Patents

Literature

32results about How to "Solve uneven flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

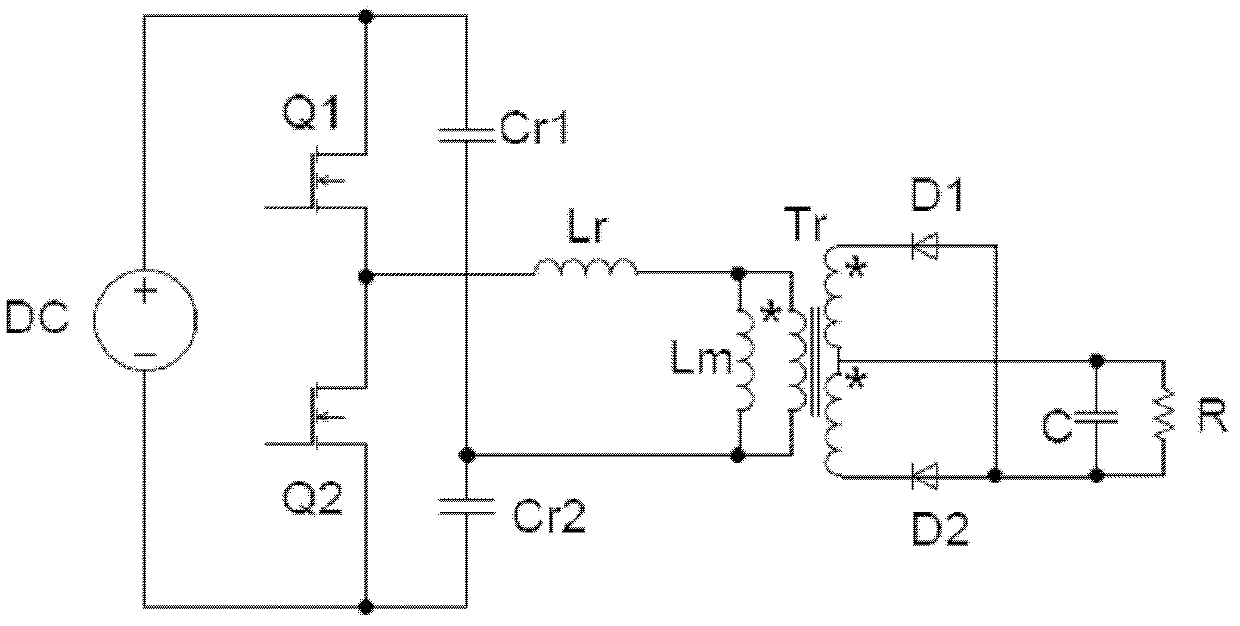

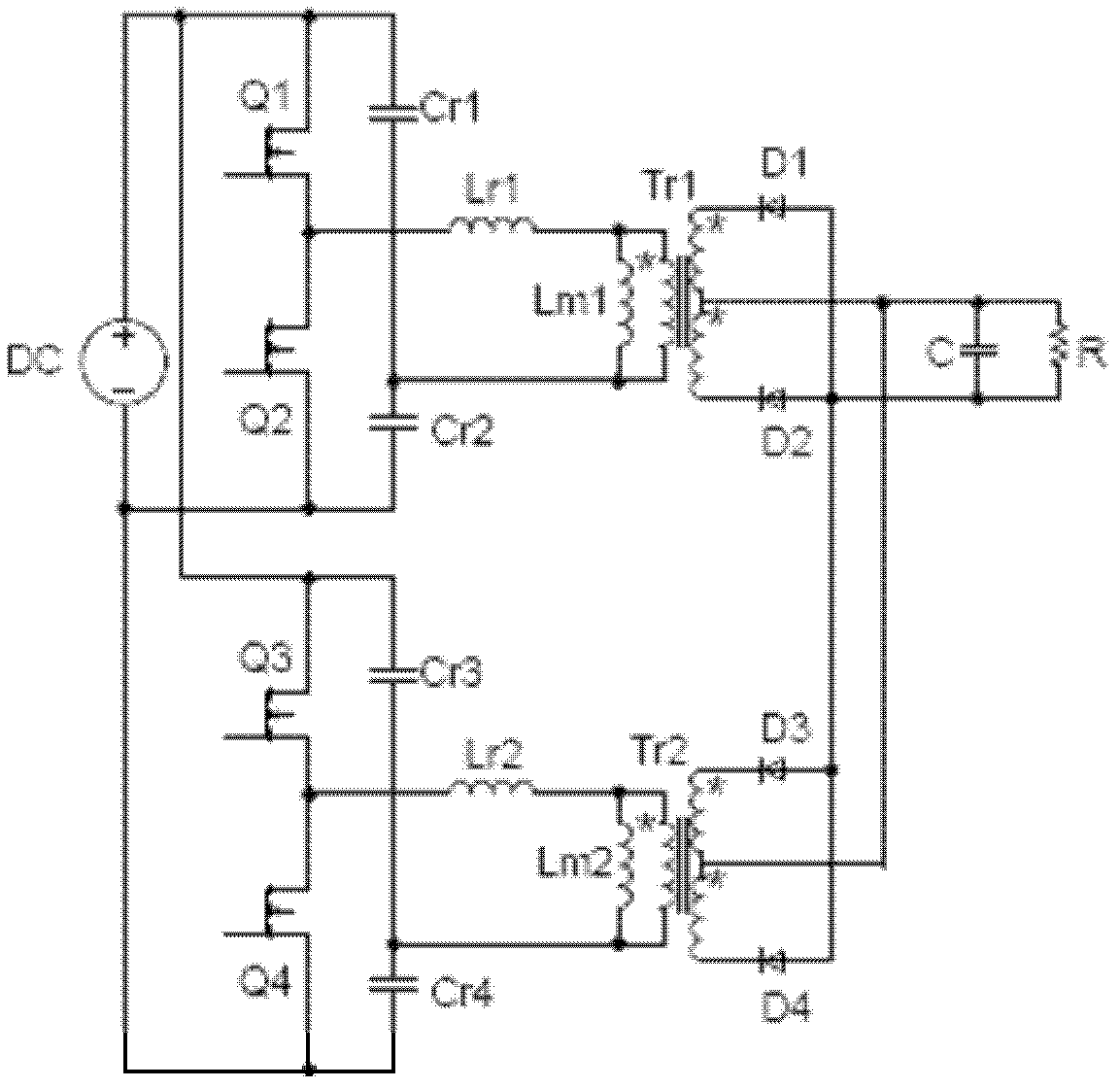

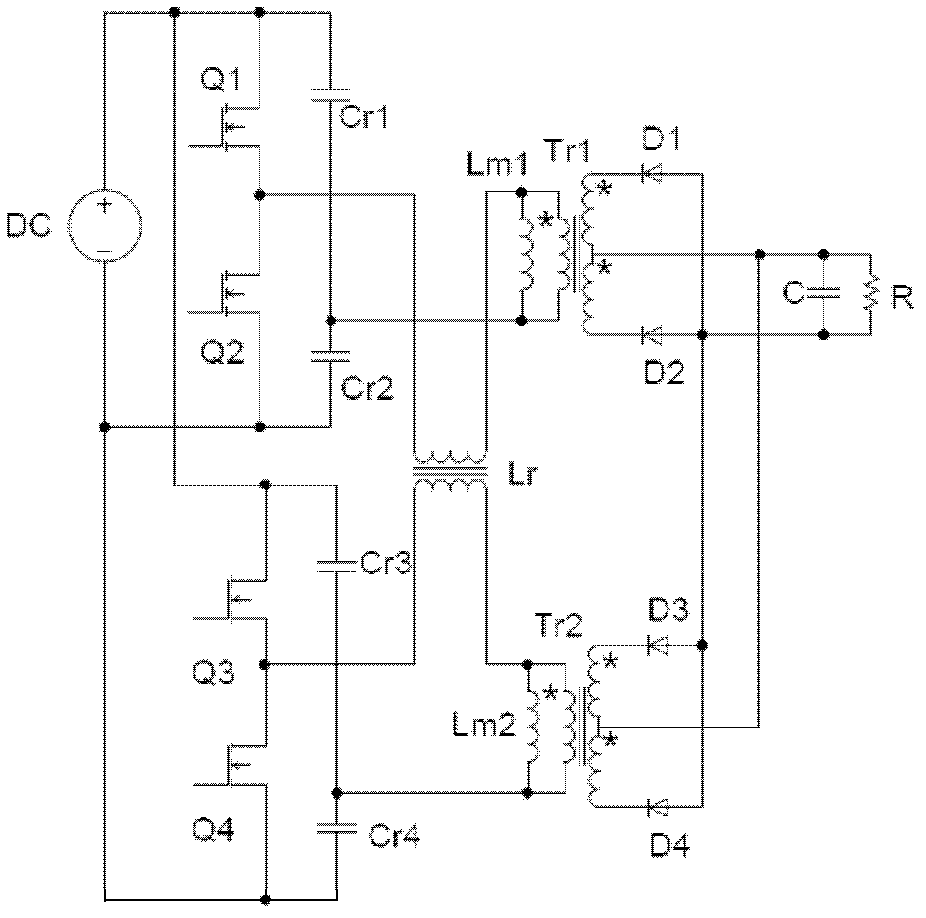

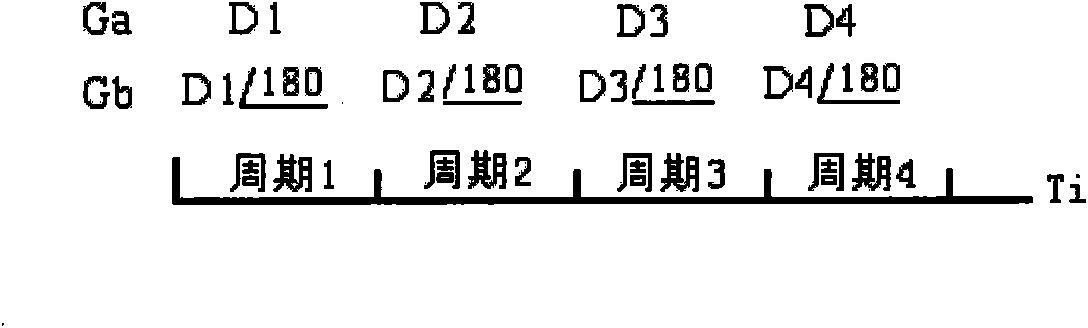

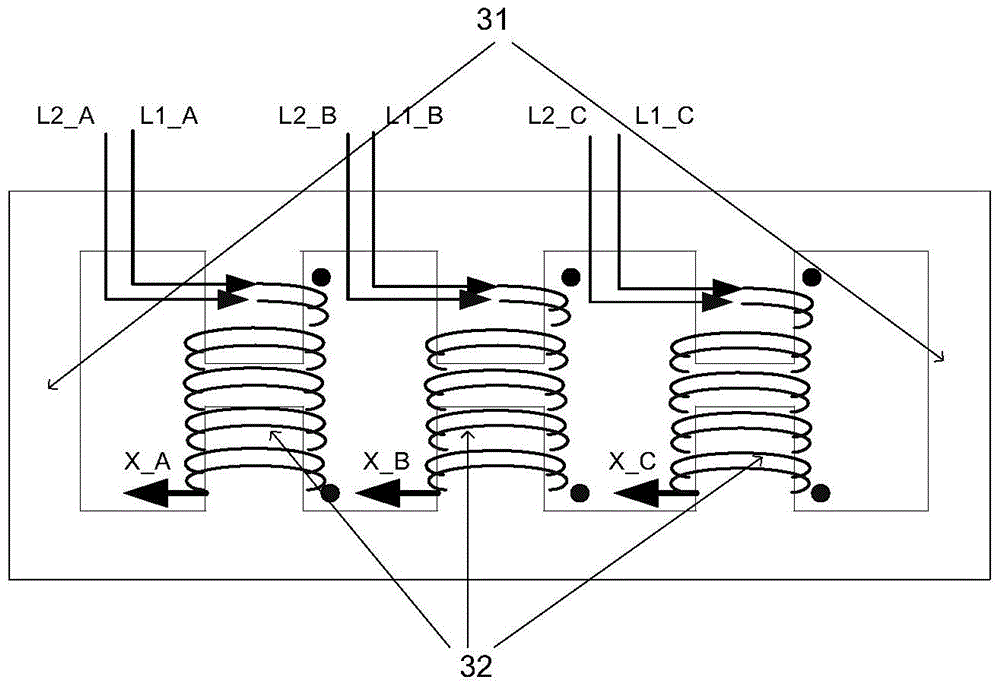

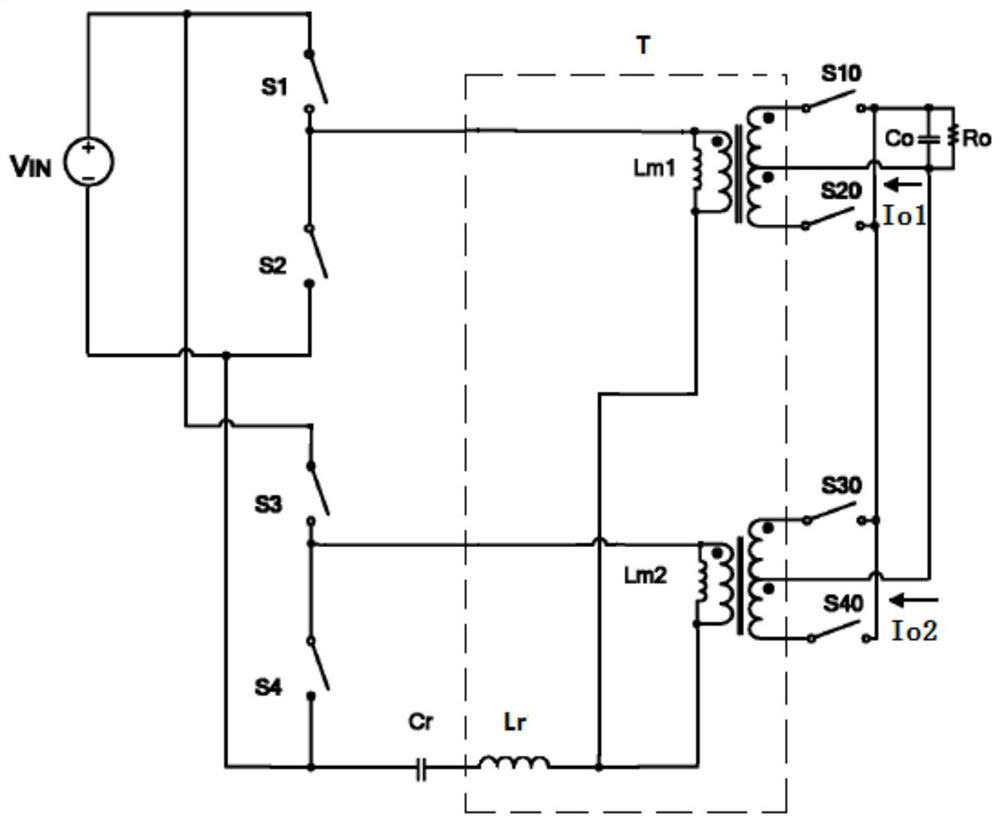

Resonant switching circuit

InactiveCN102611315ARealize current sharingSolve uneven flowEfficient power electronics conversionDc-dc conversionMagnetic coreEngineering

The embodiment of the invention provides a resonant switching circuit. The resonant switching circuit comprises at least two resonant switching circuit units, wherein the resonant switching circuit units are staggered and connected in parallel, and magnetic devices in the resonant switching circuit units are alternately and magnetically integrated on the same magnetic core. As the magnetic devices integrated on the same magnetic core can exert a magnetic path coupling effect, a self current-balancing effect can be produced by currents on circuit branches of different phases, so that the current balance of the resonant switching circuit units in the resonant switching circuit is realized, and the volume of a power supply is reduced due to the integration of the magnetic devices.

