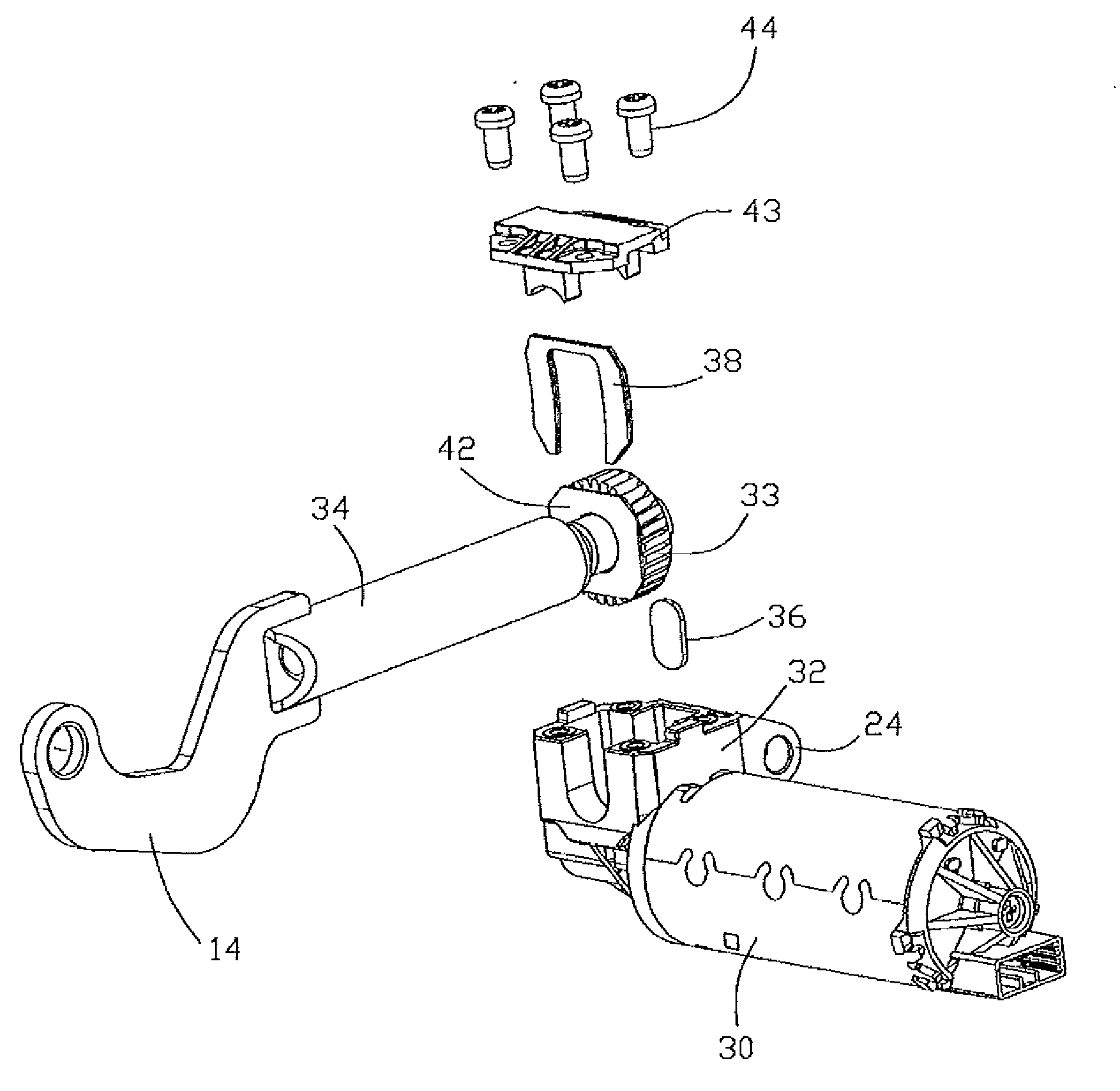

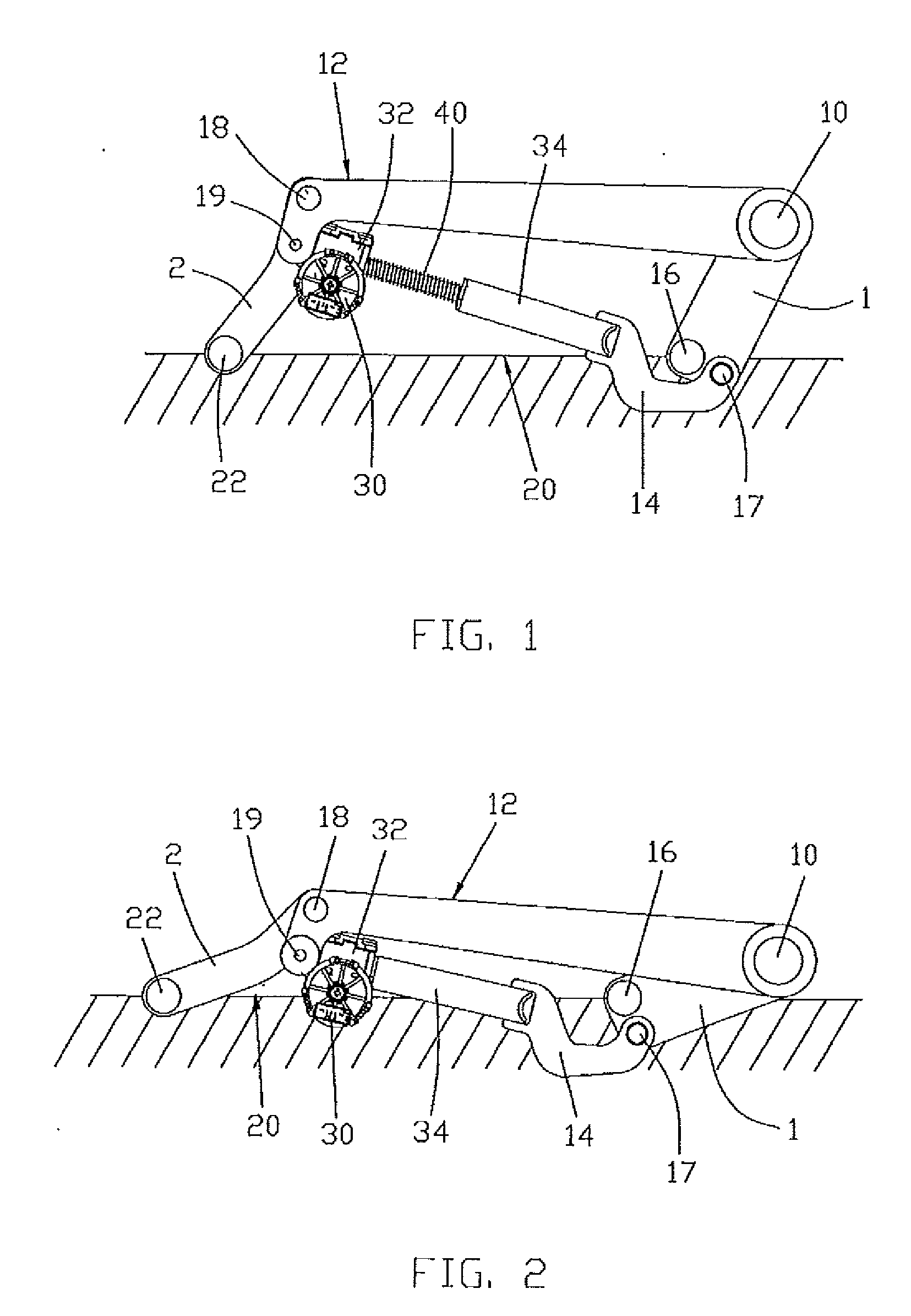

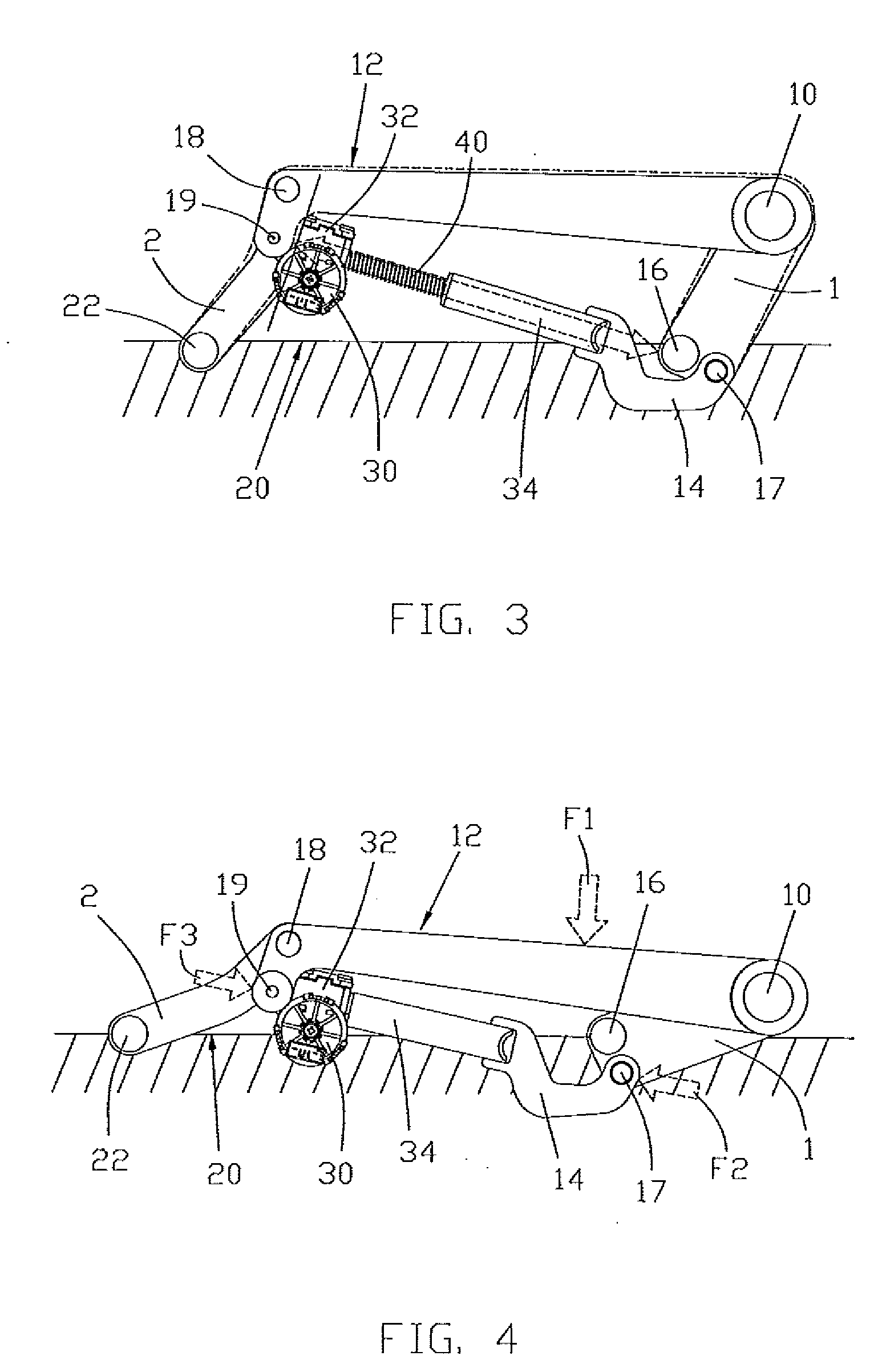

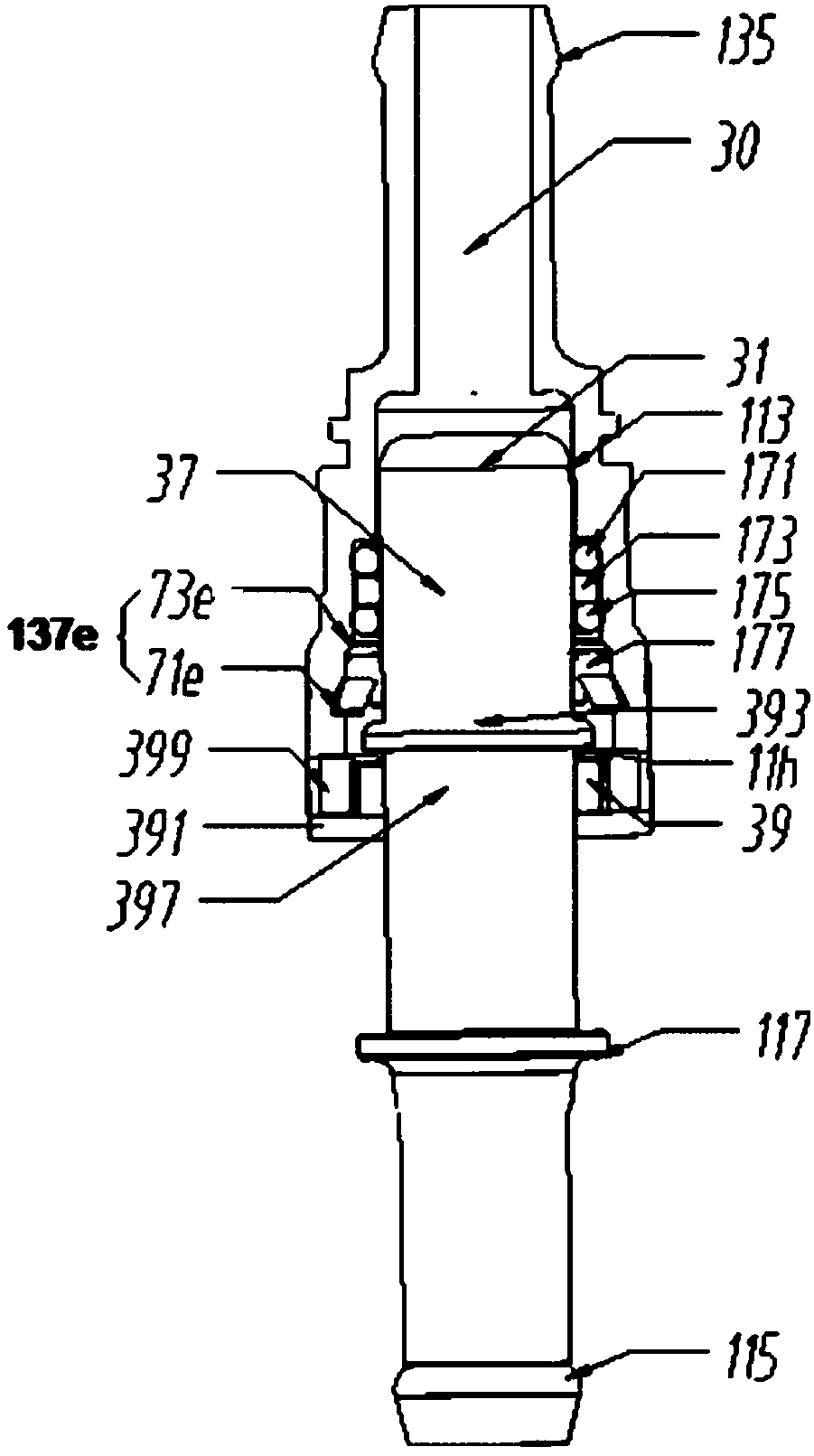

Seat adjuster assembly

A seat adjuster assembly includes an electric motor having an output shaft with a worm gear positioned in a gearbox, a spur gear meshing with the worm gear in the gearbox, a spindle shaft fixed to and driven by the spur gear coacting with a nut contained in a tube, and a linkage system connected to both a vertically movable upper vehicle seat part and a non-vertically movable lower vehicle seat part that positions vertically the upper vehicle seat part responsive to the position of the nut relative to the spindle shaft. At least one washer is provided on the spindle shaft. The spur gear is a plastic spur gear molded over the washer. A pair of leaf springs disposed in the gearbox bears against the spur gear and a wall of the gearbox.

Owner:JOHNSON ELECTRIC SA

Seat adjuster assembly

ActiveUS20090206644A1Simple designSimple structureGearingMechanical energy handlingEngineeringSpur gear

A seat adjuster assembly includes an electric motor having an output shaft with a worm gear positioned in a gearbox, a spur gear meshing with the worm gear in the gearbox, a spindle shaft fixed to and driven by the spur gear coacting with a nut contained in a tube, and a linkage system connected to both a vertically movable upper vehicle seat part and a non-vertically movable lower vehicle seat part that positions vertically the upper vehicle seat part responsive to the position of the nut relative to the spindle shaft. At least one washer is provided on the spindle shaft. The spur gear is a plastic spur gear molded over the washer. A pair of leaf springs disposed in the gearbox bears against the spur gear and a wall of the gearbox.

