Precision spraying valve

A precision and spraying material technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of large edge tolerance, large edge tolerance, inconvenient use, etc., achieve small spraying width and solve the effect of uneven spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

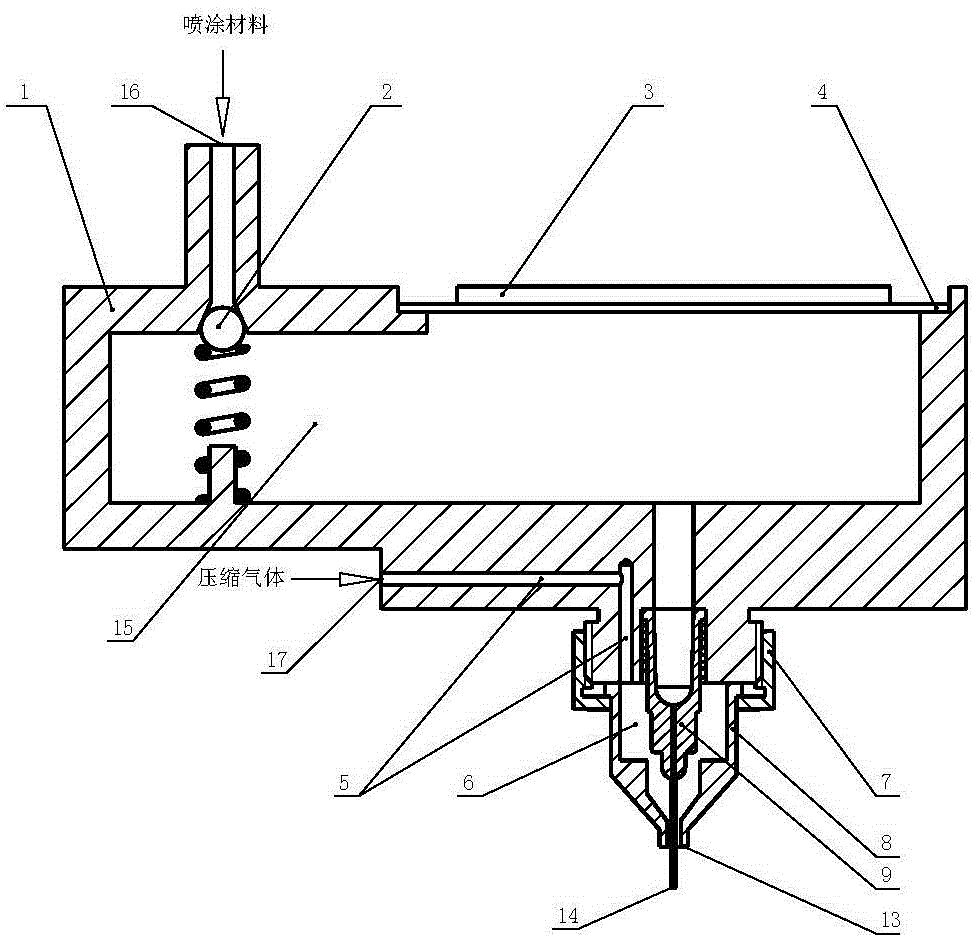

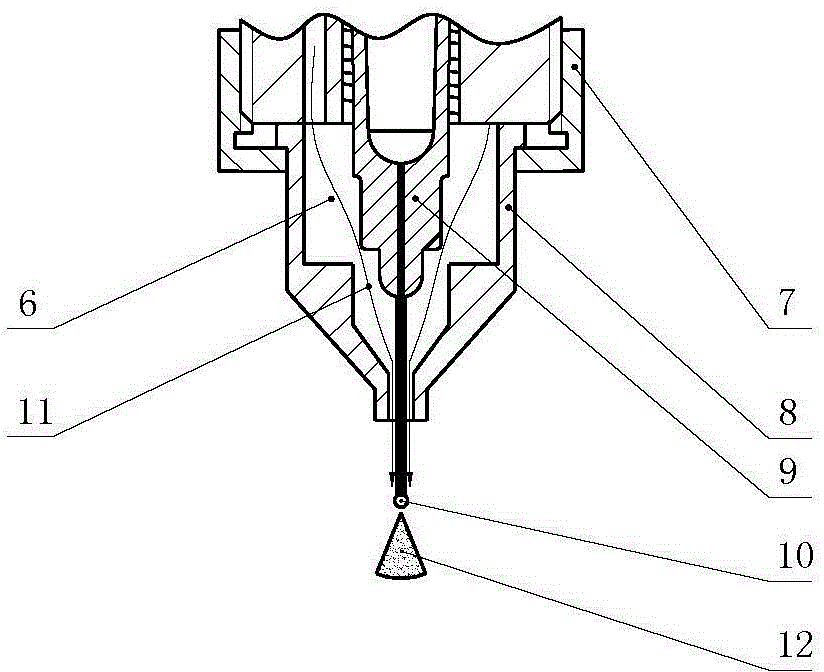

[0009] refer to figure 1 , The cavity 1, the one-way valve 2, the piezoelectric chip 3, the substrate 4 and the needle 9 constitute a supply system for spraying materials. The one-way valve 2 is used to turn on and off the entry of the spraying material. The piezoelectric wafer 3 and the substrate 4 provide the power required for the movement of the spraying material. The needle 9 is a needle commonly used for dispensing, and is connected to the cavity 1 through a Luer connector. And different needles 9 can be selected according to the width and thickness of spraying. The cavity 15 of the cavity 1 is filled with the material to be sprayed, and then the inlet 16 is connected with a certain pressure of the spray material, ready to be added to the cavity 15 in real time. The external spraying material, the spraying material in the cavity 15, and the one-way valve 2 are kept in a balanced state. The piezoelectric chip 3 drives the substrate 4 to bend upward under the action of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com