Owner:HUAWEI TECH CO LTD

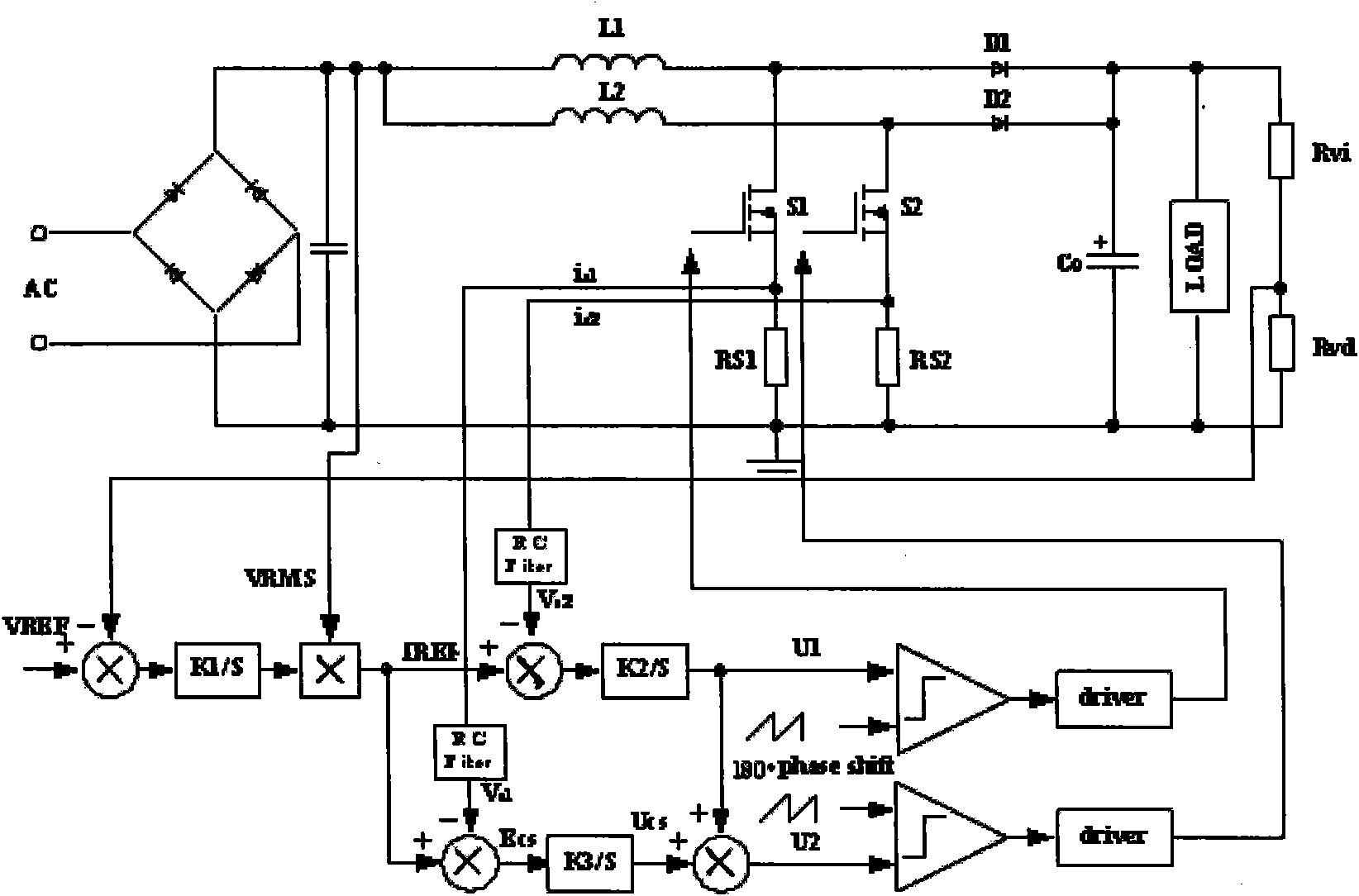

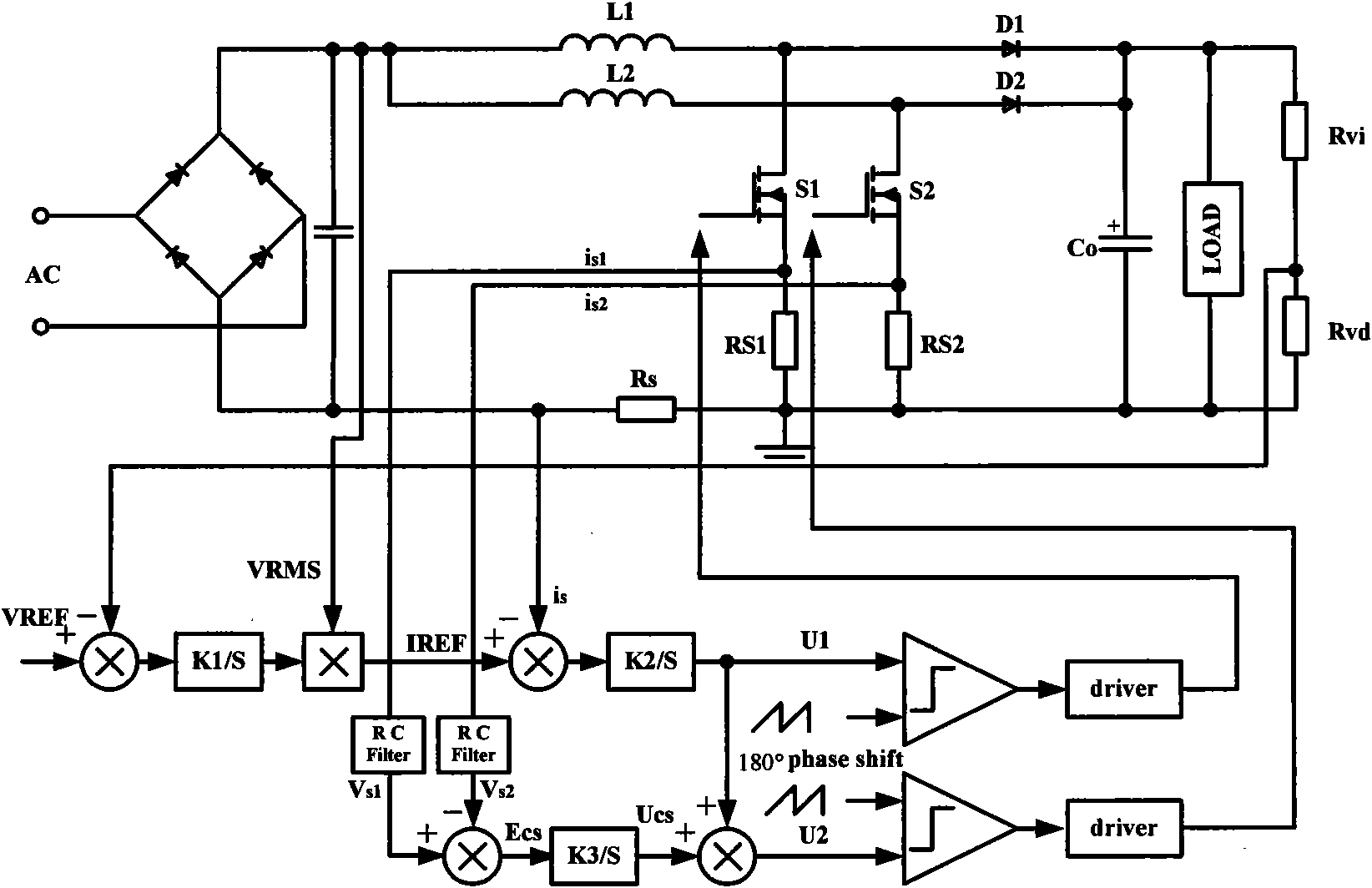

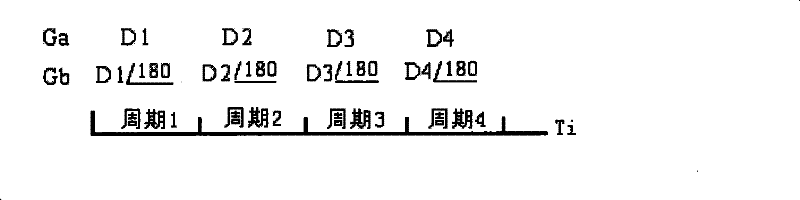

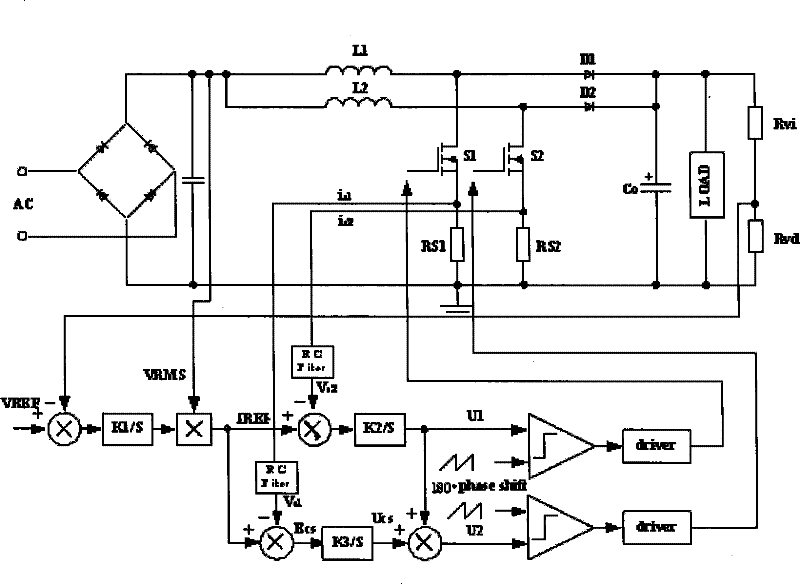

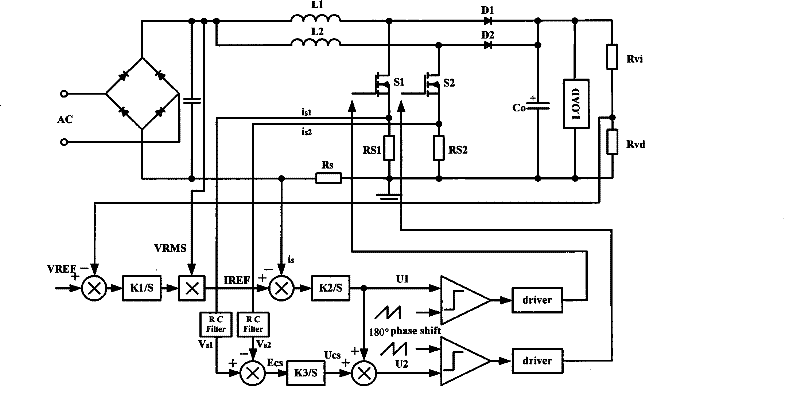

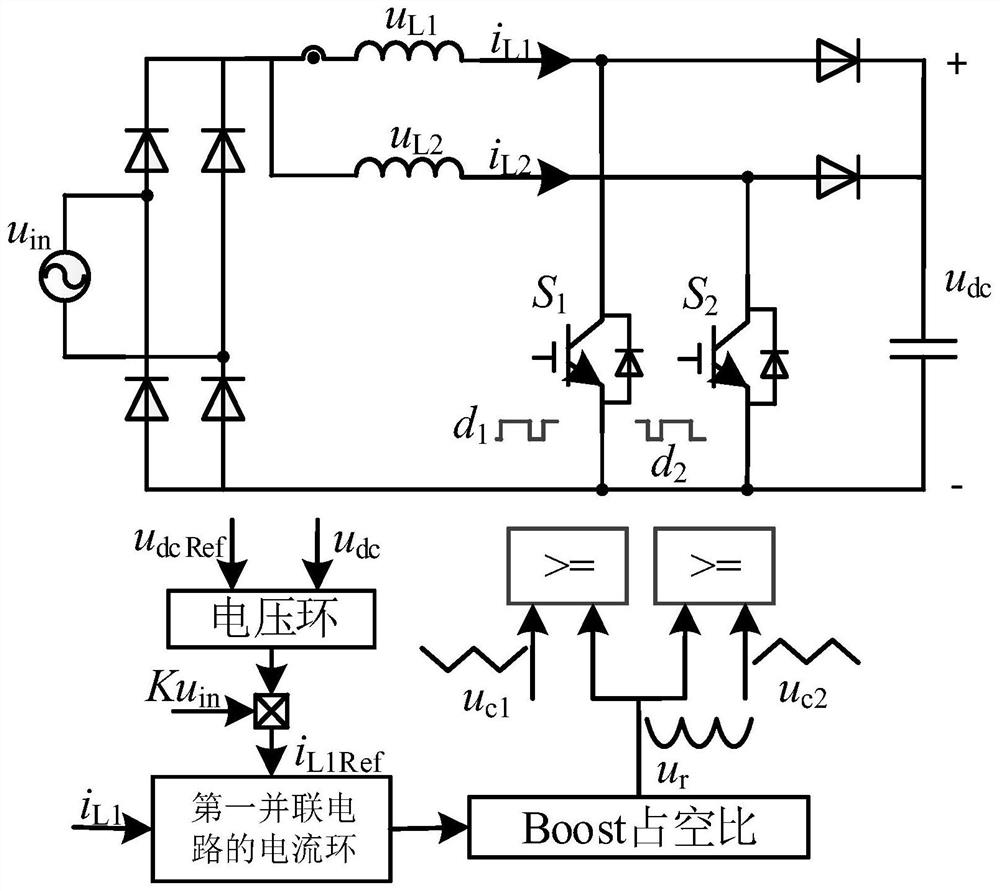

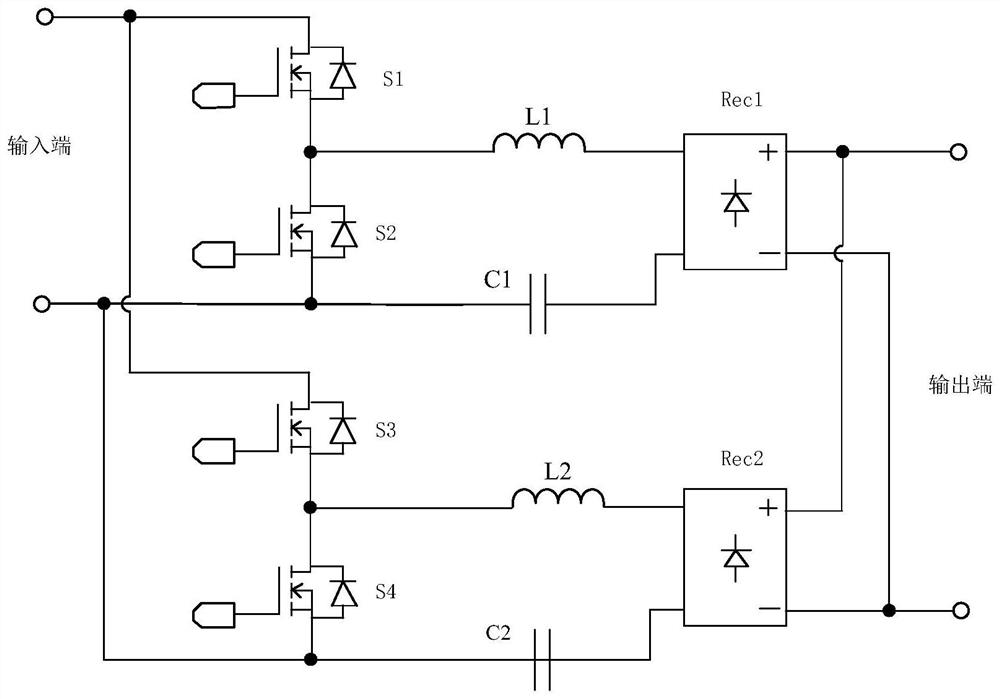

Interleaved parallel PFC control circuit and control method

ActiveCN101594049ASolve the uneven flow problemSimple circuit structureEfficient power electronics conversionPower conversion systemsCarrier signalWave shape

The invention discloses an interleaved parallel PFC control circuit for controlling parallel PFC circuits, wherein a sampling module samples alternating current input voltage, PFC bus voltage and PFC bus current; a processing module processes the sampling signals and a reference voltage signal to generate a control signal; a comparing module compares the control signal with a first carrier signal and a second carrier signal to generate a first duty ratio signal and a second duty ratio signal, wherein the first carrier signal and the second carrier signal are interleaved by a specified phase angle and have the same wave shape; and a selecting module alternates the first duty ratio signal and the second duty ratio signal respectively according to the period thereof to be used as the driving control signal of one of two parallel PFC circuits to another to be output. The invention also discloses an interleaved parallel PFC control method. The invention can effectively avoid the problem of unbalanced current caused by asymmetrical driving signals of the prior interleaved parallel circuit, and has simple realization and low cost.

Owner:EMERSON NETWORK POWER CO LTD

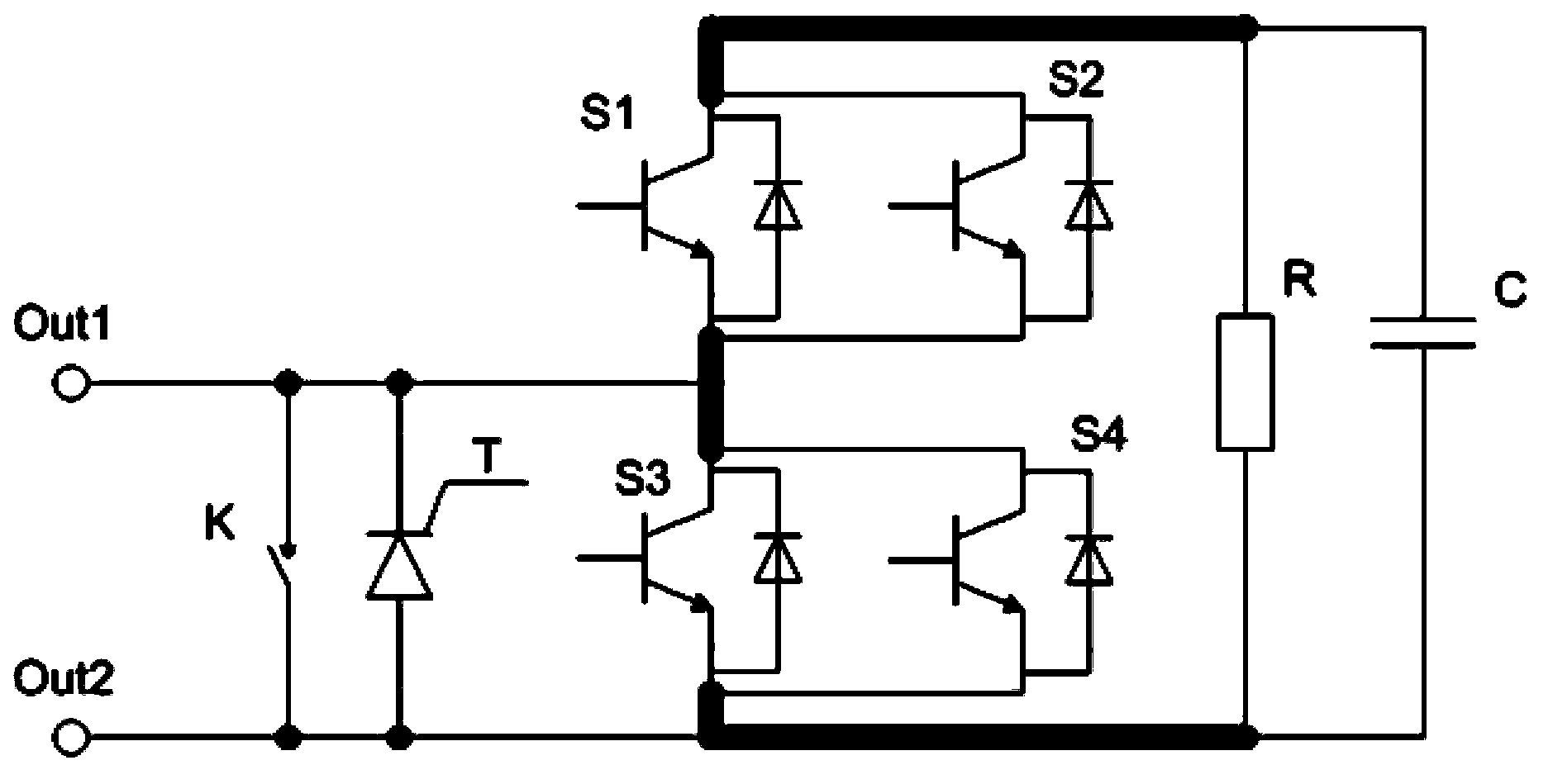

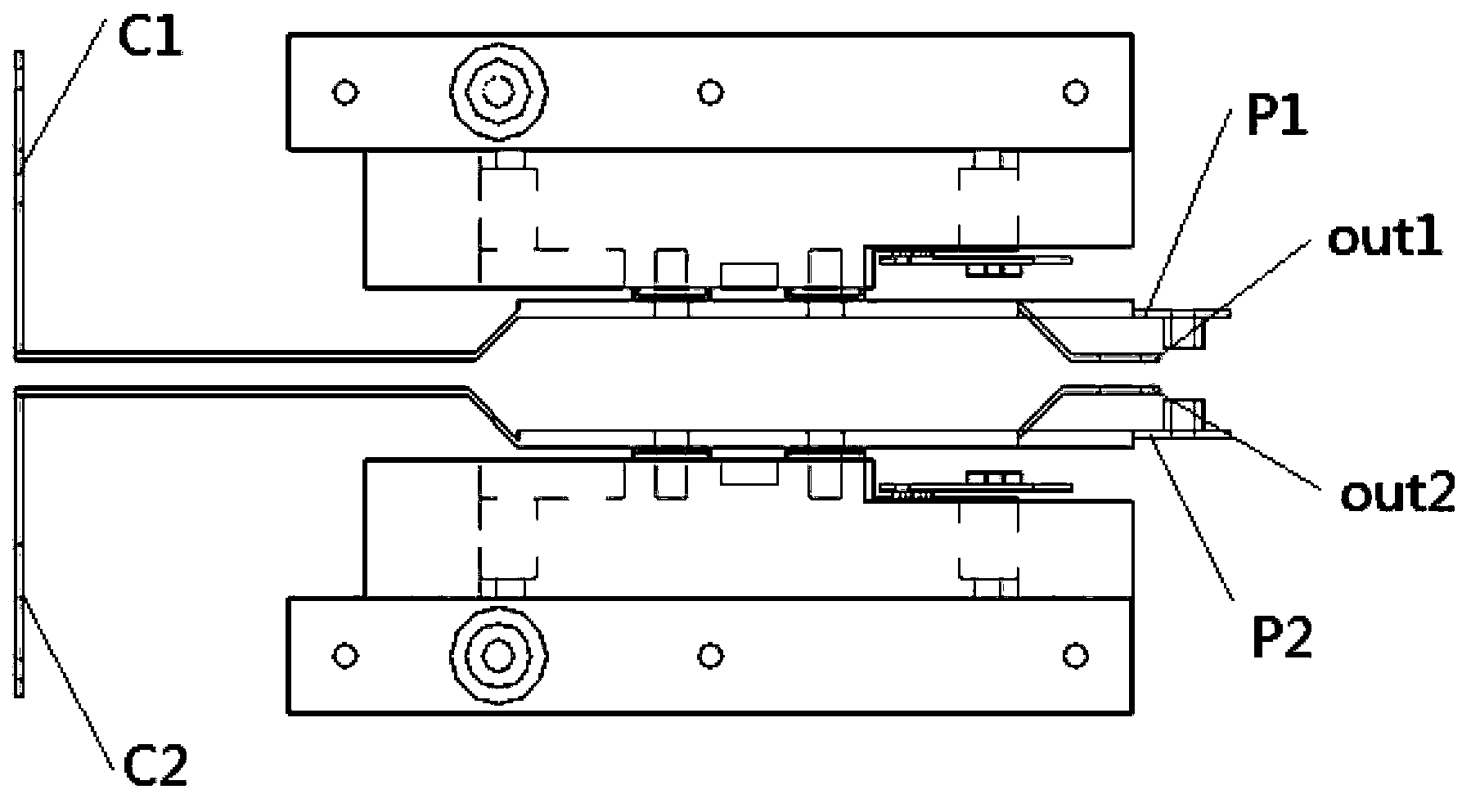

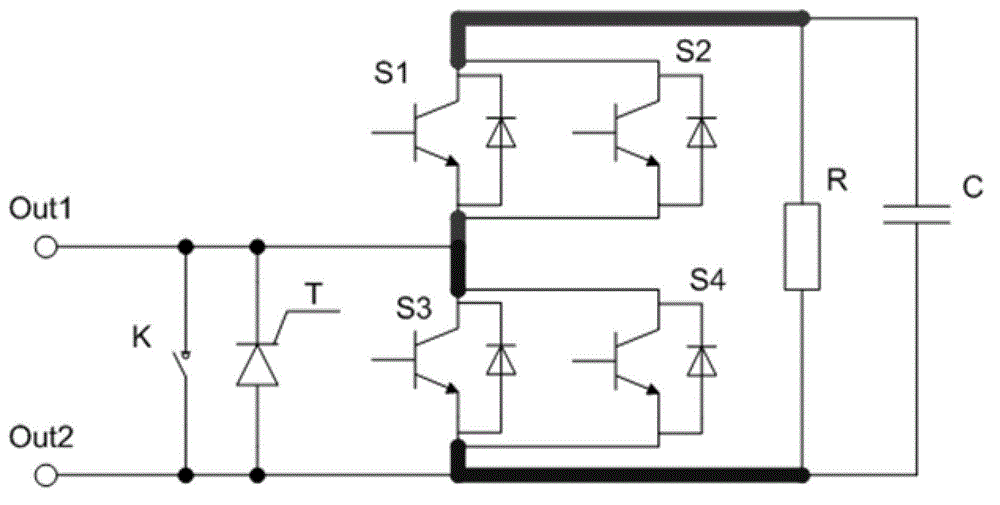

Parallel IGBT power unit

ActiveCN103354414ASolve uneven flowGuaranteed flow uniformityPower conversion systemsCapacitanceBusbar

The invention discloses a parallel IGBT power unit. The parallel IGBT power unit comprises an upper bridge IGBT module and a lower bridge IGBT module. Each IGBT module includes at least two IGBT modules which are connected in parallel, and further comprises an upper busbar and a lower busbar which are correspondingly connected with the two IGBT modules. The upper busbar is provided with a first leading-out terminal for connecting with a first main busbar and a first capacitor connecting terminal for connecting with a capacitor. The lower busbar is provided with a second leading-out terminal for connecting with a second main busbar and a second capacitor connecting terminal for connecting with a capacitor. According to the parallel IGBT power unit, the two IGBT modules and the two busbars which have identical structures and are correspondingly connected with the modules respectively are adopted; the leading-out terminals for connecting with the main busbars and the capacitor connecting terminals for connecting with the capacitors on the busbars are in conductive connection with docking connecting terminals and capacitor connecting terminals at corresponding positions of the IGBT modules of corresponding busbars by using copper bars in identical lengths; and since busbars connecting the IGBTs are identical in length, the current-sharing performance of the parallel IGBT modules on the busbars is guaranteed, and a problem of uneven current during parallel connection of the IGBTs is solved.

Owner:河南许继电力电子有限公司 +2

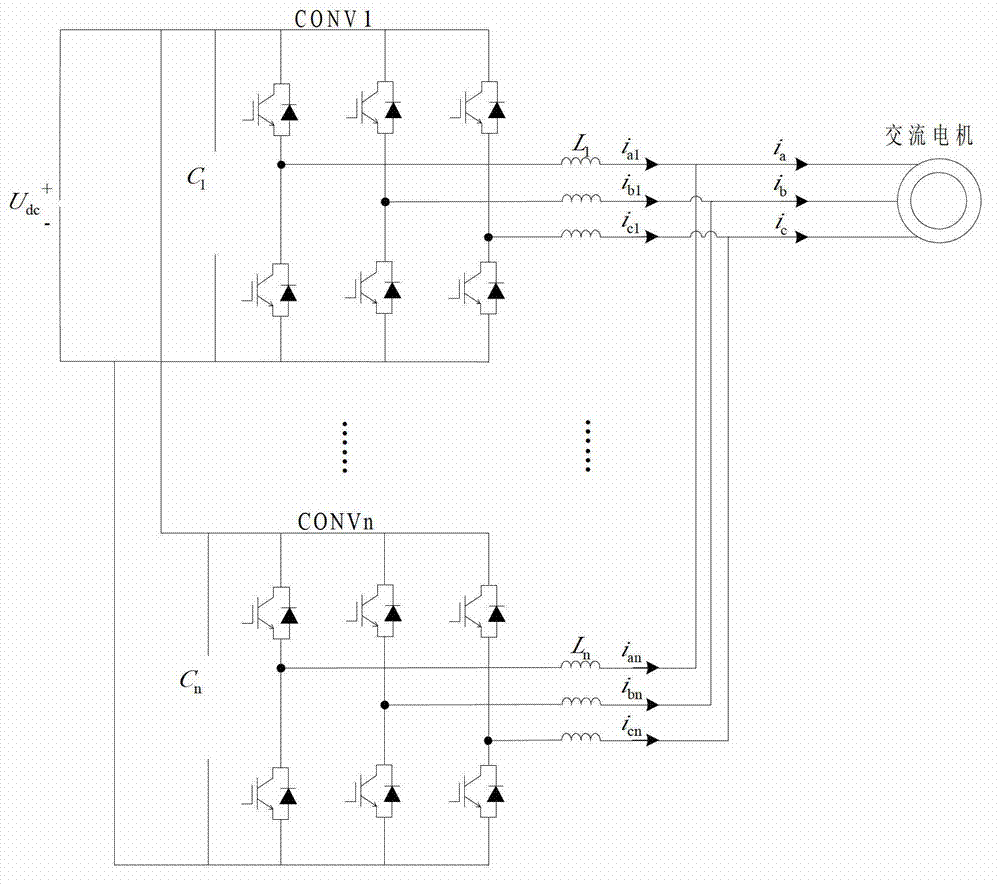

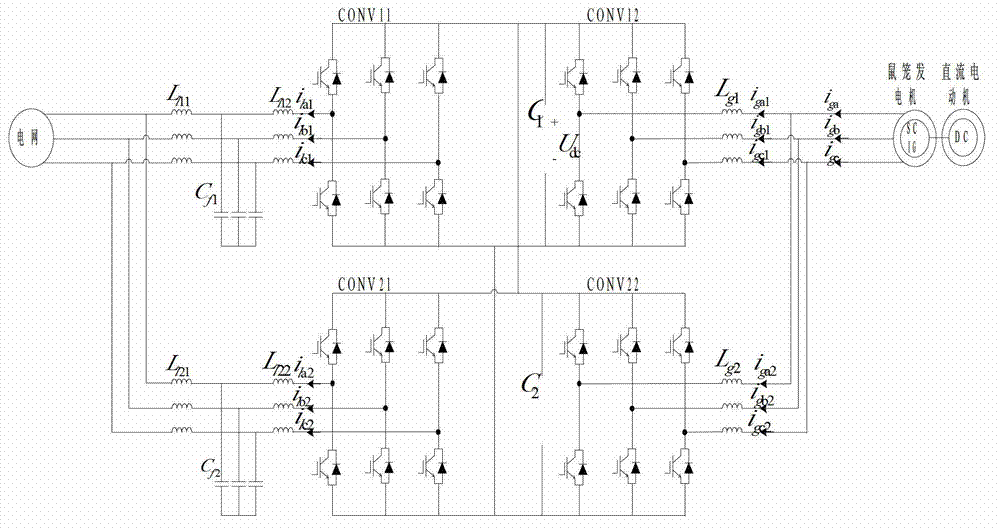

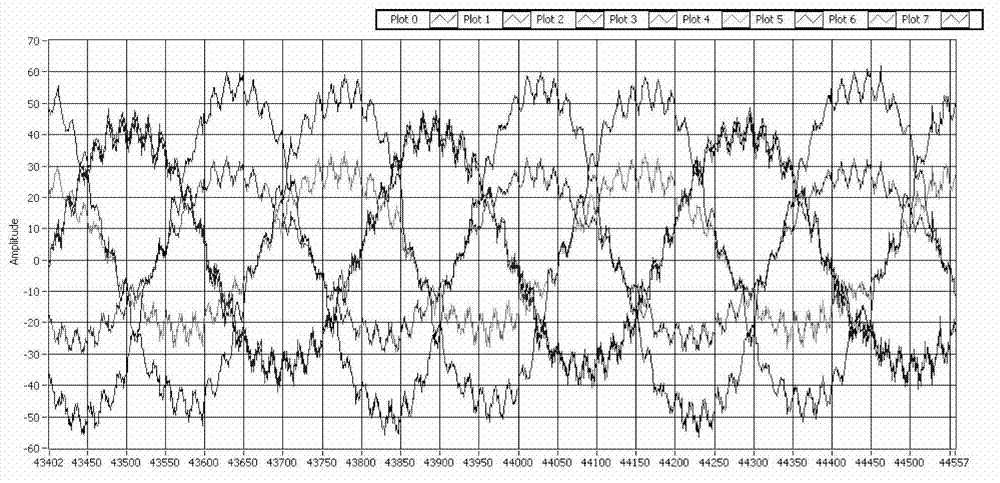

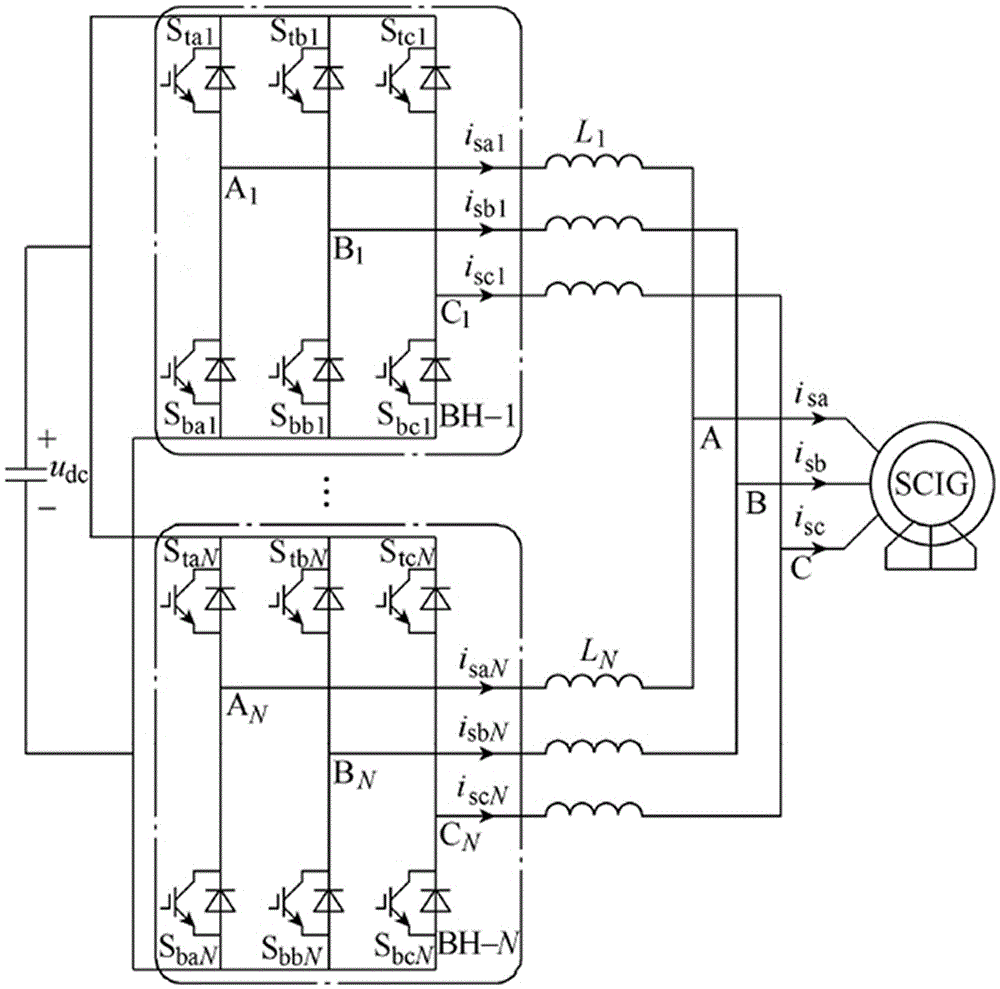

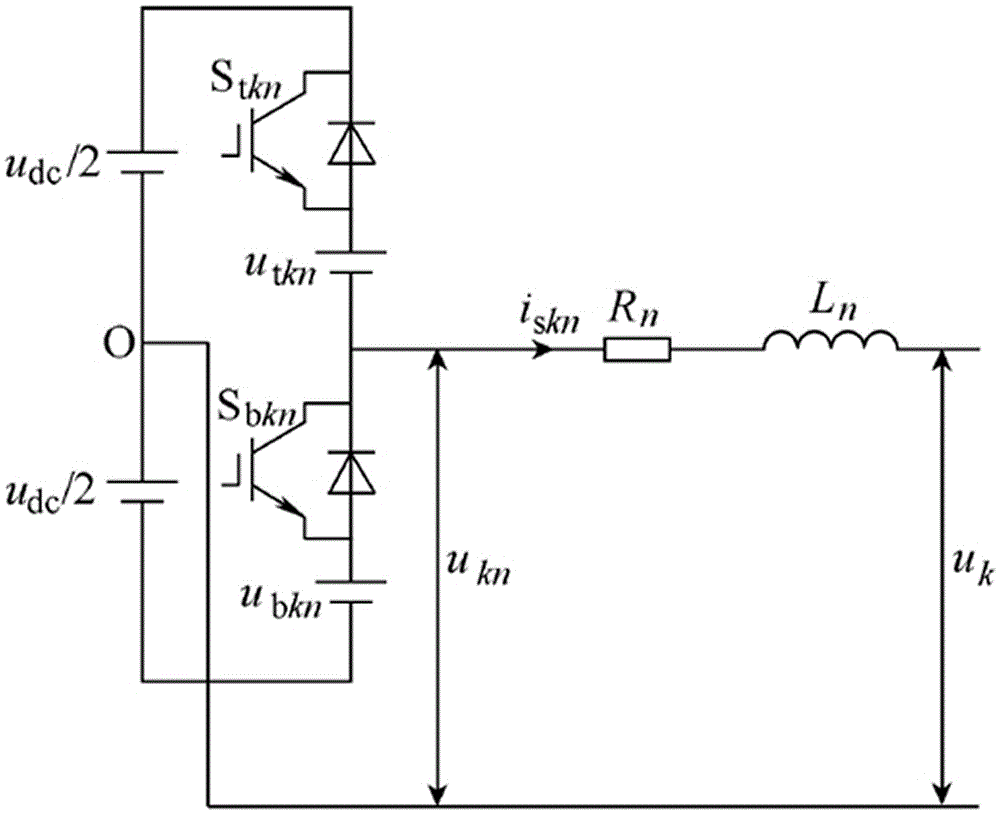

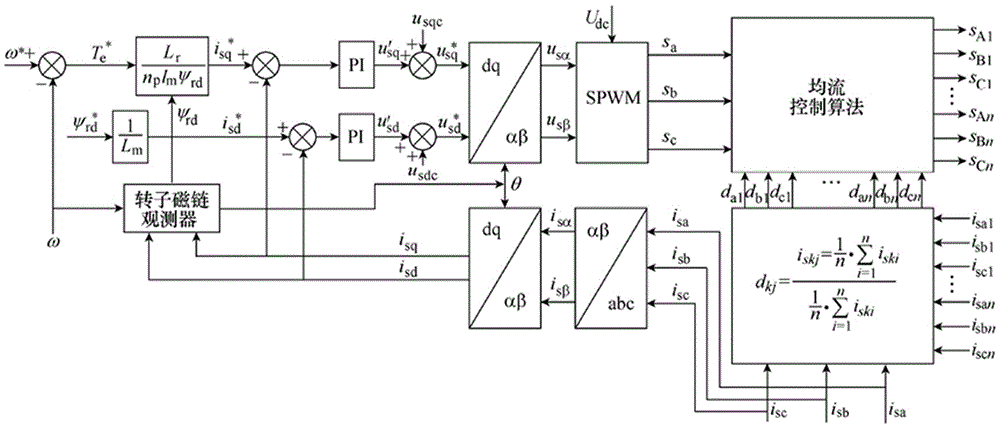

Current non-equalizing control method of converter multi-unit parallel system

ActiveCN102891612ASolve uneven flowExtended service lifeAc-dc conversionAc-ac conversionMulti unitCompensation effect

The invention provides a current non-equalizing control method of a converter multi-unit parallel system. The phenomenon of current non-equalizing during converter multi-unit parallel connection is avoided by delaying a falling edge of a control pulse, namely delaying switch-off. When a certain phase of current of a certain converter is low, the aim of increasing the phase of current is fulfilled by delaying the falling edge of the phase of control pulse. When n three-phase pulse width modulation (PWM) converters are connected in parallel, corresponding phases of (n-1) three-phase PWM converters are required to be compensated. The delay time of the falling edge of the control pulse is a current function. In order to achieve an online real-time dynamic compensation effect, a fixed delay time compensation method is employed, a current compensation effect is observed, and compensation time is continuously modified, so a relation curve of the compensation time and current is determined.

