Optical-fiber junction protector

An optical fiber splicing and protector technology, which is applied to the coupling of optical waveguides, fiber mechanical structure, etc., can solve the problems of time-consuming construction, inconvenient construction, and fiber splicing point breakage, etc., and achieves simple construction and installation. 、Double protection with obvious effect of pull-off force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

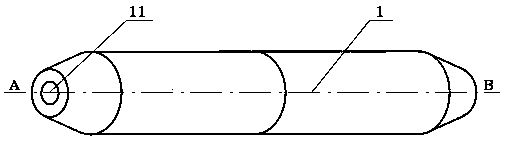

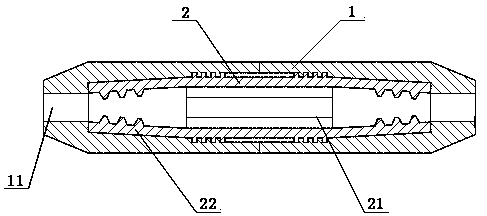

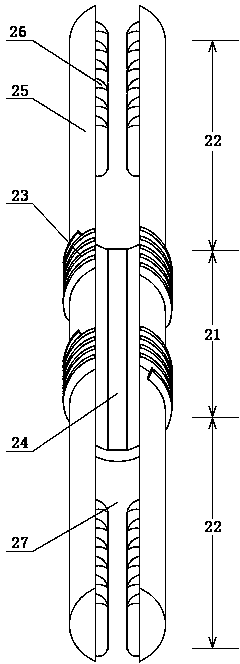

[0027] like figure 1 , figure 2 As shown, an optical fiber splice protector includes an inner shell 2 and an outer shell 1 . The structure of the inner shell 2 is as figure 2 , image 3 As shown, it is in the shape of a cylinder, including a main body 21 and a clip body 22 . The main body 21 is provided with a groove 24 along the axial direction. The groove 24 makes the main body 21 have a C-shaped cross section. Both ends of the main body 21 are respectively provided with two sets of external threads 23 . There are two clip bodies 22, which are respectively located at two ends of the main body. The clip body 22 is composed of two clip pieces 25 . One end of the clip 25 is fixed on the main body 21 . The main body 21 and the clip body 22 are an integral structure. The clip chamber 27 and the groove 24 between the two clips 25 constitute a continuous protection chamber. There are two outer shells 1, which are sleeved outside the inner shell 2. The structure of shel...

Embodiment 2

[0032] Referring to Example 1, on the basis of Example 1, this example further adds a C-shaped collar 3, such as Figure 5 shown. The structure of the C-type collar 3 is as Image 6 As shown, a C-shaped ring piece 31 and a pressure blocking piece 32 are included. The blocking piece 32 is arranged on both sides of the C-shaped ring piece 31 . like Figure 7 As shown, a C sleeve shaft 28 is provided between two sets of external threads 23 of the main body 21 of the inner shell 2 . After the installation is completed, the C-shaped collar 3 is sleeved on the outside of the C sleeve shaft 28. The blocking piece 32 is stuck between the outer shell 1 and the inner shell 2 . There is a gap between the outer shell 1 and the inner shell 2 at the C sleeve shaft 31 . The pressure blocking sheet 32 is stuck in the gap. The C-shaped ring sheet 31 of the C-shaped collar 3 is sandwiched between the two shells 1, such as Figure 5 shown. Compared with embodiment 1, in embodiment 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com