Method for improving measurement accuracy of height of oil in oil tank

A liquid height and accuracy technology, which is applied in the field of oil height measurement in oil tanks, can solve the problems that the liquid level in the measuring tube is lower than the liquid level in the tank, the temperature of the oil in the measuring tube is low, and the density increases, etc. The effect of stability, improving accuracy and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

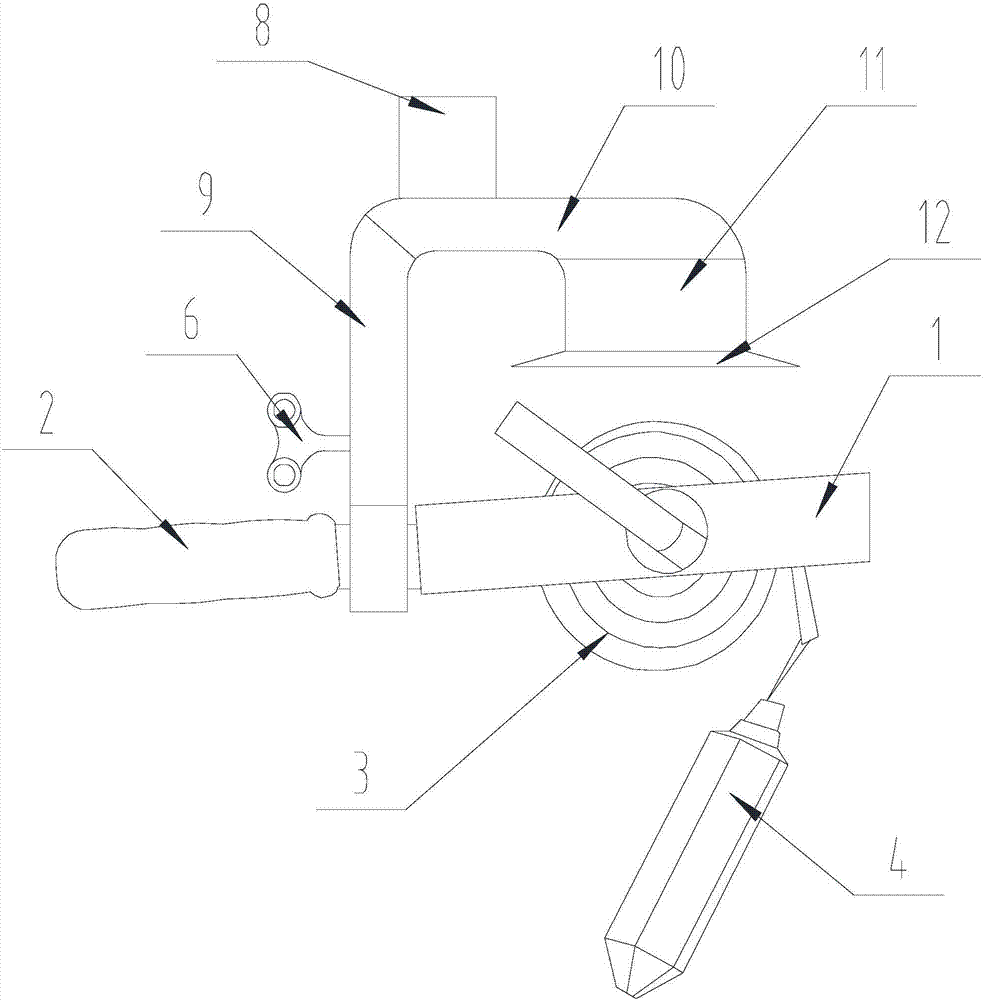

[0035] Such as Figure 1-Figure 2 As shown, the present invention improves the method for measuring the accuracy of the oil height in the oil tank, comprising the steps of:

[0036] Step A verification: verify the dipstick, and correct the tape 3 according to the verification result;

[0037] Step B heating: start the energy supply device 8, so that the heating device 7 performs the heating operation;

[0038] Step C heat dissipation: start the driving device 6, make the blowing device 5 located in the air guide tube assembly start to work, pass the air around the heating device 7 through the blowing device 5 through the opening of the air guide tube assembly, and blow to the tape 3;

[0039] Step D Open the cover and measure: when the temperature of the tape 3 and the air around the oil measuring port of the oil tank is consistent with the temperature of the oil in the tank, open the cover of the oil measuring port, and hold the handle connected to the oil dipstick frame 1 ...

Embodiment 2

[0043] The present invention is based on embodiment 1, and the present invention is further described.