Owner:SHANGHAI JIAODA INTELLECTUAL PORPERTY MANAGEMENT CO LTD +1

Dust removal airway

InactiveCN103861386AUniform air distributionSolve uneven flowDispersed particle separationExhaust valveElectrical and Electronics engineering

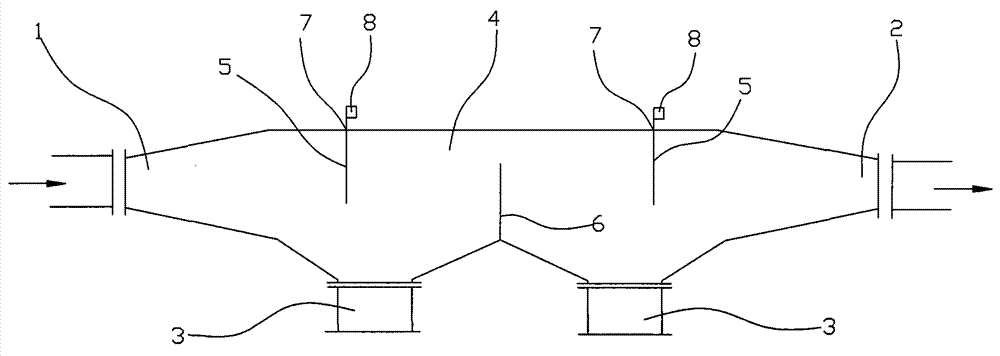

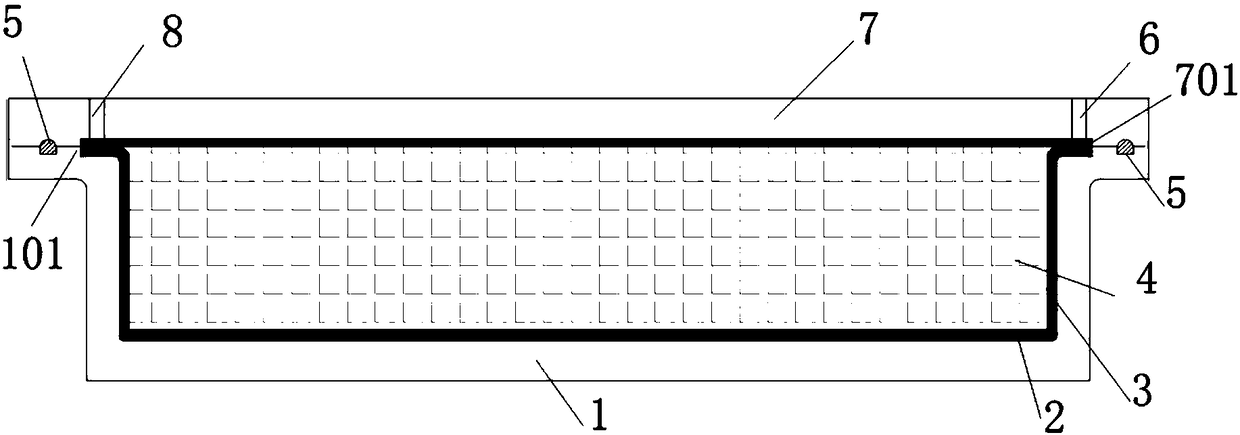

The invention provides a dust removal airway comprising an airflow channel, an air distributing hole, an exhaust hole, upper baffle plates, lower baffle plates and a dust discharge hole, wherein the air distributing hole and the exhaust hole are formed in the positions at two ends of the airflow channel; the upper baffle plates are vertically arranged above the inner wall of the airflow channel; the lower baffle plates are vertically arranged and the dust discharge hole is vertically formed below the inner wall of the airflow channel; the dust discharge hole is formed below the upper baffle plates; the air distribution hole and the exhaust hole are conical; the large ends of the conical air distribution hole and the exhaust hole are communicated with the airflow channel. The dust removal airway disclosed by the invention comprises a plurality of upper baffle plates and lower baffle plates which are arranged at intervals; the even zigzag dust removal airway is provided, and the air distribution hole and the exhaust hole are formed in conical shapes, so that air can be effectively and evenly distributed.

Owner:周汉忠

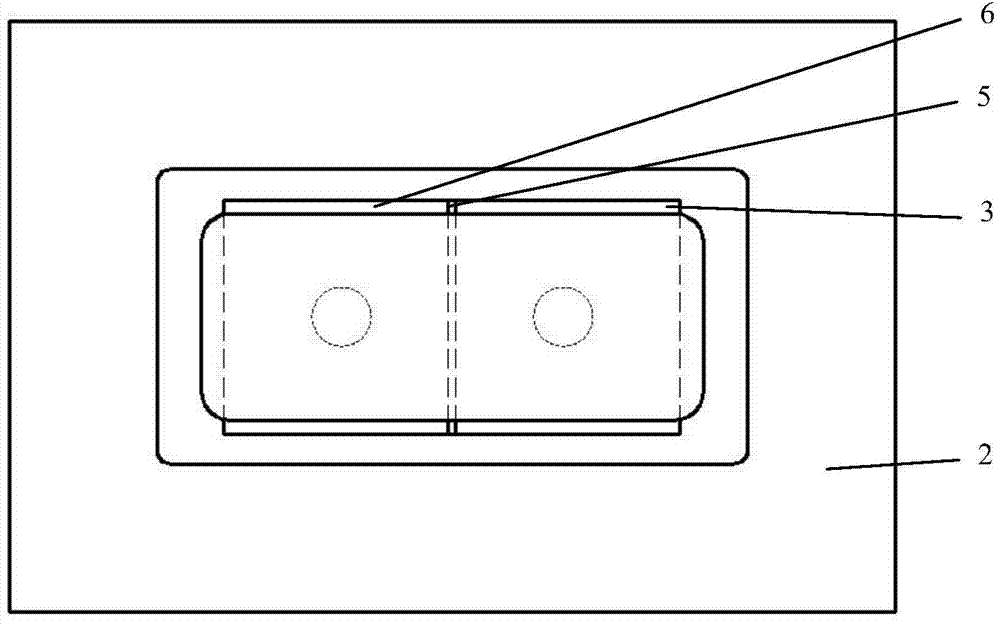

Fiberglass/PP composite fiber cloth assisting resin transfer molding (RTM) process method and molding mold

The invention relates to a fiberglass / PP composite fiber cloth assisting resin transfer molding (RTM) process method and a molding mold. The adopted mold comprises a lower mold, foam, a sealing rubberstrip, a glue injection opening, an upper mold and a vacuumizing opening. In a process, fiberglass and PP material are woven into composite fiber cloth according to required gram weight first, then needed carbon fibers or fiberglass cloth are / is laid on the surface of a mold cavity, then the fiberglass / PP composite fiber cloth is laid, the foam processed through computer numerical control (CNC) is put in, and then according to symmetrical laminates, fiberglass / PP composite fiber cloth, carbon fibers or fiberglass cloth are laid. Finally, mold assembly, vacuumizing and resin injection are conducted, after product solidification, the molding mold is opened, and a product is taken. According to the fiberglass / PP composite fiber cloth assisting resin transfer molding (RTM) process method andthe molding mold, the fiberglass / PP composite fiber cloth is adopted, PP felt and the foam are attached during material laying, the PP felt is fluffy, thus channels are provided for resin flowing, theproblem of uneven resin flowing on the surface of the foam is solved, the foam does not need slotting or punching, and machining cost of the foam is lowered greatly.

Owner:上海晋飞碳纤科技股份有限公司

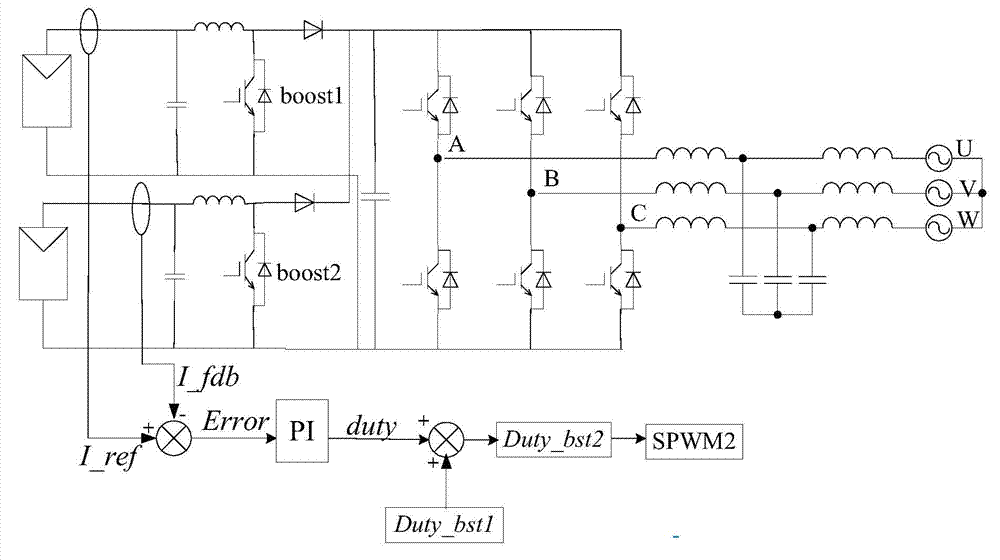

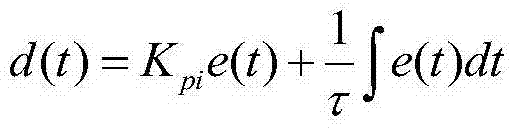

Current equalizing control method of double BOOST circuits of two-stage photovoltaic power generation system

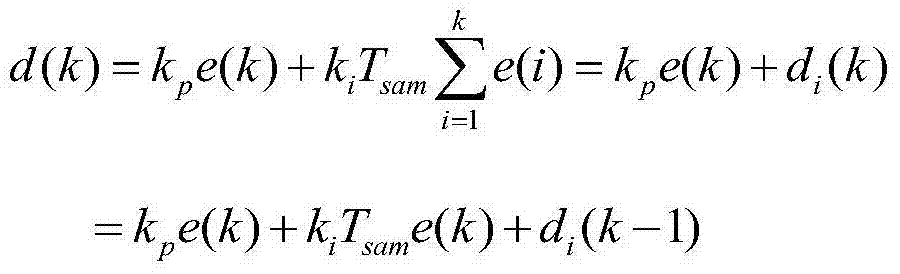

InactiveCN104283505ASolve uneven flowAvoid the problem of overcurrent shutdownAc-dc conversionDc-dc conversionElectrical currentPhotovoltaic power generation

The invention discloses a current equalizing control method of double BOOST circuits of a two-stage photovoltaic power generation system. The currents of the two BOOST circuits are sampled in real time through a system. The input current of one BOOST circuit serves as the reference, a duty ratio increment is worked out through the two BOOST input currents by means of a PI regulator, the on-off time (namely the duty ratio) of a switching device of the other BOOST circuit is corrected with the increment, and thus the currents of the two BOOST circuits are made equal. The problem that the currents of the two BOOST circuits running in parallel connection are unequal is solved, and thus the problems that the service life of a device with an overcurrent circuit becomes shorter, and an inverter is shut down due to overcurrent are avoided.