Owner:JOHNSON ELECTRIC SA

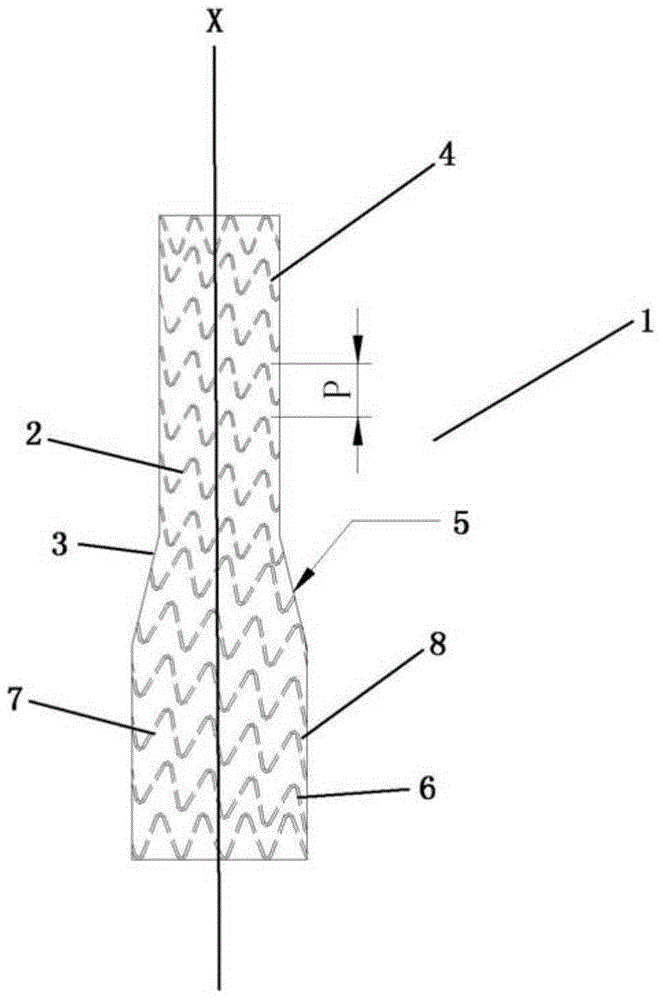

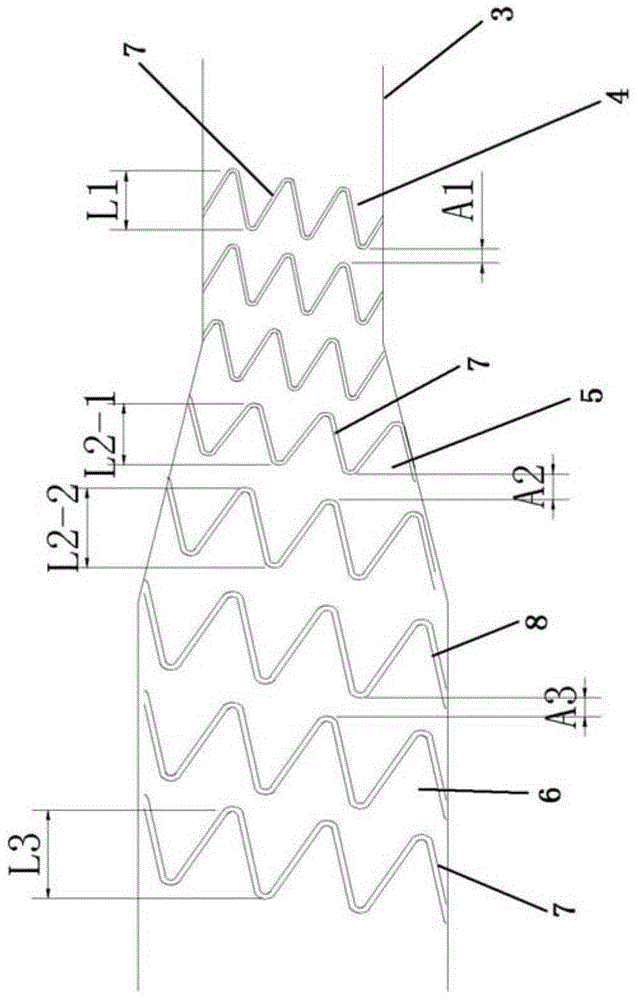

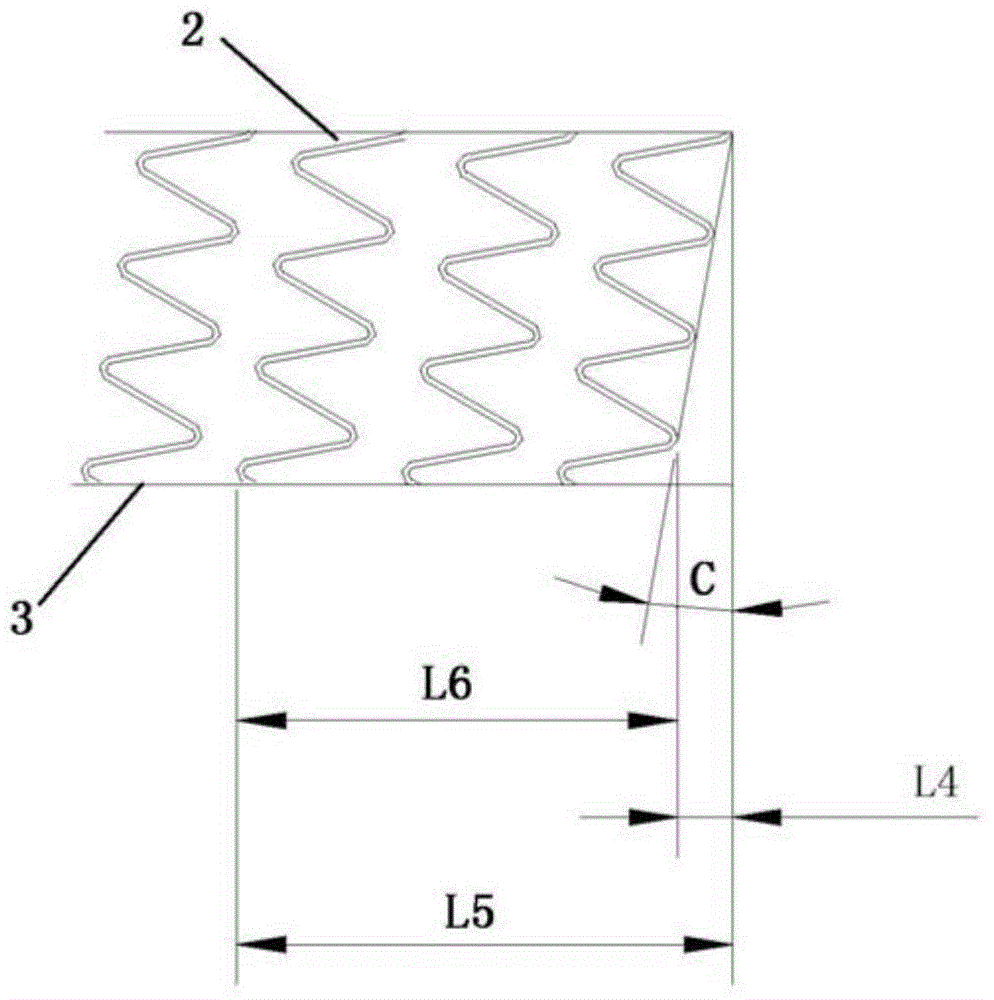

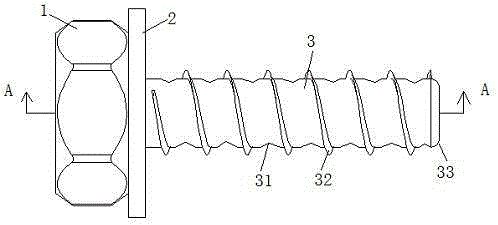

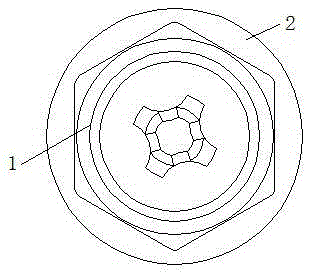

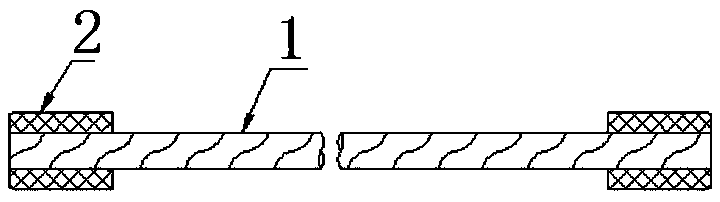

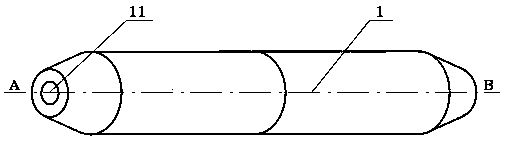

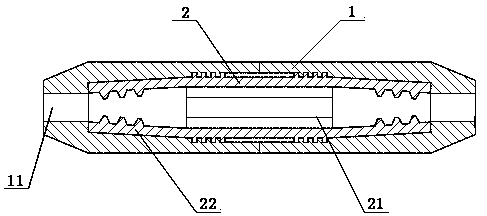

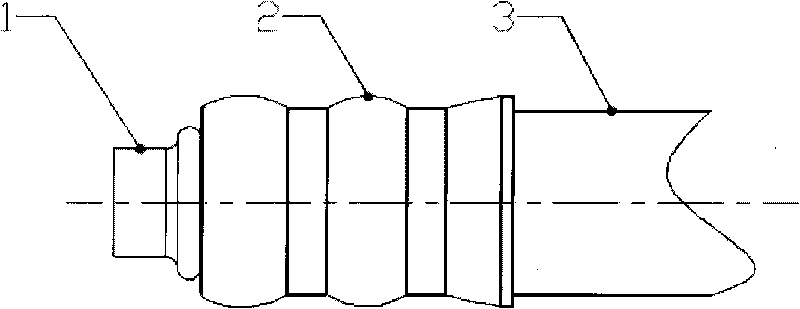

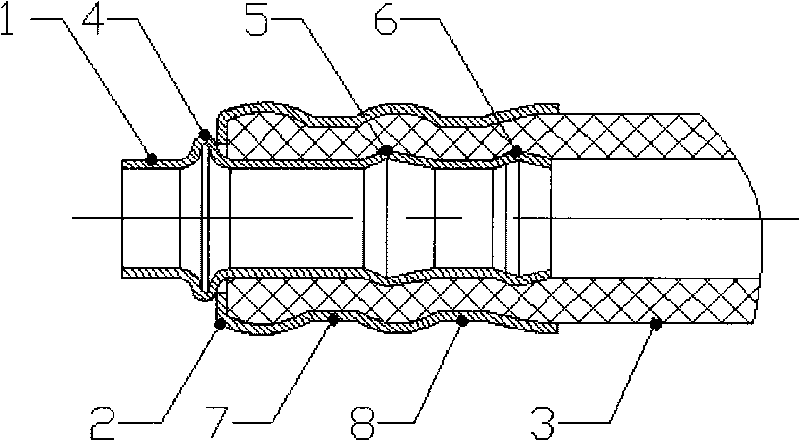

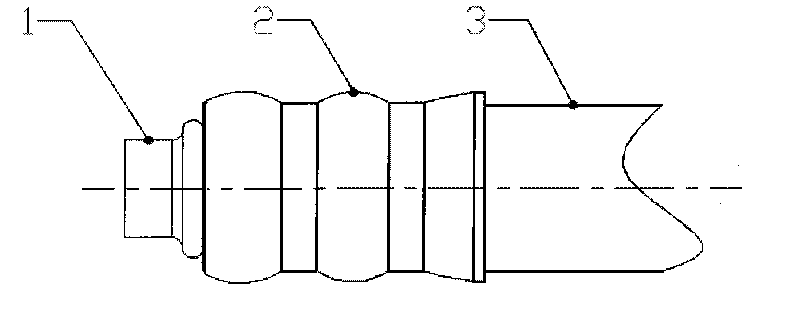

Covered stent

ActiveCN104586536AImprove bending performanceIncrease mating lengthStentsBlood vesselsStent graftingWave shape

A coated stent graft (1) comprises a stent graft main body (2) and a coat (3) fixed on the stent graft main body (2). The stent graft main body (2) is divided into multiple stent graft segments (7) along a central axis (X) of the coated stent graft (1), each stent graft segment (7) extends for a circle around the central axis (X) and each stent graft segment (7) is formed by connecting multiple wave rods (8) end-to-end in a wave-shaped structure. The stent graft main body (2) is formed by a small-diameter segment (4), a transition segment (5) and a large-diameter segment (6) along the central axis (X). The transition segment (5) connects the small-diameter segment (4) to the large-diameter segment (6). A space between adjacent stent graft segments in the transition segment (5) is greater than a space between adjacent stent graft segments in the small-diameter segment (4) and less than a space between adjacent stent graft segments in the large-diameter segment (6). The coated stent graft (1) is provided with improved bending performance.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

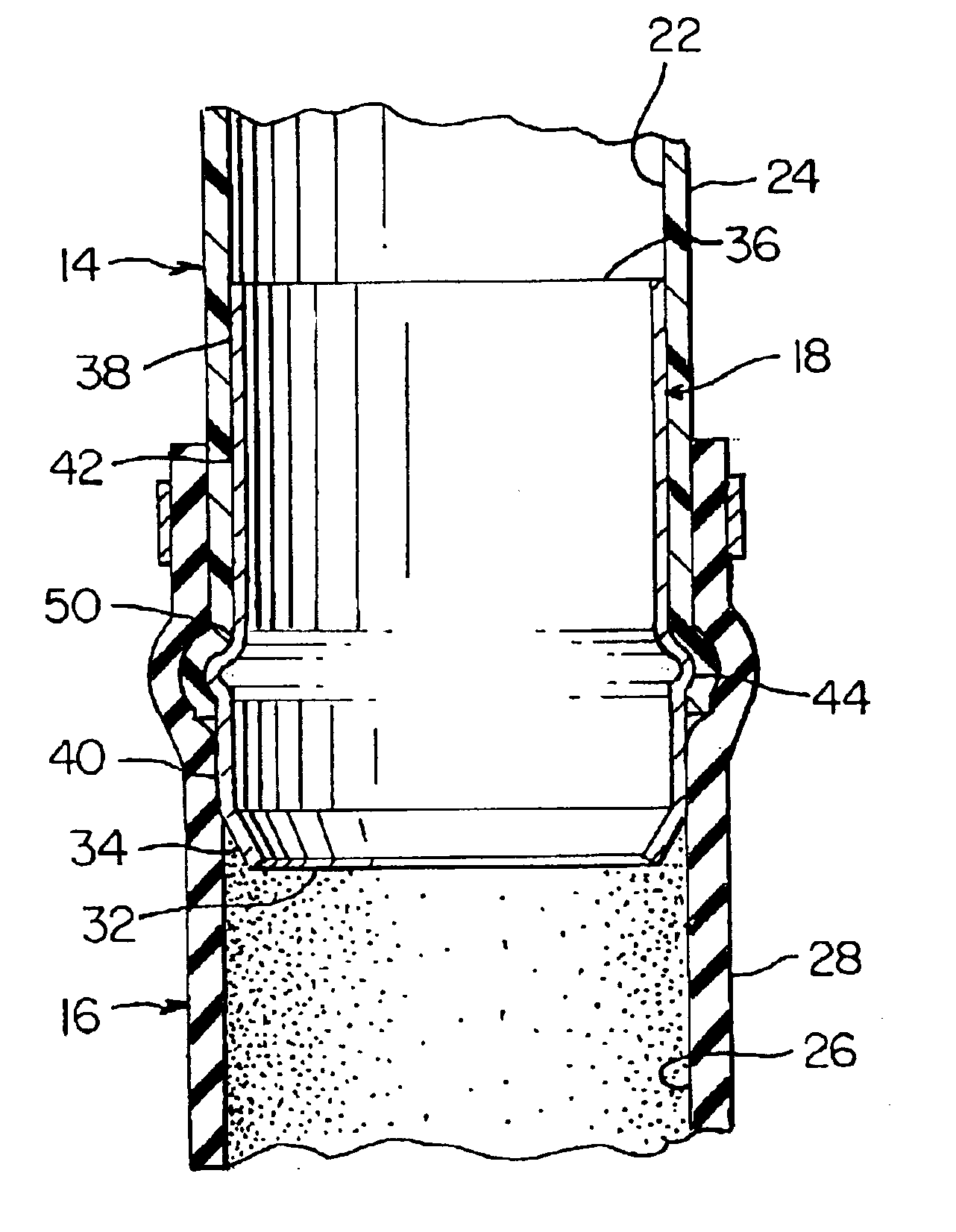

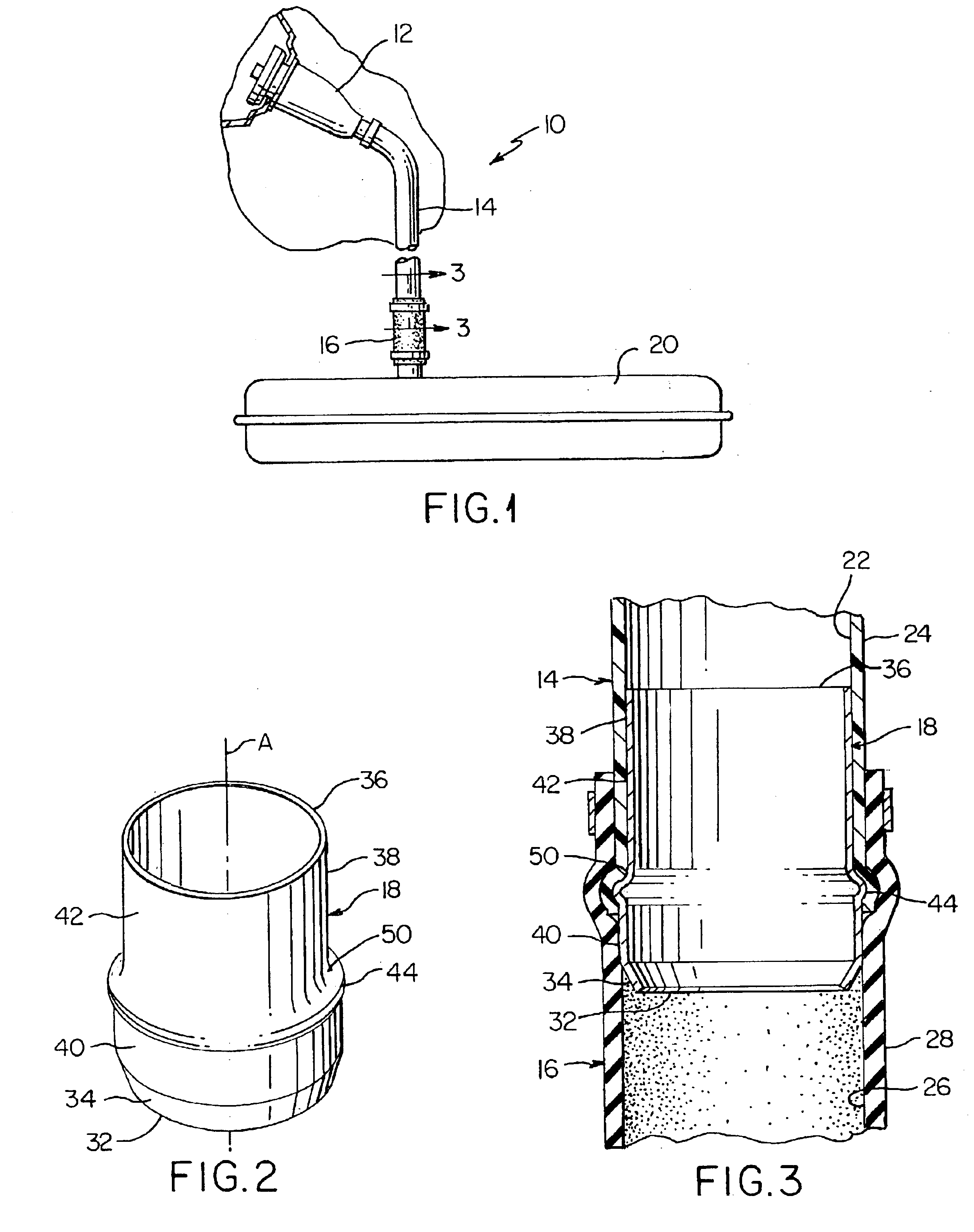

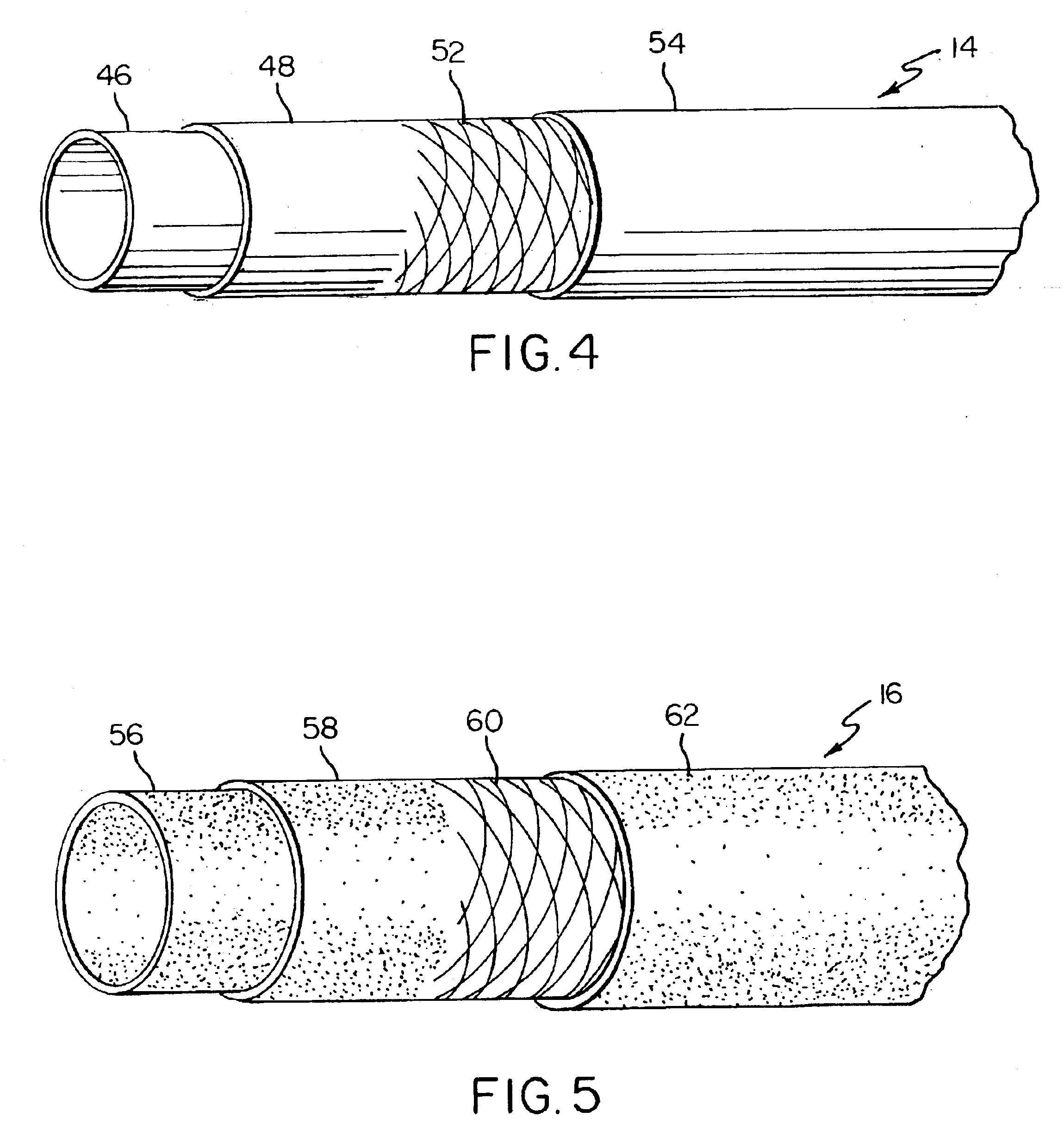

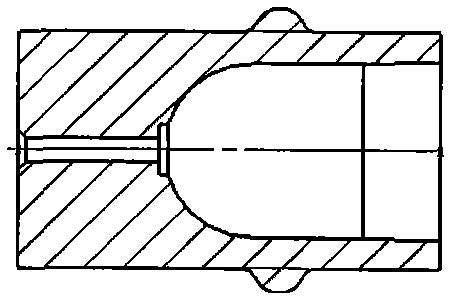

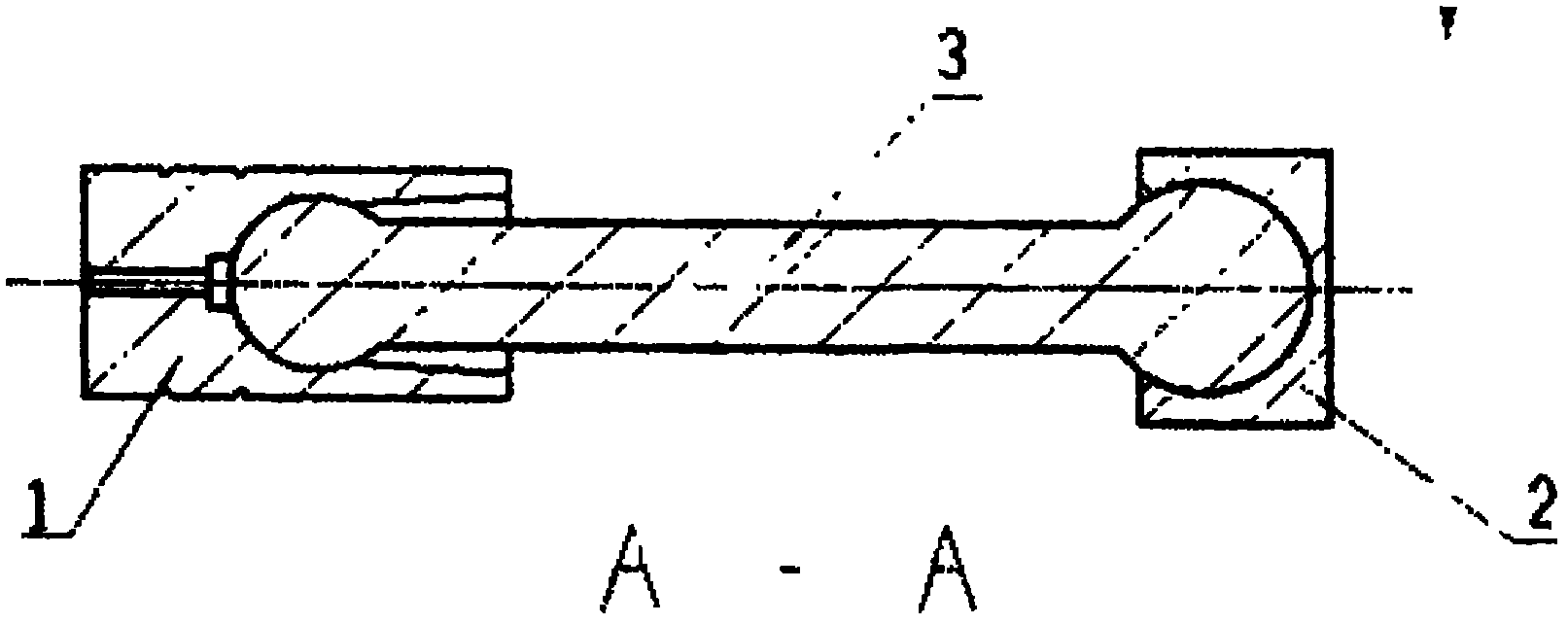

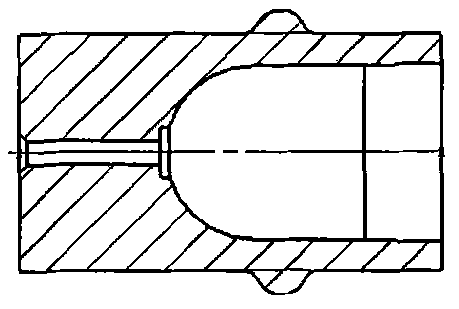

Conductive tubular insert for a fuel transport system, and method

InactiveUS6880862B2Maintain electrical continuityImprove pull off forceSleeve/socket jointsThermal insulationEngineeringConductive polymer

A conductive tubular connector insert for use in a fuel conveying system to couple a first conductive polymeric tubular member to a second conductive polymeric tubular member such that electrical conductivity is insured in the system as described. The conductive tubular connector comprises: a first end having a first annular margin; a second end having a second annular margin; a first tubular body section having a first circumference; a second tubular body section having a second circumference; and an annular rib, wherein the first tubular body section is adjacent the first end and extends toward the annular rib along a longitudinal axis, and the second tubular body section extends from the annular rib toward the second end where, at a point intermediate the circumferential rib and the second end, the second tubular body section tapers radially inward forming a tapered surface terminating in a second annular margin adjacent the second end of the second tubular body section, the configuration of the conductive connector insert being such that, upon being implanted into an end of the first polymeric tubular member, the end of the first polymeric tubular structure forms a bead around the annular rib to secure the conductive connector insert therein leaving a portion of the second tubular body section extending out of the end of the first polymeric tubular member, wherein the end of the first polymeric tubular structure having the second tubular body section extending therefrom is inserted into an end of a second polymeric tubular member such that the conductive connector insert is in conductive contact with the conductive inner surface of the first polymeric tubular member and the conductive inner surface of the second polymeric tubular member to maintain conductive continuity therein.

