Device for manufacturing portable rope head

A technology outside the rope head and device, which is applied in the field of making portable rope head devices. It can solve the problems that the 1 end of the lifting rope deviates from the plastic-coated center, the rope head is loose, and the plastic-coated plastic is not formed, so as to improve work efficiency and pull-off force. Improve, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

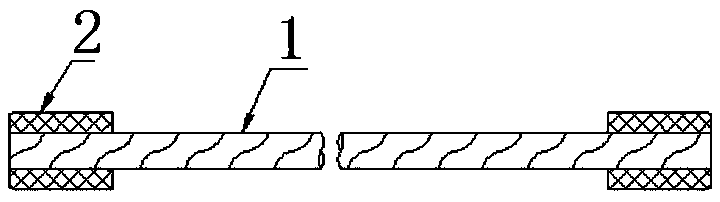

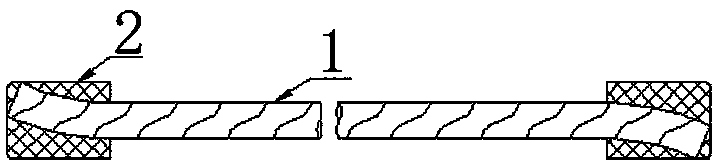

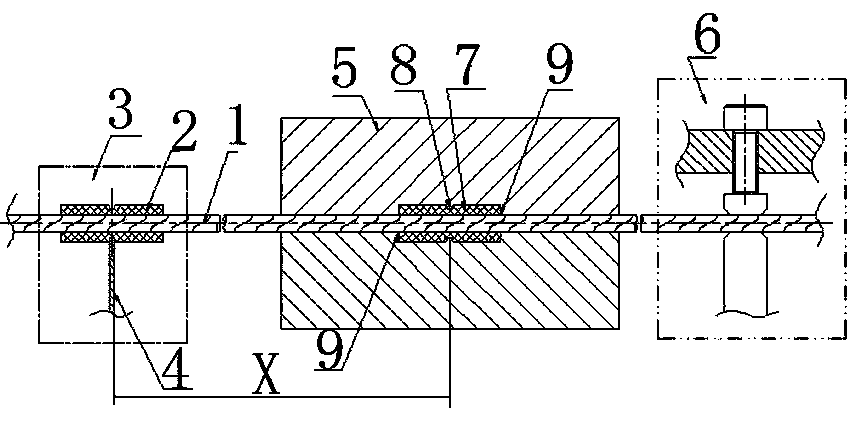

[0019] The present invention as image 3 shown.

[0020] A device for making a portable rope head, comprising a cutting device 1, a plastic wrapping device 5 is provided on one side of the cutting device 3 at a fixed length X, and a tensioning device 6 is arranged outside the plastic wrapping device 5, wherein the cutting device 3 is based on its The center of the cutting knife 4 and the overmolding device 5 has a fixed length X, and the mold cavity of the overmolding device 5 is provided with a double overmolding head cavity 7, and is provided with a guide rope groove 9 from both sides, and the tensioning device 6 is provided with a lift Rope 1.

[0021] The cavity 7 of the double-packed plastic head is provided with an even boundary knife flute 8 .

[0022] The cutting device 3, the double overmolding head cavity 7 of the overmolding device 5, and the tensioning device 6 are arranged in parallel.

[0023] During production, the lifting rope 1 is an overall length, and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com