Owner:XJ ELECTRIC +1

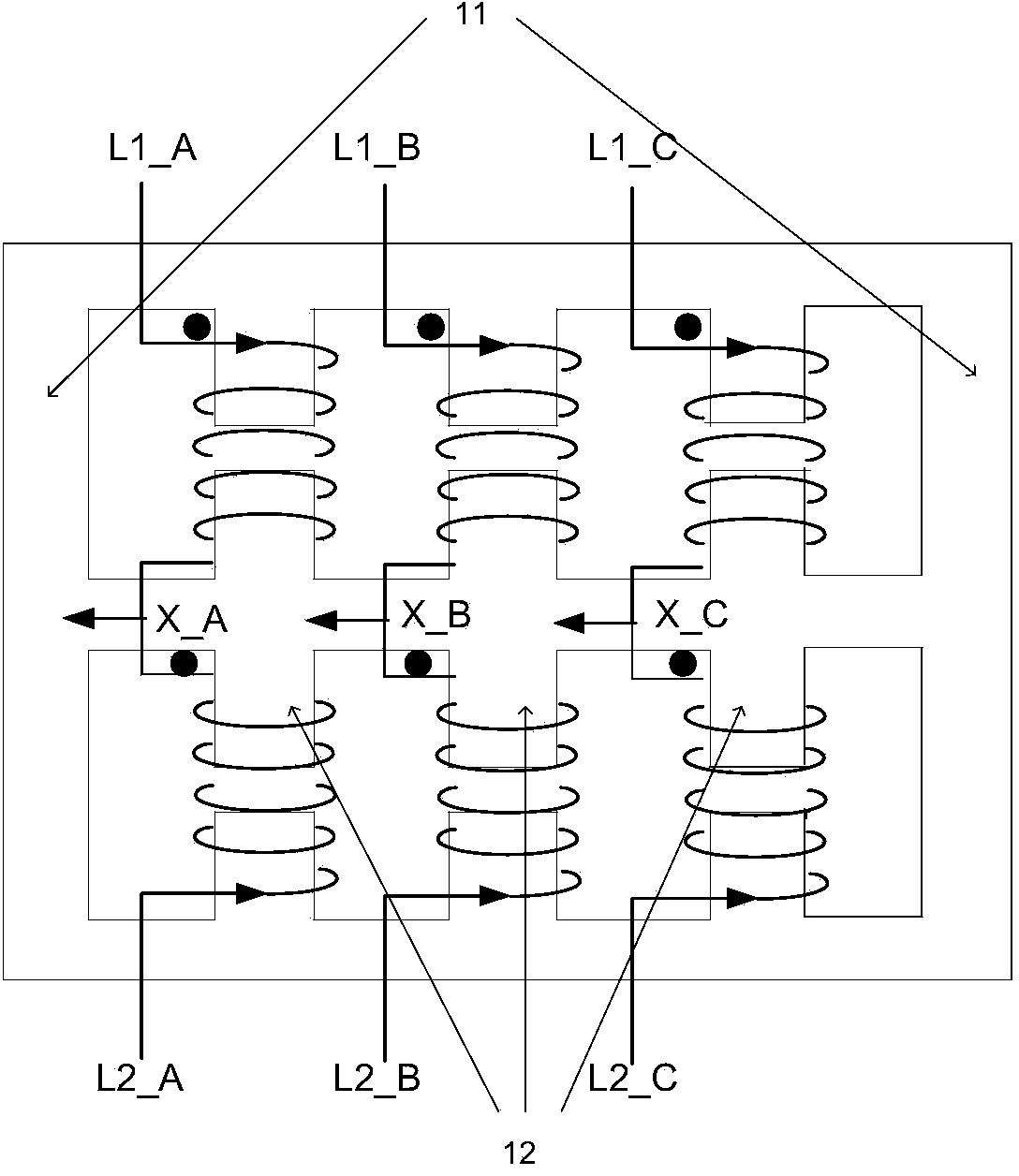

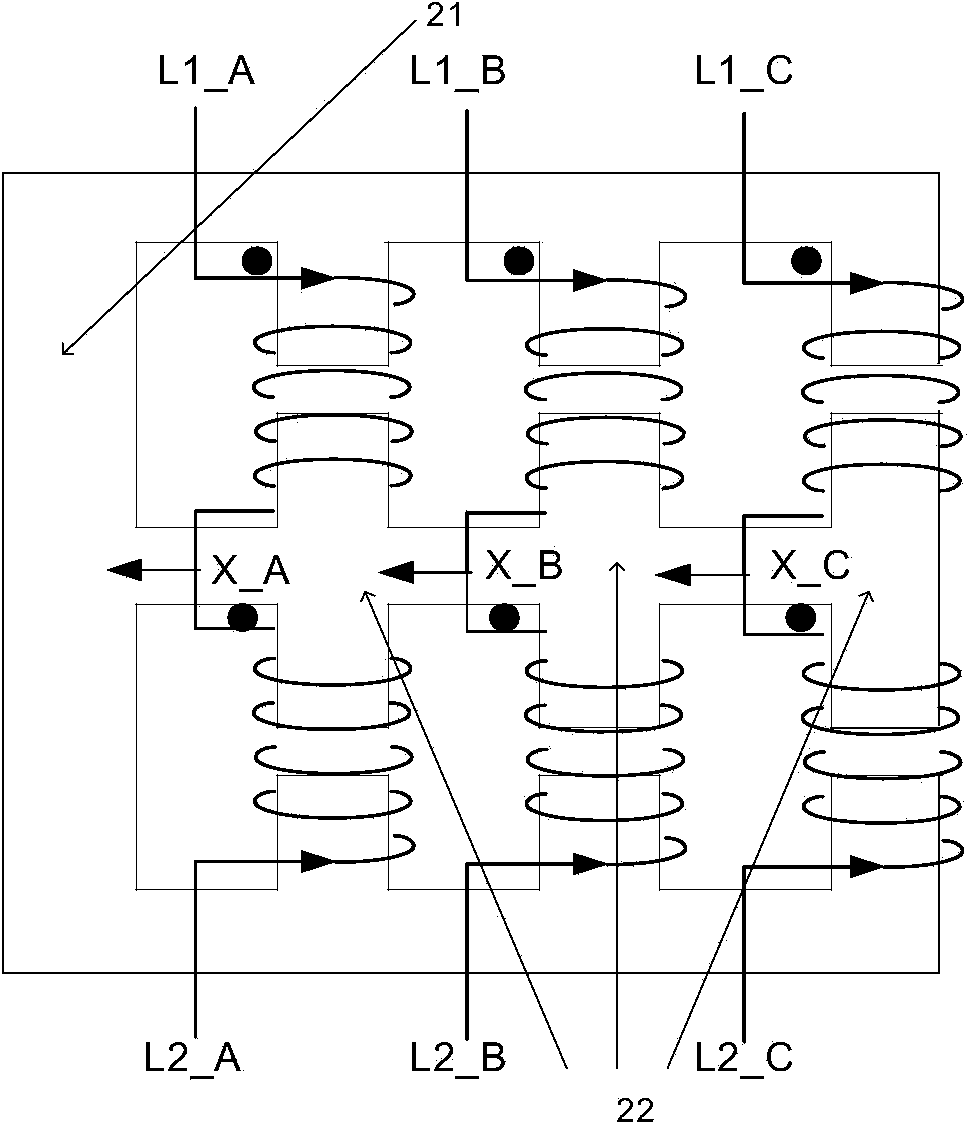

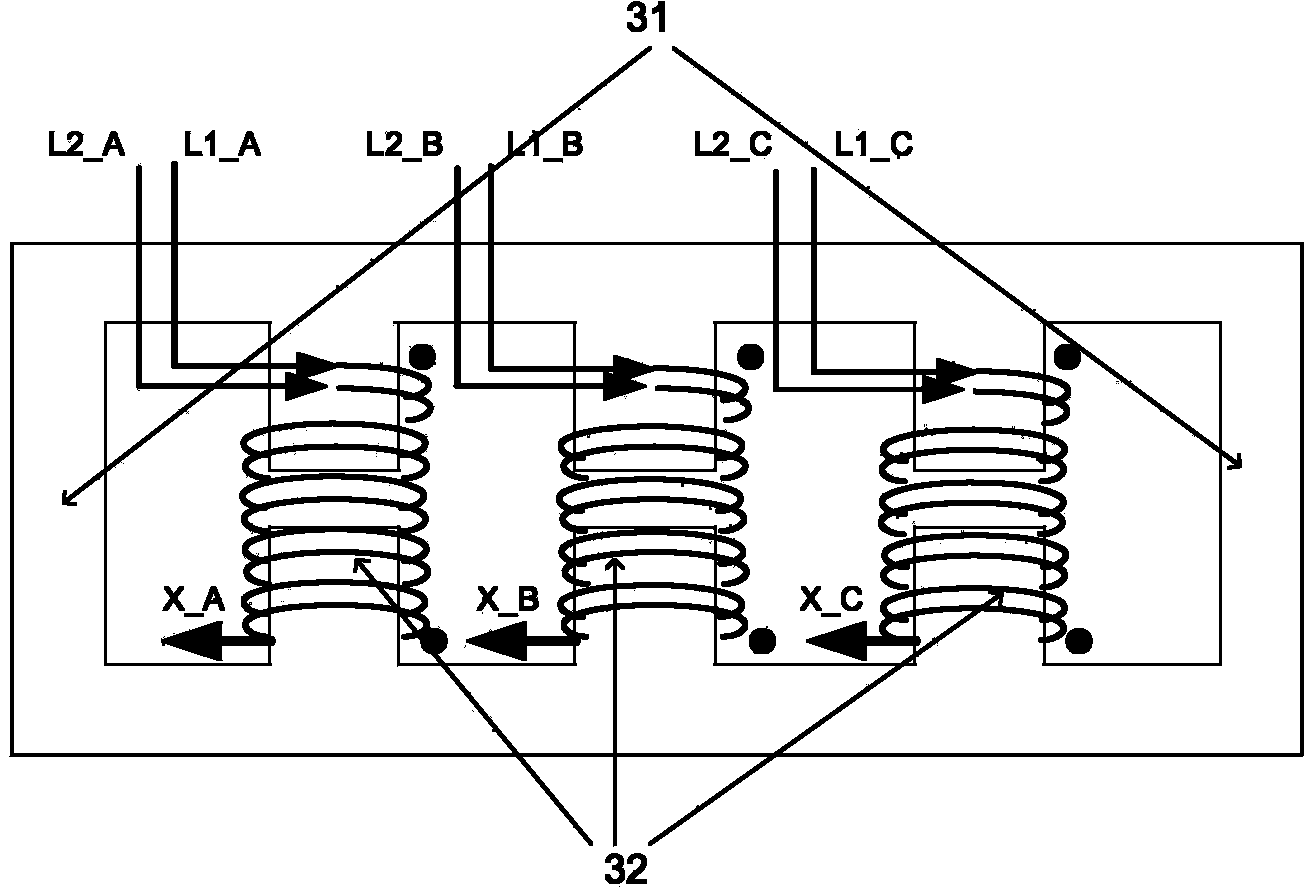

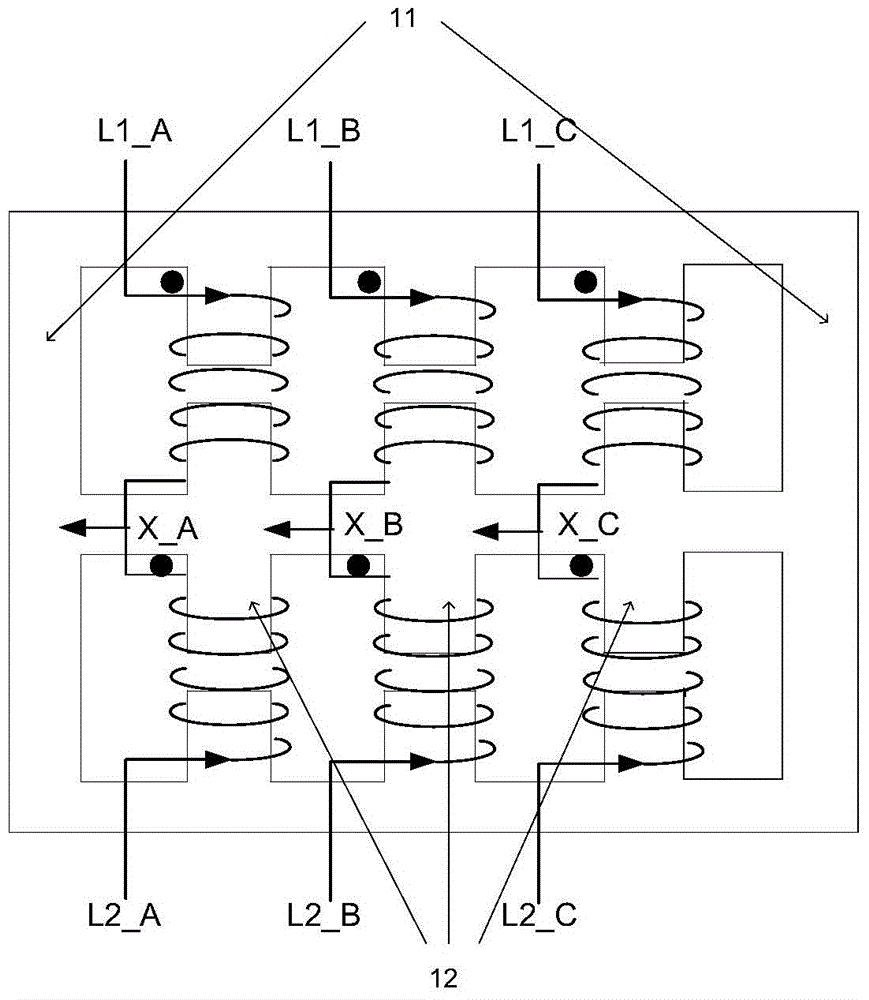

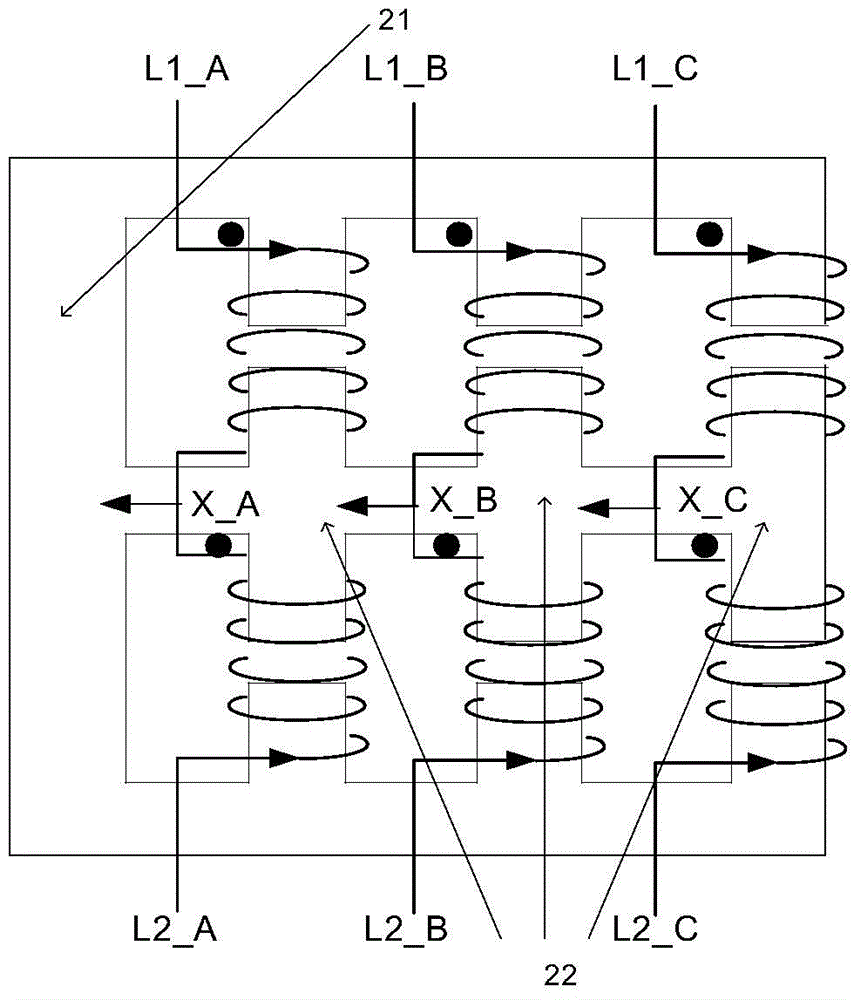

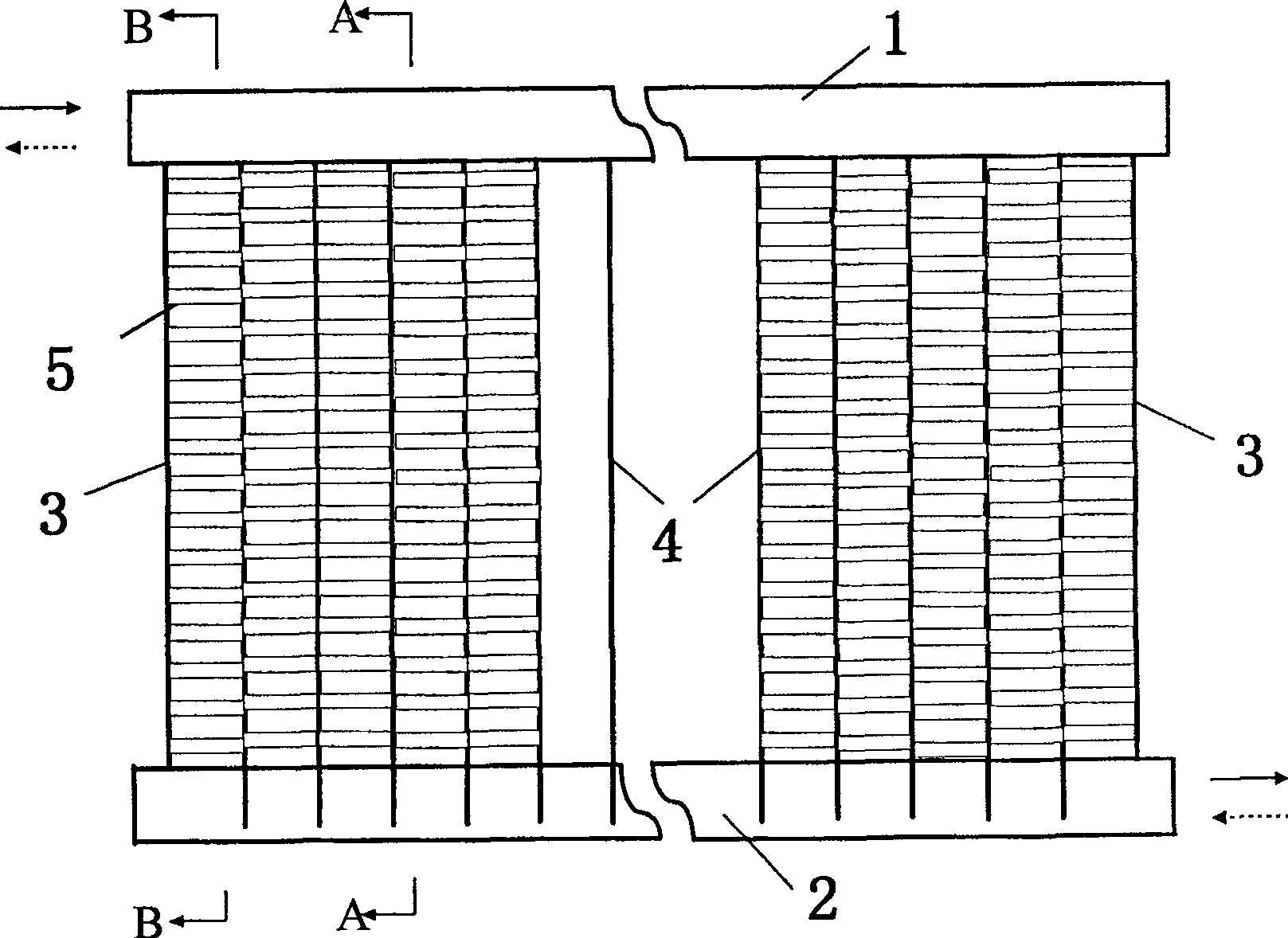

Three-phase coupling reactor and converter

ActiveCN104078195AReduce volumeLow costTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresNuclear engineeringCoupling

The invention discloses a three-phase coupling reactor and a converter. The three-phase coupling reactor comprises an iron core and six windings, the iron core comprises an upper iron yoke, a lower iron yoke, at least one first iron core post without a gas gap and three second iron core posts with gas gaps, wherein the first iron core post and the second iron core posts are located between the upper iron yoke and the lower iron yoke; two windings wind each second iron core post, and the ends of the two windings on the same second iron core post in different names are connected in a short circuit mode. According to the three-phase coupling reactor and converter, the zero sequence circulating current impedance of the converter system is increased through the coupling between windings, and accordingly the problem of uneven current of parallel power modules due to zero sequence circulating current is effectively solved.

Owner:SUZHOU INOVANCE TECH CO LTD

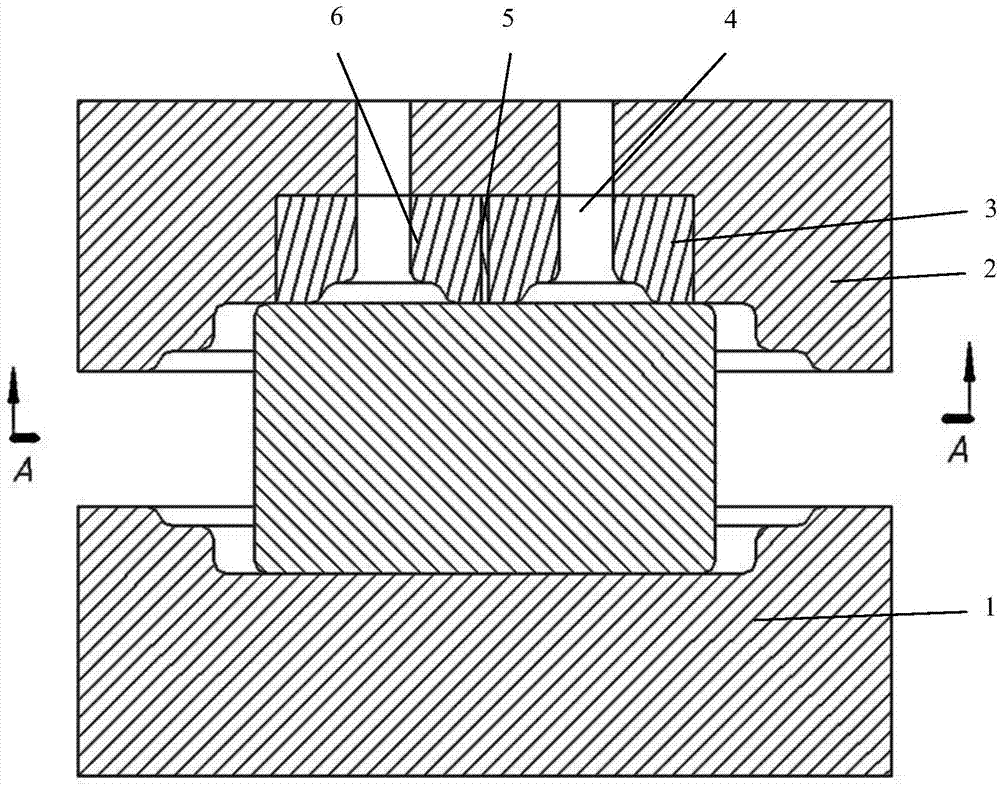

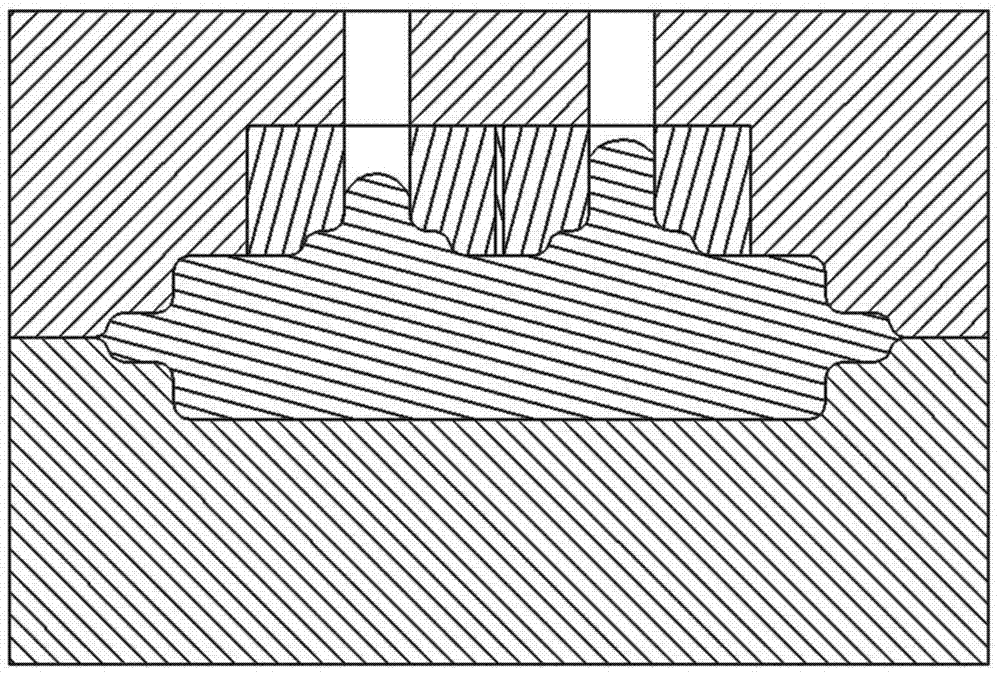

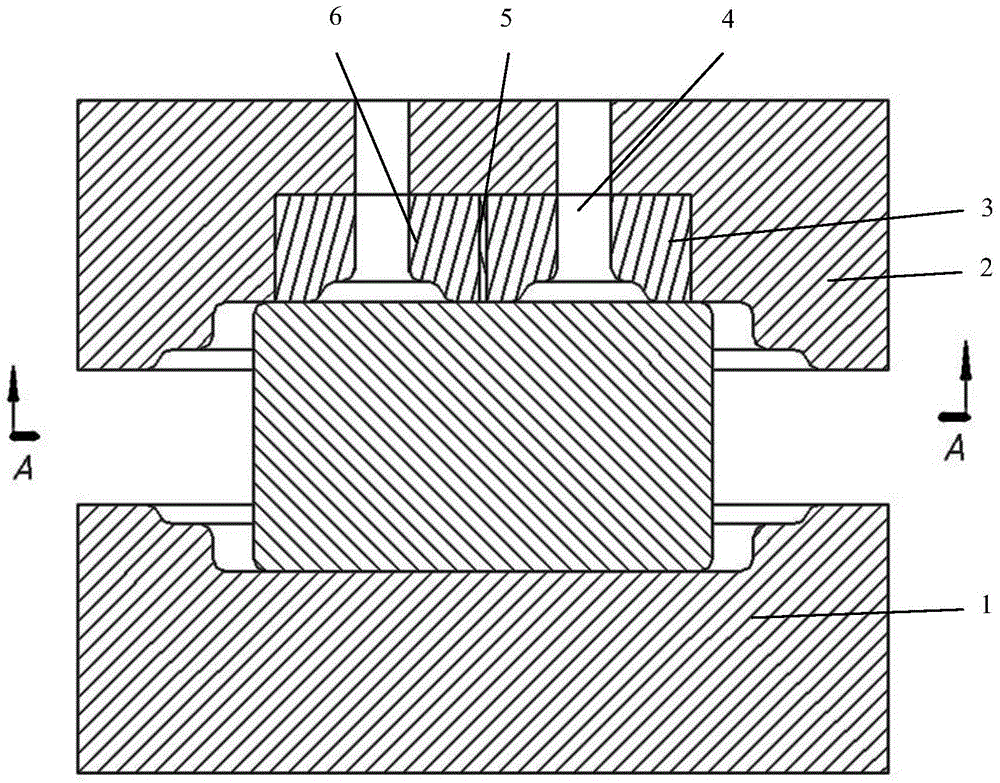

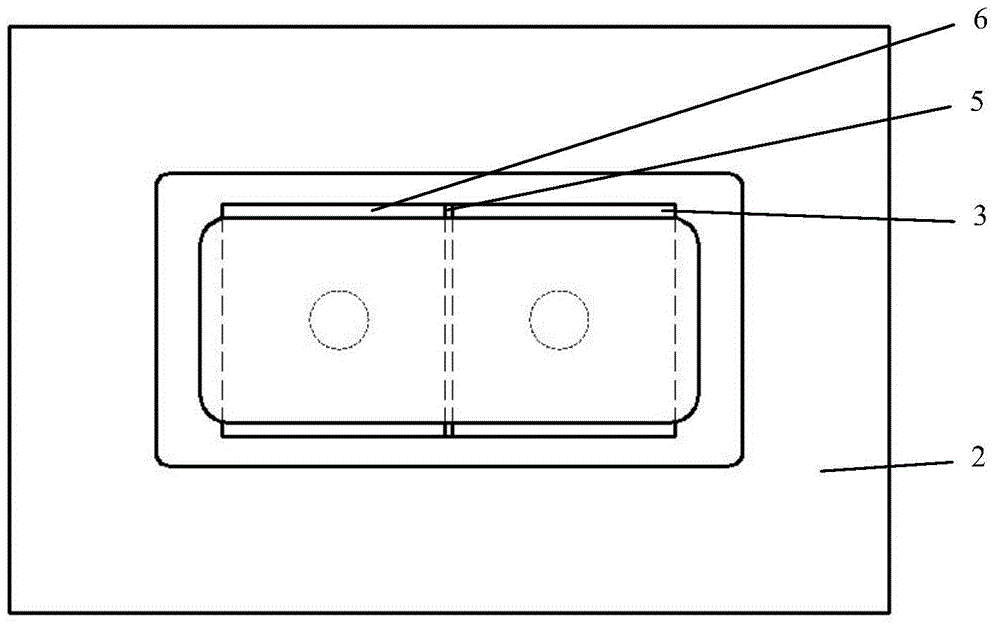

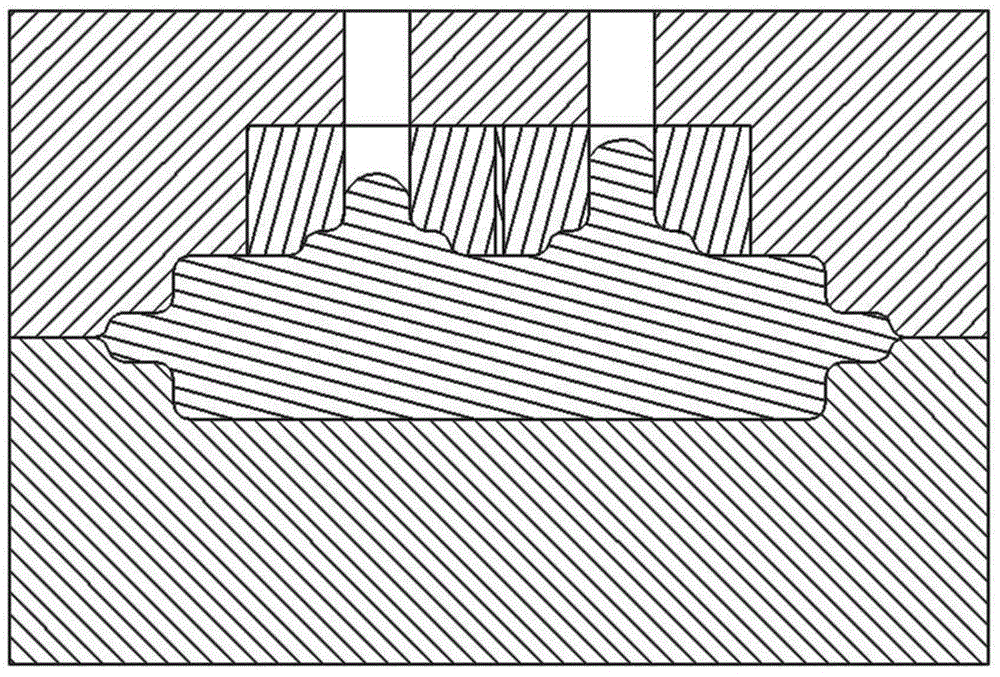

Die forging piece forming device and method based on differential temperature control

ActiveCN103878284ASolve uneven flowFix production issuesForging/hammering/pressing machinesTemperature controlHeater Rod

The invention discloses a forging piece forming method based on differential temperature control. The method comprises the steps of placing a whole forging piece into a heating furnace, heating the forging piece to the temperature ranging from 600 DEG C to 800 DEG C, keeping the temperature for 2 hours to 3 hours, taking the forging piece out of the heating furnace, placing the forging piece inside a die cavity, warping a local low-temperature area by heat preservation cotton, placing the forging piece into the furnace again, and taking out the forging piece when the whole temperature of the forging piece is increased to range from 1000 DEG C to 1020 DEG C for forging, wherein at the moment, the temperature of the portion wrapped by the heat preservation cotton is 50 DEG C to 100 DEG C slightly lower than that of the other portions; placing a die forging piece forming device into the heating furnace, heating the die forging piece forming device to the temperature ranging from 200 DEG C to 250 DEG C, inserting a heating stick into a heating hole in an upper die insert, partially heating the die forging piece forming device to the temperature ranging from 350 DEG C to 400 DEG C, taking out the die forging piece forming device for forging, and utilizing the die forging piece forming device for forging and forming the forging piece. According to the forging piece forming method based on the differential temperature control, the forging piece forming filling rate is high, the service life of the die is long, grains of the forging piece are fine, the forming force of the die forging piece can be reduced to the great extent, and the service life of the hot-forging die is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

Multi-inverter parallel current-sharing control method

InactiveCN106887967ASolve the circulation problemSolve uneven flowAc-dc conversionPower inverterClosed loop

The invention discloses a multi-inverter parallel current equalization control method, which comprises four parts: multi-inverter parallel circuit, delay pulse width compensation, SPWM modulation and current equalization control. The circulating current problem existing in the parallel system is solved, and the uneven current problem of the output current of the inverter is solved by pulse delay compensation. The advantage of the pulse modulation method being the closed-loop compensation method is that it can realize automatic compensation and can adapt to the multi-inverter parallel system with different parallel numbers. Therefore, by changing the pulse modulation method to SPWM modulation method, the circulating current in the parallel system is effectively suppressed. question.

Owner:范洪国

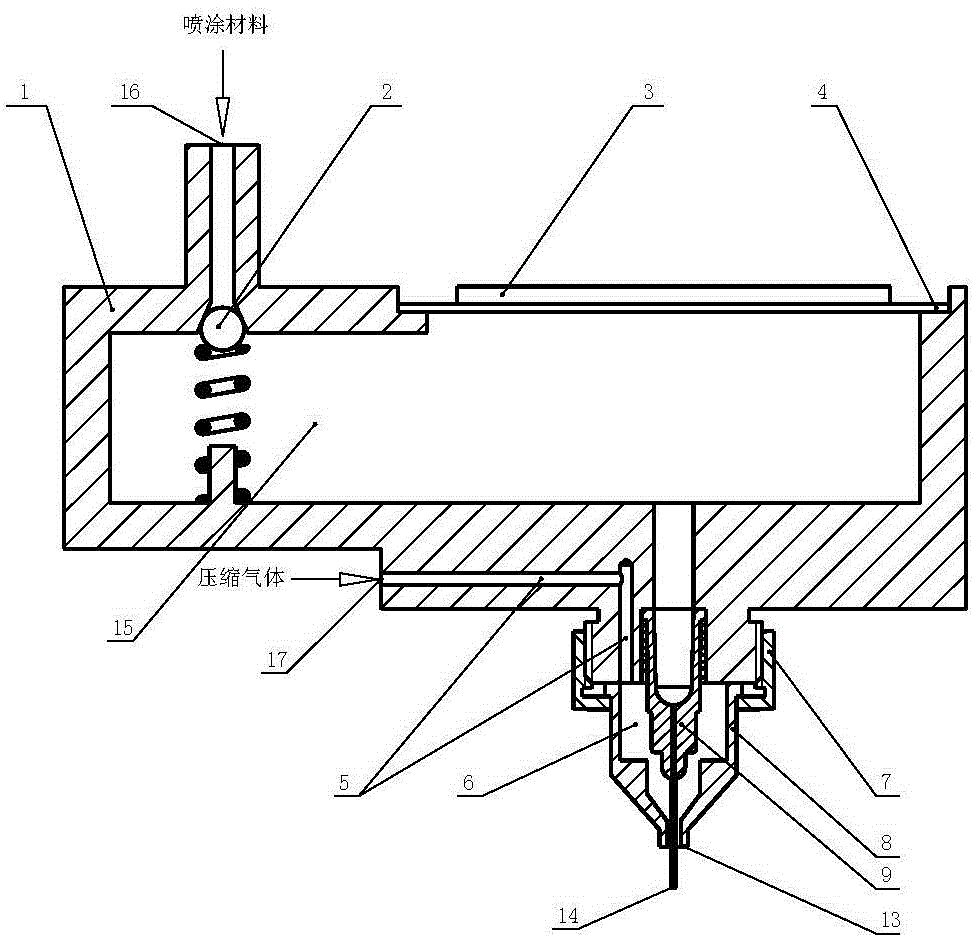

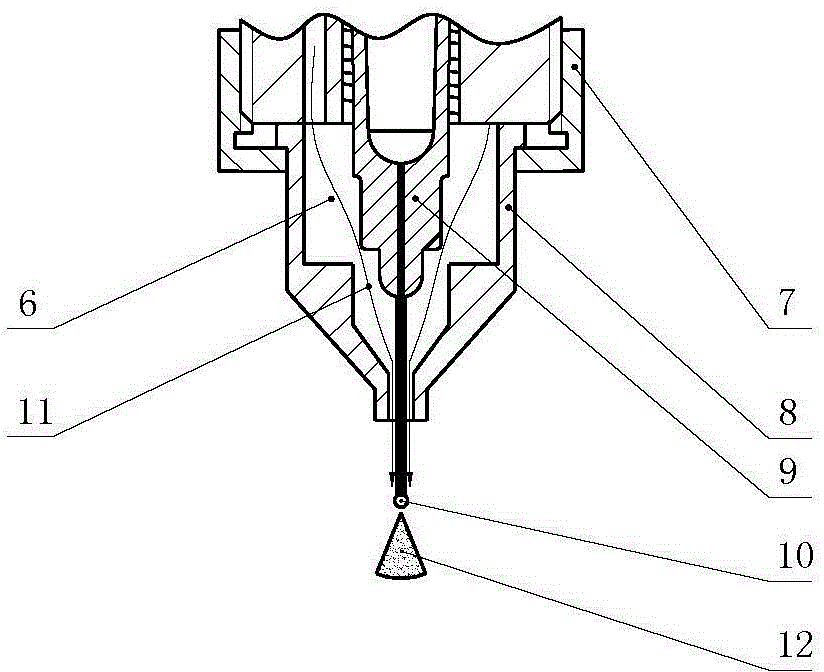

Precision spraying valve

InactiveCN104668126ASolve uneven flowSolve for uniformityLiquid spraying apparatusEngineeringMechanical engineering

The invention relates to a precision spraying valve with a piezoelectric wafer serving as a driving source. The precision spraying valve comprises a cavity, a one-way valve, the piezoelectric wafer, a needle head, a gas hood and the like. The piezoelectric wafer serving as the driving source presses spraying materials into the needle head, compressed gas in the gas hood descends to disperse the spraying materials into tiny liquid beads to be deposited on the surface of a workpiece. Since a traditional needle valve is not used for controlling spraying or spraying stop of the spraying materials, when the precision spraying valve is used for precision spraying, large edge allowance caused by factors such as eccentricity and form and location tolerance of the needle valve is eliminated.

