Pressing pump

A technology of indenter and braces, which is applied in the field of pressing pump, can solve the problems of complexity, difficulty in processing half molds, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

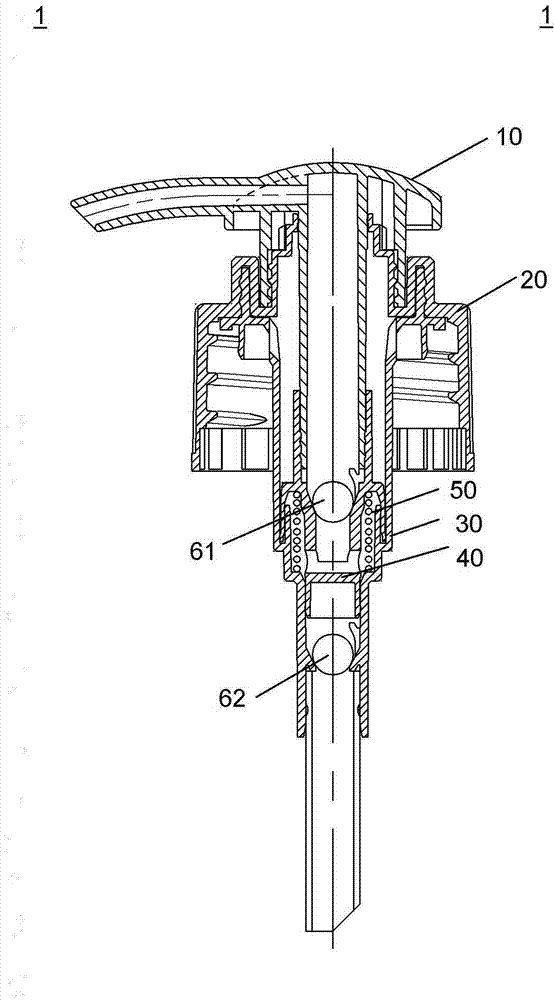

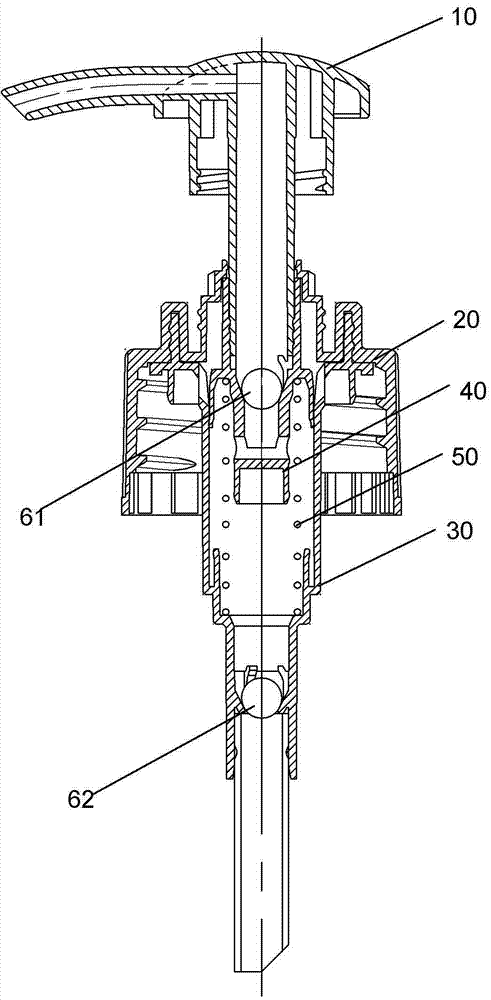

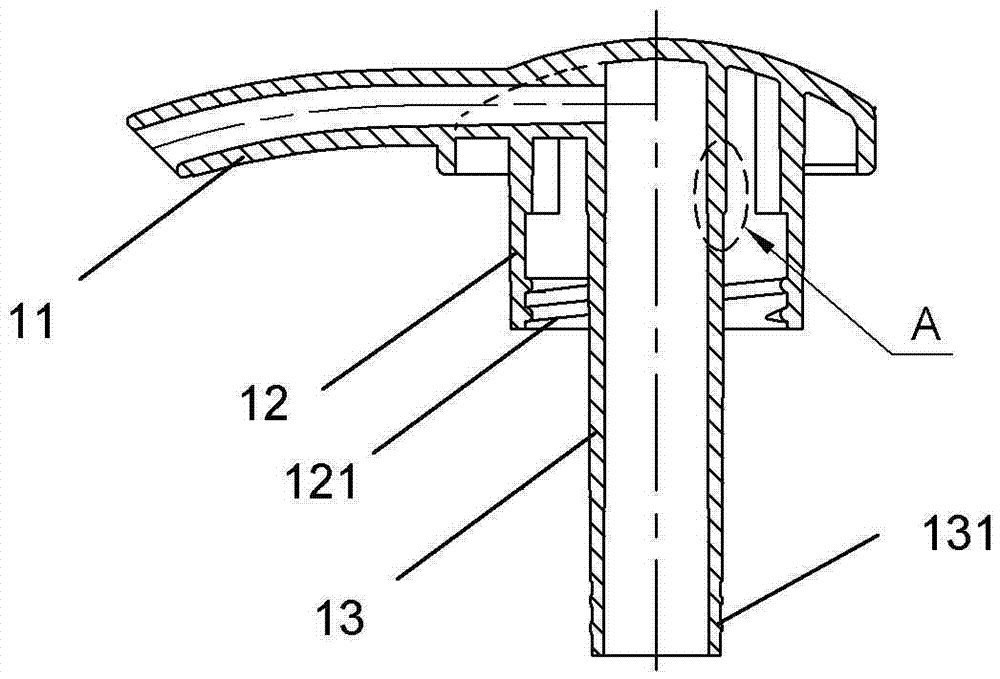

[0041] The following will be combined with Figures 1a-5b A specific embodiment of the present invention will be described in detail. It should be understood that what is shown in the drawings is only a preferred embodiment of the present invention, which is not intended to limit the scope of the present invention. Those skilled in the art can make various obvious modifications, variations and equivalent replacements to the present invention on the basis of the embodiments shown in the drawings, all of which fall within the protection scope of the present invention.

[0042] It should also be noted here that the words about direction such as "upper" and "lower" used herein are placed in a vertical orientation relative to the push pump (that is, the push pump is arranged so that its axis direction is opposite to the vertical direction). consistent) and determined.

[0043] like Figure 1a and 1b As shown, the compression pump 1 of the present invention includes a pressure he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com