Floating type axial sealing structure

A technology of axial sealing and sealing structure, which is applied in the field of compressors, can solve the problems of unable to meet the long-term stable gas circulation, reduce the sealing effect of sealing strips, and increase radial leakage, etc., so as to increase the gas pressure, improve the sealing effect, Effect of Reducing Axial Backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

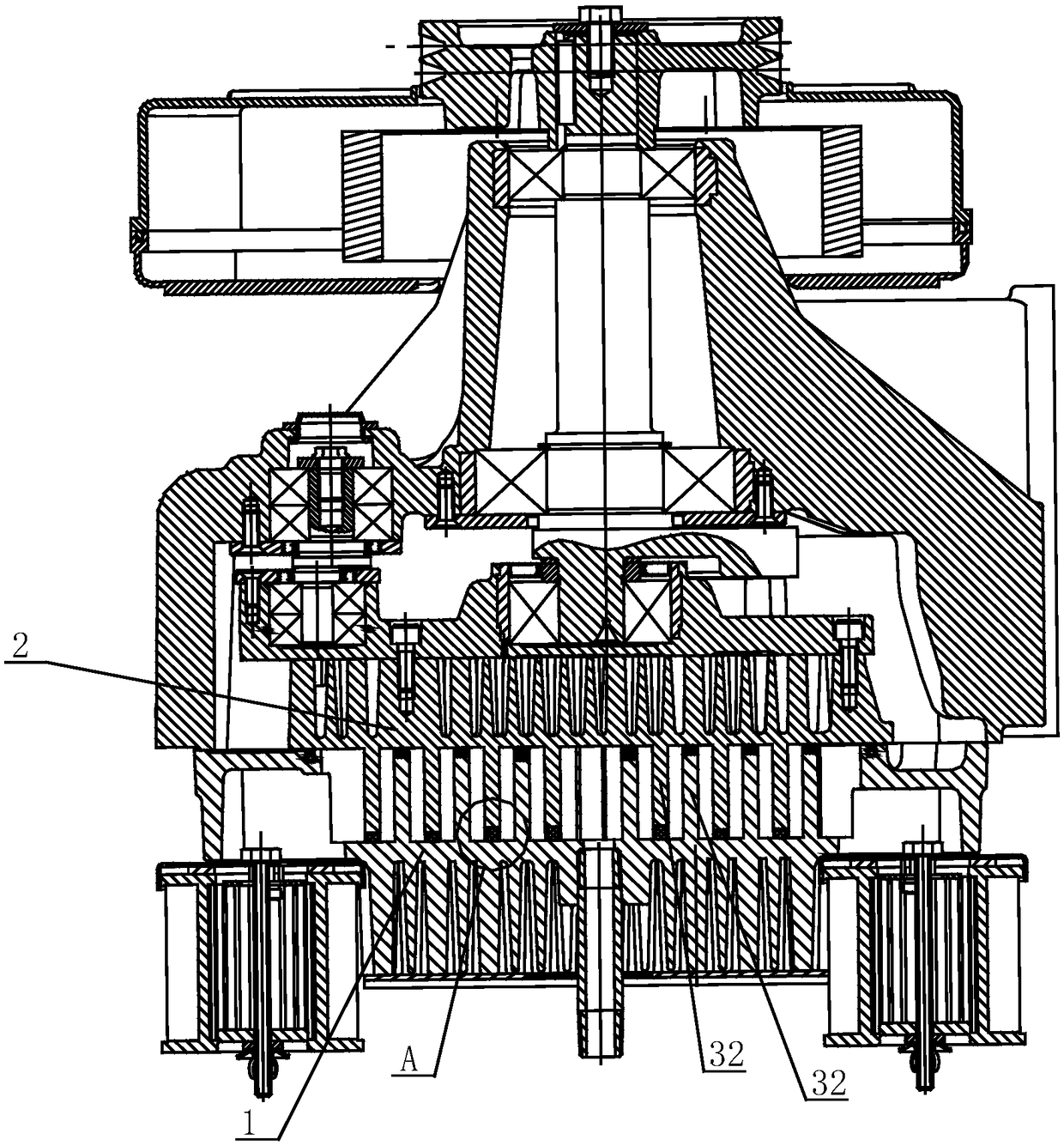

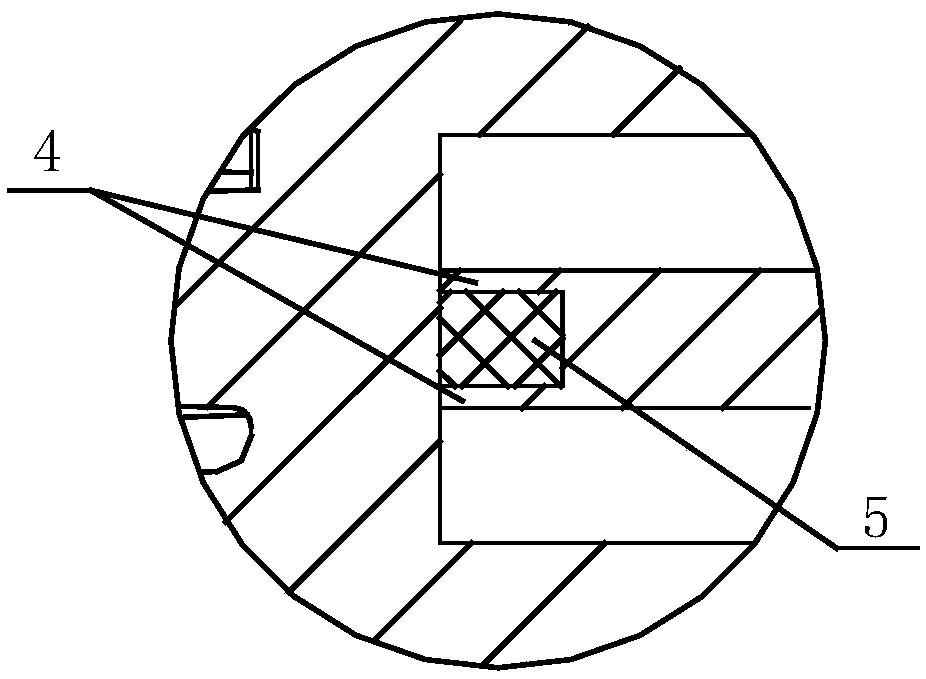

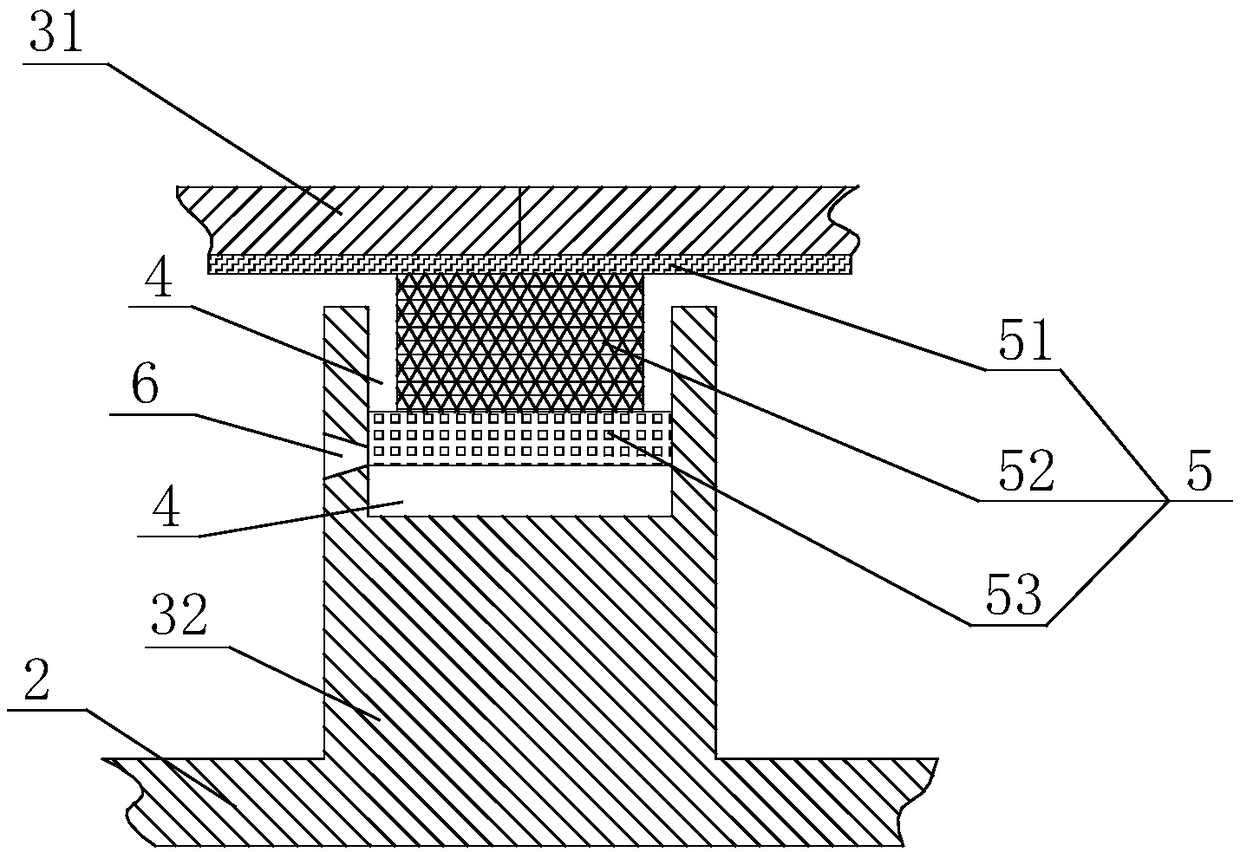

[0025] Such as figure 1 As shown, the oil-free scroll compressor includes a fixed scroll 1 and a movable scroll 2, and the fixed scroll 1 and the movable scroll 2 are installed opposite to each other at 180°. Sealing grooves 4 are provided on the first scroll teeth 31 of the fixed scroll 1 and the second scroll teeth 32 of the movable scroll 2 . Because the fixed scroll 1 and the first scroll 31 and the second scroll 32 of the movable scroll 2 have the same structure, they are arranged oppositely. In order to save space, the second scroll on the movable scroll 2 is used below 32 as an example. Wherein, the interface surface between the fixed scroll 1 and the second scroll 32 or the interface surface between the movable scroll 2 and the first scroll 31 is used as the end surface of the scroll, and the first scroll 31 or the second scroll 31 is used as the end surface of the scroll. The groove surface of the second spiral tooth 32 (that is, the surface provided with the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com