Owner:CHANGZHOU GAO KAI PRECISION MACHINERY CO LTD

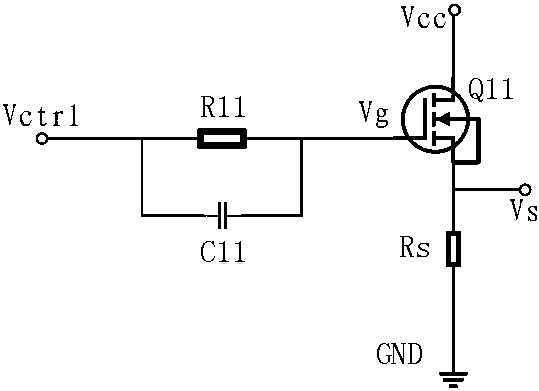

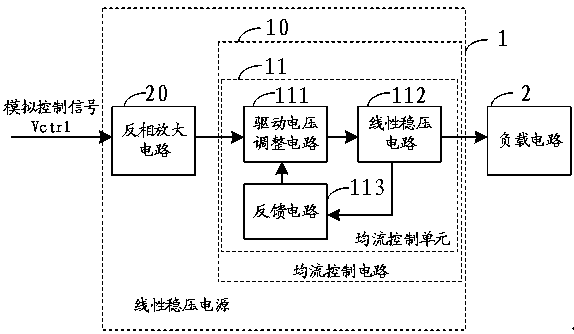

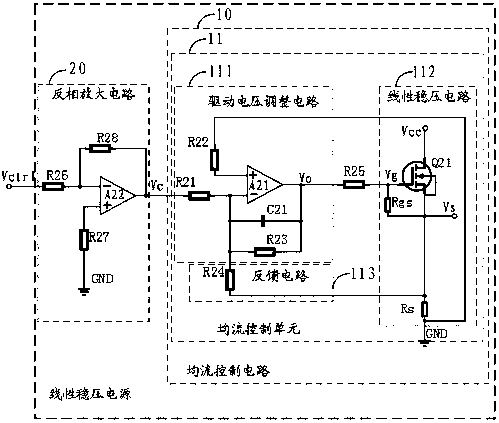

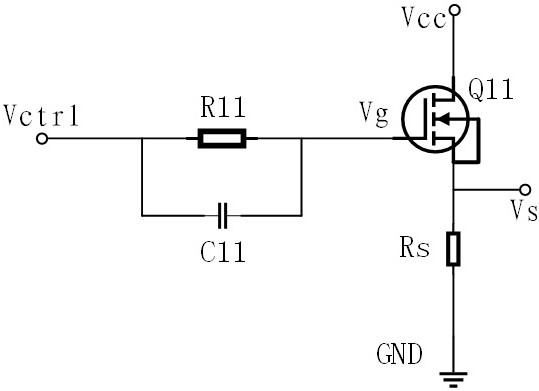

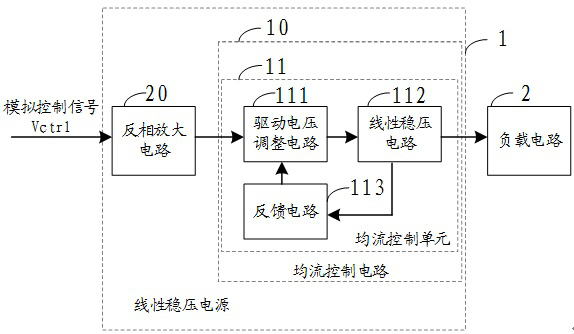

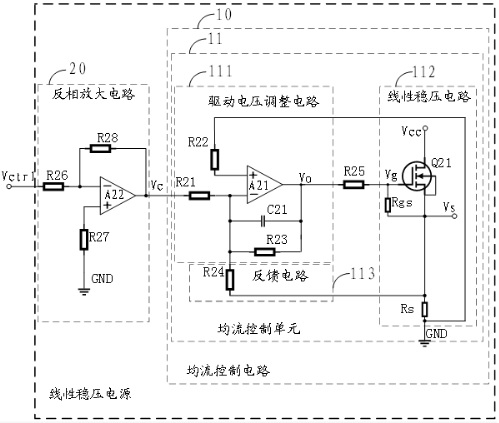

Linear regulated power supply

ActiveCN111309089ASolve uneven flowImprove stabilityElectric variable regulationFeedback circuitsControl theory

The invention discloses a linear voltage-stabilizing power supply which comprises a current-sharing control circuit. The current sharing control circuit comprises at least one current sharing controlunit, and each current sharing control unit comprises a driving voltage adjusting circuit, a linear voltage stabilizing circuit and a feedback circuit, wherein the feedback circuit is used for feedingback the voltage of a current sampling resistor of the linear voltage stabilizing circuit to the driving voltage adjusting circuit; the driving voltage adjusting circuit adjusts the current of the analog control signal Vctrl input into the current sharing control unit according to the voltage value of the current sampling resistor and then outputs the adjusted current to the linear voltage stabilizing circuit, so that the output power of the linear voltage stabilizing circuit is adjusted by adjusting the voltage of the current sampling resistor. Due to the fact that the output power of the linear voltage stabilizing circuit of each current sharing control unit can be adjusted, the problem that the linear voltage stabilizing power supply is uneven in current is solved, stability of the linear voltage stabilizing power supply is improved, and the service life of the linear voltage stabilizing power supply is prolonged.

Owner:SHENZHEN CITY SIGLENT TECH

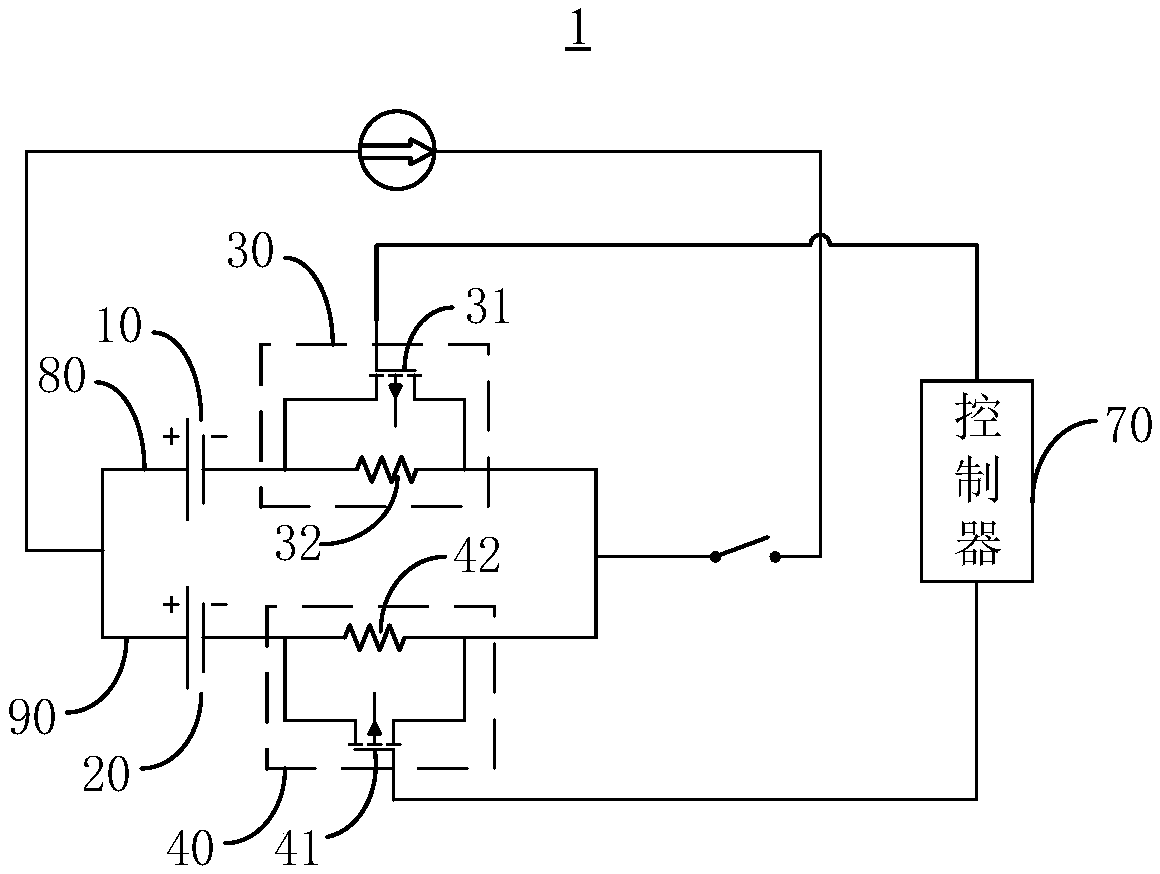

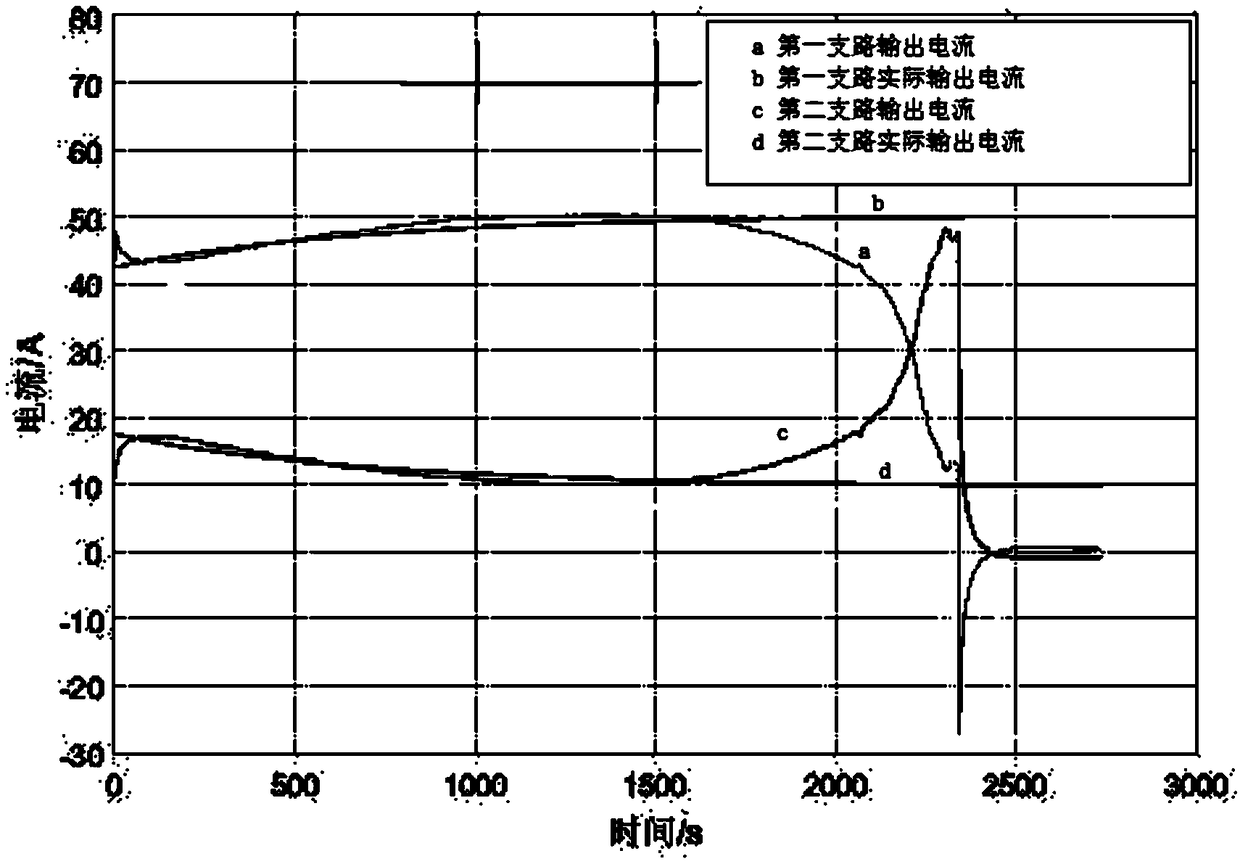

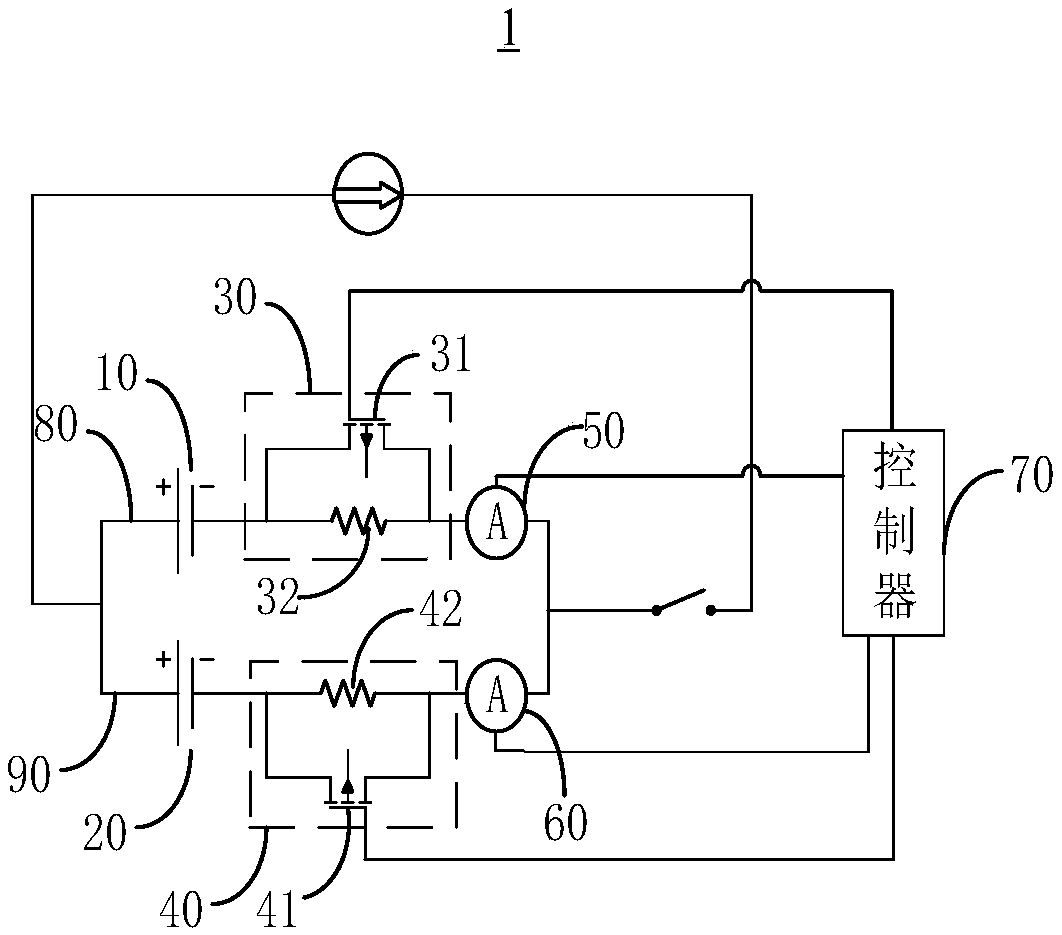

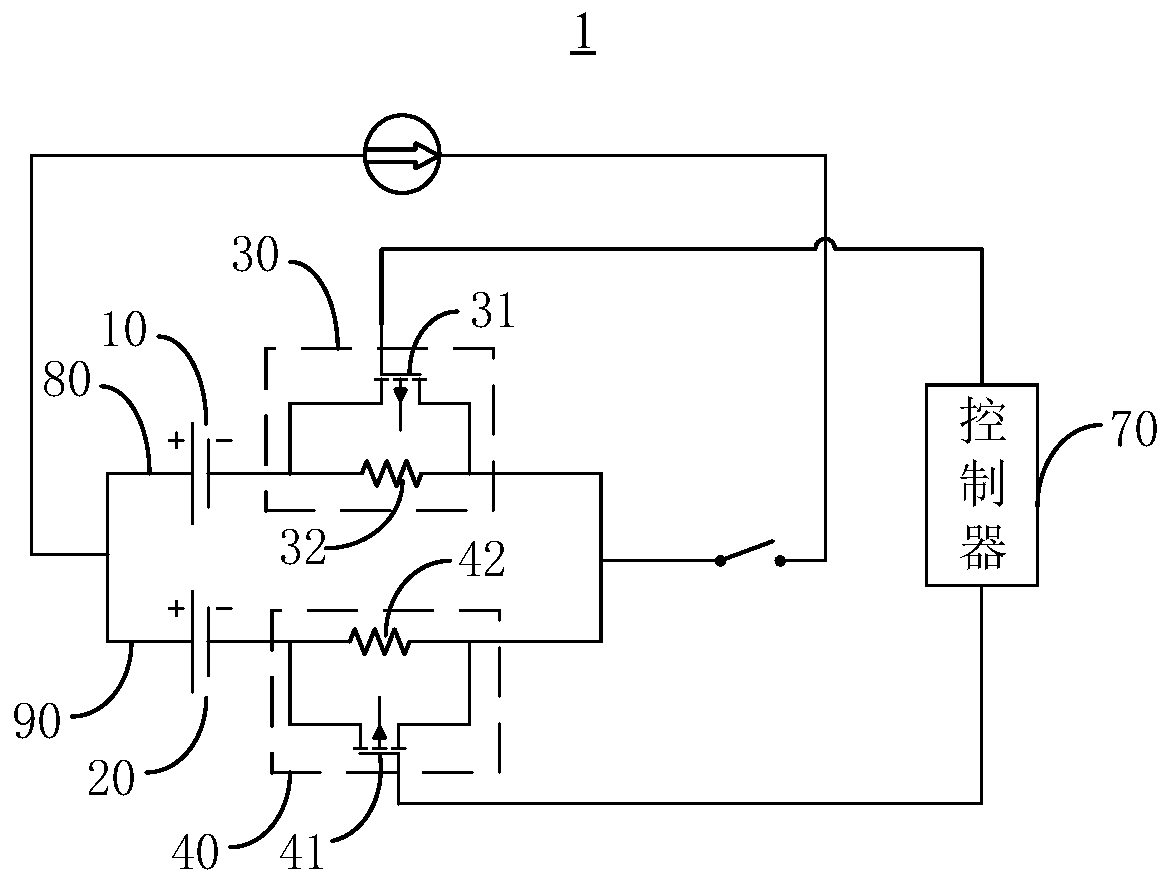

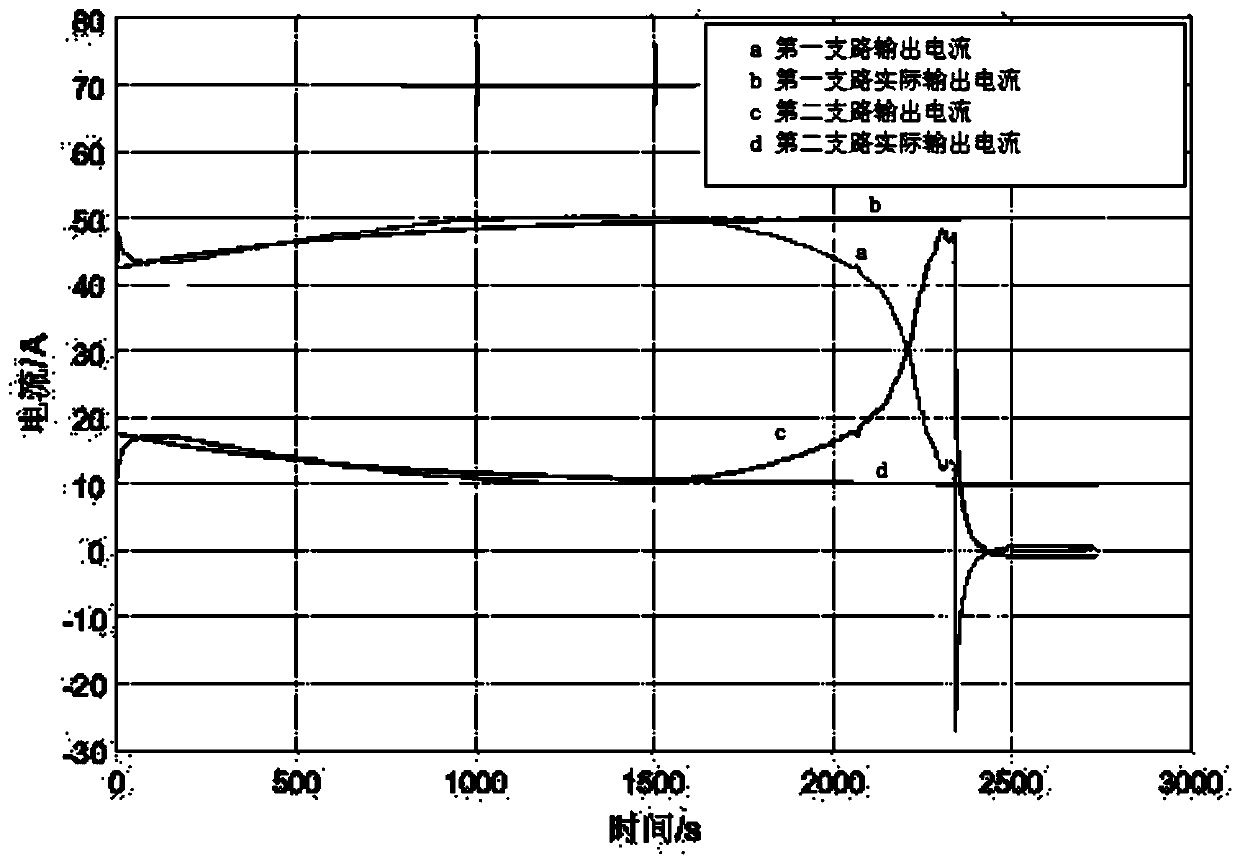

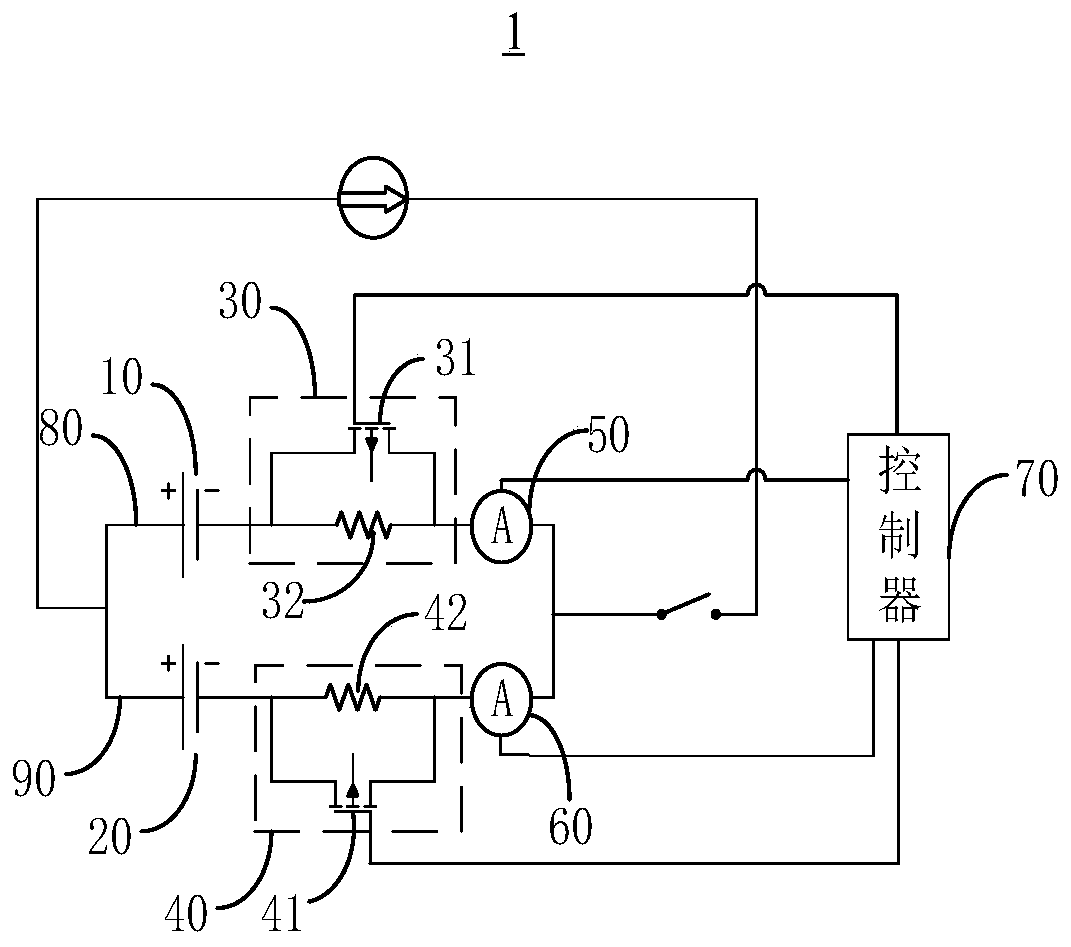

A battery system and an electric vehicle

ActiveCN109037802ASolve the circulation problemSolve uneven flowCells structural combinationVehicular energy storageElectricityElectrical resistance and conductance

The embodiment of the invention provides a battery system and an electric vehicle, and relates to the technical field of battery application. The battery system comprises at least two battery branchesand a controller, wherein each battery branch comprises a battery and a regulating unit, each battery branch is connected in parallel with each other, the battery in each battery branch is connectedin series with the regulating unit in each battery branch, and the controller is electrically connected with the regulating unit in each battery branch; The controller is used for regulating the resistance value of the regulating unit in each battery branch according to a pre-established mathematical model, thereby regulating the output current of each battery branch. The battery system and the electric vehicle provided by the embodiment of the invention can solve the problem that the output current distribution of each branch of the battery system is unbalanced.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +2

Interleaved parallel PFC control circuit and control method

ActiveCN101594049BSimple structureReduce complexityEfficient power electronics conversionPower conversion systemsControl signalWave shape

The invention discloses an interleaved parallel PFC control circuit for controlling parallel PFC circuits, wherein a sampling module samples alternating current input voltage, PFC bus voltage and PFC bus current; a processing module processes the sampling signals and a reference voltage signal to generate a control signal; a comparing module compares the control signal with a first carrier signaland a second carrier signal to generate a first duty ratio signal and a second duty ratio signal, wherein the first carrier signal and the second carrier signal are interleaved by a specified phase angle and have the same wave shape; and a selecting module alternates the first duty ratio signal and the second duty ratio signal respectively according to the period thereof to be used as the drivingcontrol signal of one of two parallel PFC circuits to another to be output. The invention also discloses an interleaved parallel PFC control method. The invention can effectively avoid the problem ofunbalanced current caused by asymmetrical driving signals of the prior interleaved parallel circuit, and has simple realization and low cost.

