Self-separating finned tube type heat exchanger for air conditioner

A technology for tubular heat exchangers and air conditioners, used in evaporators/condensers, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as insufficient utilization of heat exchange area and uneven refrigerant flow , to achieve the effect of facilitating timely discharge, solving uneven flow, and maintaining pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The structure and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

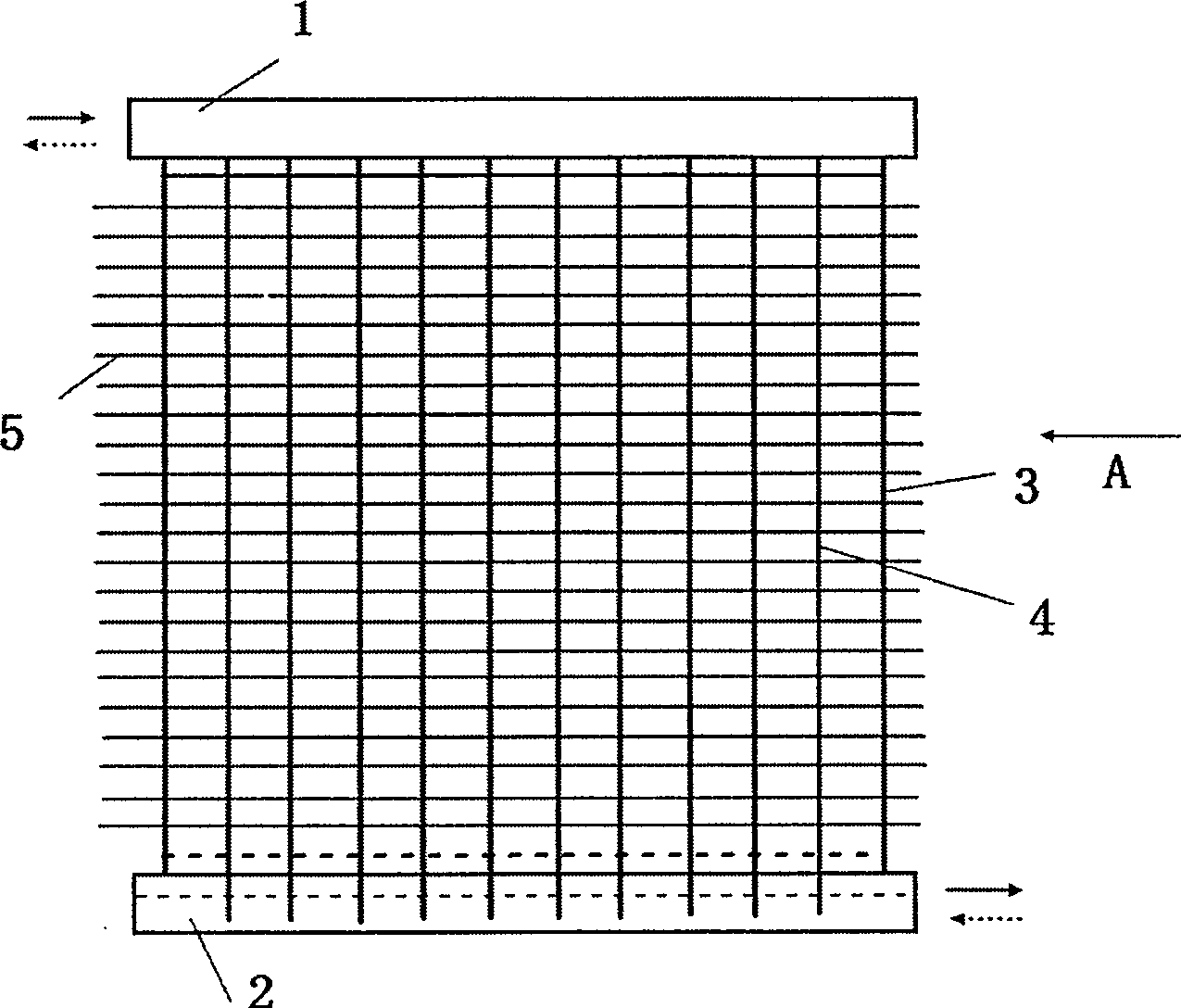

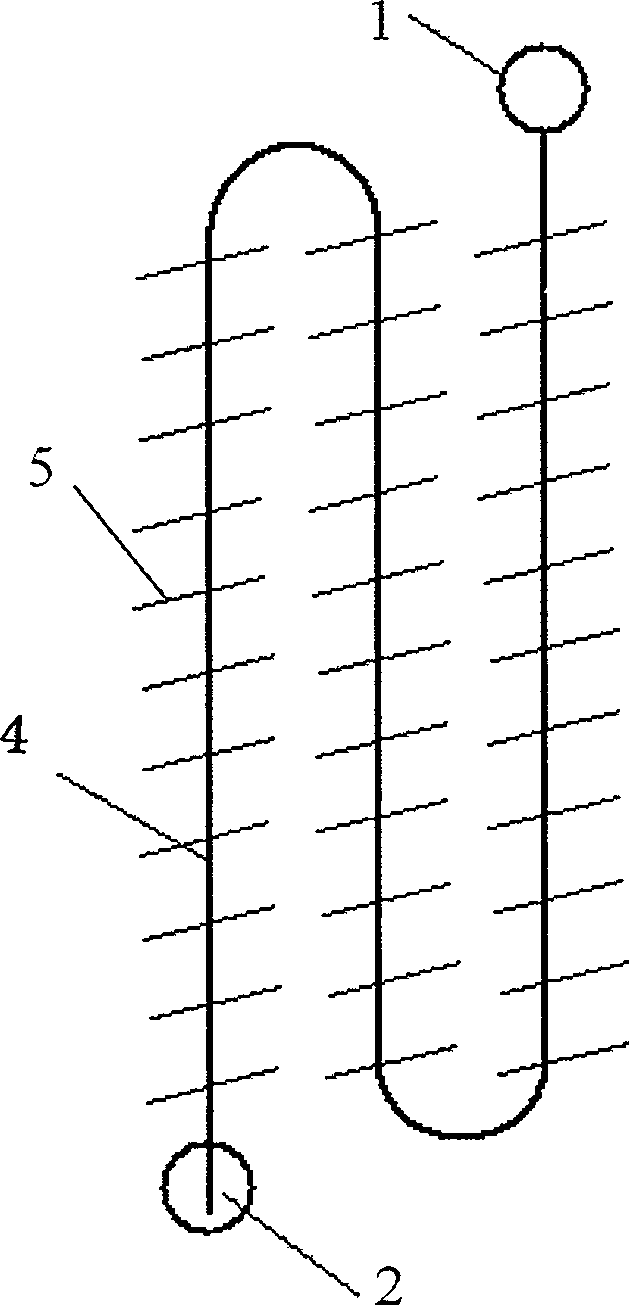

[0013] figure 1 Schematic diagram of the structure of the self-liquid-separating fin-tube heat exchanger for an air conditioner provided by the present invention. The heat exchanger consists of an upper header 1, a lower header 2, a connecting pipe 3 and a connecting pipe 4 arranged in parallel between the upper and lower headers, and the connecting pipe and the connecting pipe are made of ribbed snakes. Shaped pipe, the connecting pipe 3 is provided with two or more, two of which are respectively arranged at the two ends of the lower header, and each connecting pipe is directly connected with the upper header and the lower header; the connecting pipe 4 The upper end communicates directly with the upper header 1, and the lower end communicates with the lower header 2 and penetrates into the liquid in the lower header. The ribs 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com