Connection structure for automotive power steering oil return pipe

A technology of automobile power steering and connection structure, which is applied in the field of auto parts, can solve problems such as insufficient stability of performance, and achieve the effects of enhanced reliability, enhanced sealing performance, and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

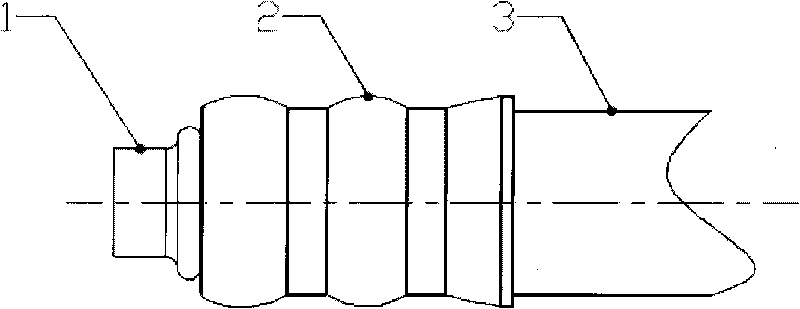

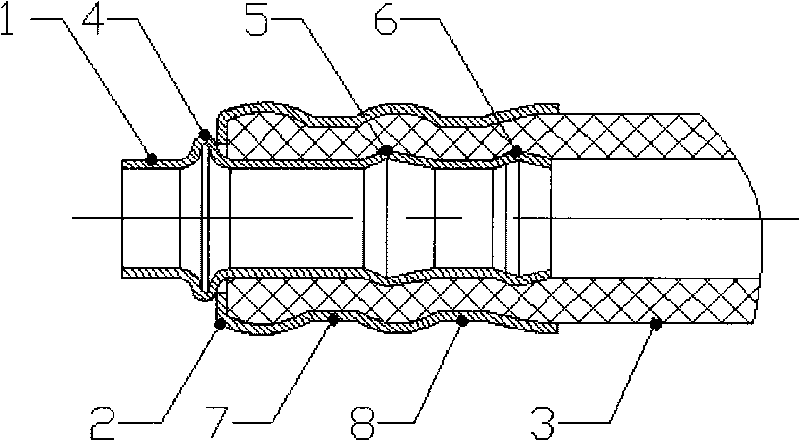

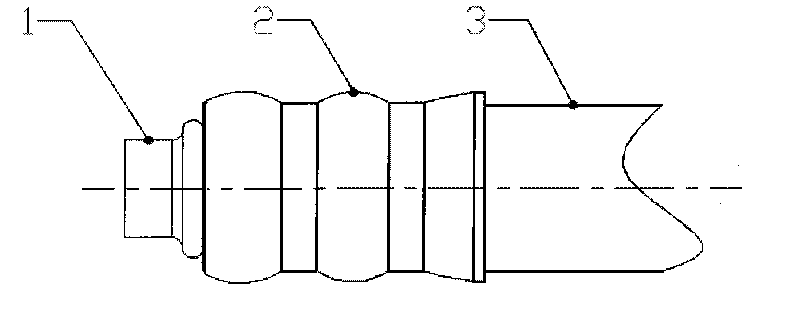

[0011] like figure 1 , figure 2 shown. A connection structure for an automobile power steering oil return pipe, comprising a metal pipe 1, a rubber hose 3 on the outside of the front end of the metal pipe 1, a metal sleeve 2 on the outer casing of the rubber hose 3 near the end of the metal pipe 1, and formed at the end of the metal pipe 1 There is an annular retaining ring 4, two annular protrusions 5, 6 are sequentially formed on the body of the metal pipe 1 close to the end, the rubber hose 3 is set on the corresponding position of the annular protrusions 5, 6 on the metal pipe 1, and the metal sleeve 2 is set on the rubber hose 3, the end of the metal sleeve 2 is provided with a retaining edge that can be pressed against the annular retaining ring 4, and is limited by the annular retaining ring 4. Constrictions 7 and 8 are radially locked on the metal sleeve 2 corresponding to the position between the annular protrusion 5 of the metal pipe 1 and the annular retaining ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com