Owner:FLUID ROUTING SOLUTIONS

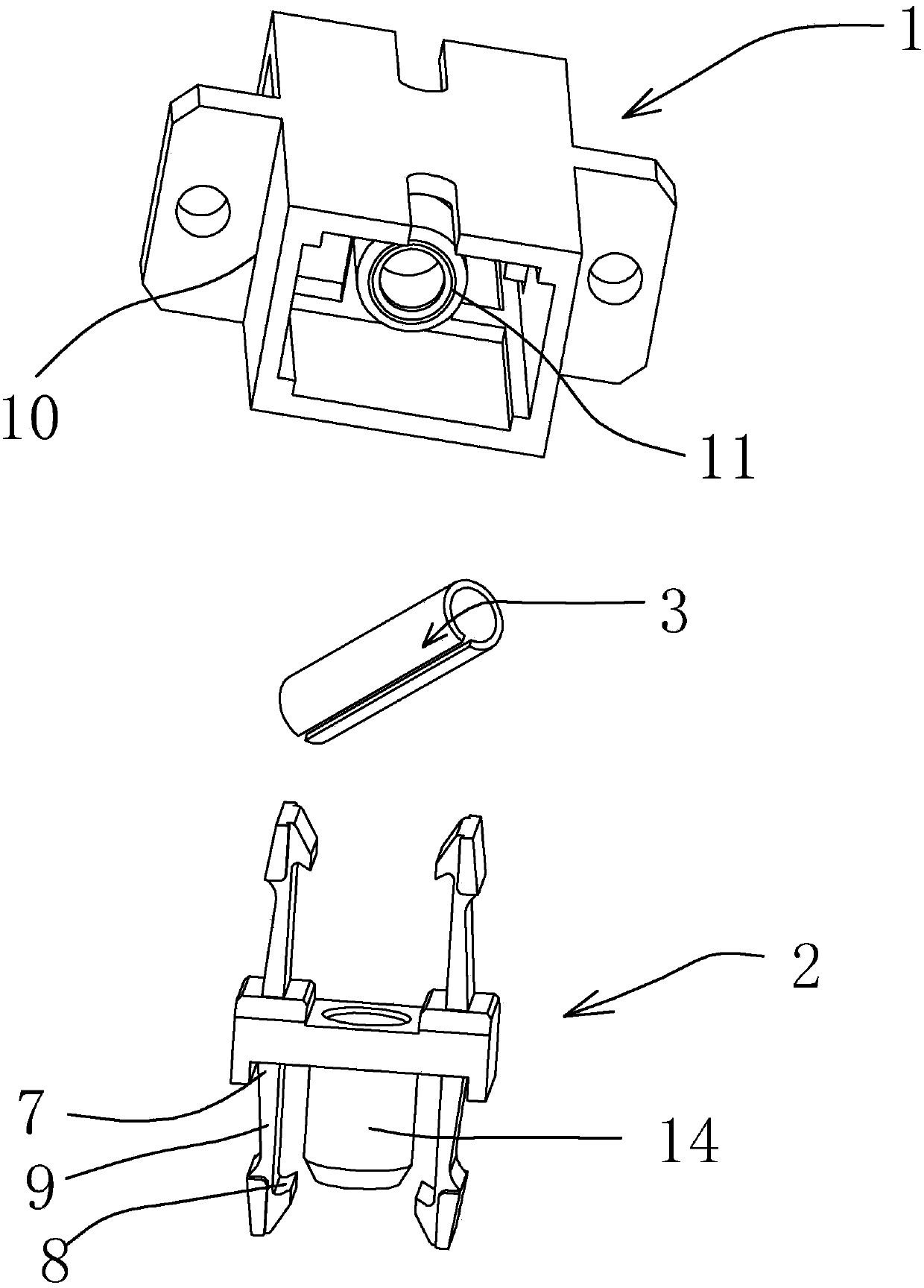

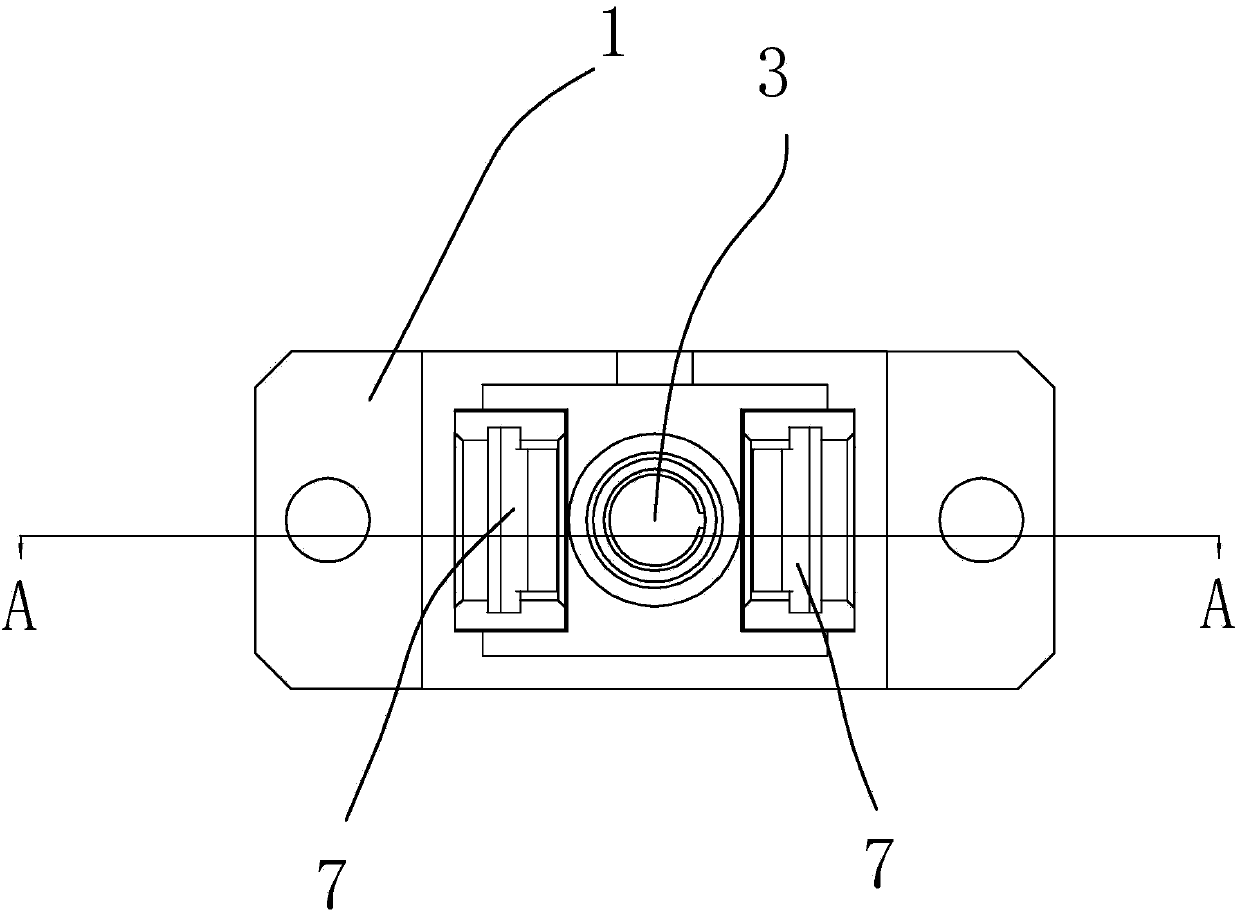

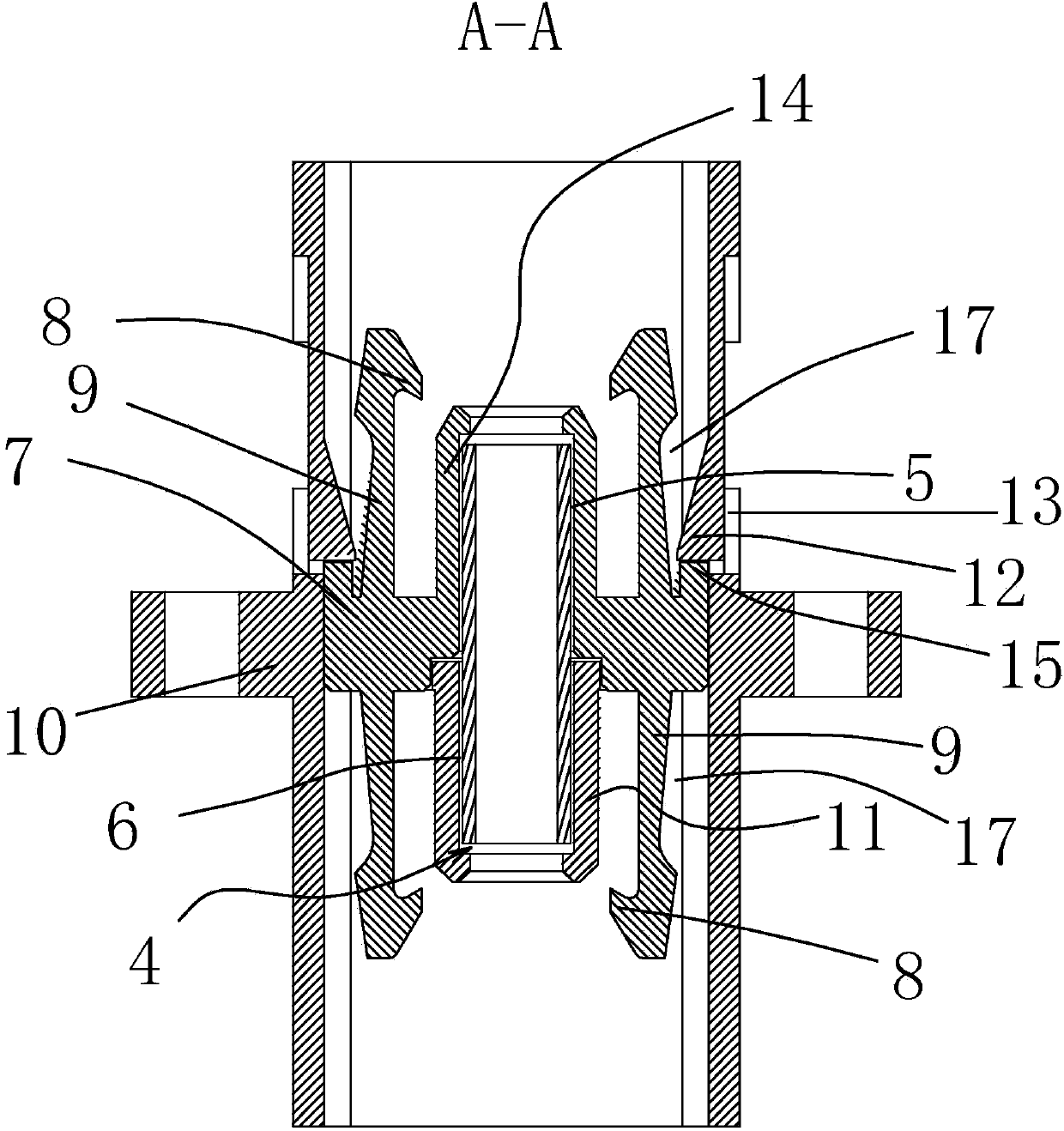

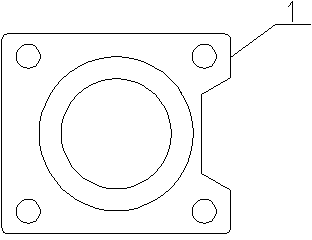

SC adapter of improved structure

The invention belongs to the field of electric technique, and provides an SC adapter of an improved structure. The SC adapter comprises an outer shell, a plug and a ceramic sleeve, wherein a containing space used for containing the ceramic sleeve is formed in the inner middle position after the plug and the outer shell are assembled, the upper end and the lower end of the plug are respectively provided with a fixing end fastener portion, each fixing end fastener portion is provided with a connector plug, fastener arms will deform and rotate towards the outer side direction when the connector plugs are in interaction with fastener heads, 60-degree inclination is formed between each fastener head and the vertical Y direction, the length of each fastener arm is 5.56cm, and 95-degree inclination is formed between the outer side of each fastener arm and the horizontal X length direction. According to the SC adapter, under the standard precondition that plugging and pulling force is less than 19.6N, pulling-out force is improved to 70N, and good reliability and safety are guaranteed. The whole SC adapter has very few parts and only uses three parts. Due to the design that the plug penetrates upwards from the lower portion of the outer shell and then is fastened through an inclined inverse buckle on the outer shell, the SC adapter has the advantages that few parts are used, production simplicity is achieved, and products are safe and reliable.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

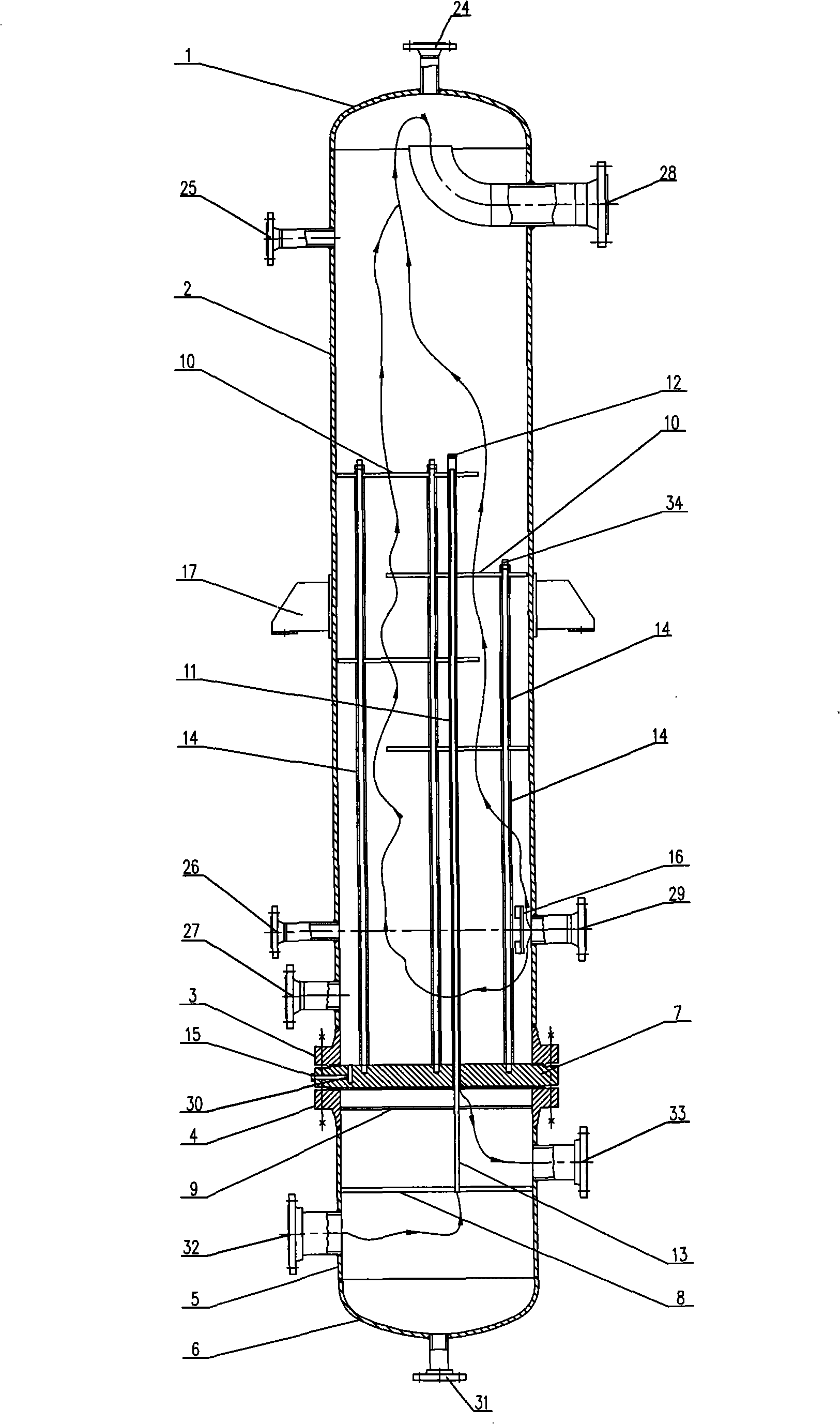

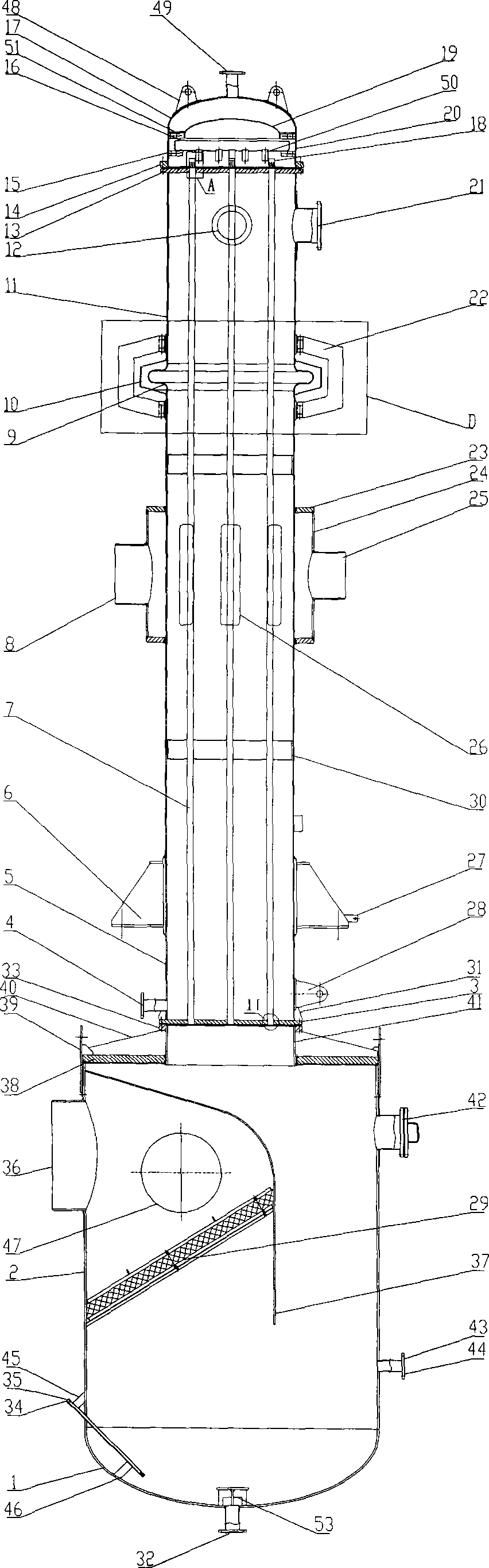

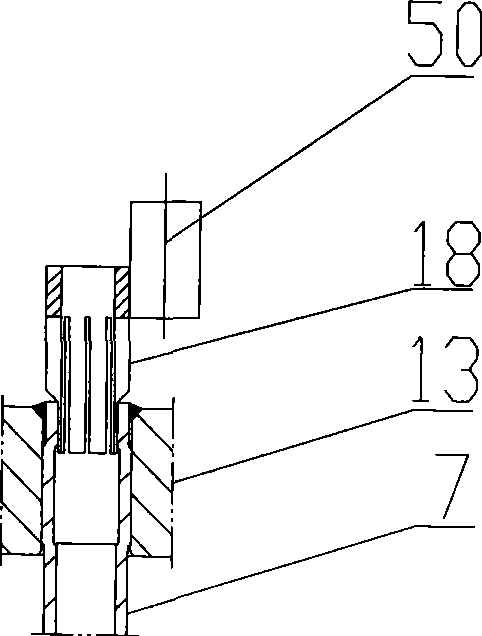

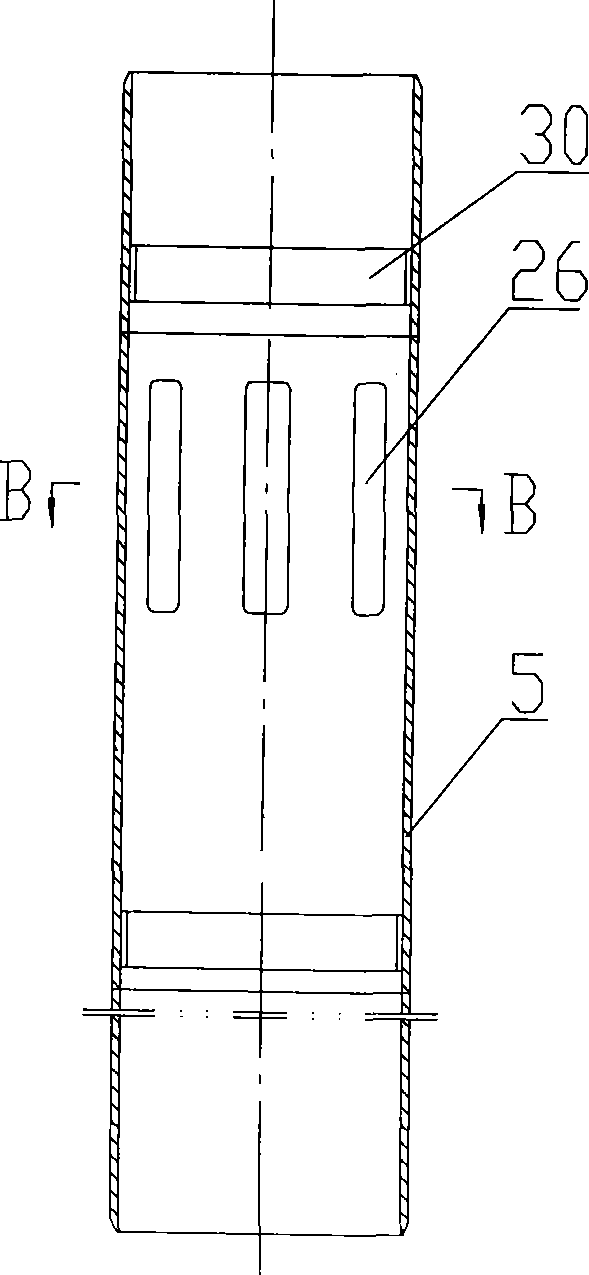

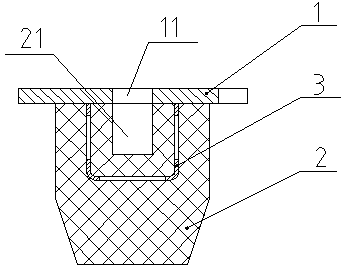

Chlorine liquid carburetor

ActiveCN101311613AImprove pull-off forceImprove safety and reliabilityPressure vesselsContainer discharging from pressure vesselsCarburetorEngineering

The invention relates to a liquid chlorine vaporizer which utilizes the following technical scheme: a shell-side head is connected with a shell-side cylinder, a tube-side cylinder is connected with a tube-side head and a shell-side equipment flange, a tube-side equipment flange and a tube sheet connect the shell-side cylinder with the tube-side cylinder; a pull rod penetrates a distance tube and the two ends of the pull rod are connected with a shell-side support plate and the tube sheet which is provided with a heat-exchanging external tube hole which is provided with a groove and the heat-exchanging external tube hole is fixed with a heat-exchanging external tube the pointed end of which is closed by a plug; the inside of the tube-side cylinder is provided with the tube-side tube sheet and the tube-side support plate which is provided with a heat-exchanging internal tube hole and an air vent and the upper end of the heat-exchanging internal tube which is inserted into the heat-exchanging external tube is provided with a thorn; the shell-side head is provided with an overpressure relief outlet; the shell-side cylinder is provided with a self-control liquid-level gauge outlet, a liquid drainage outlet, a chlorine outlet and a liquid chlorine inlet; the lateral side of the tube sheet is provided with a purging outlet; the tube-side head is provided with a purging outlet and the tube-side cylinder is provided with a steam inlet and a condensed water outlet. The liquid chlorine vaporizer is low in creation cost and safe in operation, and the heat-exchanging tube is easy to be replaced.