Owner:EMERSON NETWORK POWER CO LTD

A device and method for forming die forgings based on differential temperature control

ActiveCN103878284BSolve uneven flowFix production issuesForging/hammering/pressing machinesTemperature controlFilling rate

The invention discloses a forging piece forming method based on differential temperature control. The method comprises the steps of placing a whole forging piece into a heating furnace, heating the forging piece to the temperature ranging from 600 DEG C to 800 DEG C, keeping the temperature for 2 hours to 3 hours, taking the forging piece out of the heating furnace, placing the forging piece inside a die cavity, warping a local low-temperature area by heat preservation cotton, placing the forging piece into the furnace again, and taking out the forging piece when the whole temperature of the forging piece is increased to range from 1000 DEG C to 1020 DEG C for forging, wherein at the moment, the temperature of the portion wrapped by the heat preservation cotton is 50 DEG C to 100 DEG C slightly lower than that of the other portions; placing a die forging piece forming device into the heating furnace, heating the die forging piece forming device to the temperature ranging from 200 DEG C to 250 DEG C, inserting a heating stick into a heating hole in an upper die insert, partially heating the die forging piece forming device to the temperature ranging from 350 DEG C to 400 DEG C, taking out the die forging piece forming device for forging, and utilizing the die forging piece forming device for forging and forming the forging piece. According to the forging piece forming method based on the differential temperature control, the forging piece forming filling rate is high, the service life of the die is long, grains of the forging piece are fine, the forming force of the die forging piece can be reduced to the great extent, and the service life of the hot-forging die is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

Inverter heat-radiating device with air duct partition plates

PendingCN107846823AThe temperature does not exceed the limitSolve uneven flowModifications for power electronicsAir volumeEngineering

Owner:BEIJING JINGYI RENEWABLE ENERGY ENG

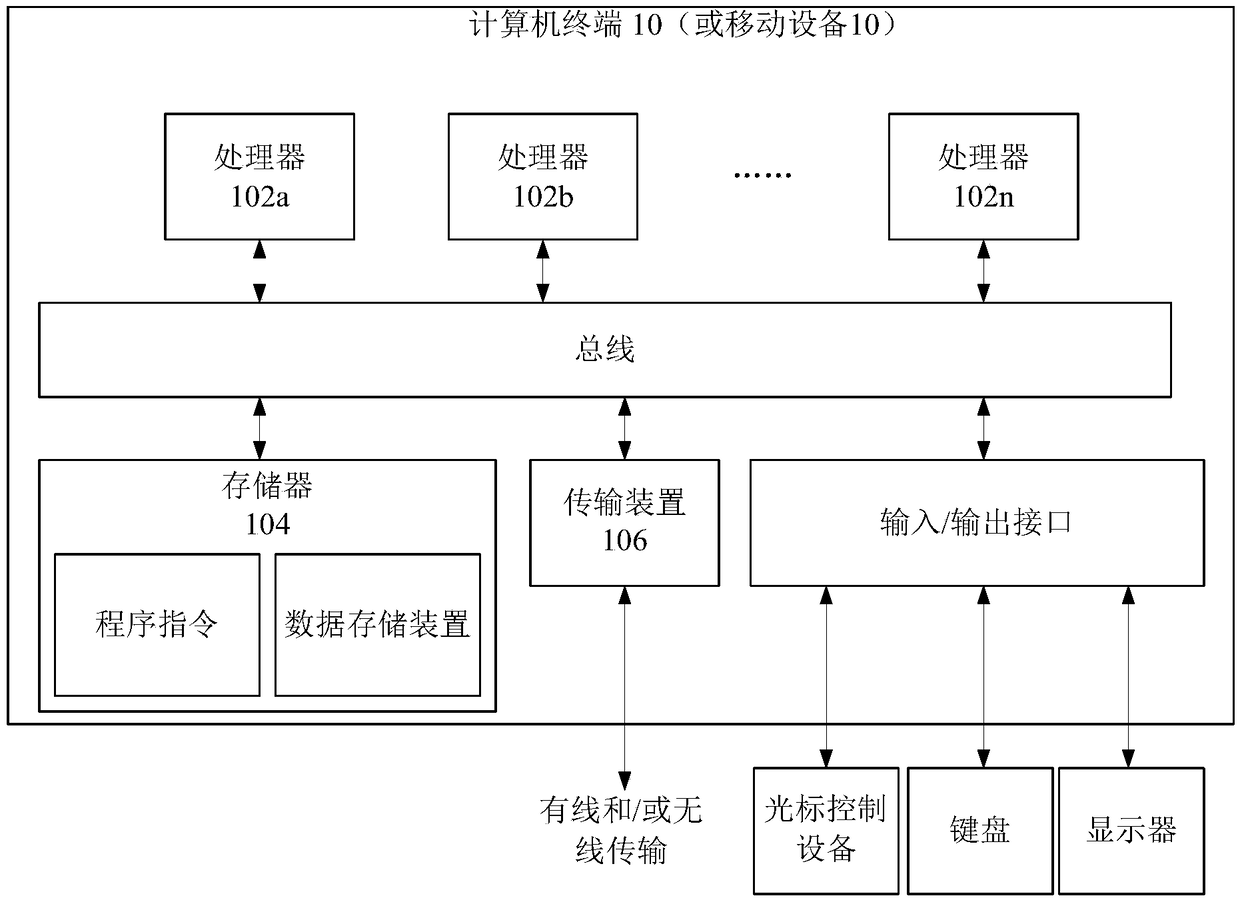

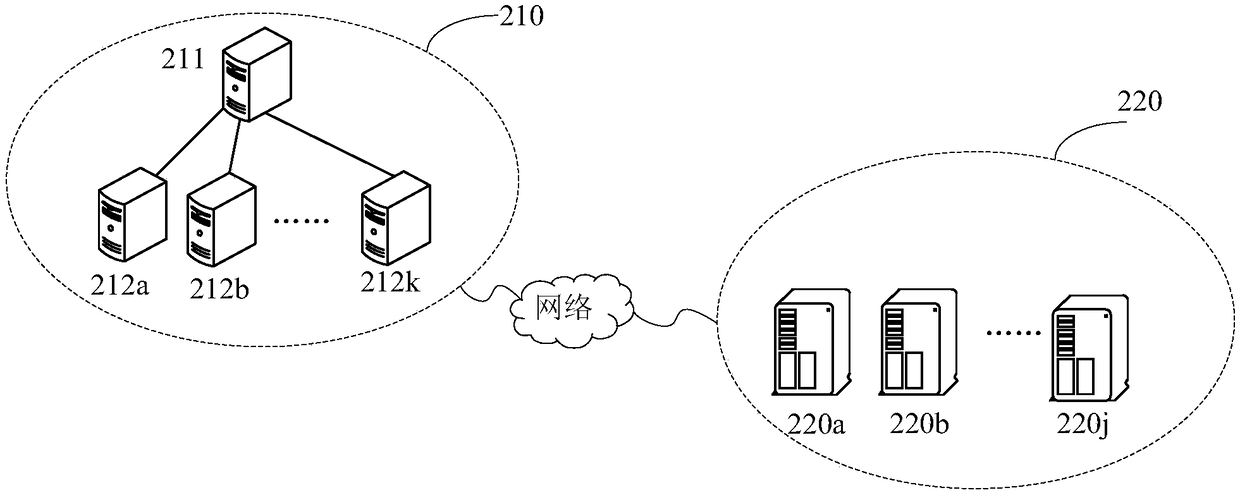

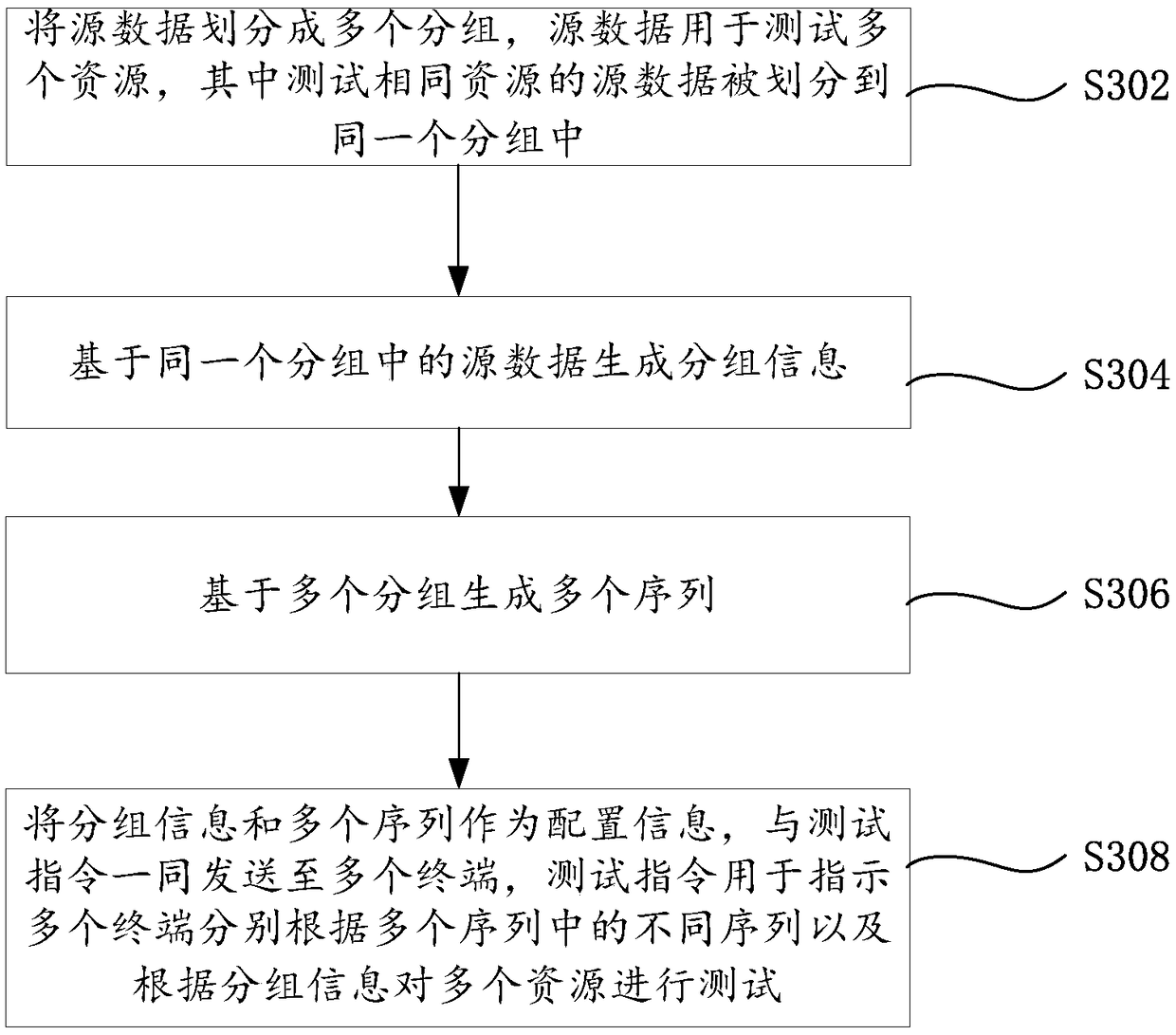

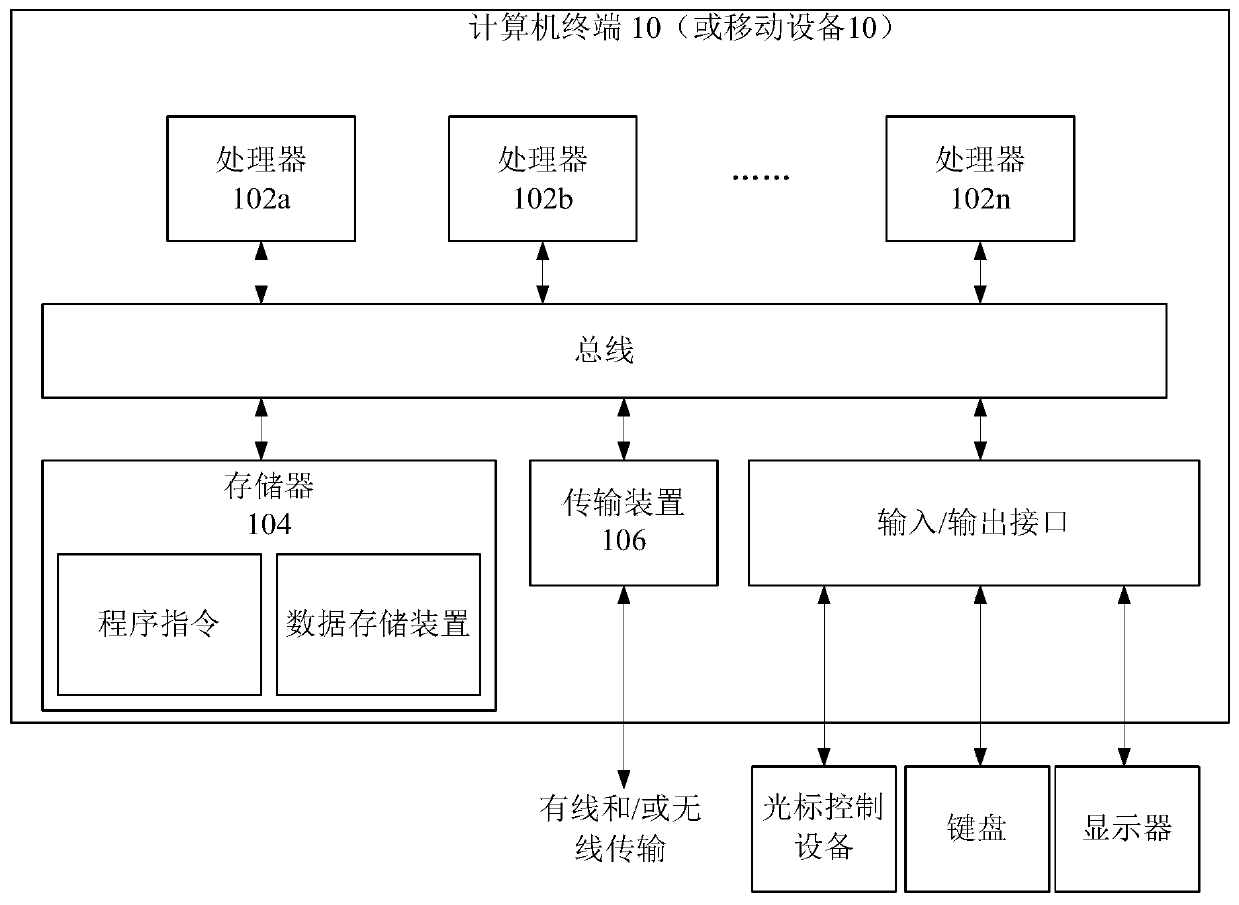

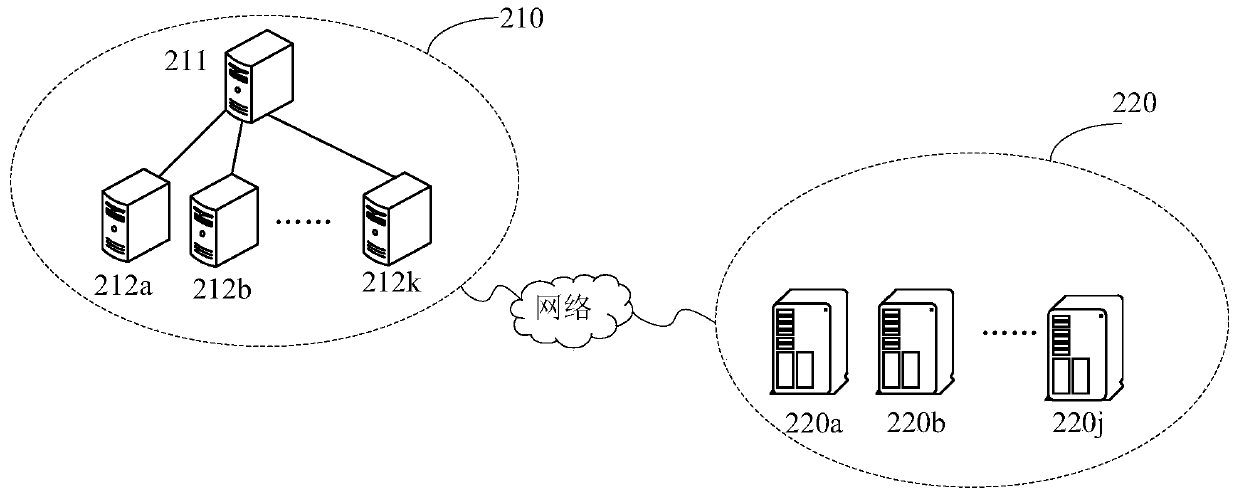

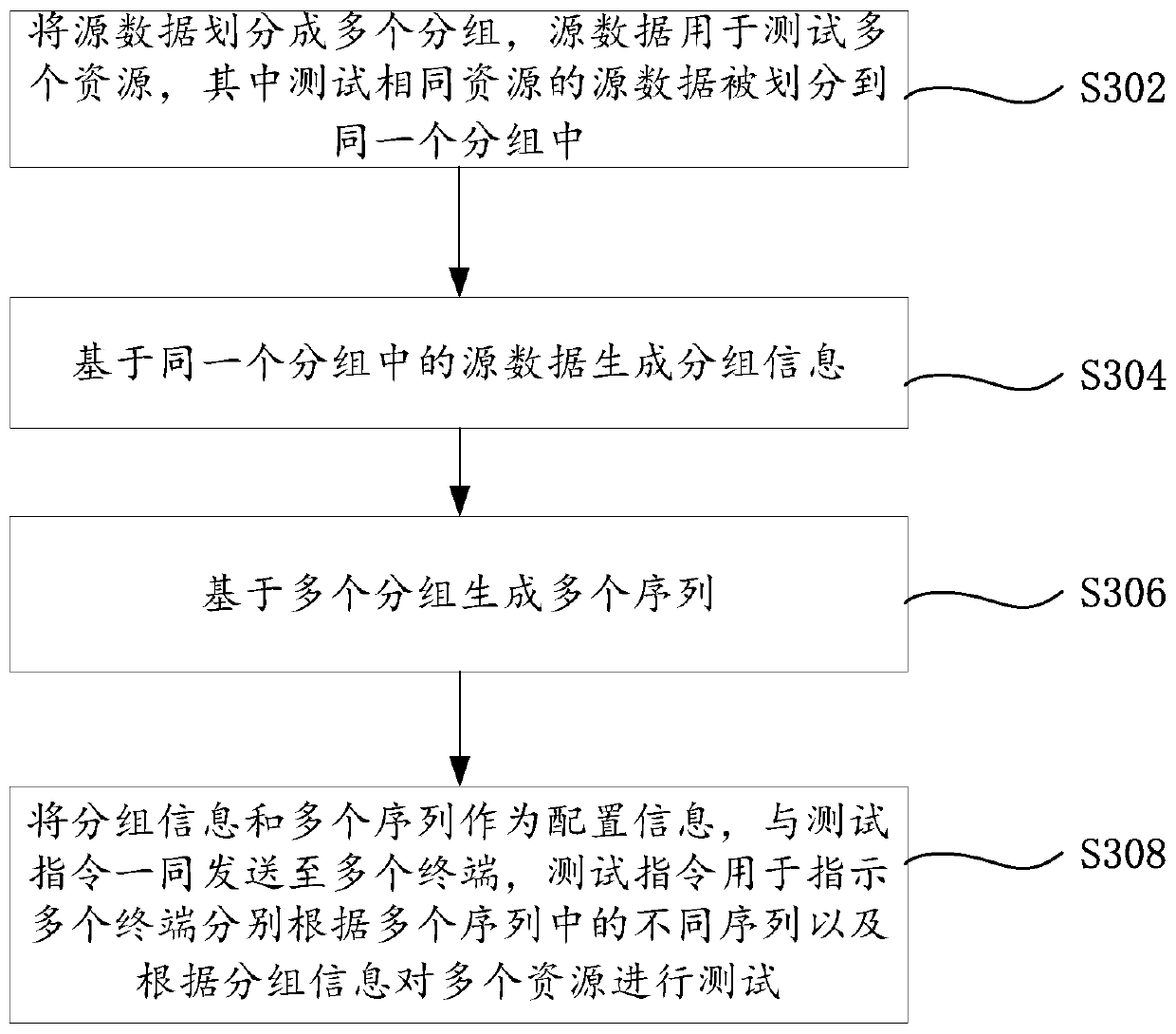

Test method, test system and test equipment

ActiveCN108737162AImprove accuracySolve uneven flowData switching networksSource dataSoftware engineering

The invention discloses a test method, a test system and test equipment. The test method comprises the following steps: dividing source data into a plurality of groups, wherein the source data are used for testing a plurality of resources, and the source data that test the same resource are divided into the same group; generating grouping information based on the source data in the same group; generating a plurality of sequences based on the plurality of groups; and taking the grouping information and the plurality of sequences as configuration information, sending the configuration information to a plurality of terminals together with a test instruction, wherein the test instruction is used for instructing the plurality of terminals to test the plurality of resources according to different sequences in the plurality of sequences and according to the grouping information.

Owner:TENCENT TECH (SHENZHEN) CO LTD

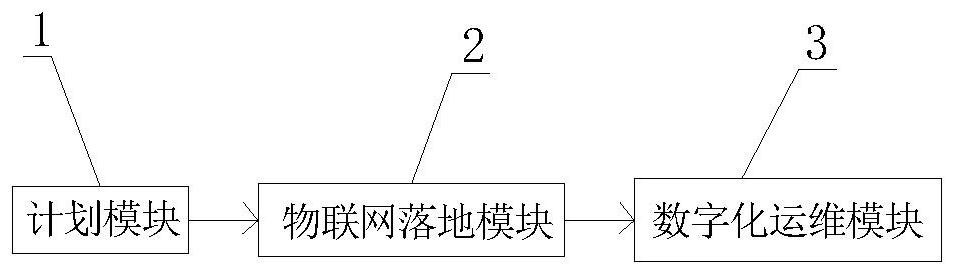

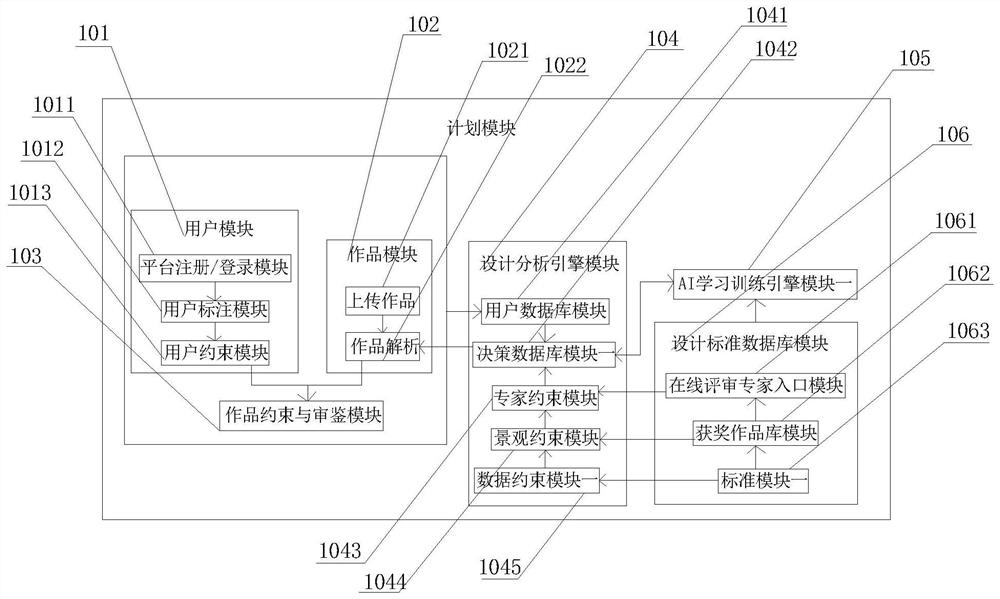

Modular intelligent garden management and cultivation system

PendingCN112991126ASolve water pressureSolve uneven flowOffice automationResourcesEnvironmental resource managementThe Internet

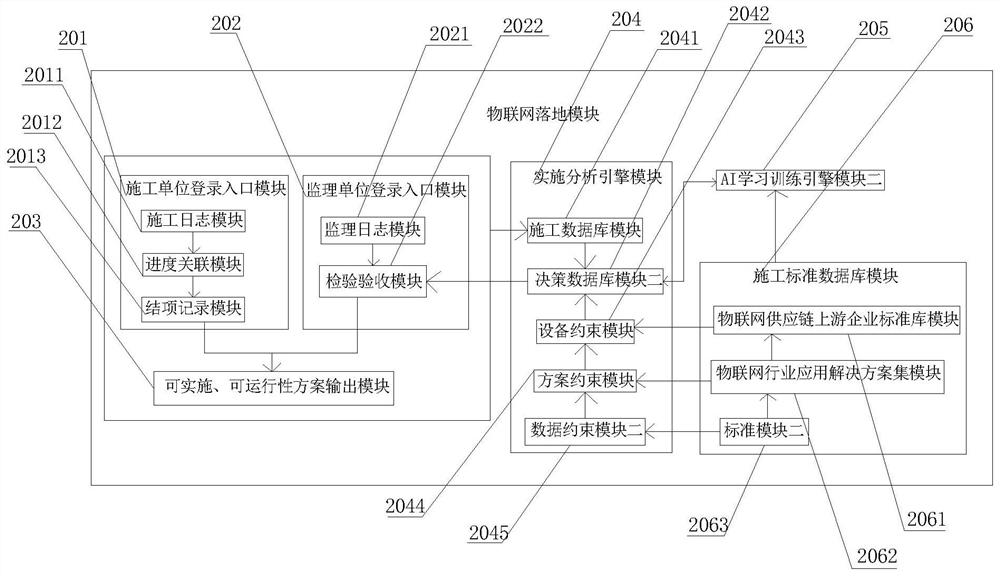

The invention relates to the technical field of gardens, and discloses a modular intelligent garden management and cultivation system, which comprises a planning module, an Internet of Things landing module and a digital operation and maintenance module, the planning module comprises a user module, a work module, a work constraint and verification module, a design analysis engine module, a first AI learning training engine module and a design standard database module, and the user module comprises a platform registration / login module and a user labeling module. According to the modular intelligent garden management and cultivation system, through platform-level accurate operation and maintenance management, the problems of low efficiency, high cost and poor effect of traditional extensive management can be significantly solved; the problem of unbalanced water pressure and flow of an urban garden irrigation water supply network is solved through effective deployment of the Internet of Things intelligent terminal and scientific scheduling of digital operation and maintenance; the platform is combined with constraints such as vegetation characteristics and maintenance standards, and accurate maintenance and management can be carried out for different vegetation in different periods.