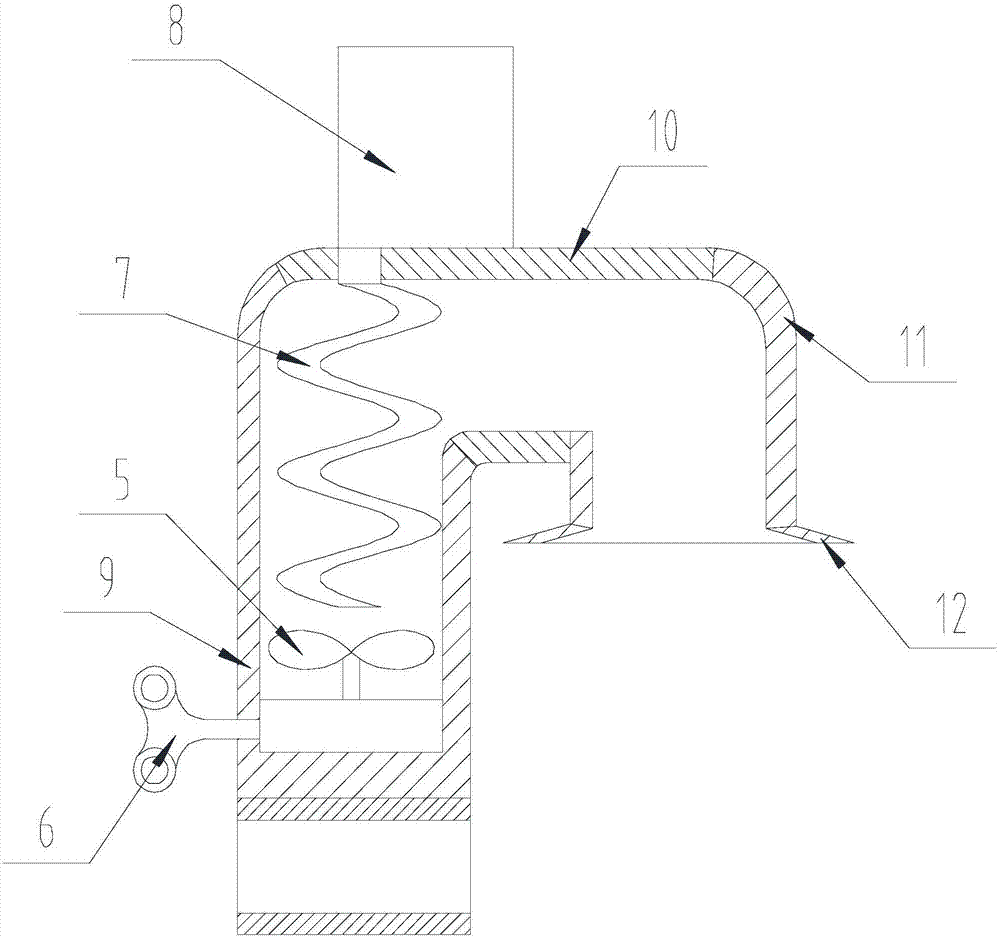

[0044] Such as Figure 1-Figure 2 As shown, the present invention improves the method for measuring the accuracy of the oil level in the oil tank. The air guide tube assembly includes the installation tube 9, the horizontal tube 10 and the guide tube 11 which are sequentially communicated in the inner cavity. One end of the installation tube 9 Vertically connected to the handle 2, the other end of the installation cylinder 9 is connected to the guide cylinder 11 through the horizontal cylinder 10, and the axis of the horizontal cylinder 10 is parallel to the axis of the handle 2, and the axis of the guide cylinder 11 is parallel to the axis of the installation cylinder 9, And the end of the guide cylinder 11 away from the horizontal cylinder 10 faces the tape 3;

[0045] Both the blowing device 5 and the driving device 6 are located at the end of the inner cavity of the in...

Embodiment 3

[0048] The present invention is based on embodiment 1, and the present invention is further described.

[0049] Such as Figure 1-Figure 2 As shown, the present invention improves the method for measuring the accuracy of the oil height in the oil tank, the blowing device 5 is a fan, and the driving device 6 is a clockwork device, and when the coiled steel bar of the clockwork device is unclamped, the fan's The fan blades rotate.

[0050] Open flames and the activation of ordinary electronic equipment are prohibited around the oil tank to avoid contact with air when the electronic equipment is activated, which may cause a fire. Setting the driving device 6 as a clockwork device avoids sparks when the motor is started and ensures the safety of the staff.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com