Owner:沈阳东方钛业股份有限公司

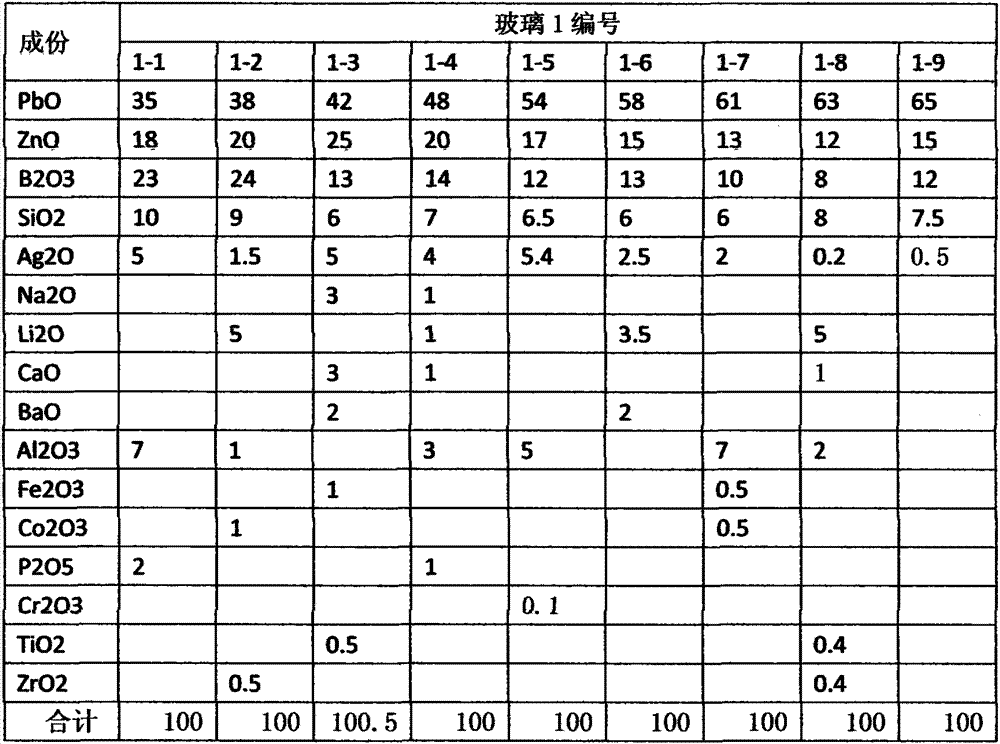

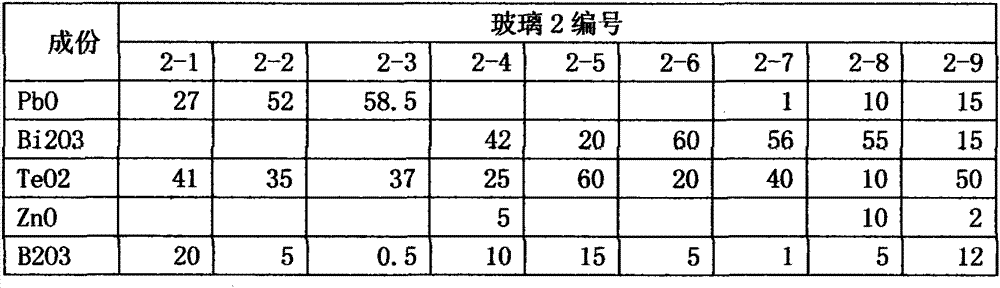

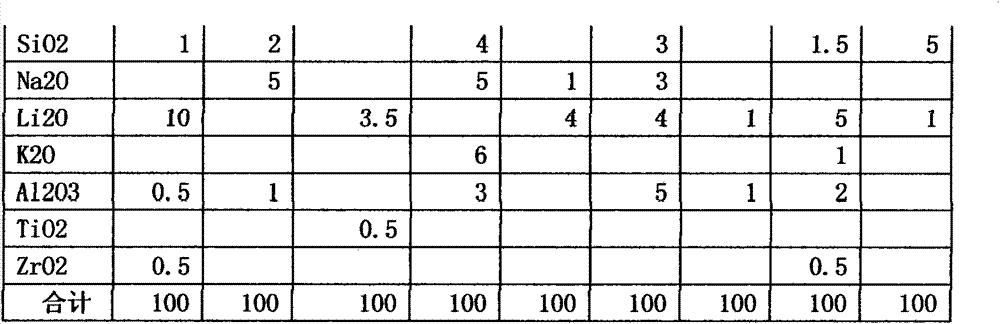

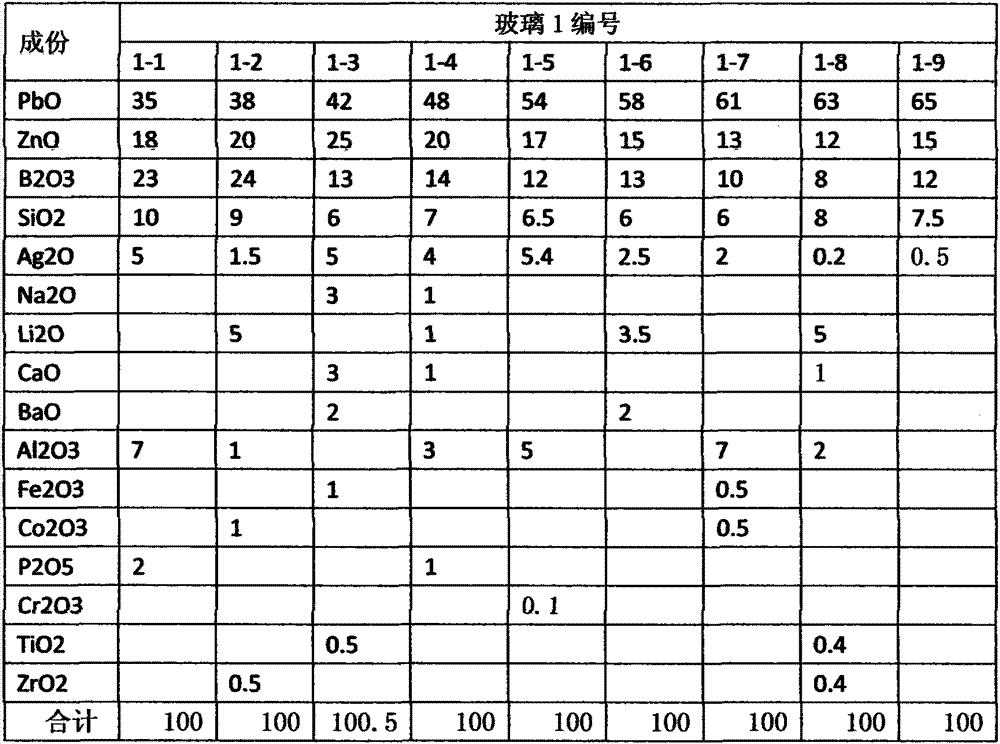

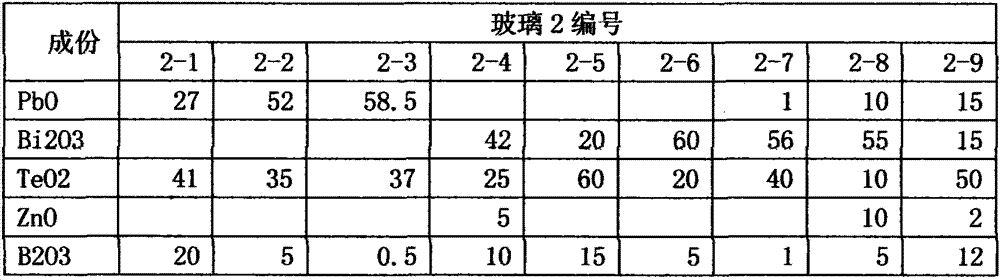

Glass dust for back silver paste of solar battery and preparation method of glass dust

The invention relates to glass dust for the back silver paste of a solar battery. The glass dust is prepared by grinding and mixing the following raw materials in percentage by weight: 40-99 percent of glass dust A, 0-60 percent of glass dust B and 0-10 percent of inorganic addition agents. According to the invention, when the mixed glass dust is used for preparing solar energy back electrode paste, small amounts of glass dust is used, and the cost of the paste is reduced; the solar energy back electrode paste has large pulling-out force after being sintered, and the photoelectric conversion efficiency of the battery is high.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

Technology capable of improving tension of main grid of photoinductive electroplating battery

InactiveCN103390694AReduce tensionIncrease contactFinal product manufactureSemiconductor devicesSilver pasteScreen printing

The invention discloses a technology capable of improving tension of a main grid of a photoinductive electroplating battery. The technology comprises the following steps: a, taking a battery piece of finishing silicon nitride in preceding and printing and sintering at the back, and selectively corroding the surface of the battery through corrosion slurry or laser grooving to provide a seed layer; b, activating the front of the battery piece after grooving with HF with lower concentration and plating a layer of thin nickel as a base layer; c, silk-screen printing a layer of low temperature silver paste on the main grid position and drying; d, sintering in a sintering furnace to form well ohmic contact; and e, forming a complete front grid line with copper plating and silver plating. According to technology, the using unit consumption of the used low temperature silver paste 'RuXing' 33-750 is lower, so that excellent ohmic contact and cohesive force can be guaranteed during low temperature sintering, and the quality of the nickel layer can not be affected during sintering, and as a result, good pulling-out force of the front main grid is guaranteed finally.

Owner:泰州德通电气有限公司

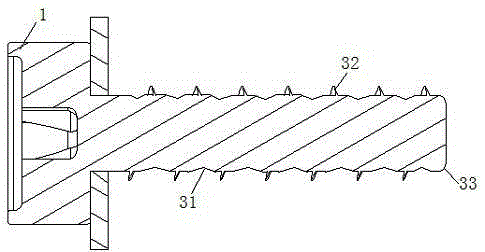

Self-tapping screw for plastic part

The invention discloses a self-tapping screw for a plastic part and belongs to the field of self-tapping screws. The self-tapping screw comprises a nut and a screw rod and further comprises a washer. The nut is arranged at one end of the screw rod, and the other end of the screw rod is a flat-head end face; a transition arc is disposed in the combining position of the flat-head end face and the side surface of the screw rod; the screw rod is provided with a screw thread which is arranged in the whole length direction of the screw rod; the washer is fixedly connected with the screw rod; one end face of the washer abuts against the nut; the nut is a hexagonal pan head nut; a cross-shaped countersunk head groove is formed in the center of the upper end face of the nut. By means of the technical scheme, the mounting performance is high when the self-tapping screw fastens the plastic part, damage to the plastic part is avoided at the same time, and the self-tapping screw is reasonable in structural design, simple in principle and low in cost.

Owner:WUHU HENGXIN AUTO INTERIOR TRIM COMPANY

Single-effect evaporator

ActiveCN101444674APrevent liquid level fluctuationsEven and smooth inflowEvaporators with vertical tubesSingle effectEngineering

The invention relates to a single-effect evaporator. The technical proposal is that the single-effect evaporator comprises a tube pass and a shell pass. A cylinder body of the tube pass, a sealing end of the tube pass and an upper cover of the tube pass constitute the tube pass, an alkaline liquid outlet, an anti-swirl baffle, a meter inserting tube, a liquid level meter inserting tube, a steam outlet and a liquid level meter alarm port are arranged on the tube pass, a wire mesh demister and a baffle are arranged in the tube pass; an expansion joint which is sleeved with a protective cover of the expansion joint and a protective support connects the upper and the lower cylinder bodies of the shell pass, and the two ends of a short joint of the shell pass are connected with the upper cylinder body of the shell pass and the sealing end of the shell pass; the sealing end of the shell pass is provided with an alkaline liquid inlet; the short joint of the shell pass is provided with a distributing cover, a receiving plate, a distributing plate and a downcomer; the steam inlet is connected with the lower cylinder body of the shell pass through a shell body and the annular plate; the lower cylinder body of the shell pass is provided with a condensate outlet; a tube supporting frame is arranged in the lower cylinder body of the shell pass; the short joint of the tube pass is connected with the lower cylinder body of the shell pass; a tube plate is provided with a heat exchange tube hole, a heat exchange tube penetrates the two ends of the tube supporting frame to be connected with the tube plate, and one end thereof is connected with a distributing tube. The single-effect evaporator improves the stability and the pull-out force of the heat exchange tube and reduces the energy consumption and the production cost.