Owner:易维集控(北京)园林科技有限公司

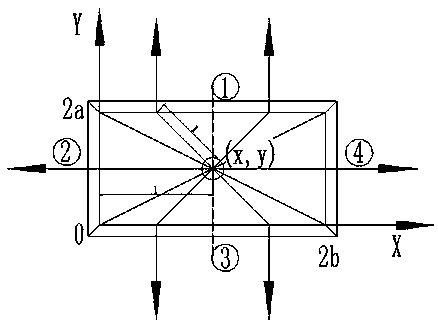

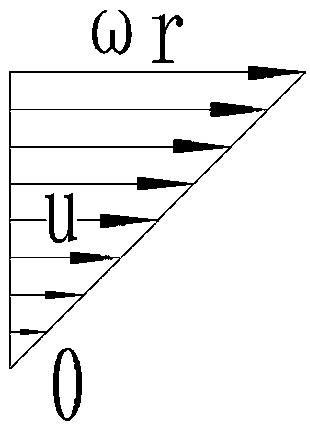

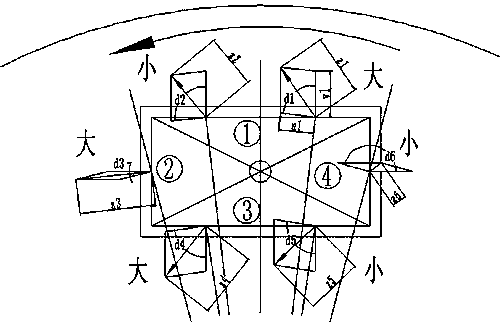

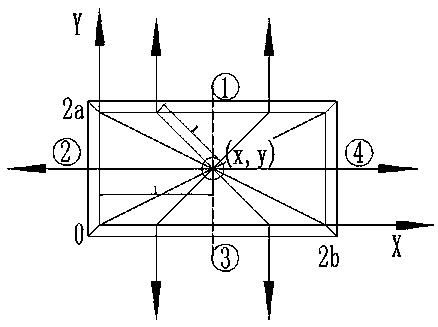

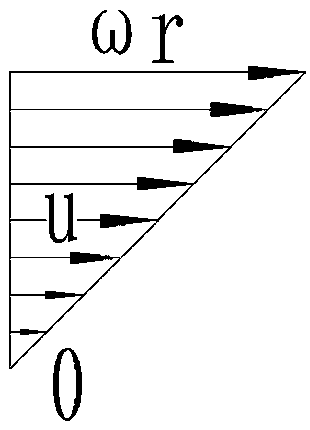

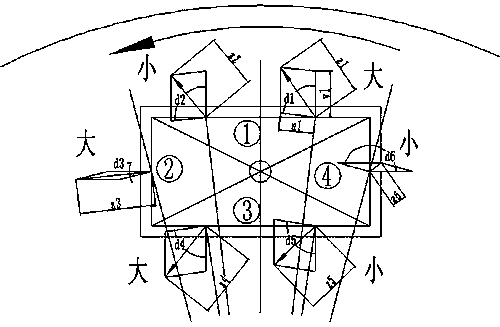

Method for determining oil outlet position of double rectangular cavity static pressure sliding bearing

The invention provides a method for determining an oil outlet position of a double rectangular cavity static pressure sliding bearing; during the operation process of the static pressure sliding bearing, due to the influence of the position of the oil outlet, the shape and rotary speed of an oil chamber, the flow rate of the hydraulic oil flowing out of each oil sealing edge is different, so the operation stability of the static pressure equipment is reduced. In order to balance the flow of the oil sealing edge, reduce the influence of the rotary speed on the flow distribution and improve thebearing performance and stability of the static pressure sliding bearing, the invention provides the method for determining the oil outlet position of the double rectangular cavity static pressure sliding bearing. The method comprises the following steps of: step A: establishing a single rectangular cavity to simplify the flow rate vector; step B: establishing a rotary speed vector of a turntable,and synthesizing with the hydraulic oil flow rate vector to obtain a resultant velocity; step C: analyzing the flow change of each oil sealing edge by the resultant velocity, and performing integralsum calculation; step D: obtaining a liquid resistance ratio from the flow rate ratio, wherein the distance from the oil outlet to the oil sealing edge is larger, and calculating the coordinates of the oil outlet by the integral ratio method; and step E: calculating the position of the oil outlet of another oil chamber by the geometric method.

Owner:HARBIN UNIV OF SCI & TECH

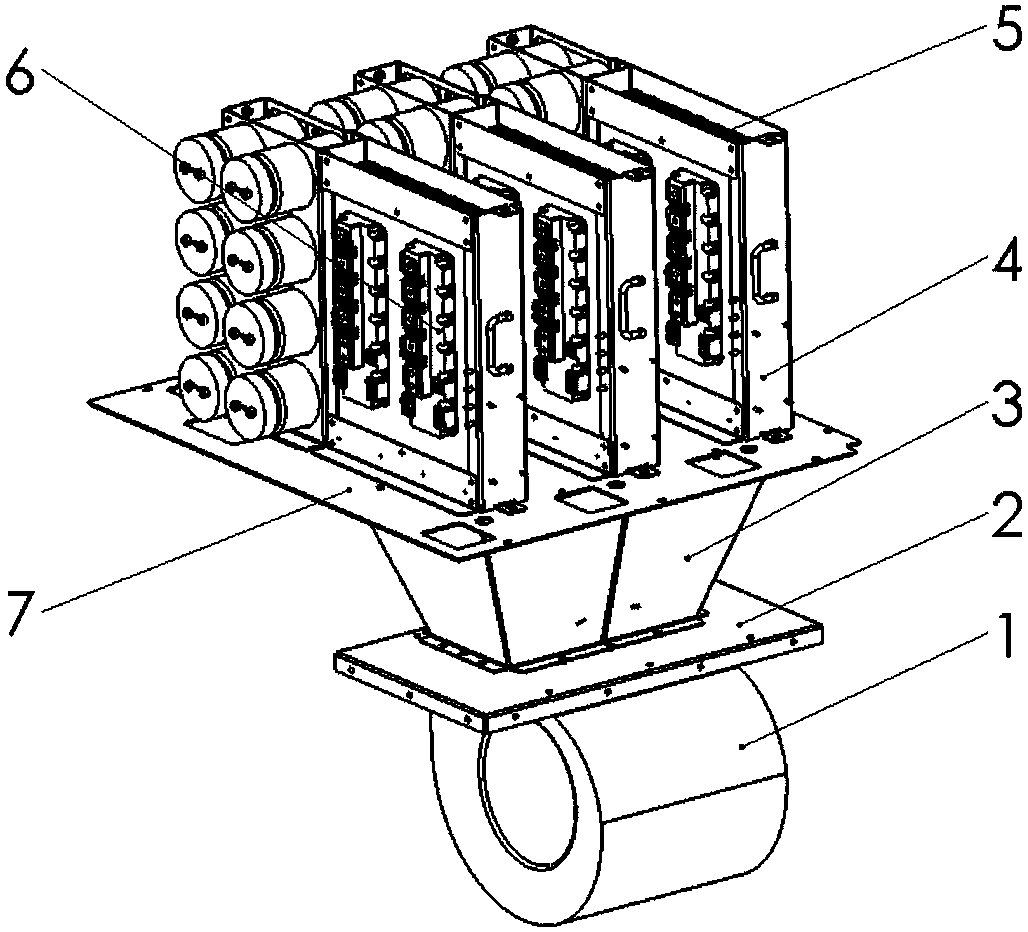

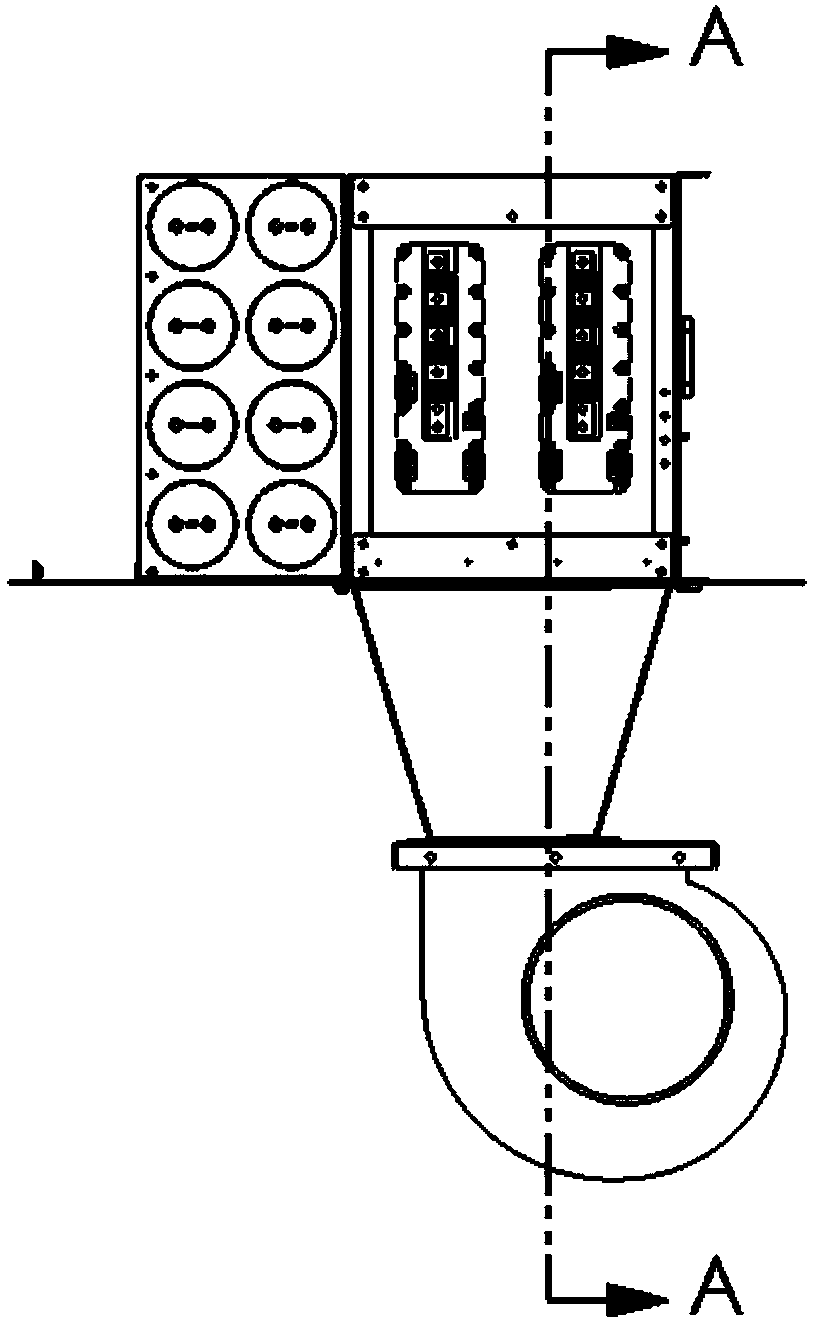

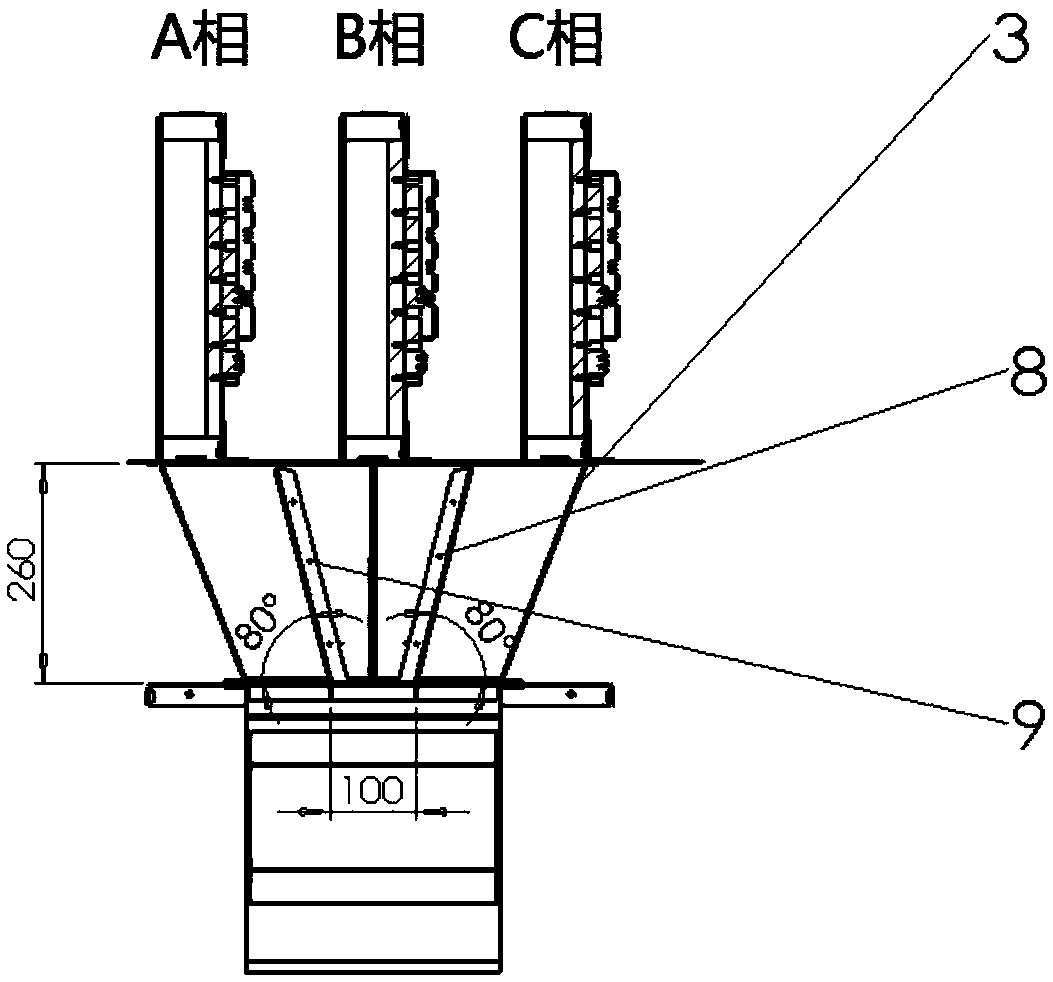

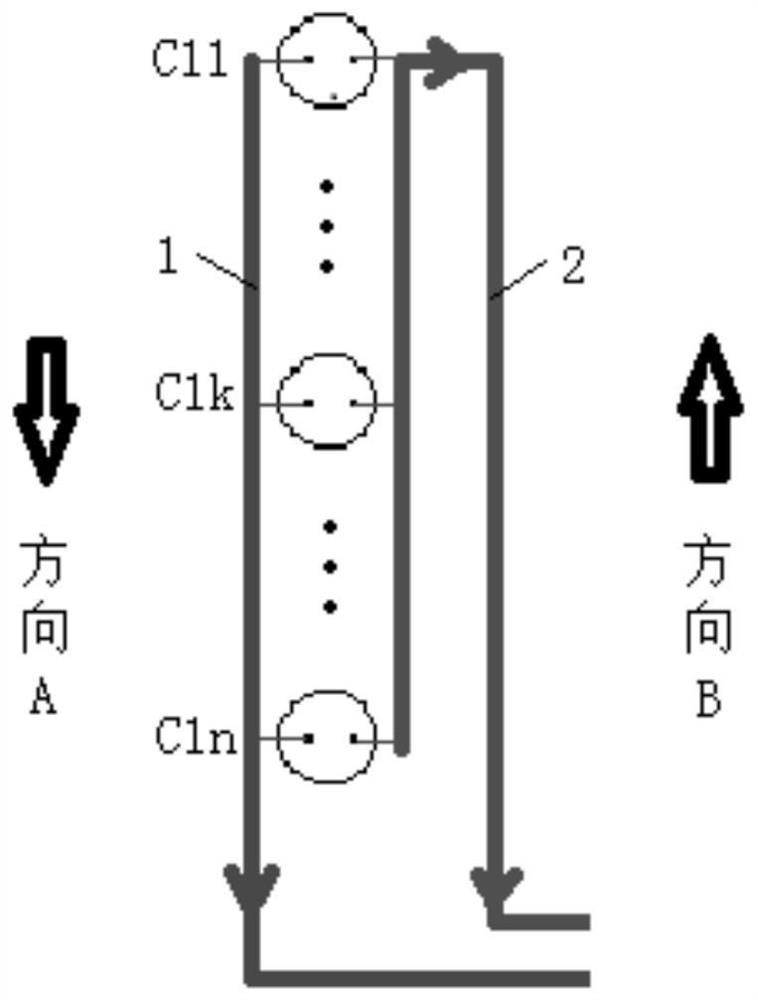

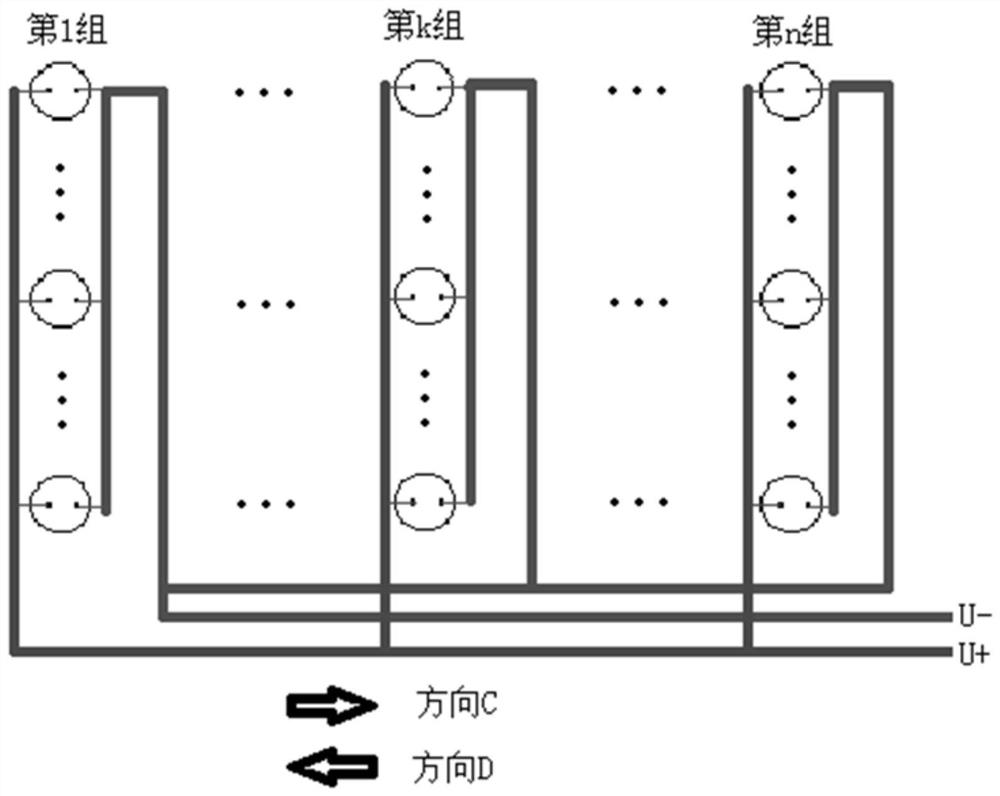

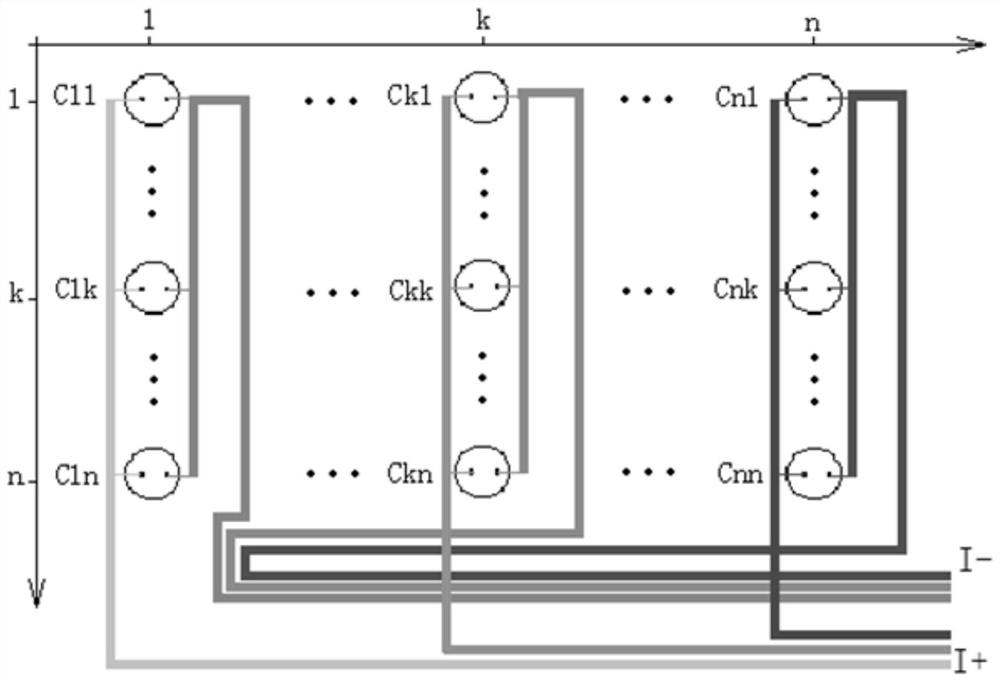

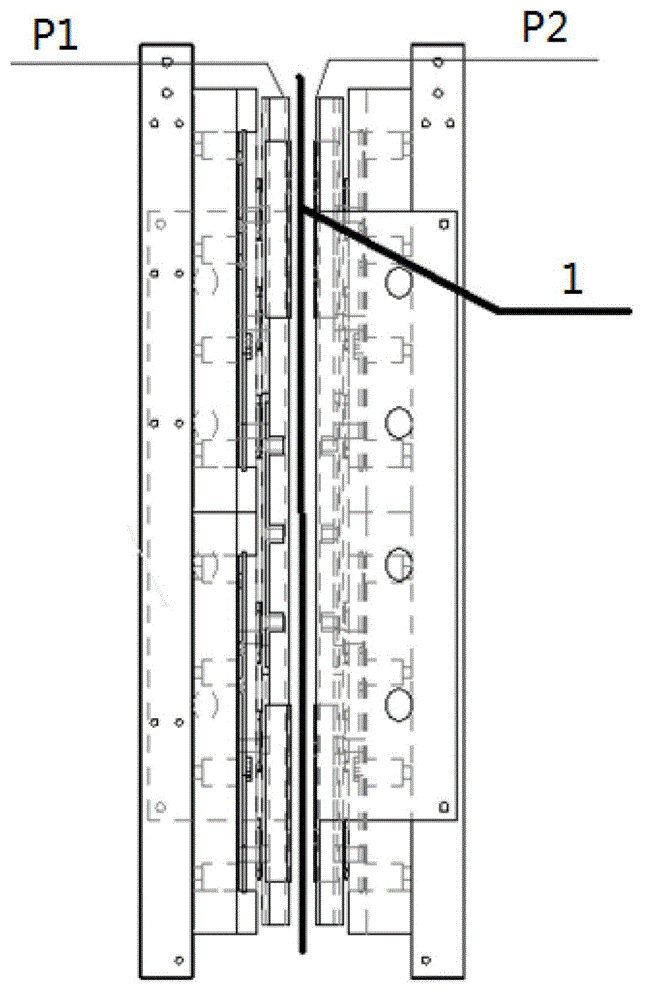

Current sharing circuit structure with large number of capacitors connected in parallel and spheromak device power supply

ActiveCN113162020ASolve uneven flowLow costElectrical storage systemCharge equalisation circuitCapacitanceHemt circuits

The invention discloses a current sharing circuit structure with a large number of capacitors connected in parallel and a spheromak device power supply. According to the current sharing circuit structure, a single-group capacitor structure comprises a plurality of capacitors, a positive group connecting bar and a negative group connecting bar, the plurality of capacitors are connected in parallel, the positive electrodes of all the capacitors are connected to the positive group connecting bar, the positive group connecting bar is connected with the positive electrodes of all the capacitors and then leads out along a capacitor arrangement direction A, the negative electrodes of all the capacitors are connected to the negative group connecting bar, the negative group connecting bar is connected with the negative electrodes of all the capacitors and then leads out along a capacitor arrangement direction B, the wiring direction is changed to be along the capacitor arrangement direction A by rotating 180 degrees at the position of the last capacitor, the wiring direction and the outgoing line of the positive group connecting bar are gathered and led out to form a loop, and the direction A and the direction B are parallel and opposite; and multiple groups of capacitor structures comprise multiple groups of single-group capacitor structures, and the multiple groups of single-group capacitor structures are arranged side by side to form a capacitor group parallel matrix structure. According to the invention, the capacitor group parallel matrix structure can achieve the current sharing effect without adding extra devices.

Owner:SOUTHWESTERN INST OF PHYSICS

A linear regulated power supply

ActiveCN111309089BSolve uneven flowImprove stabilityElectric variable regulationFeedback circuitsControl theory

The application discloses a linear stabilized voltage power supply, which includes a current sharing control circuit. The current sharing control circuit includes at least one current sharing control unit, and each current sharing control unit includes a driving voltage adjustment circuit, a linear voltage stabilization circuit and a feedback circuit. Wherein, the feedback circuit is used to feed back the voltage of the current sampling resistor of the linear voltage stabilizing circuit to the driving voltage adjusting circuit, and the driving voltage adjusting circuit adjusts the current of the analog control signal Vctrl input to the current sharing control unit according to the voltage value of the current sampling resistor before Output to the linear voltage stabilizing circuit, so as to adjust the output power of the linear voltage stabilizing circuit by adjusting the voltage of the current sampling resistor. Since the output power of the linear voltage stabilizing circuit of each current sharing control unit can be adjusted separately, the problem of uneven current of the linear voltage stabilizing power supply can be solved, so as to improve the stability and service life of the linear voltage stabilizing power supply.

Owner:SHENZHEN CITY SIGLENT TECH

A battery system and electric vehicle

ActiveCN109037802BSolve the circulation problemSolve uneven flowCells structural combinationPropulsion by batteries/cellsElectrical batteryCurrent distribution

The embodiment of the invention provides a battery system and an electric vehicle, and relates to the technical field of battery application. The battery system comprises at least two battery branchesand a controller, wherein each battery branch comprises a battery and a regulating unit, each battery branch is connected in parallel with each other, the battery in each battery branch is connectedin series with the regulating unit in each battery branch, and the controller is electrically connected with the regulating unit in each battery branch; The controller is used for regulating the resistance value of the regulating unit in each battery branch according to a pre-established mathematical model, thereby regulating the output current of each battery branch. The battery system and the electric vehicle provided by the embodiment of the invention can solve the problem that the output current distribution of each branch of the battery system is unbalanced.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +2

Three-phase coupling reactor and converter

ActiveCN104078195BReduce volumeLow costTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresNuclear engineeringCoupling

The invention discloses a three-phase coupling reactor and a converter. The three-phase coupling reactor comprises an iron core and six windings, the iron core comprises an upper iron yoke, a lower iron yoke, at least one first iron core post without a gas gap and three second iron core posts with gas gaps, wherein the first iron core post and the second iron core posts are located between the upper iron yoke and the lower iron yoke; two windings wind each second iron core post, and the ends of the two windings on the same second iron core post in different names are connected in a short circuit mode. According to the three-phase coupling reactor and converter, the zero sequence circulating current impedance of the converter system is increased through the coupling between windings, and accordingly the problem of uneven current of parallel power modules due to zero sequence circulating current is effectively solved.

