Single-effect evaporator

An efficient evaporation and combined technology, which is applied in vertical tube evaporators and other directions, can solve the problems of large energy consumption, high cost, and short service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

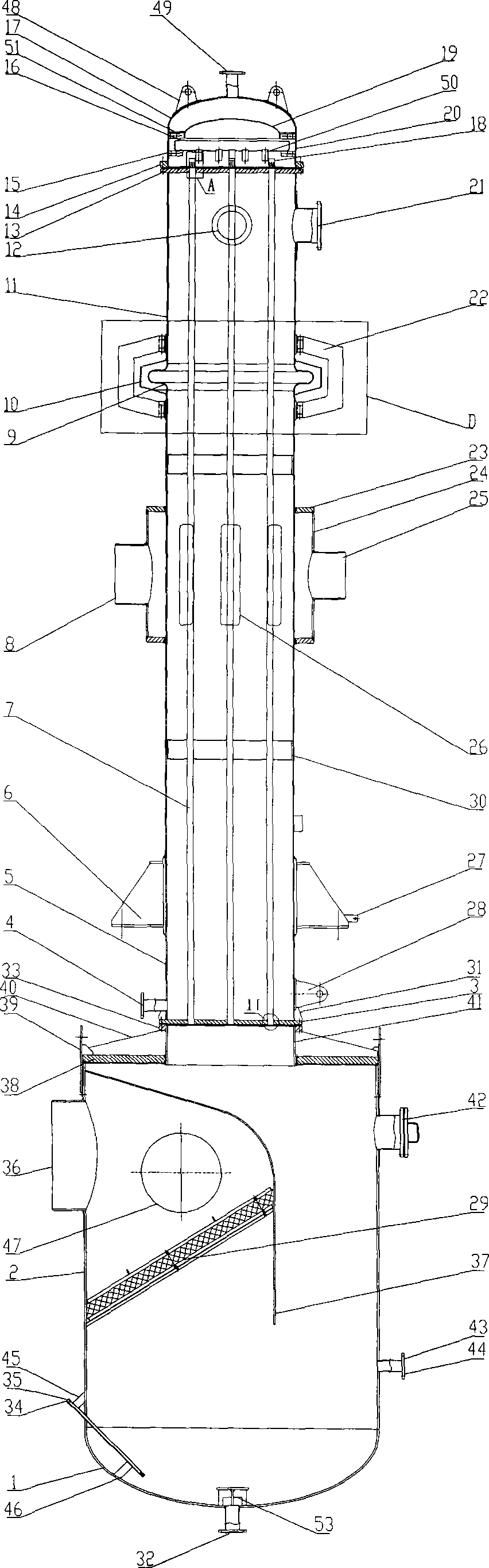

[0030] Such as Figure 1 to Figure 10 As shown, a one-effect evaporator consists of two parts, the tube side and the shell side.

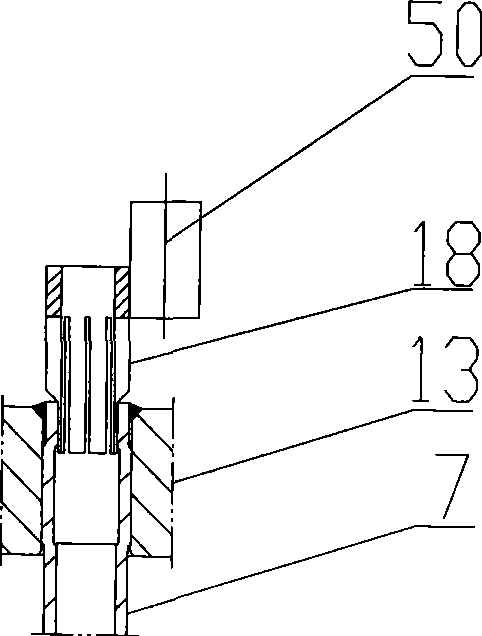

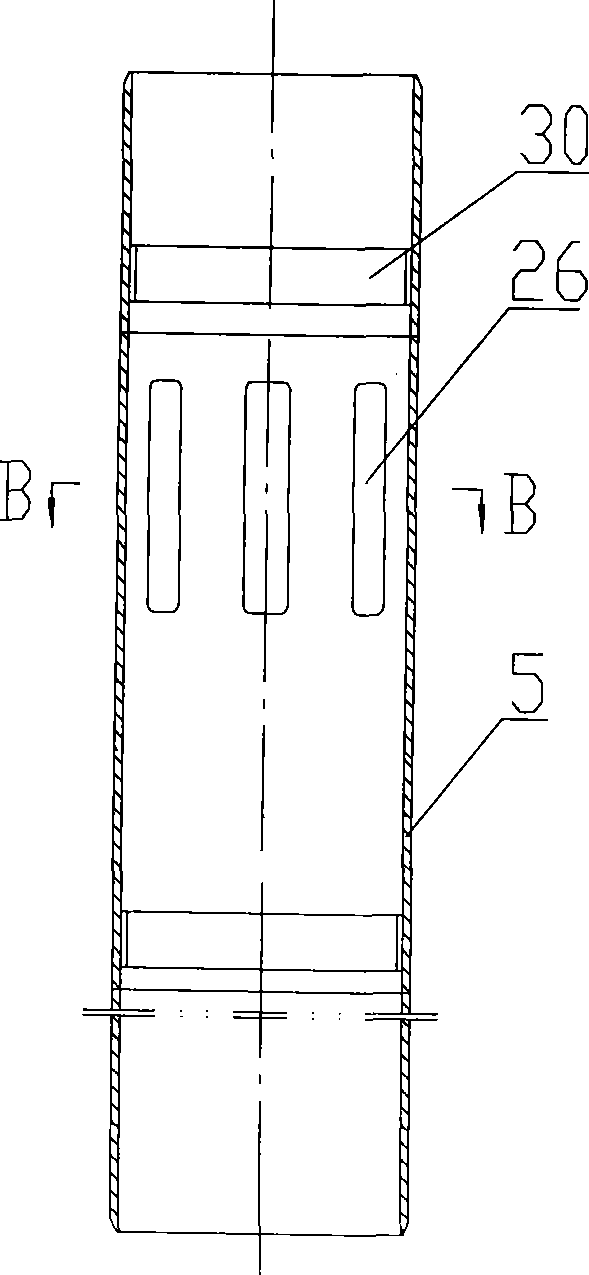

[0031] The tube pass is: the tube pass head 1 is connected to the tube pass cylinder body 2, and the tube pass cylinder body 2 and the tube pass nipple 41 are connected together through the tube pass upper cover 38, the rib plate 40 and the side wall ear 39; The lye outlet 32 and the anti-eddy current baffle 53 are arranged on the process head 1, and the instrument gauge intubation 34 and the liquid level gauge intubation 35 are connected to the tube-side cylinder 2 and the tube-side head 1 through ribs 45, 46. Together; on the tube side cylinder body 2, there are hand openings 42, steam outlets 36, manhole openings 47, liquid level gauge ports 43 and liquid level gauge alarm ports 44, and the tube side cylinder body 2 is provided with a wire mesh defoamer Device 29 and baffle plate 37, one end of baffle plate 37 is connected with tube pass shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com