Owner:沈阳东方钛业股份有限公司

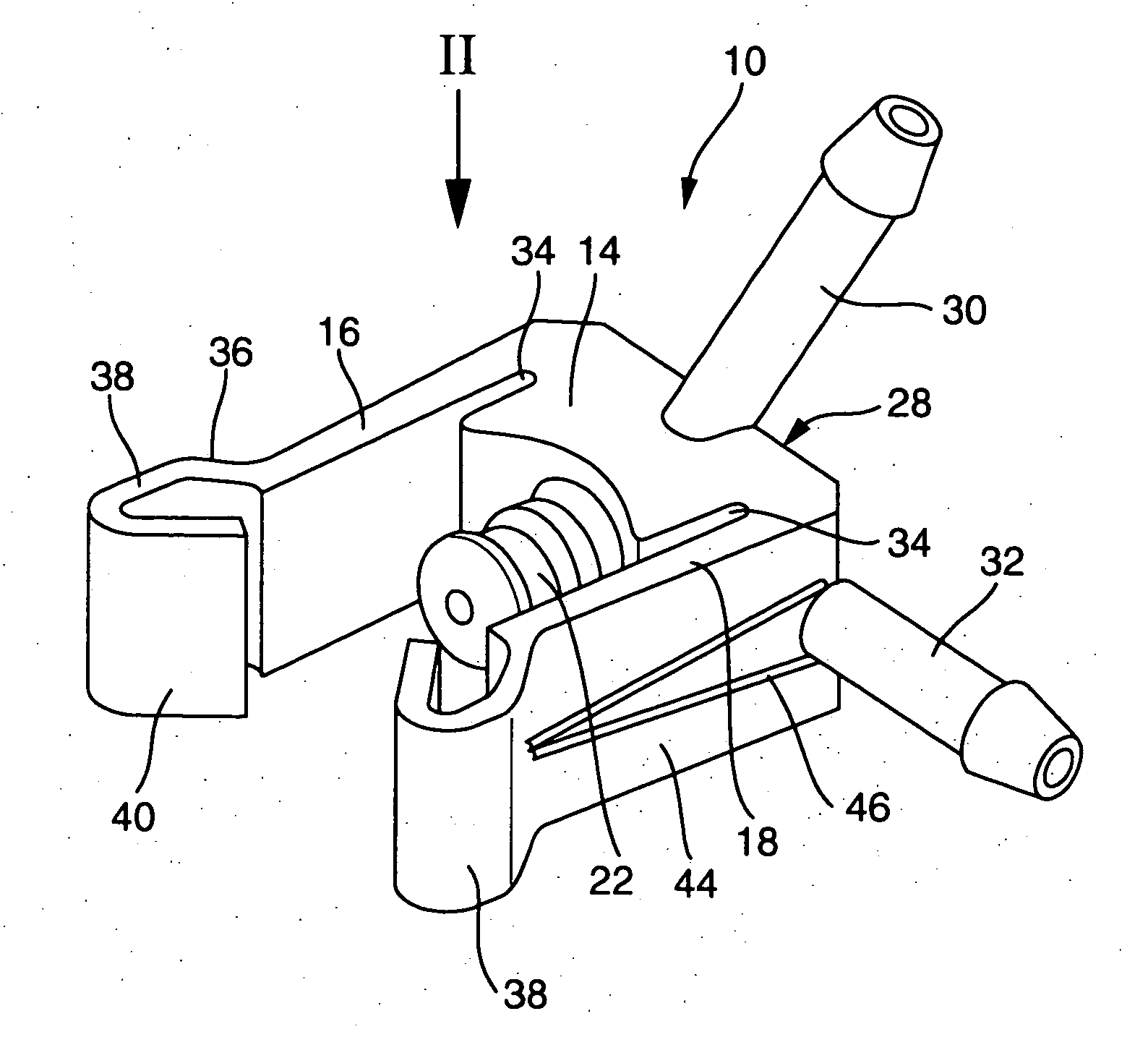

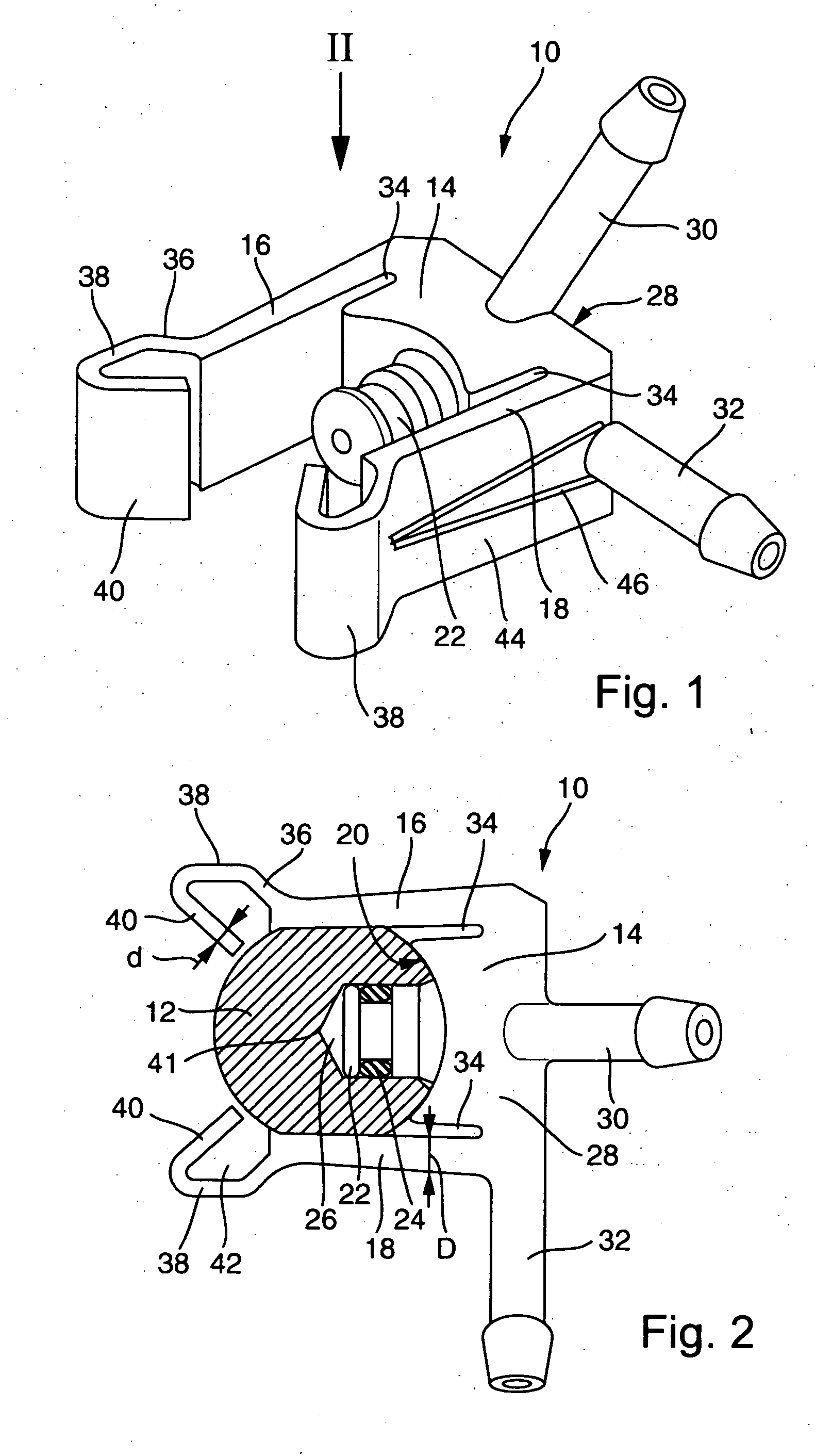

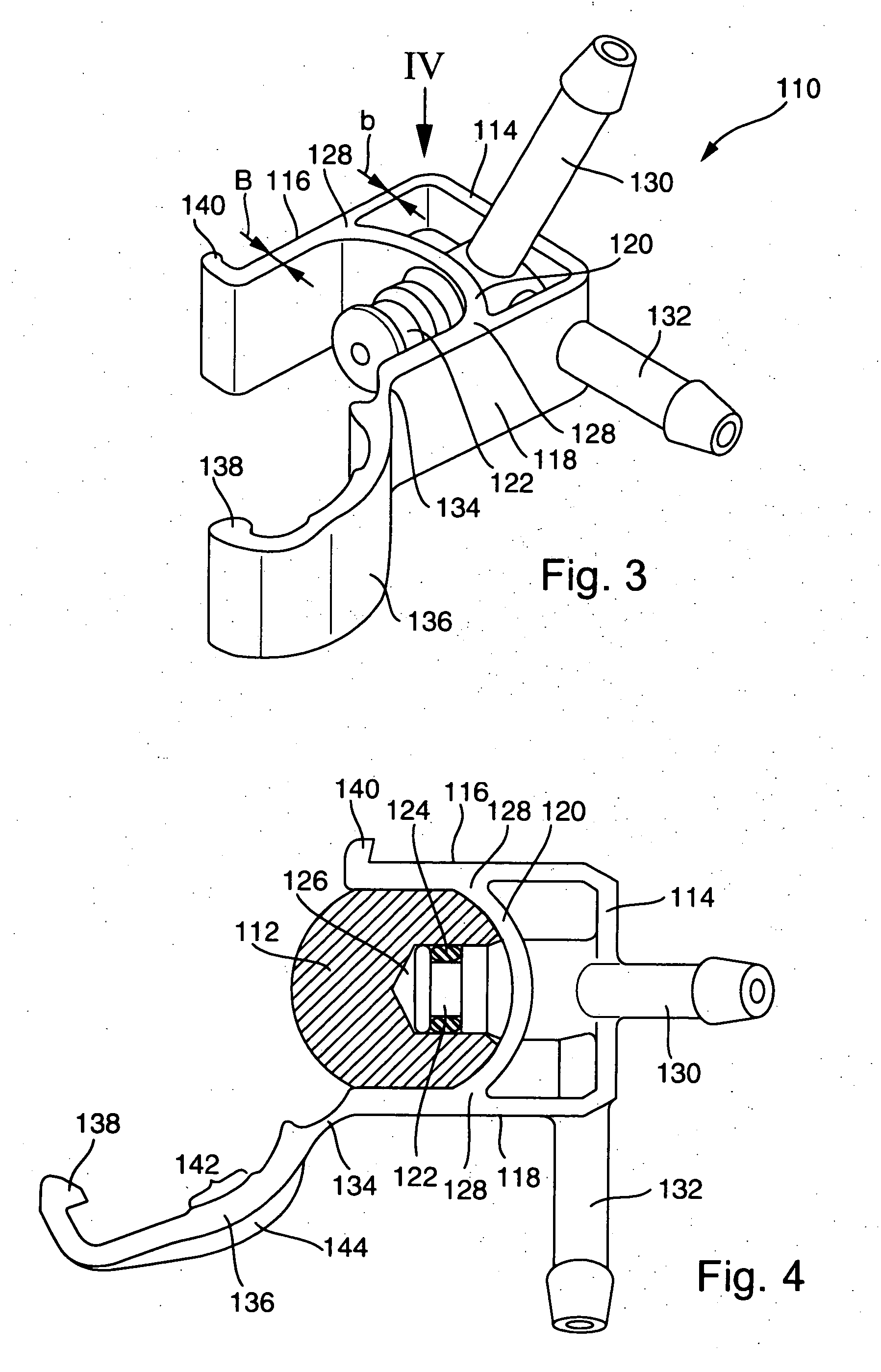

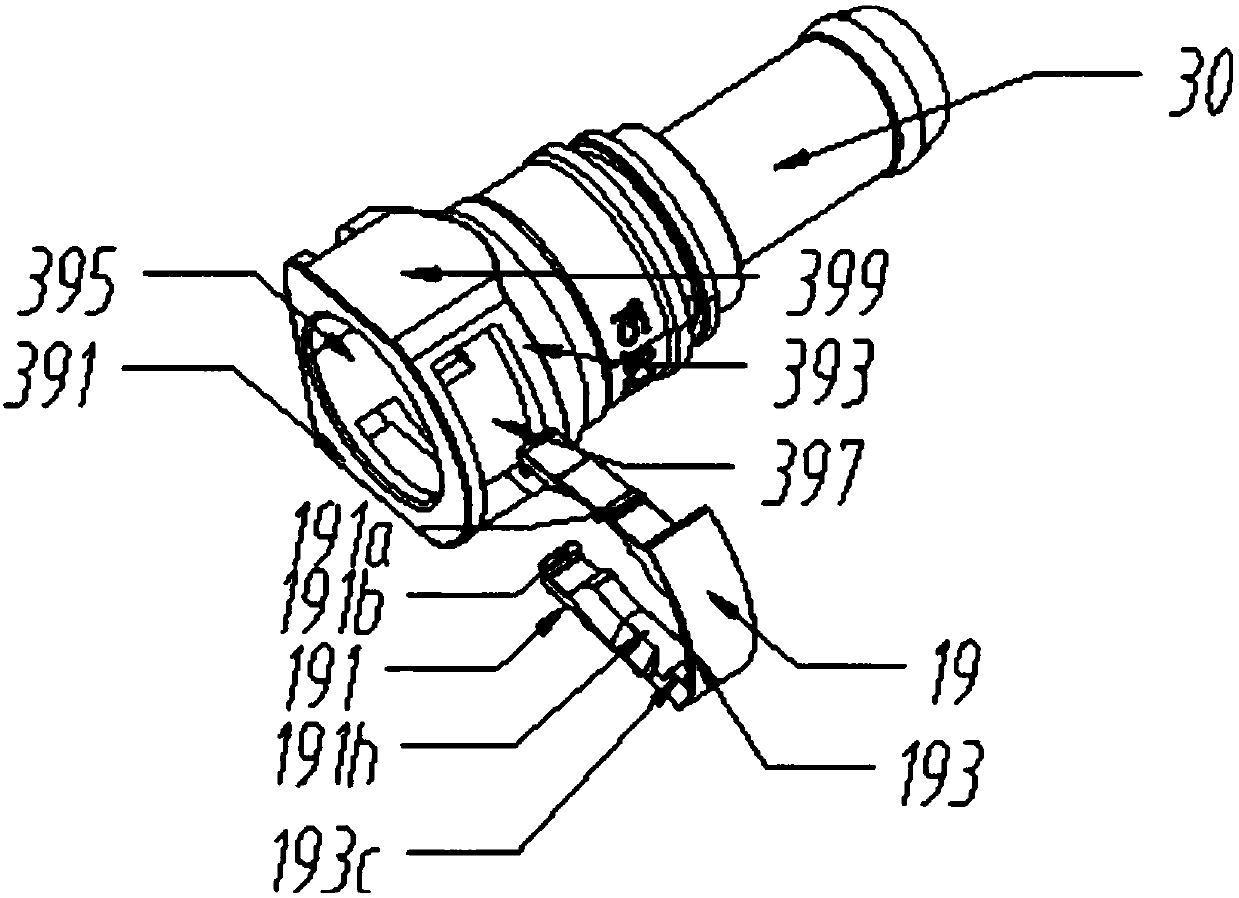

Device to attach a fuel return line to a fuel injector and device to suction fuel from a fuel injector

ActiveUS20060107928A1Low production costEasy to engageJet pumpsMachines/enginesElectrical and Electronics engineeringInjector

A device to suction fuel from a fuel injector and a device to attach a fuel return line to a fuel injector with a C-shaped main body partially encircling the fuel injector having two retaining arms which abut the fuel injector and grip it from the back at least to a small degree, with a connector coacting with a drain passage of the fuel injector and at least one connecting fitting for the fuel return line. The connecting fitting and the connector are electrically connected. The free ends of the retaining arms have a first section in which they are angled towards each other and towards the base of the main body.