Owner:SUZHOU INOVANCE TECH CO LTD

Test method, test system and test equipment

ActiveCN108737162BAvoid concurrent access problemsImprove accuracyData switching networksAlgorithmTest equipment

The invention discloses a test method, a test system and test equipment. The test method comprises the following steps: dividing source data into a plurality of groups, wherein the source data are used for testing a plurality of resources, and the source data that test the same resource are divided into the same group; generating grouping information based on the source data in the same group; generating a plurality of sequences based on the plurality of groups; and taking the grouping information and the plurality of sequences as configuration information, sending the configuration information to a plurality of terminals together with a test instruction, wherein the test instruction is used for instructing the plurality of terminals to test the plurality of resources according to different sequences in the plurality of sequences and according to the grouping information.

Owner:TENCENT TECH (SHENZHEN) CO LTD

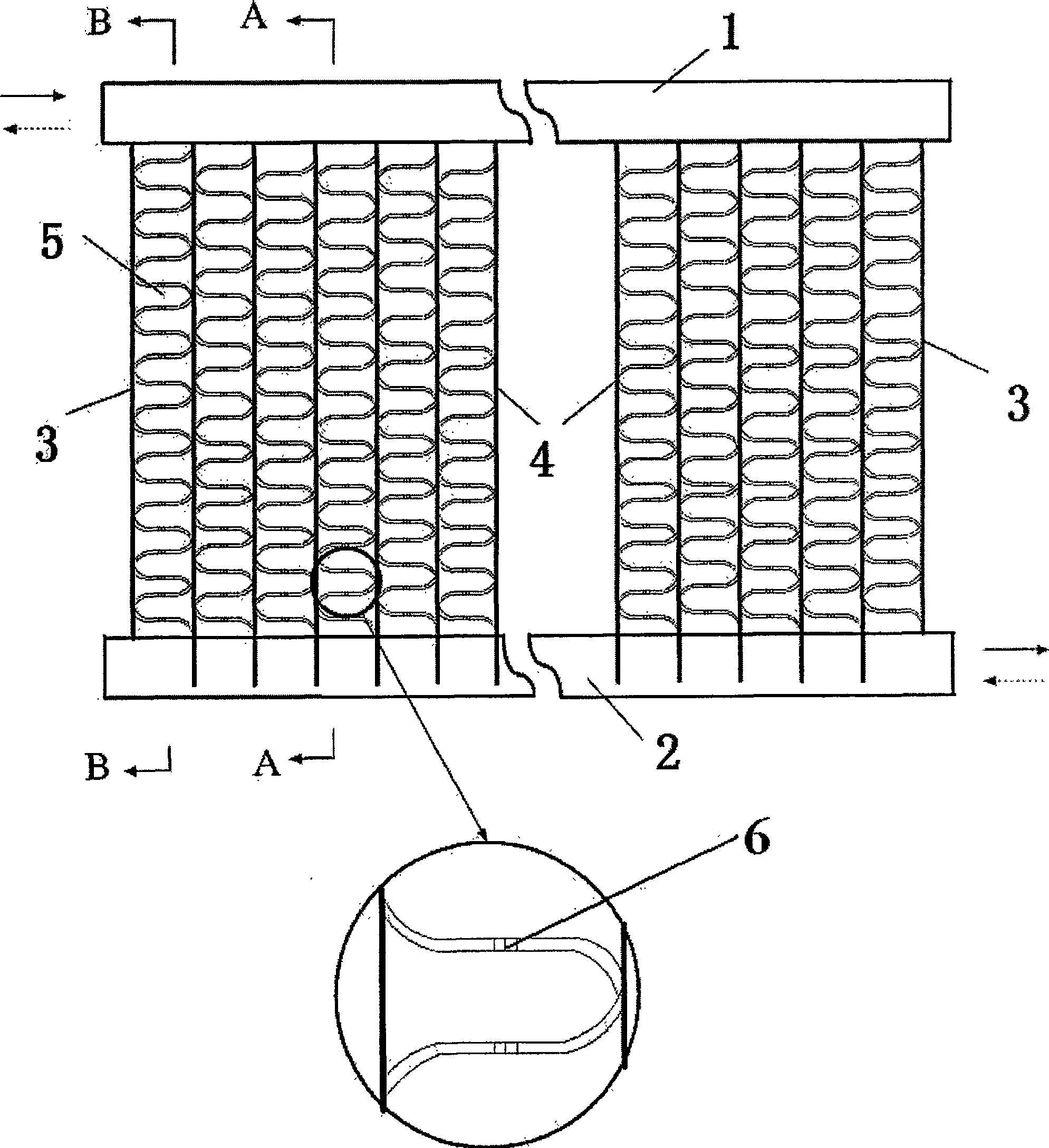

Tiny channel aluminum strip tubular mode heat pump type heat exchanger of air conditioner

This invention relates to a micro-channel ribbon tube hot pump air-condition / exchanger composed of an upper collector, a lower collector, micro-channel ribbon tubes and ribs, which are plane or wave ones with drainage grooves distributed slantly against the wind to exhaust condensed water or frost water timely, in which a liquid separation structure is applied for the connection of upper and lower collectors with the micro-channel ribbon tubes to solve the problem that heat-exchange area can't be used fully since cooling agent can't flow uniformly among channels when the heat exchanger is used as an evaporator.

Owner:TSINGHUA UNIV +1

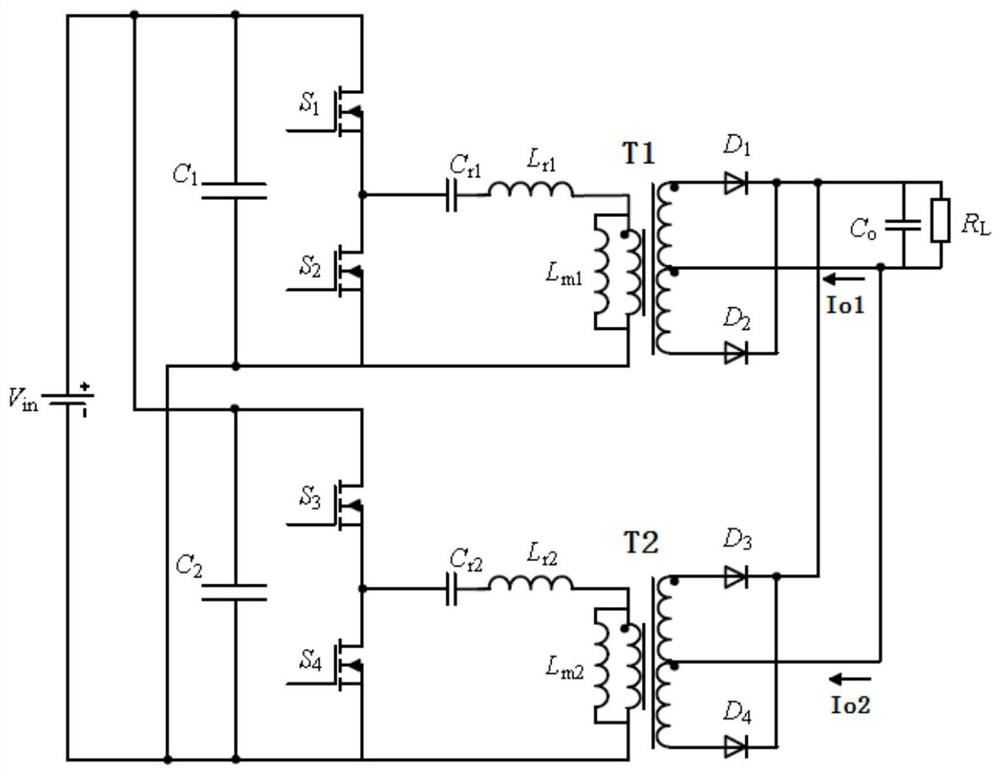

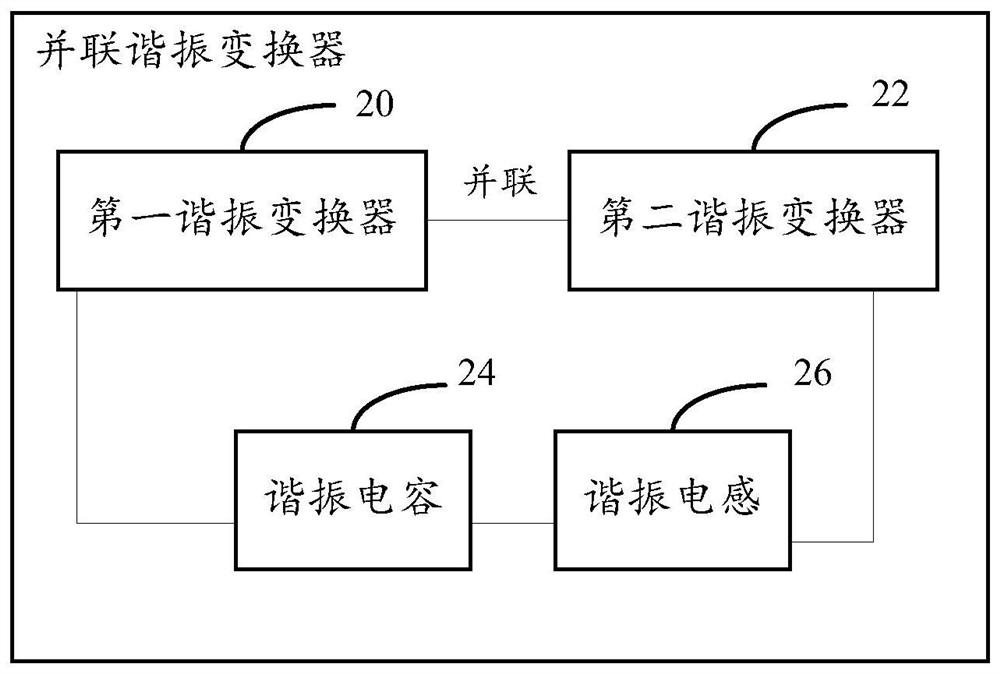

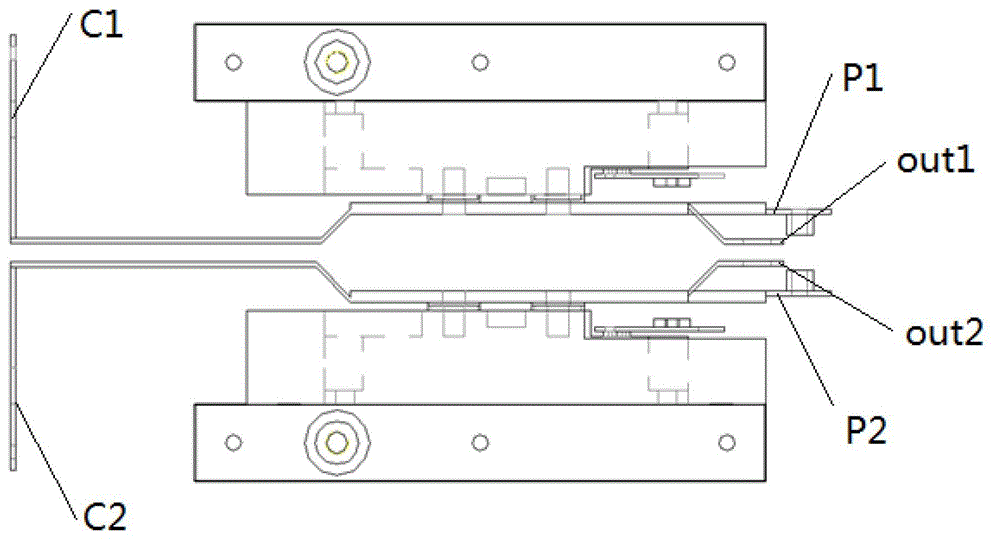

Parallel resonant converter and power supply

PendingCN112104232ASolve uneven flowEfficient power electronics conversionDc-dc conversionCapacitanceSoftware engineering

The invention discloses a parallel resonant converter and a power supply. The parallel resonant converter comprises at least two paths of parallel resonant converters, and the at least two paths of parallel resonant converters share a resonant capacitor and a resonant inductor. According to the invention, a problem that current sharing does not exist in the parallel resonant converter in the priorart is solved so that natural current sharing is realized between the two resonant converters.

Owner:ZTE CORP

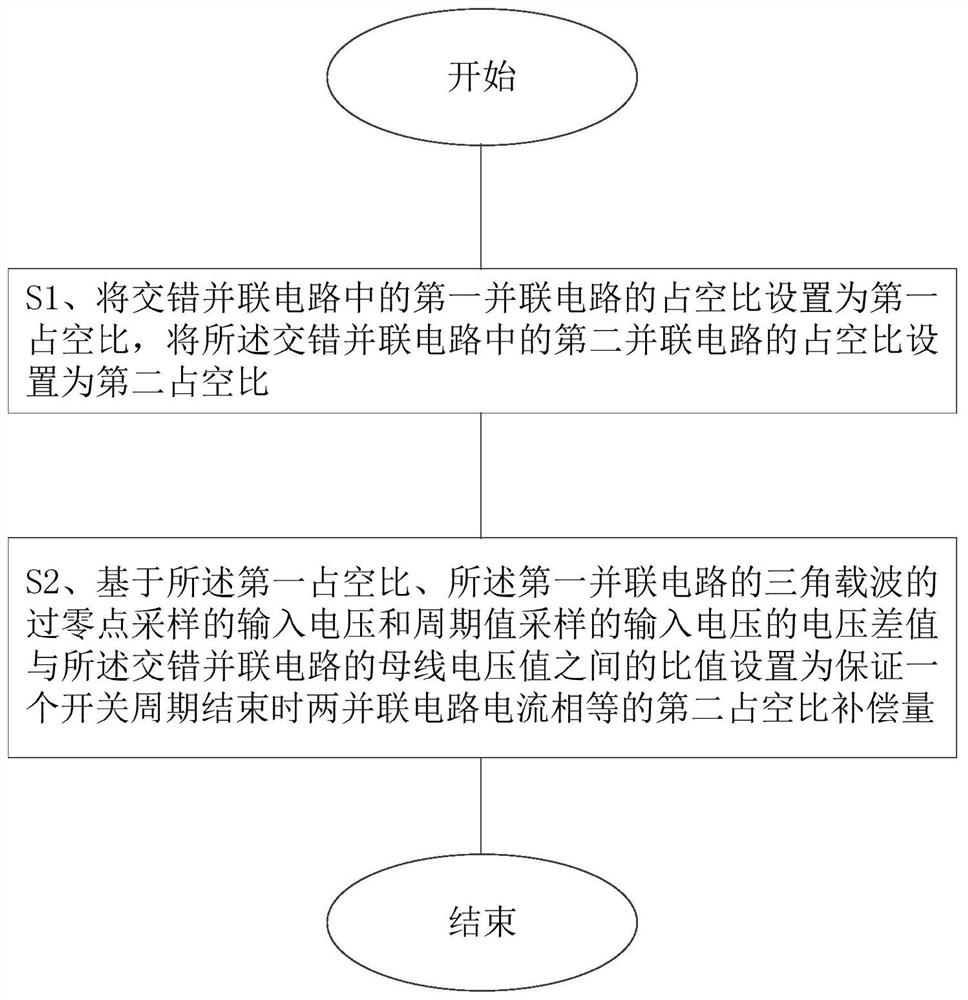

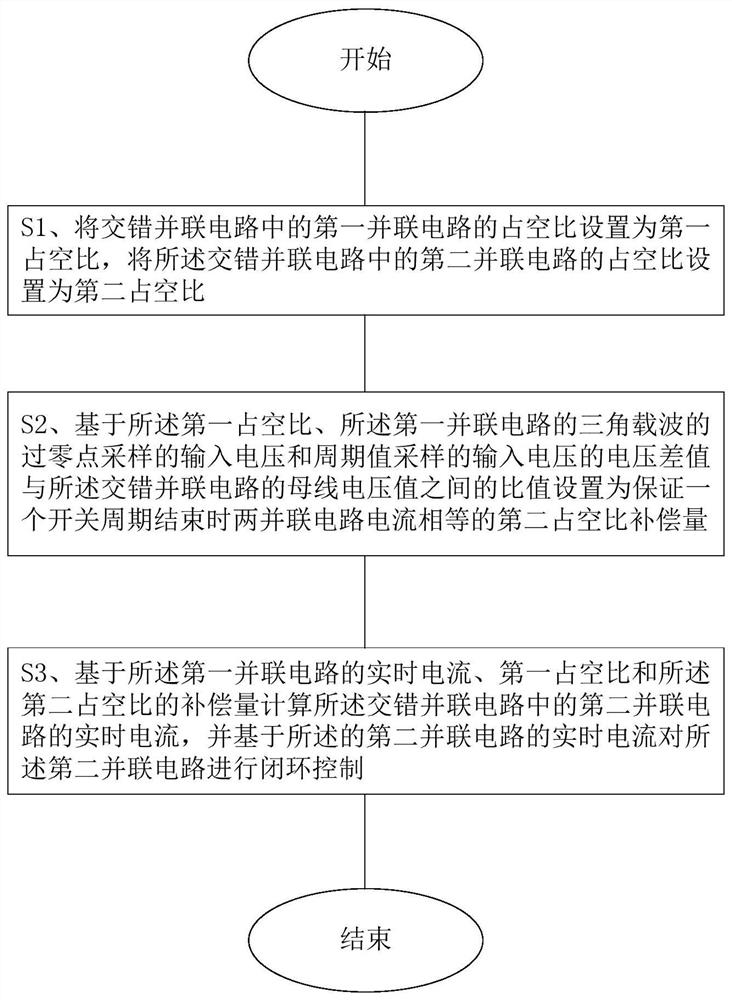

Current sharing method of centralized control type interleaved parallel circuit, computer readable storage medium and centralized control type interleaved parallel circuit

PendingCN114696638AFast dynamic responseIncrease sineAc-dc conversionDc-dc conversionComputer architectureCarrier signal

The invention relates to a current sharing method of a centralized control type interleaving parallel circuit, which comprises the following steps of: setting the duty ratio of a first parallel circuit in the interleaving parallel circuit as a first duty ratio, and setting the duty ratio of a second parallel circuit in the interleaving parallel circuit as a second duty ratio; based on the first duty ratio; and the ratio of the voltage difference value of the input voltage sampled at the zero crossing point of the triangular carrier wave of the first parallel circuit and the input voltage sampled at the periodic value to the bus voltage value of the interleaved parallel circuit is set as a second duty ratio compensation amount which ensures that the currents of the two parallel circuits are equal when one switching period is ended. The invention further relates to a computer readable storage medium and a centralized control type interleaving parallel circuit. According to the invention, the problem of non-uniform current between circuits can be solved in a low-cost and easy-to-implement manner, and the sine degree of the second parallel circuit is improved.

Owner:VERTIV CORP

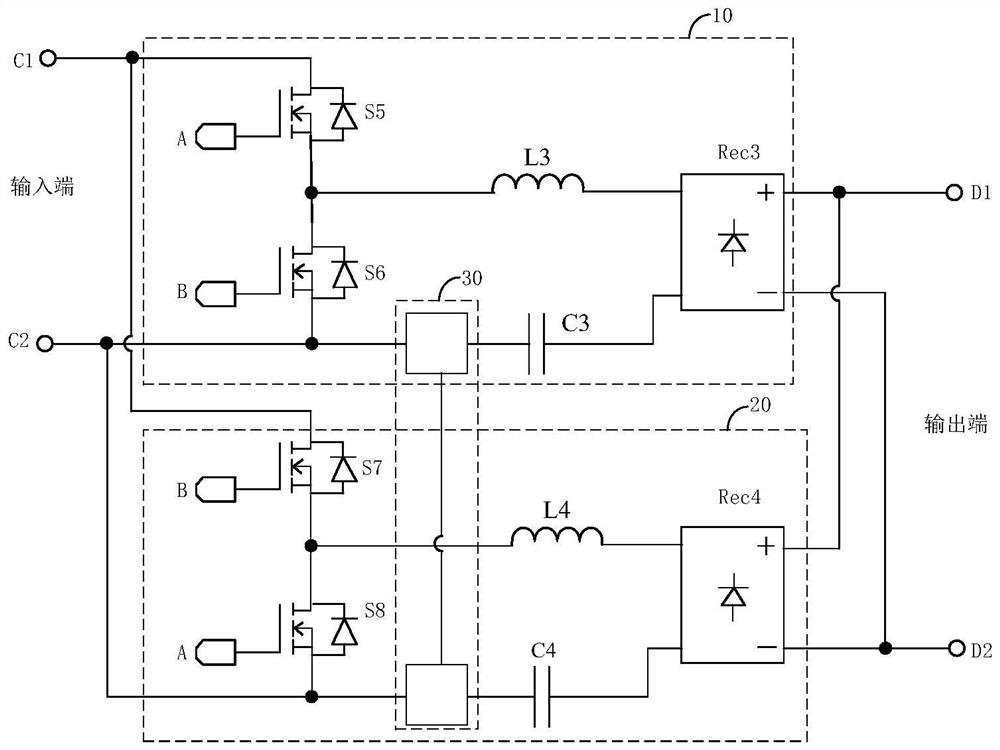

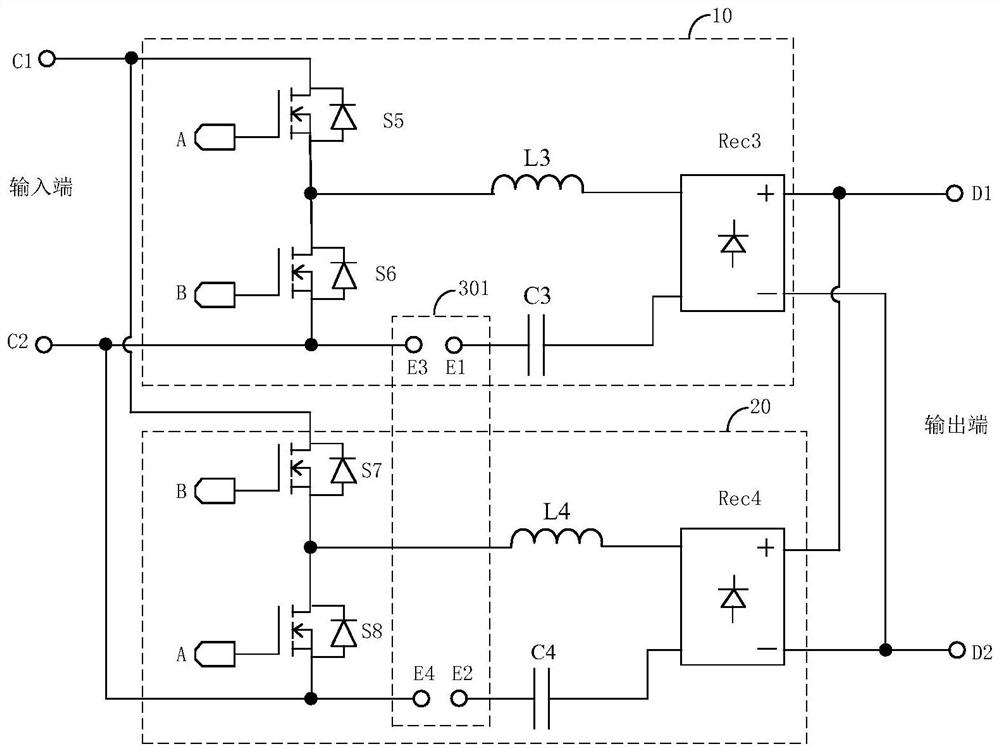

LLC resonant conversion circuit and LLC resonant converter

PendingCN114598156ASolve the uneven flow of parallel currentSolve uneven flowEfficient power electronics conversionDc-dc conversionResonant cavityHemt circuits

The invention discloses an LLC resonant conversion circuit and an LLC resonant converter, the LLC resonant conversion circuit comprises an input end, a first half-bridge LLC circuit, a second half-bridge LLC circuit, an output end, a conversion device, a first driving end and a second driving end, the first half-bridge LLC circuit and the second half-bridge LLC circuit are connected in parallel between the input end and the output end, the conversion device is respectively connected with the resonant cavities of the two half-bridge LLC circuits and is used for connecting the two resonant cavities in series, and the two driving ends input different driving signals in a crossed manner, so that the current of the resonant cavity of each half-bridge LLC circuit passes through the resonant cavity of the other half-bridge LLC circuit, and the current of the resonant cavities of the two LLC circuits is equal; rectified output currents of the two half-bridge LLC circuits are also equal, so that the problem of non-uniform parallel currents can be solved.

Owner:西安图为电气技术有限公司

A method for determining the position of the oil outlet of a double rectangular cavity hydrostatic sliding bearing

The invention provides a method for determining an oil outlet position of a double rectangular cavity static pressure sliding bearing; during the operation process of the static pressure sliding bearing, due to the influence of the position of the oil outlet, the shape and rotary speed of an oil chamber, the flow rate of the hydraulic oil flowing out of each oil sealing edge is different, so the operation stability of the static pressure equipment is reduced. In order to balance the flow of the oil sealing edge, reduce the influence of the rotary speed on the flow distribution and improve thebearing performance and stability of the static pressure sliding bearing, the invention provides the method for determining the oil outlet position of the double rectangular cavity static pressure sliding bearing. The method comprises the following steps of: step A: establishing a single rectangular cavity to simplify the flow rate vector; step B: establishing a rotary speed vector of a turntable,and synthesizing with the hydraulic oil flow rate vector to obtain a resultant velocity; step C: analyzing the flow change of each oil sealing edge by the resultant velocity, and performing integralsum calculation; step D: obtaining a liquid resistance ratio from the flow rate ratio, wherein the distance from the oil outlet to the oil sealing edge is larger, and calculating the coordinates of the oil outlet by the integral ratio method; and step E: calculating the position of the oil outlet of another oil chamber by the geometric method.

Owner:HARBIN UNIV OF SCI & TECH

A parallel igbt power unit

ActiveCN103354414BSolve uneven flowGuaranteed flow uniformityPower conversion systemsCapacitanceBusbar

The invention discloses a parallel IGBT power unit. The parallel IGBT power unit comprises an upper bridge IGBT module and a lower bridge IGBT module. Each IGBT module includes at least two IGBT modules which are connected in parallel, and further comprises an upper busbar and a lower busbar which are correspondingly connected with the two IGBT modules. The upper busbar is provided with a first leading-out terminal for connecting with a first main busbar and a first capacitor connecting terminal for connecting with a capacitor. The lower busbar is provided with a second leading-out terminal for connecting with a second main busbar and a second capacitor connecting terminal for connecting with a capacitor. According to the parallel IGBT power unit, the two IGBT modules and the two busbars which have identical structures and are correspondingly connected with the modules respectively are adopted; the leading-out terminals for connecting with the main busbars and the capacitor connecting terminals for connecting with the capacitors on the busbars are in conductive connection with docking connecting terminals and capacitor connecting terminals at corresponding positions of the IGBT modules of corresponding busbars by using copper bars in identical lengths; and since busbars connecting the IGBTs are identical in length, the current-sharing performance of the parallel IGBT modules on the busbars is guaranteed, and a problem of uneven current during parallel connection of the IGBTs is solved.

Owner:河南许继电力电子有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com