Dustproof cover of shock absorber

A technology of dust cover and shock absorber, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

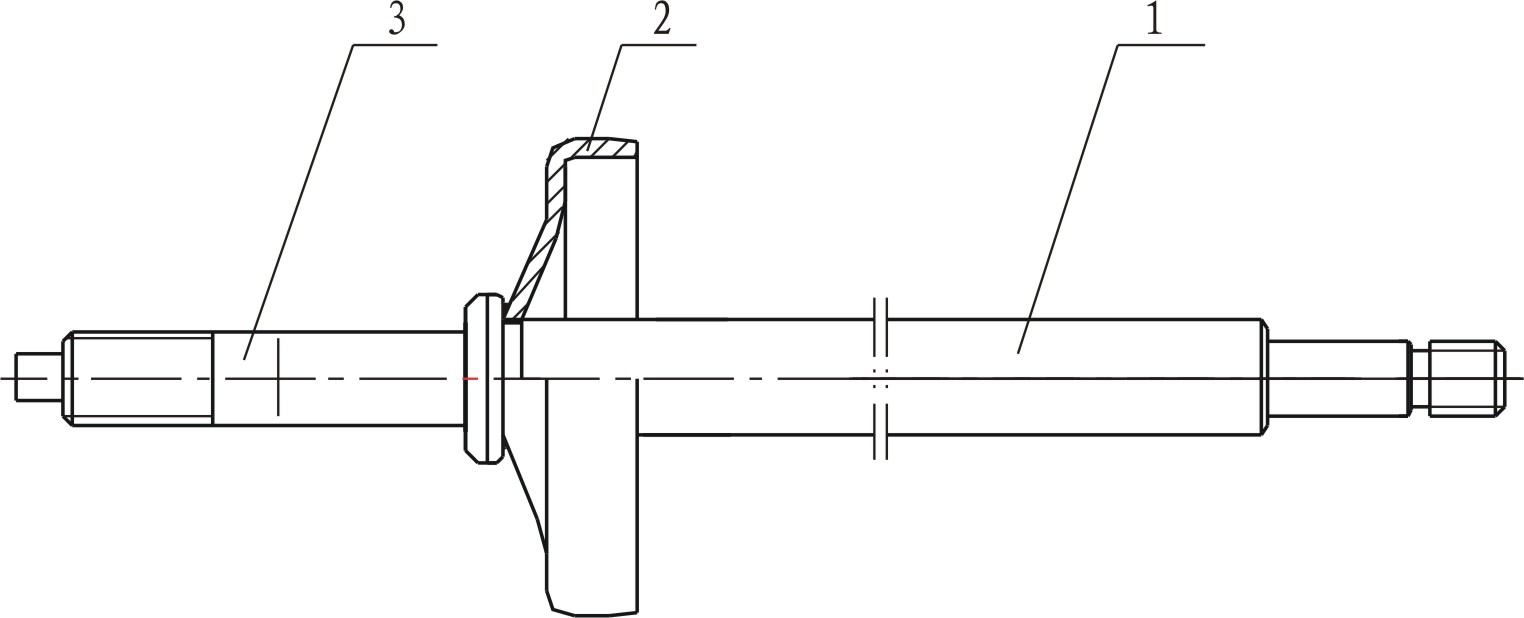

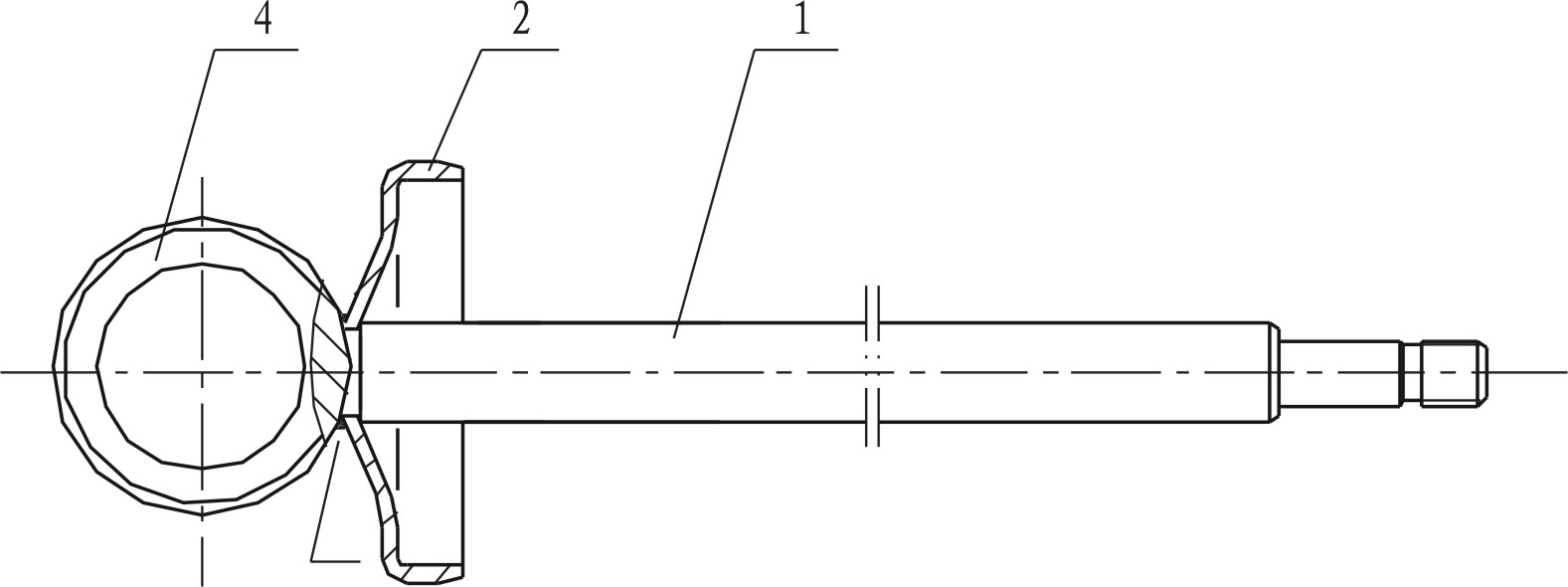

[0022] like Figure 5 The shock absorber dust cover 2 shown has a circular welding opening 21 in the center of the top, and the cover body at the circular welding opening 21 is upward in the axial direction, and then extends radially outward to form a curling edge 22 .

[0023] In order to keep the dust cover 2 coaxial with the connecting rod 1 better, the inner diameter of the bead 22 is designed to be the same as the inner diameter of the welding port 21 .

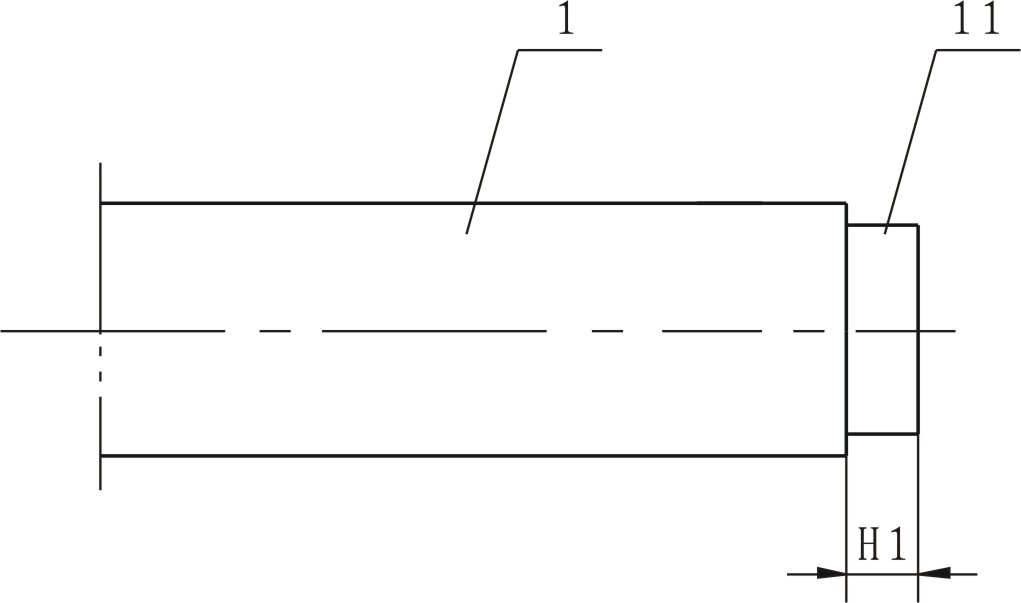

[0024] In order to better participate in the friction welding of the shock absorber dust cover 2 and better maintain coaxiality with the connecting rod 1, the upper end surface 24 of the bead 22 is an annular plane perpendicular to the axis of the shock absorber dust cover 2 , the diameter of the step 11 is the same as the inner diameter of the bead 22 .

[0025] The inner wall of the curling 22 and the welding port 21 forms an inner facade 23. In order to prevent welding slag from accumulating in the curling, affectin...

Embodiment 2

[0030] like Figure 5 As shown, the structure of the shock absorber dust cover 2 is the same as the first embodiment. The outer diameter of the curling 22 is 16±0.1mm, the inner diameter is 10.5+0.10mm, the thickness is 2.10-0.1mm, and the height H2 of the inner facade is 3.60-0.1mm.

[0031] Welding parameters:

[0032]

Embodiment 3

[0034] like Figure 5 As shown, the structure of the shock absorber dust cover 2 is the same as that of the first embodiment. The outer diameter of the curling 22 is 20±0.1mm, the inner diameter is 14.5+0.10mm, the thickness is 2.10-0.1mm, and the height H2 of the inner facade is 3.60-0.1mm.

[0035] Welding parameters:

[0036]

[0037] Effects and advantages and disadvantages:

[0038]

[0039] To sum up, after the improved dust cover is put on the step of the end face of the connecting rod, the junction of the inner elevation and the upper end face of the curling is at right angles, so as to avoid the accumulation of welding slag in the curling, and the connection between the connecting rod and the joint or the lifting ring and A part of the beading on the dust cover (the third part of the beading in the height of the inner facade) participates in welding at the same time, and is assembled into an assembly through rotational friction welding, so that the three parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com