Owner:COOPER STANDARD AUTOMATIVE INC

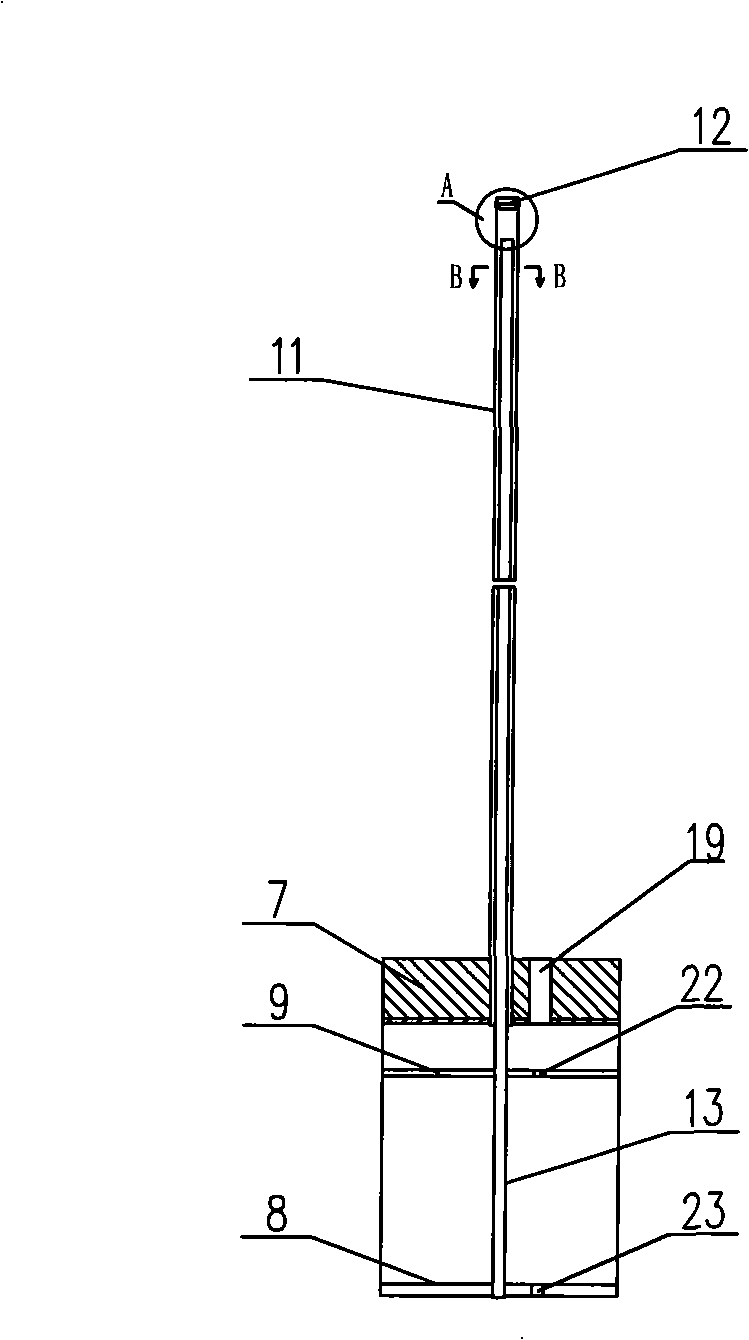

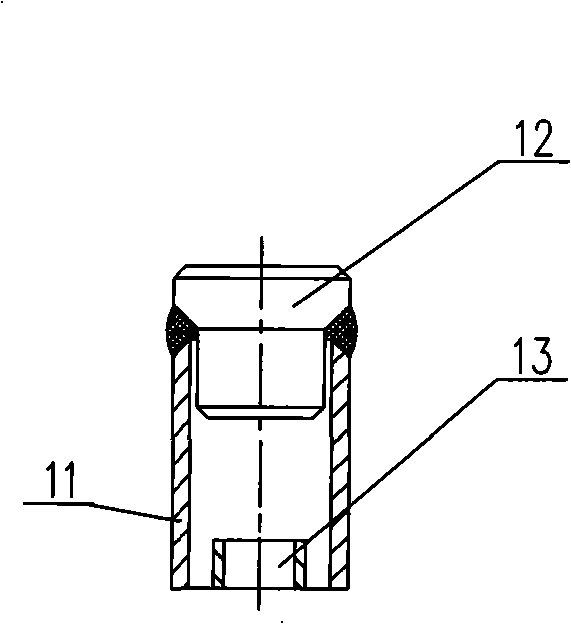

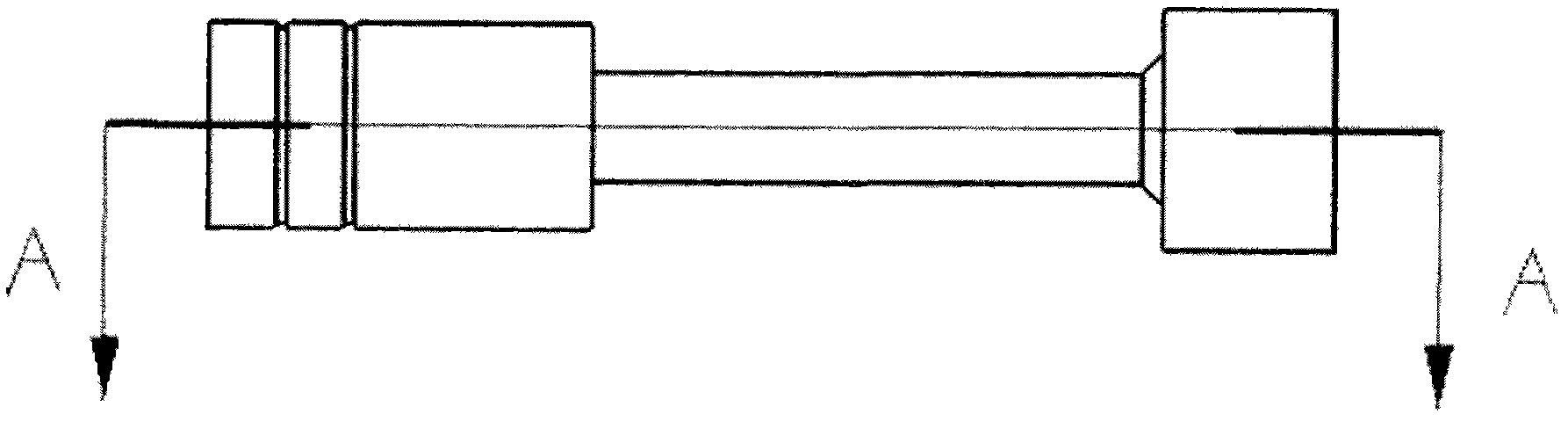

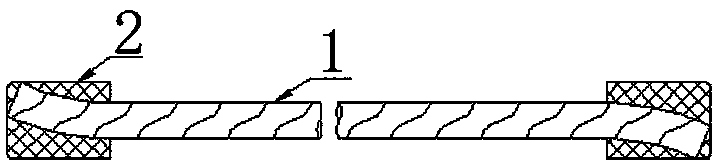

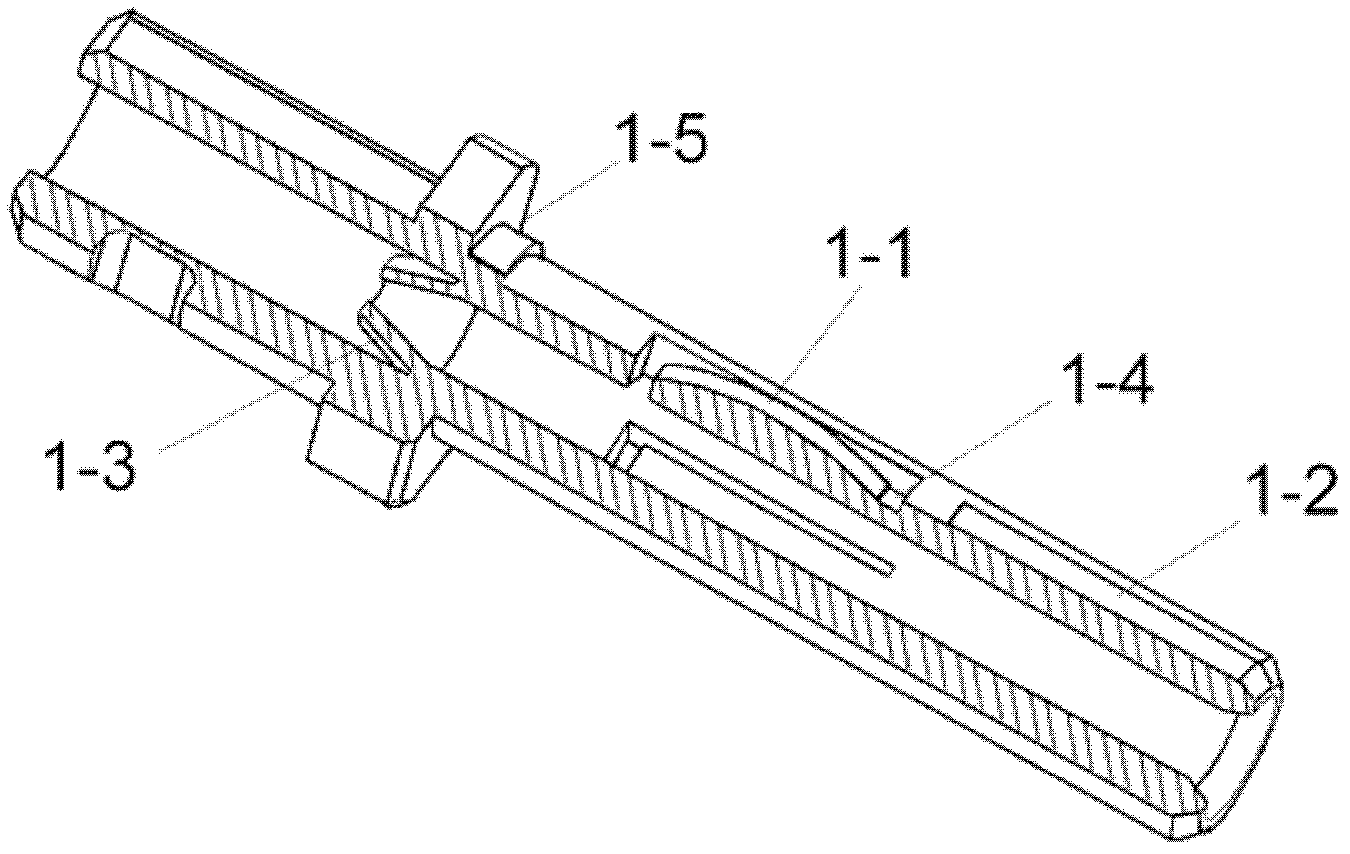

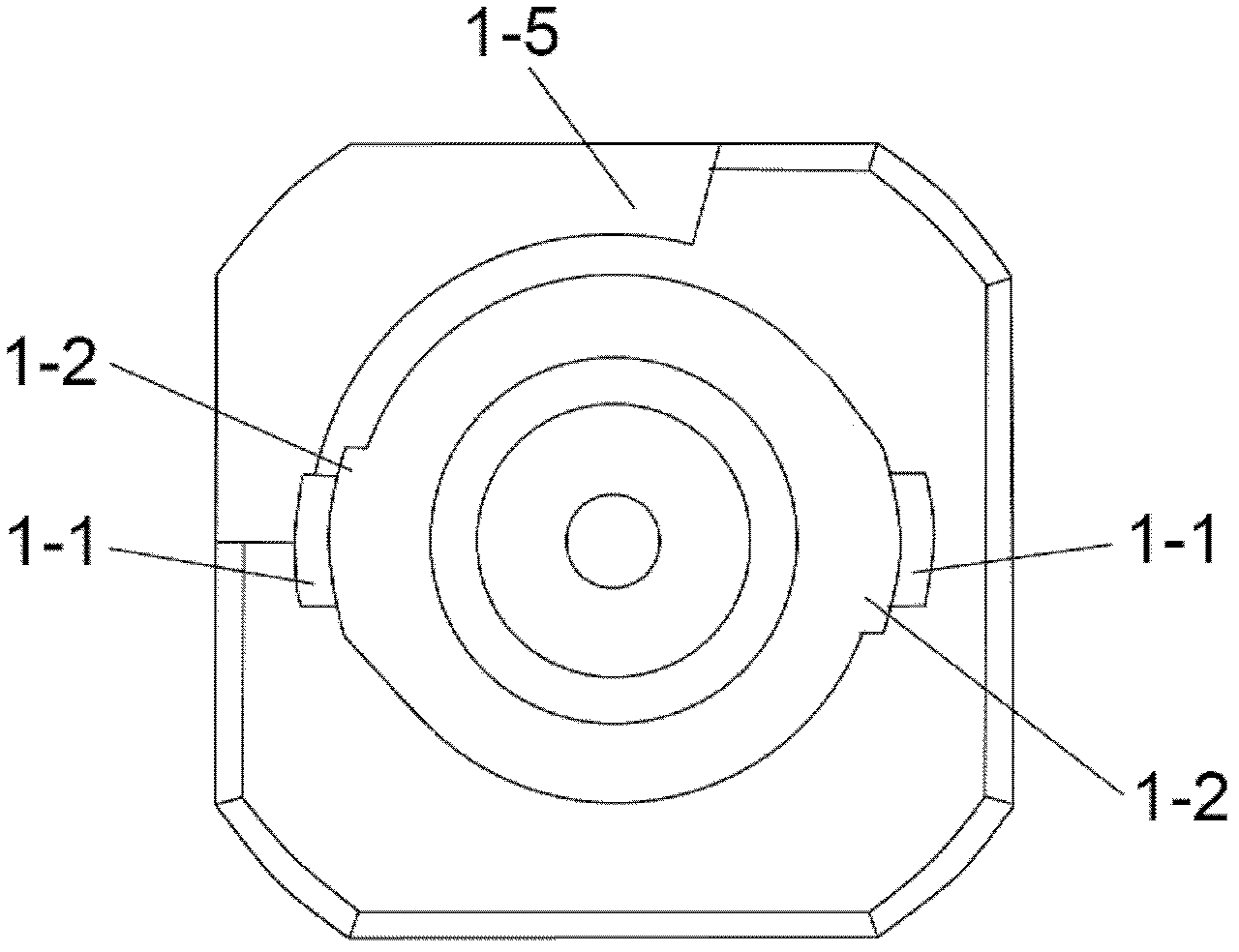

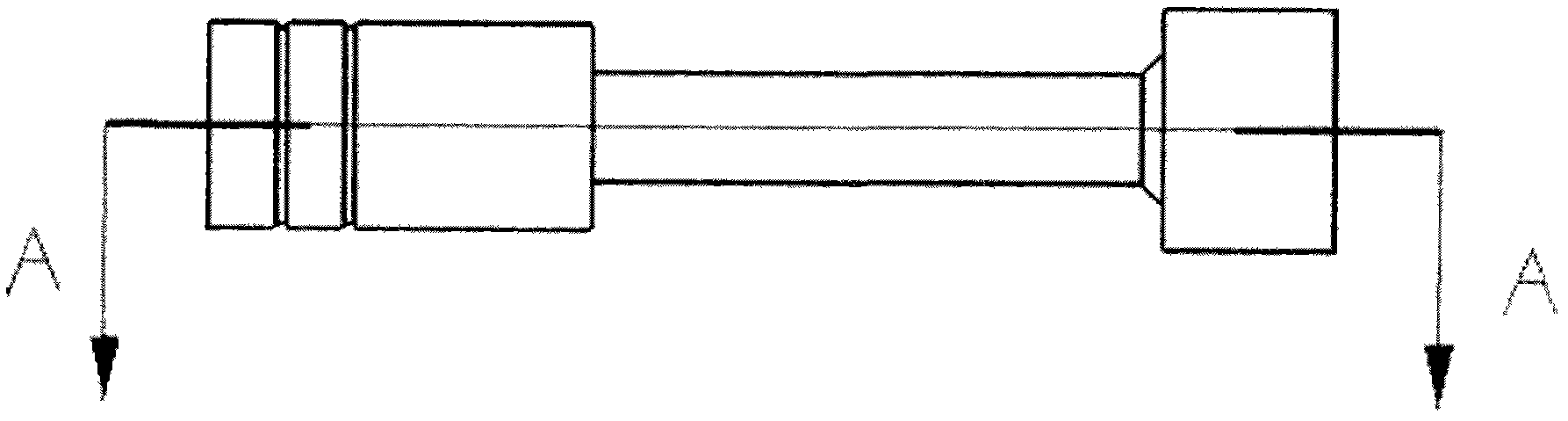

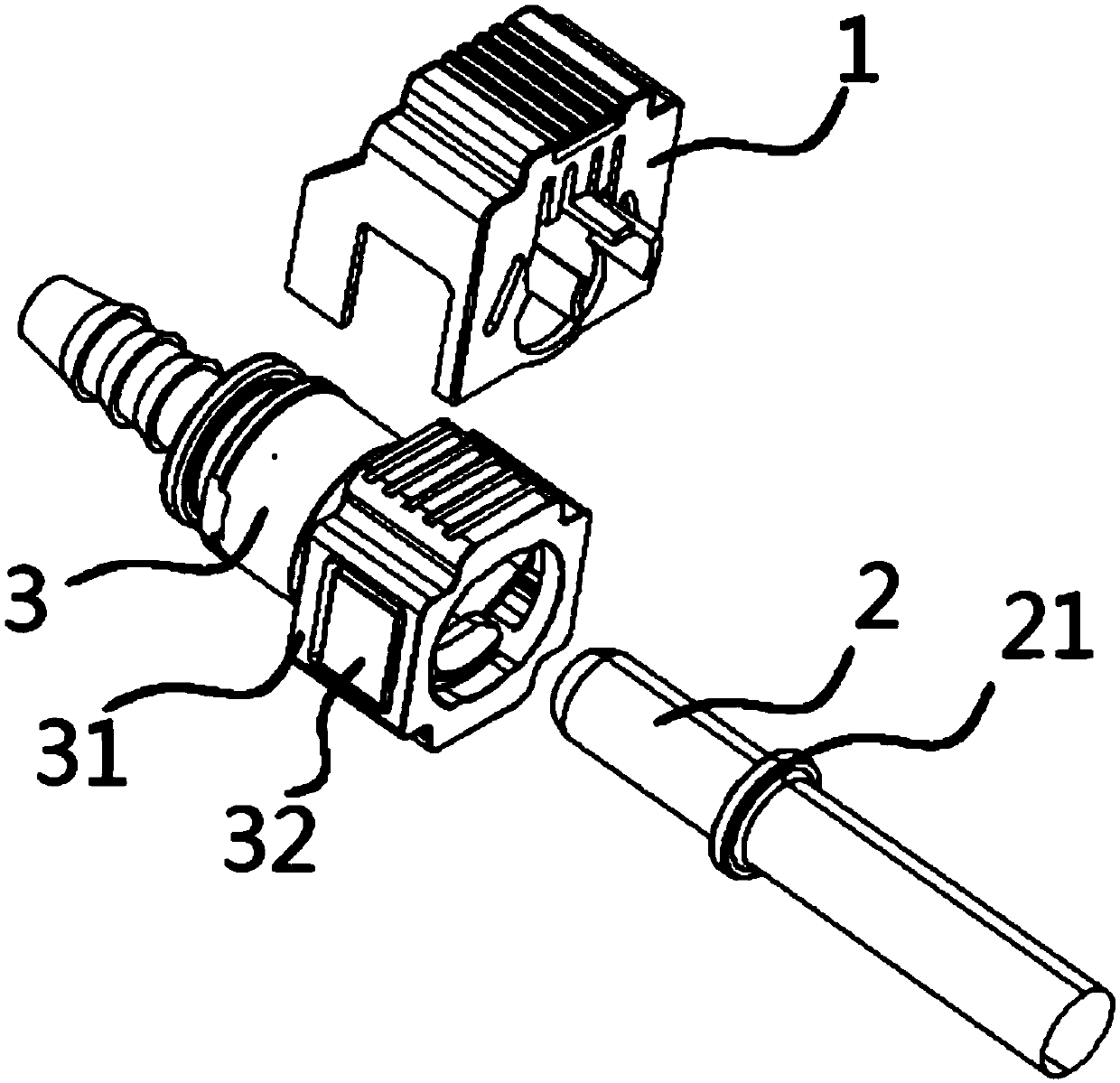

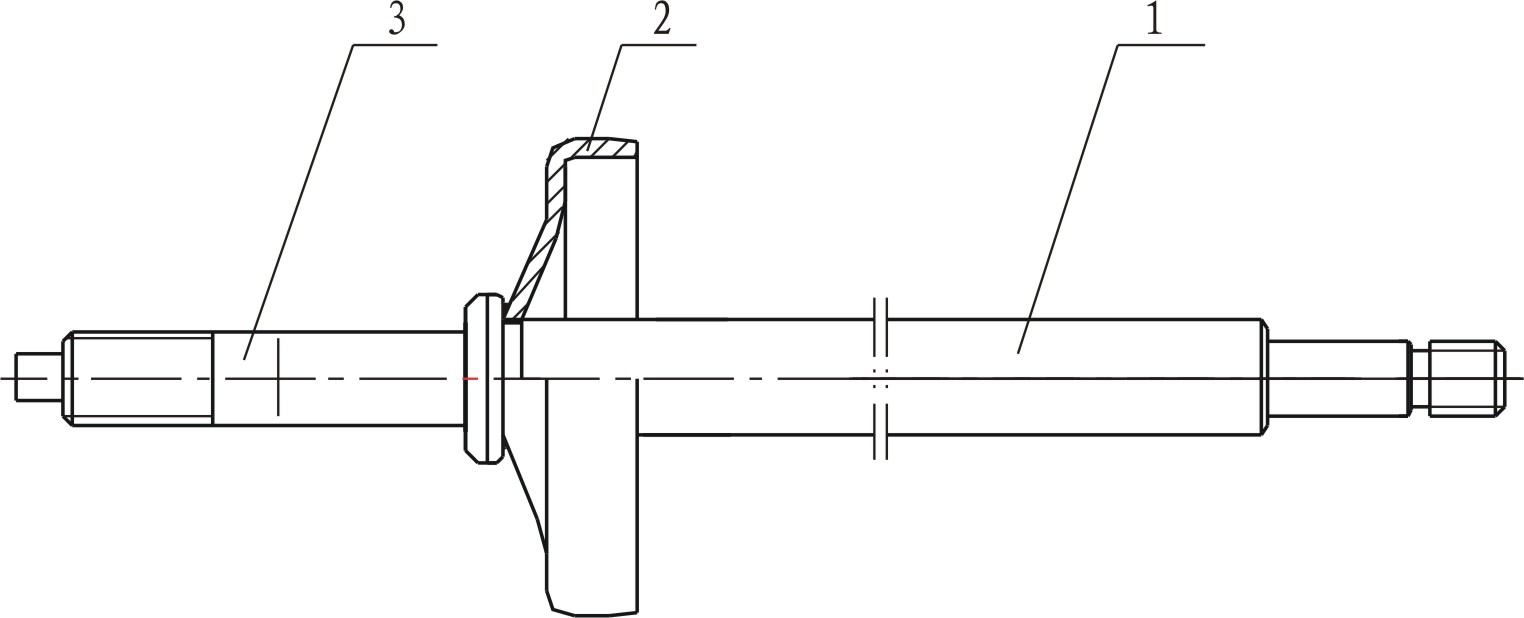

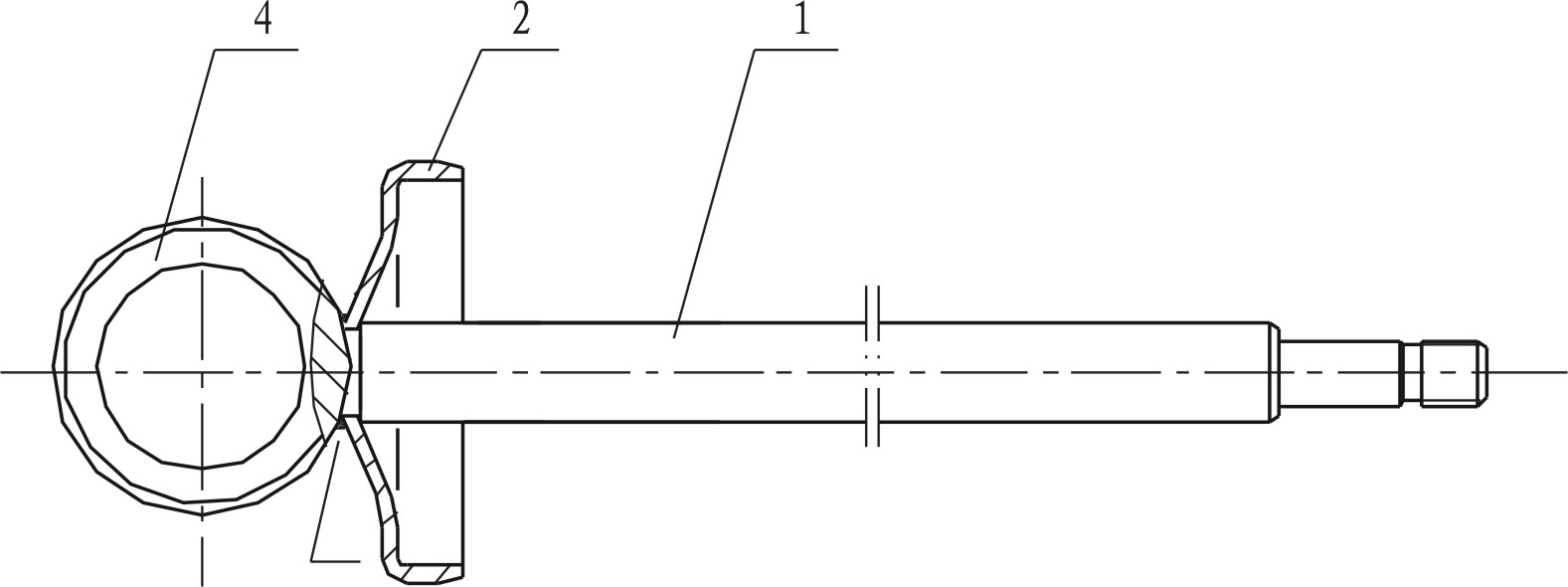

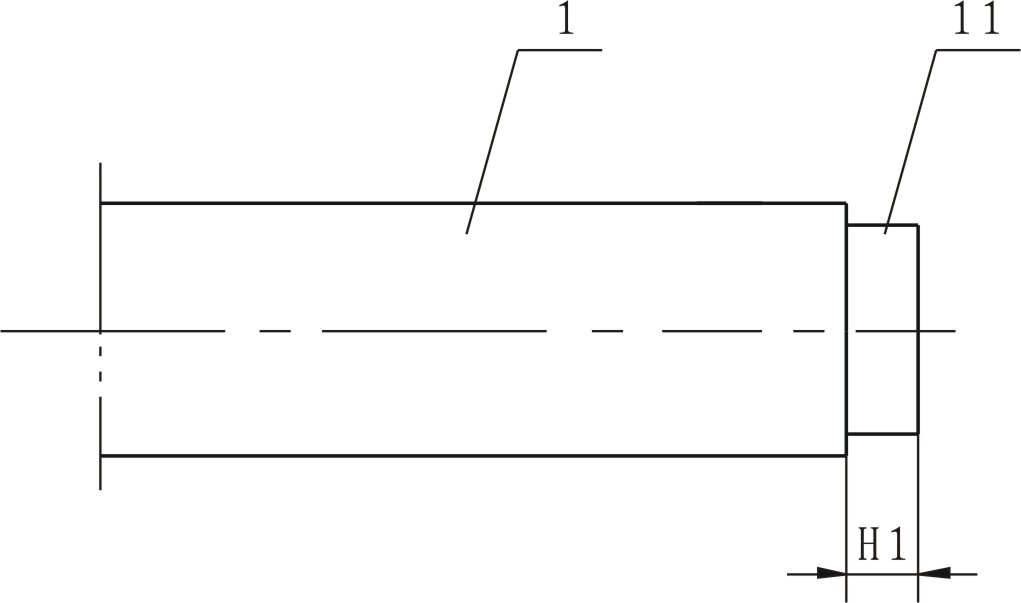

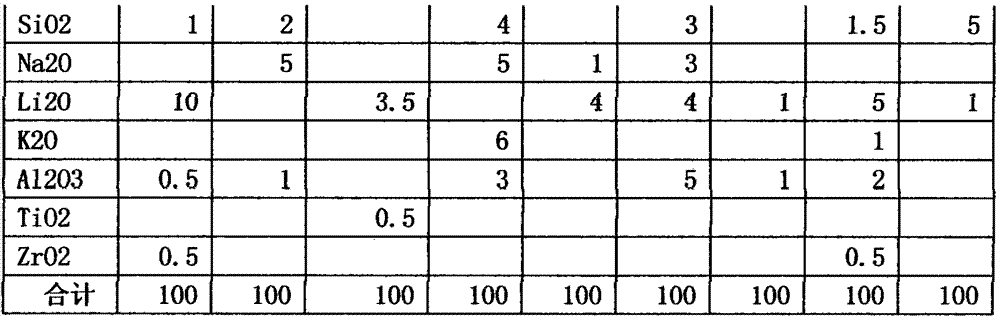

Method for manufacturing connecting rod type plunger

ActiveCN102489966AMeet the dimensional accuracyMeet the technical requirementsAviationSurface roughness

The invention belongs to the field of aviation machinery, and relates to a method for manufacturing a connecting rod type plunger. The method includes the steps of respectively manufacturing a projection on the outer surfaces of a piston (1) and a socket (2); closing up the piston (1) and the socket (2) by respectively using a tapered opening bush (4), a base component (5) and a pressure head (6); respectively rolling the outer surfaces of the piston (1) and the socket (2) so that the plunger can flexibly swing; and finishing the outer surfaces of the piston (1) and the socket (2). The method is fine in closing quality and maximum in breakaway force, and meets the requirements of the piston on dimensional precision, technical conditions and surface roughness, a piston rod can flexibly swing in the piston and the socket without blocking, and normal oil supply of a plunger pump is further ensured.

Owner:CHANGCHUN AVIATION HYDRAULIC CONTROL

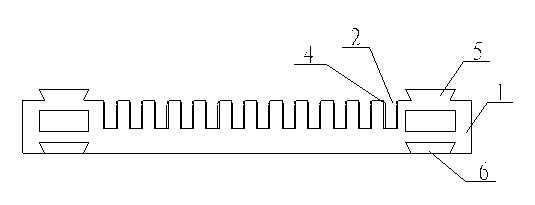

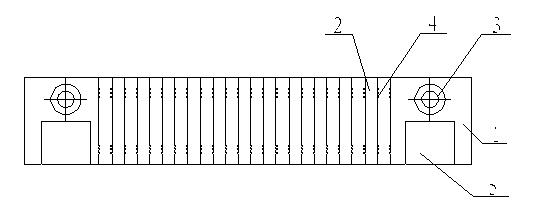

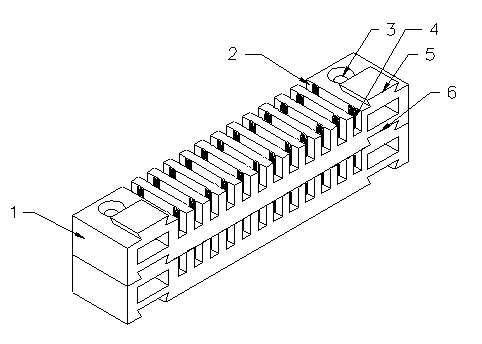

Sliding block type rubber-insulated optical cable fixing device

InactiveCN102707396AReduce construction difficultyShorten the construction periodFibre mechanical structuresPull forceCombined use

The invention relates to a sliding block type rubber-insulated optical cable fixing device, relates to a supporting product of a wall-mounted box applied in indoor light distribution and division of a fiber to the home (FTTH). The sliding block type rubber-insulated optical cable fixing device comprises a fixing device body, the upper parts of the two ends of the fixing device body are provided with a dovetail-shaped bulge, the lower parts of the two ends of the fixing device body are provided with a dovetail-shaped groove, and the upper part of the fixing device body is provided with a plurality of rubber-insulated optical cable mounting slots. The two sides of the rubber-insulated optical cable mounting slots are provided with corrugated bulges, and the anti-pulling force of rubber-insulated wires can be effectively enhanced after fixation. The dovetail-shaped bulges on the upper parts of the two ends of the fixing device body are provided with mounting holes on one side, and the fixing device is fixedly connected with a box body through the mounting holes. When in combined use, the two sliding block type rubber-insulated optical cable fixing device are assembled into a whole via matching of the dovetail-shaped bulges on the upper parts of the two ends of the fixing device body and the dovetail-shaped grooves on the lower parts of the two ends of the fixing device body, so the requirements for use of household rubber-insulated optical cables with a large number of cores can be satisfied.

Owner:ZHONGTIAN BROADBAND TECH

Device for manufacturing portable rope head

The invention provides a device for manufacturing a portable rope head. A plastic coating device is arranged at one side of a cut-off device in a fixed length manner; a tensioning device is arranged outside the plastic coating device, wherein the length of the cut-off device is fixed by the centers of a cutter and the plastic coating device; a dual-plastic-coating-head die cavity with dividing cutter edges is arranged in the die cavity of the plastic coating device, rope guiding slots are formed in two sides of the dual-plastic-coating-head die cavity, and a portable rope is arranged on the tensioning device; a plurality of cut-off devices, dual-plastic-coating-head die cavities of the plastic coating devices and tensioning devices are arranged in parallel. The portable rope has an integrated length in production, one end of the portable rope is straightened at the cut-off device, so that the portable rope and the tension device form a straight line; plastic injection is performed in the rope guiding slots of the dual-plastic-coating-head die cavity, so that two plastic coating heads are formed on the portable rope once; fixed-length circulating plastic coating is performed from the middle parts of the two plastic coating heads to the cut-off device, and the plastic coated portable rope which is drawn out of the cut-off device is cut at the cut position to form a portable rope finished product; portable ropes can be constantly and continuously produced in a reciprocating circulation manner.

Owner:十堰奕郎工贸有限公司

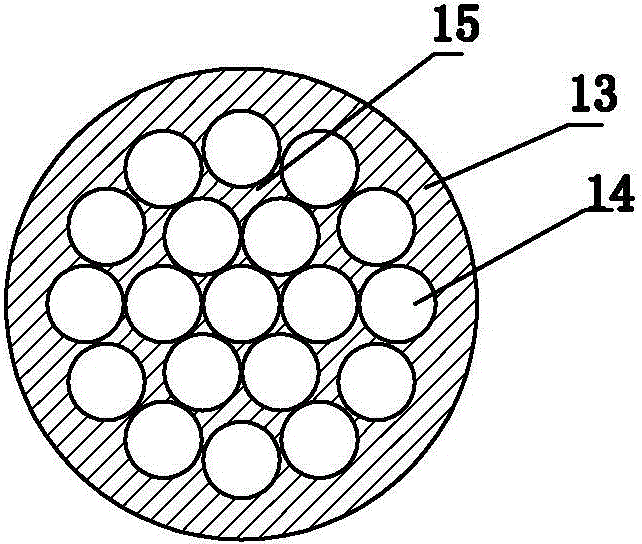

Technology for producing stainless steel cable for automobile

InactiveCN101776119ASimple production processReduce processing costsLighting and heating apparatusSpace heating and ventilation detailsManufacturing technologyProcessing core

The invention discloses technology for producing a stainless steel cable for an automobile, which comprises the following steps: (a) performing drawing treatment on a stainless steel wire to manufacture a stainless steel core wire which meets the diameter requirement; (b) manufacturing needed composite sleeve and protection sleeve by using plastic manufacturing technology; (c) sleeving the protection sleeve on the composite sleeve and inserting the stainless steel core wire into the composite sleeve to ensure that the composite sleeve can slide back and forth on the stainless steel core wire; and (d) processing core wire joints at two ends of the stainless steel core wire according to the shape requirement. The core wire of the cable for the automobile manufactured by adopting the process method is made of stainless steel. Therefore, the cable for the automobile can prevent rust and the tensile strength is improved. The core wire joints at the two ends of the core wire and the core wire are combined into an integral structure, the connection strength between the core wire joints and the core wire is increased, and the pulling-out force between the core wire joints and the core wire is improved. Therefore, the cable is hardly damaged, and the service life of the cable is prolonged.

Owner:SHANGHAI QUNLI RUBBER & PLASTIC PROD

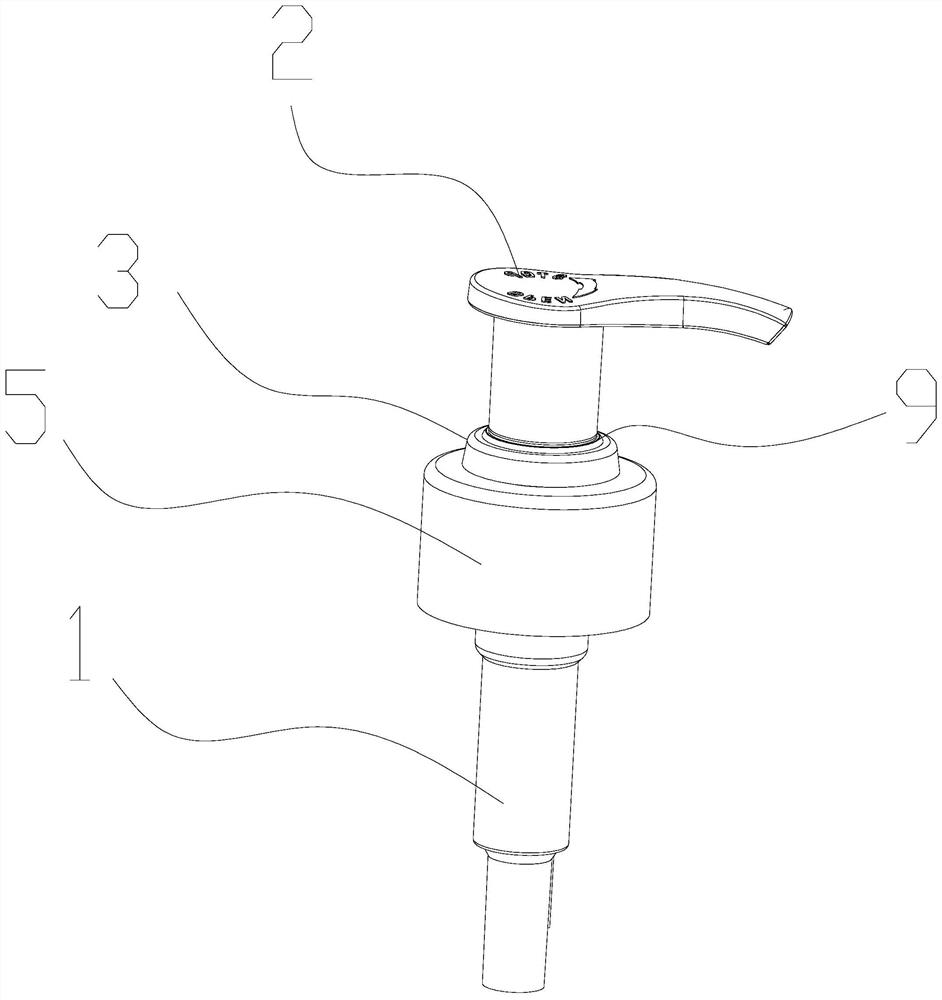

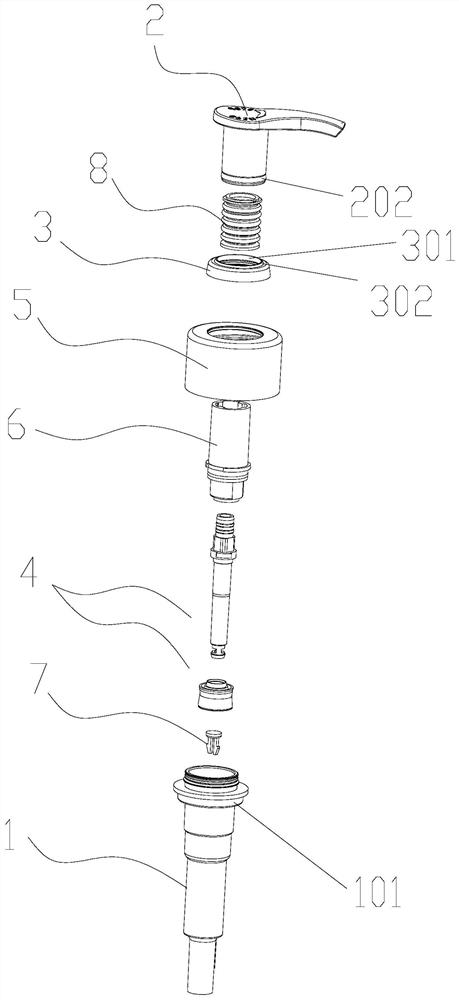

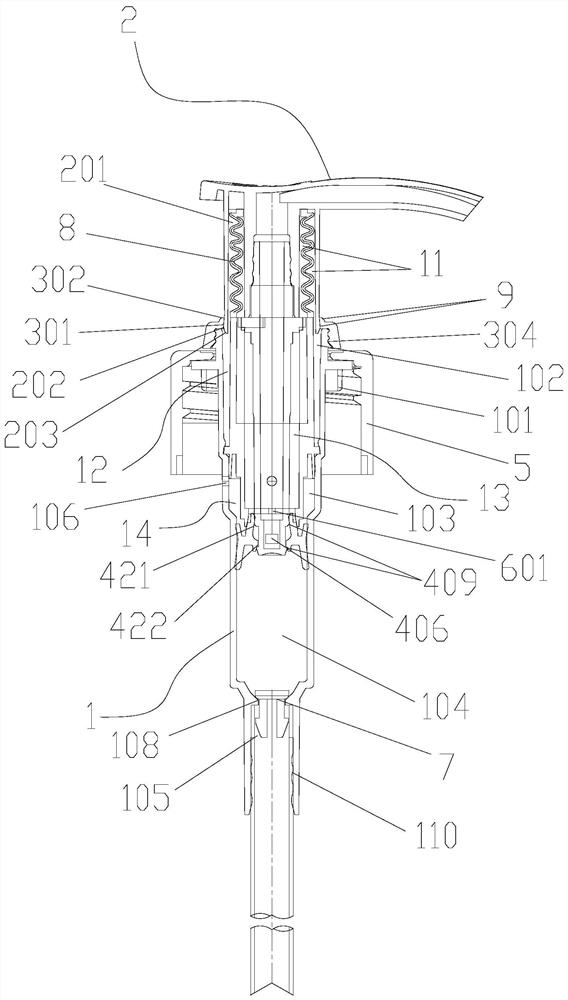

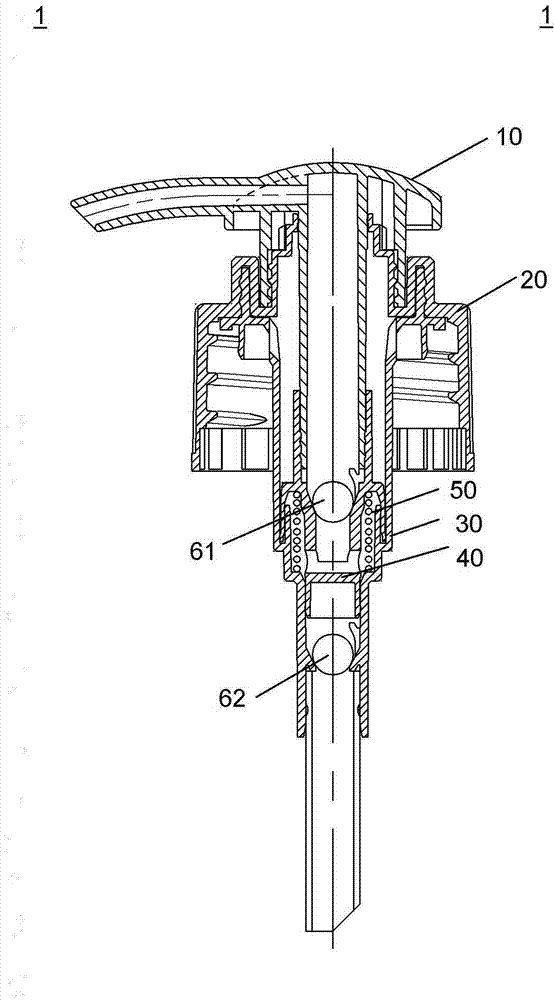

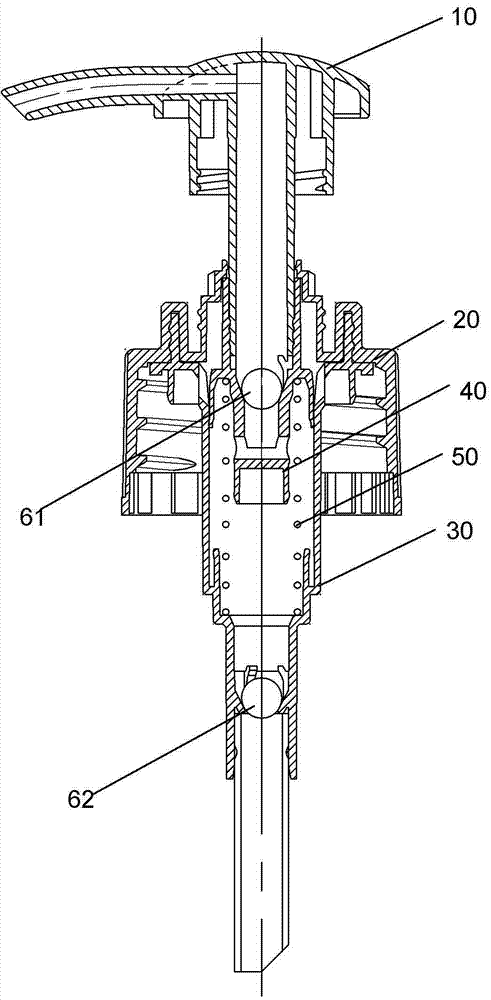

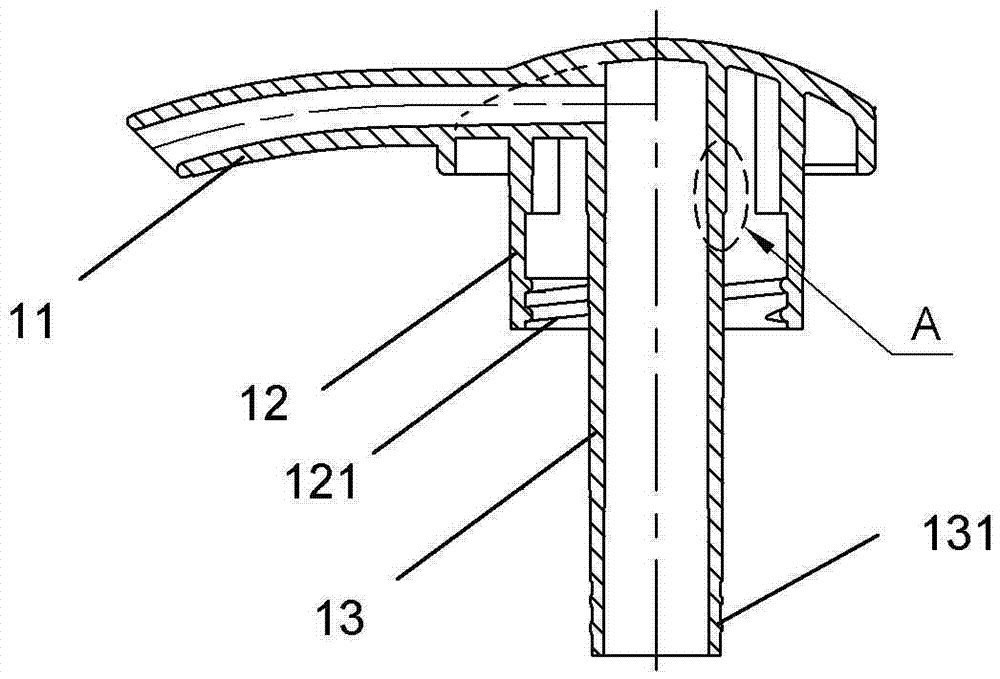

Liquid pump

PendingCN112193609AEliminate the risk of bacteriaAchieve waterproof functionClosuresSingle-unit apparatusPlastic materialsEngineering

The invention discloses a liquid pump. The pump comprises a pump body made of full-plastic materials, a pressing pump head, a combination cover, a threaded cover, a piston assembly, a connecting pieceand a valve piece, wherein a spring cavity is formed inside the pressing pump head, a sealed spring is arranged inside the spring cavity, and the sealed spring and the spring cavity form an air pressure type elastic pressing structure; a water retaining structure is arranged between the pressing pump head and the combination cover; and the pressing pump head and the piston assembly are connectedin a sealed mode through an anti-pull-off structure, and the piston assembly penetrates the interior of the connecting piece and is connected to the connecting piece in an opening and closing mode through an opening and closing structure. Through the design of a waterproof structure, the risk that external water leaks into a liquid container to cause liquid bacteria in a using process of the liquid pump is avoided, the problem of damage or liquid leakage during falling is solved by designing new structural force such as pull-off prevention and rotation stopping on each part and through a toughening material, and the overall sealing performance is improved.

Owner:NINGBO SHENGJIE SPRAY

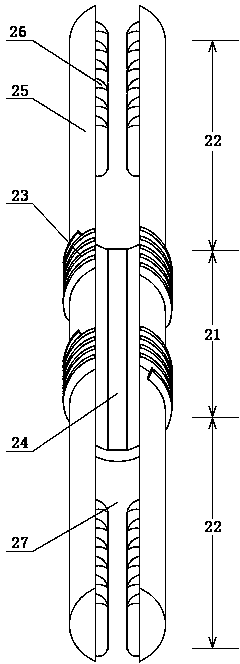

Optical-fiber junction protector

ActiveCN103412377AImprove the anti-pull-off indexImprove pull-off forceCoupling light guidesFibre mechanical structuresEngineeringOptical fiber

The invention discloses an optical-fiber junction protector. The optical-fiber junction protector comprises an inner shell, outer shells and a C-shaped lantern ring. The inner shell is of a cylinder shape and comprises a main body and clamping bodies. A groove is formed in the main body in the axial direction. Two external threads are arranged at the two ends of the main body respectively. A C-shaped sleeve is arranged between the two external threads. The number of the clamping bodies is two, wherein the clamping bodies are located at the two ends of the main body and comprise two clamping pieces. Each clamping piece is provided with a tooth-shaped body. A clamping cavity between the clamping pieces and the groove of the main body form a junction protection cavity. The number of the outer shells is two, and the inner shell is sleeved with the outer shells. Each outer shell is of a cylinder structure, wherein one end of the outer shell is a thread opening, and the other end of the outer shell is an optical fiber opening. The C-shaped lantern ring comprises a C-shaped ring piece and blocking compression pieces arranged on the two sides of the C-shaped ring piece. The C-shaped sleeve is sleeved with the C-shaped lantern ring. The blocking compression pieces are clamped between the outer shells and the inner shell. The C-shaped ring piece is clamped between the two outer shells. The C-shaped lantern ring and the inner shell are both made of transparent materials. The optical-fiber junction protector is convenient to construct, greatly increases the pulling-out force index, and enables the state of an optical fiber at a junction to be seen.

Owner:NANJING HUAMAI TECH +1

Outer skin fastening device for small optical cable

ActiveCN102540373AWon't hurtReduce the risk of injuryFibre mechanical structuresEngineeringUltimate tensile strength

The invention discloses a outer skin fastening device for a small optical cable, comprising a tail handle with at least one pair of pressure clamps and push tubes which are sleeved on the tail handle and extrude the pressure clamps; the device is characterized in that: at least one circular arc-shaped cutting benches are arranged on the tail handle; the circular arc-shaped cutting benches and the pressure clamps are arranged in the same angle in the axis direction of the tail handle; the radiuses of one sides to the other sides of the circular arc-shaped cutting benches in the circumferential direction of the tail handle are gradually increased; and circular arc-shaped cut grooves which are matched with the circular arc-shaped cutting benches on the tail handle are arranged in the push tubes. According to the outer skin fastening device for the small optical cable, a fully hand pressure technology is adopted, so that the outer skin of the optical cable can be firmly fixed without any special tool, the pull-out force is more than 10N, the fastening of the optical cable is safe, the optical fiber is not damaged, no extra insertion loss is produced, the optical cable is protected against potential damage risks, the operation is simple, and the construction intensity is small.

Owner:NANJING XIUDEA COMM TECH CO LTD

Tension end machining method for car parking and braking cables

The invention discloses a tension end machining method for car parking and braking cables. The method includes the specific steps: 1) peeling one end of one cable; 2) treating the front end of the peeled cable with a punching process to enable the front end of the cable to form a wire rope expansion structure; 3) utilizing high-pressure hot air to blow away plastic fillers in the wire rope expansion structure; 4) subjecting the wire rope expansion structure to treatment of a die casting process to form a die-casting head serving as the tension end of the cable. The method has the advantages that after the plastic fillers in the wire rope expansion structure are blown away with the high-pressure hot air, the die-casting head is formed by means of treatment of the die-casting process; due to the fact that the plastic fillers are removed, air holes cannot be left inside the die-casting head, metal materials on die castings are distributed more uniformly and densely, pulling-out force of the die-casting head is increased effectively and can be increased to about 9000N, and fatigue test can reach 100,000-120,000 times under the same conditions.

Owner:宁波华骏机械有限公司

Pressing pump

ActiveCN106904364AImprove pull-off forceImprove reliabilityClosuresSingle-unit apparatusEngineeringPiston

The invention discloses a pressing pump. The pressing pump comprises an air cylinder, a threaded sleeve connected to the air cylinder, a pressing head and a piston connected to the lower portion of an inner ring, wherein the pressing head is provided with an outer ring and the inner ring, the inner ring extends downwards to the interior of the air cylinder, and the outer ring is connected with the threaded sleeve; the pressing head can move between a locking position and an unlocking position; in the locking position, the outer ring of the pressing head is fixed to the threaded sleeve, and in the unlocking position, the pressing head moves upwards, so that the outer ring is separated from the threaded sleeve, and the lower end of the inner ring still extends into the threaded sleeve or the air cylinder. The pressing pump is simple in structure, and all parts are easy to mold.

Owner:丁要武

Motor tricycle steel spring platen

InactiveCN103174783AImprove pull-off forceImprove securityHigh internal friction springsEngineeringSpring steel

The invention discloses a motor tricycle steel spring platen. The motor tricycle steel spring platen comprises a spring steel plate pressing platen, limiting rubber is arranged on the spring steel plate pressing plate, the lower portion of the limiting rubber is cylindrical, the upper portion of the limiting rubber is in the shape of a flat-topped cone, a round through hole is arranged in the central position of the spring steel plate pressing platen, and a cylinder corresponding to the position of the round through hole is arranged inside the limiting rubber. A rubber anti-pull-off plate is further arranged inside the limiting rubber, the rubber anti-pull-off plate is arranged at the external side of the cylinder, and a distance is reserved between the rubber anti-pull-off plate and the cylinder. The spring steel plate pressing plate is prone to falling after the vulcanized limiting rubber is under pressure, and therefore the rubber anti-pull-off plate is designed to be welded on the spring steel-plate pressing plate component, limiting rubber anti-pull-off force is increased, and the rubber anti-pull-off plate is squeezed to enable the middle of the anti-pull-off plate to be sleeved more tightly. A thin plate strong in elasticity is used by the anti-pull-off plate so that the anti-pull-off plate can restore the normal position after being squeezed with the rubber at the same time, and safety performance of the whole motor tricycle is improved.

Owner:万李

Matte flame-retardant PVC composition as well as preparation method and application thereof

The invention provides a matte flame-retardant PVC composition as well as a preparation method and application thereof. The composition comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 40-50 parts of a plasticizer, 5-8 parts of a stabilizer, 15-25 parts of calcium carbonate, 0.3-0.5 part of a lubricant, 6-10 parts of a flame retardant, 2-5 parts of extinction powder and 5-8 parts of a toughening agent. The invention also provides a preparation method of the composition. The composition can be used as an automobile wire harness zipper sleeve, operation and wire installation are convenient, cost is low, the interior of the sleeve is smooth, and wires can be well protected.

Owner:ANHUI CHUZHO DEWEI NEW MATERIAL

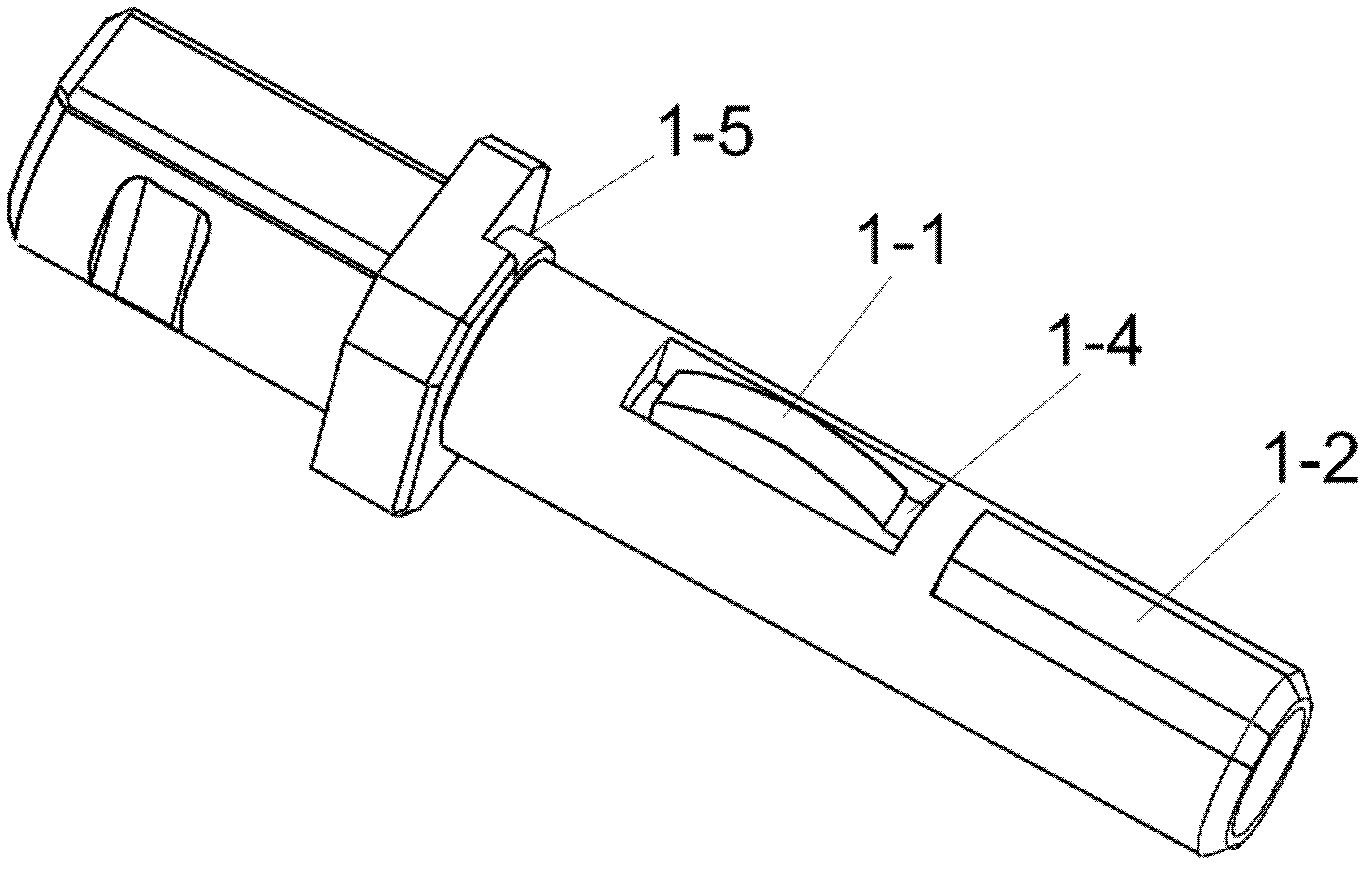

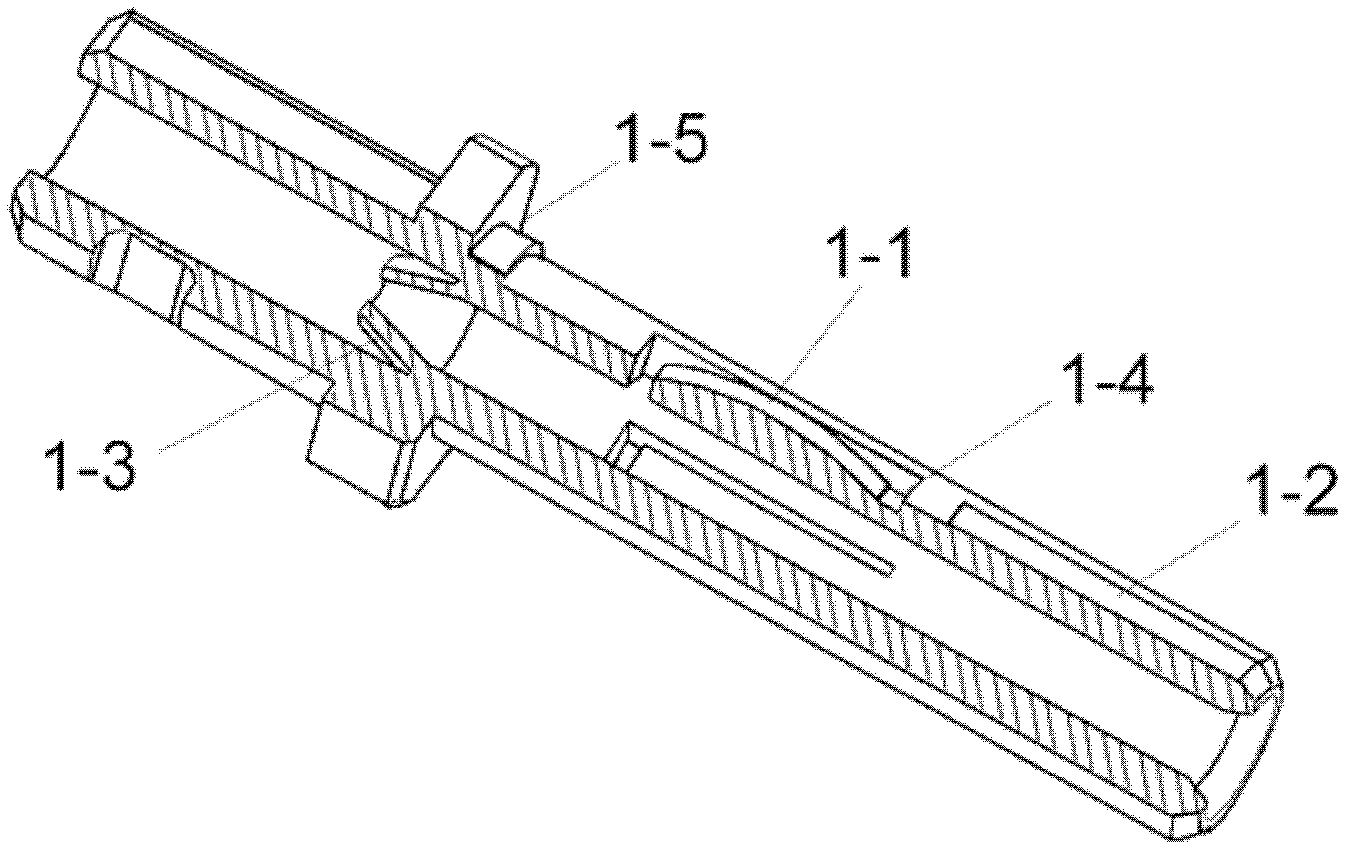

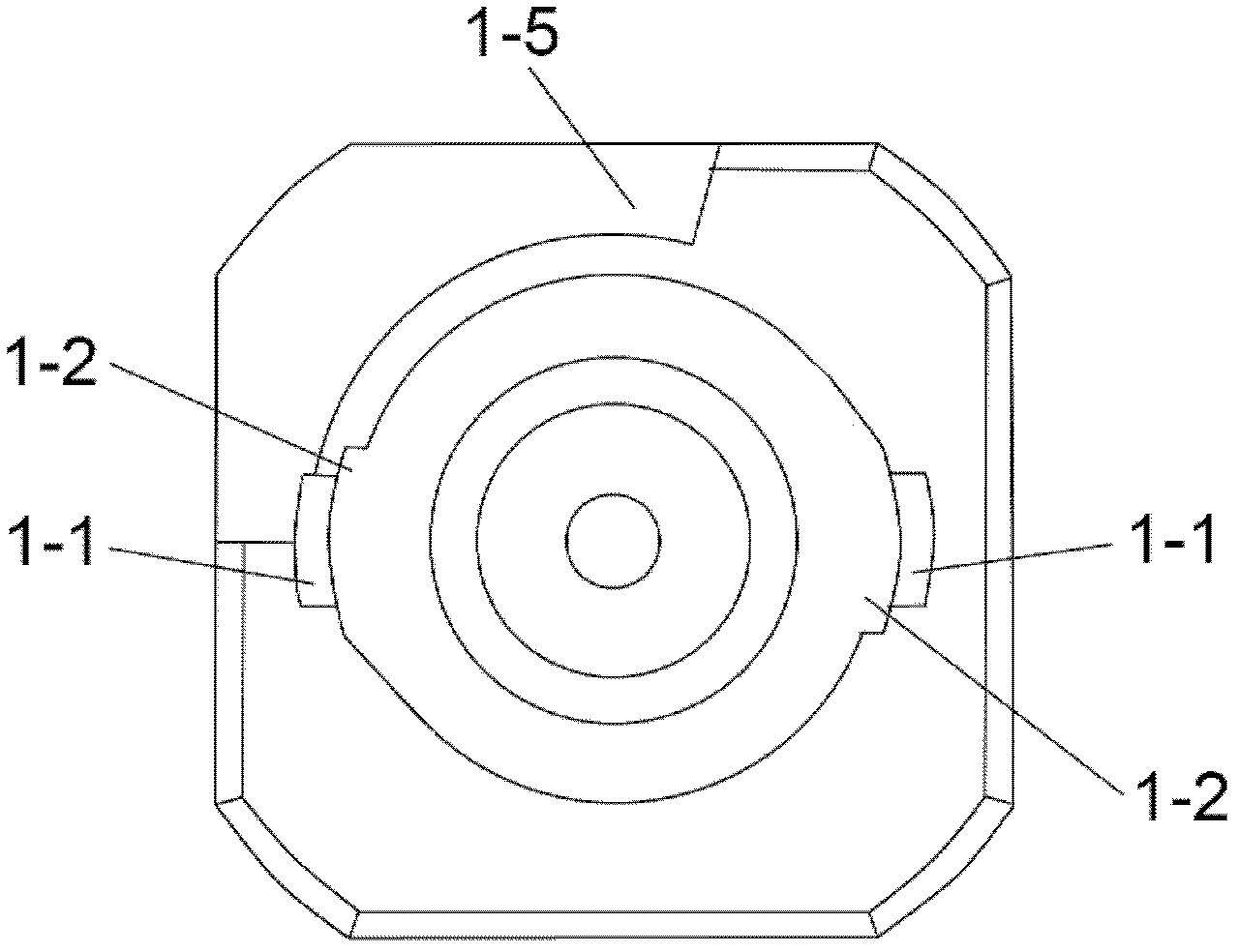

Method for manufacturing connecting rod type plunger

ActiveCN102489966BAchieve flexible and non-blocking phenomenonEnsure normal oil supply workAviationSurface roughness

The invention belongs to the field of aviation machinery, and relates to a method for manufacturing a connecting rod type plunger. The method includes the steps of respectively manufacturing a projection on the outer surfaces of a piston (1) and a socket (2); closing up the piston (1) and the socket (2) by respectively using a tapered opening bush (4), a base component (5) and a pressure head (6); respectively rolling the outer surfaces of the piston (1) and the socket (2) so that the plunger can flexibly swing; and finishing the outer surfaces of the piston (1) and the socket (2). The method is fine in closing quality and maximum in breakaway force, and meets the requirements of the piston on dimensional precision, technical conditions and surface roughness, a piston rod can flexibly swing in the piston and the socket without blocking, and normal oil supply of a plunger pump is further ensured.

Owner:CHANGCHUN AVIATION HYDRAULIC CONTROL

Quick connector

The invention relates to a quick connector. According to the quick connector, a male connector can drive a button to move from a limit unlocking position corresponding to a locking block and an abutting part to an allowable unlocking position corresponding to the locking block and an avoidance part in the insertion direction, an elastic piece used for keeping the button in the limit unlocking position is arranged between an elastic arm and the end surface of a tubular section, when the button is in the limit unlocking position, the abutting part restricts the locking block from being separatedfrom a convex ring, and when the button is in the allowable unlocking position, an elastic pressing arm can be pressed to drive the elastic arm to open from the center back on to a female connector to enable the locking block to be separated from the convex ring so as to relieve the locking on the female connector.

Owner:宁波海连汽配科技有限公司

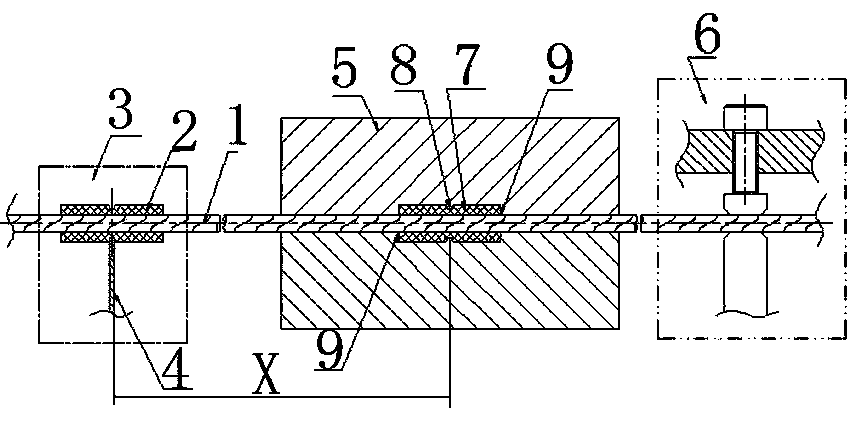

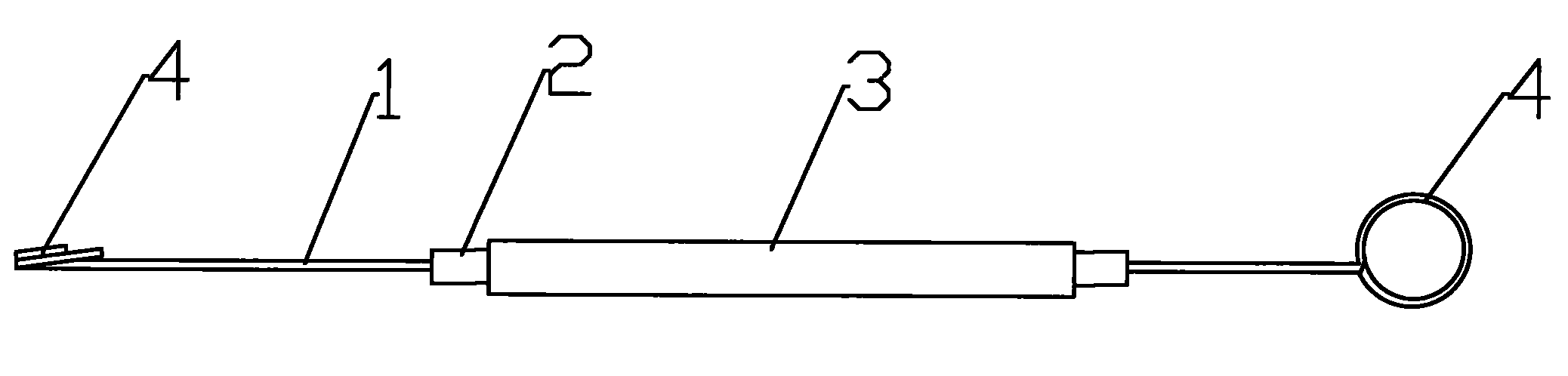

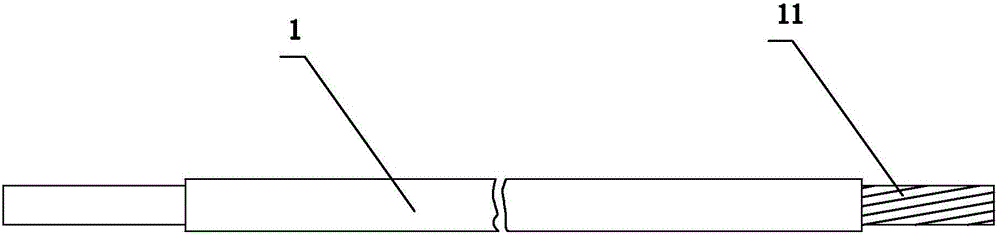

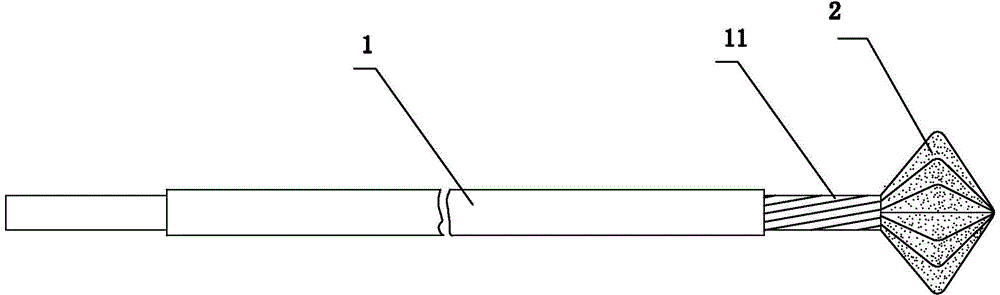

Integrated control inhaul cable

InactiveCN105715661AFirmly connectedGuaranteed number of reciprocationsShaft for linear movementEngineeringSteel rope

The invention discloses an integrated control inhaul cable. The integrated control inhaul cable comprises an inhaul cable steel rope body, a casing pipe composite member A, a casing pipe composite member B, a spring pipe in the middle of the inhaul cable, a plastic part sleeving the spring pipe and metal heads at the two ends of the inhaul cable, wherein the casing pipe composite member A and the casing pipe composite member B are symmetrically arranged on the two sides of the inhaul cable, and the metal heads at the two ends of the inhaul cable are the inhaul cable metal head A and the inhaul cable metal head B. The inhaul cable steel rope body is of a steel wire rope structure. The integrated control inhaul cable is convenient to machine, high in production efficiency and low in manufacturing cost, and the pulling-out force of the metal heads and the steel rope body is large.

Owner:SUZHOU KAZHIMEI ELECTRONICS TECH CO LTD

Dustproof cover of shock absorber

InactiveCN102562919APrevent looseningAvoid accumulationSpringsShock absorbersEngineeringShock absorber

The invention discloses a dustproof cover of a shock absorber. A circular welding joint is arranged at the center of the top of the dustproof cover, and a cover body at the circular welding joint axially extends upwards and then radially extends outwards to form a turned edge. The inner diameter of the turned edge is as same as that of the welding joint, and the upper end face of the turned edge is an annular plane perpendicular to the axis of the dustproof cover of the shock absorber. The inner walls of the turned edge and the welding joint form an inner vertical face, and a right angle is formed at the junction of the inner vertical face and the upper end face. The height of the inner vertical face is equal to that of a step of a connecting rod. After the improved dustproof cover is sleeved on the step on the end face of the connecting rod, the right angle is formed at the junction of the inner vertical face and the upper end face of the turned edge, welding slag is prevented from being accumulated in the turned edge, the connecting rod, a connector or hanging ring and part of the turned edge of the dustproof cover (one third of the height of the inner vertical face close to the turned edge) are simultaneously involved in welding, welded into a component by means of rotary friction and become rigid parts, loosening of the dustproof cover is prevented, and breakaway force and qualification rate are greatly increased.

Owner:成都九鼎科技(集团)有限公司

Connection structure for automotive power steering oil return pipe

The invention discloses a connection structure for an automotive power steering oil return pipe, which comprises a metal tube. A rubber tube is sleeved outside a front end of the metal tube, and a metal sleeve is sleeved outside the rubber tube close to the end head of the metal tube. An annular retainer ring is molded at the end head of the metal tube. Two annular protrusions are molded on the tube body of the metal tube close to the end head in turn. The rubber tube is sleeved at the position corresponding to the annular protrusions on the metal tube. The metal sleeve is sleeved outside the rubber tube, and the end part of the metal sleeve is provided with a baffle edge which can be propped against the annular retainer ring and limited by the annular retainer ring. Compared with a single protrusion structure, the connection structure is provided with one more annular protrusion, and the front parts of the two annular protrusions corresponding to the metal tube on the metal sleeve are provided with a shrinking part, so the connecting pulling-out force is greatly increased, the connecting reliability is greatly enhanced, the tightness is enhanced, the quality is stable, and the connection structure can adapt to higher pressure and wider temperature range.

Owner:邱强

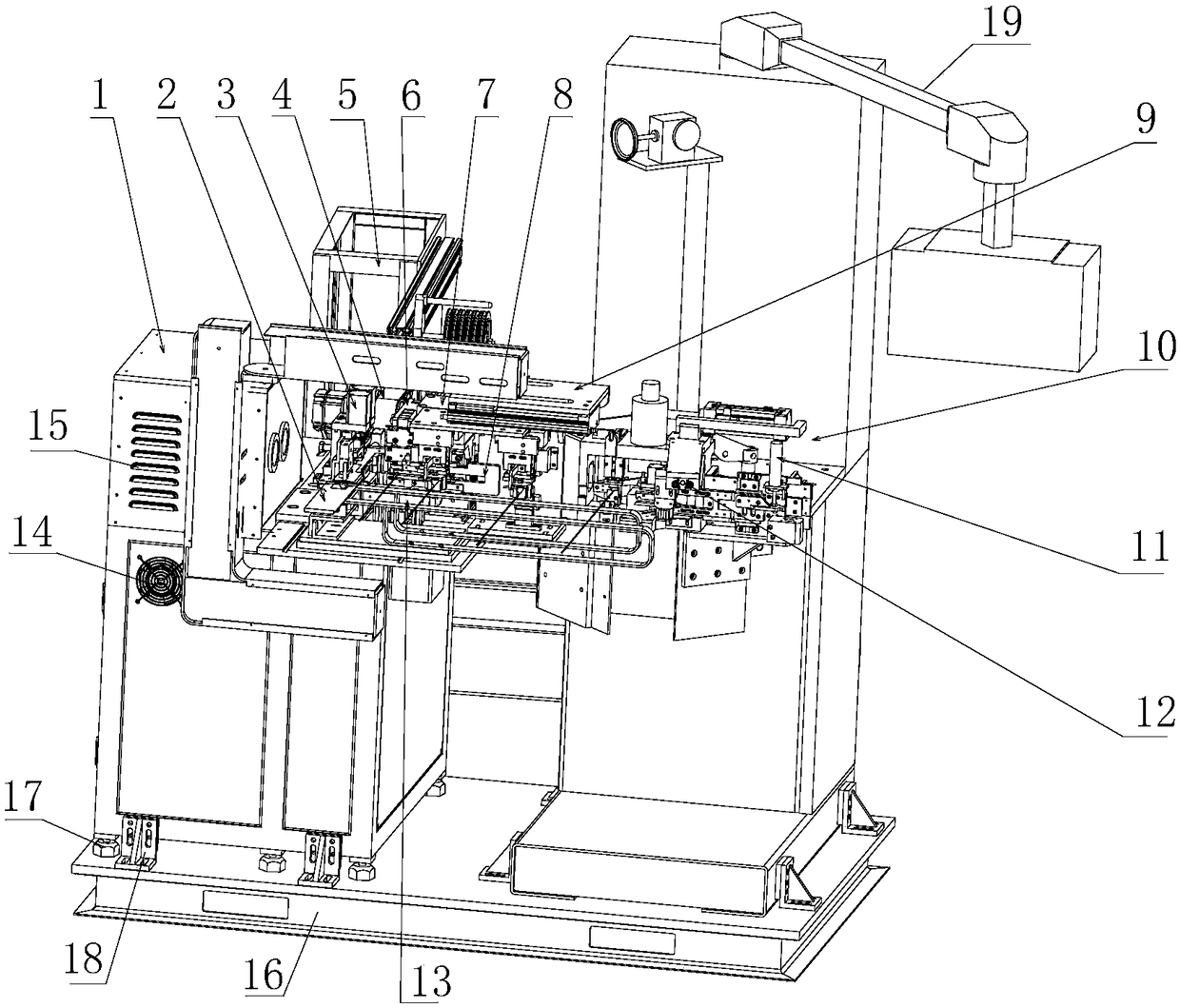

Multifunctional steel wire rope unloading and upsetting die-casting machine

InactiveCN108326552AGuaranteed tension pay-offStable positionOther manufacturing equipments/toolsMoving partsWire rope

The invention discloses a multifunctional steel wire rope unloading and upsetting die-casting machine. The multifunctional steel wire rope unloading and upsetting die-casting machine comprises a control console, wherein a movable guide part is mounted in the middle of the control console; an electric spark fusing part is mounted right above the movable guide part; a steel wire rope feeding part ismounted on the right side of the electric spark fusing part; a pay-off rack is mounted on the back side of the steel wire rope feeding part; a re-shearing part is mounted on the right side of the steel wire rope feeding part; an upsetting part is mounted on the right side of the re-shearing part; a clamping part is mounted at the bottom of the upsetting part; and a material moving part is mountedon the right side of the top of the clamping part. According to the multifunctional steel wire rope unloading and upsetting die-casting machine disclosed by the invention, a steel wire rope electricspark unloading step, a re-shearing step, an upsetting step and a die-casting step are finished on one piece of equipment in a centralized manner, so that the labor productivity can be improved, two operators can be reduced, the production site can be saved, and the quality of produced products can be improved under the circumstance of an invariable capacity.

Owner:长沙礼恩派拉线工业有限公司

A kind of glass powder for solar battery back silver paste and preparation method thereof

The invention relates to a glass powder for silver paste on the back of a solar cell, which is formed by grinding and mixing raw materials including the following weight percentages: glass powder A40-99, glass powder B0-60, and inorganic additives 0-10. When the mixed glass powder of the invention is used to prepare the solar back electrode paste, the amount of glass powder is low, which reduces the cost of the paste; after the solar back electrode paste is sintered, the pull-off force is large, and the photoelectric conversion efficiency of the cell is high.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

Outer skin fastening device for small optical cable

ActiveCN102540373BFastening solutionCard into the strokeFibre mechanical structuresEngineeringUltimate tensile strength

The invention discloses a outer skin fastening device for a small optical cable, comprising a tail handle with at least one pair of pressure clamps and push tubes which are sleeved on the tail handle and extrude the pressure clamps; the device is characterized in that: at least one circular arc-shaped cutting benches are arranged on the tail handle; the circular arc-shaped cutting benches and the pressure clamps are arranged in the same angle in the axis direction of the tail handle; the radiuses of one sides to the other sides of the circular arc-shaped cutting benches in the circumferential direction of the tail handle are gradually increased; and circular arc-shaped cut grooves which are matched with the circular arc-shaped cutting benches on the tail handle are arranged in the push tubes. According to the outer skin fastening device for the small optical cable, a fully hand pressure technology is adopted, so that the outer skin of the optical cable can be firmly fixed without any special tool, the pull-out force is more than 10N, the fastening of the optical cable is safe, the optical fiber is not damaged, no extra insertion loss is produced, the optical cable is protected against potential damage risks, the operation is simple, and the construction intensity is small.

Owner:NANJING XIUDEA COMM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com