Pump comprising an integrated engine

An electric motor and integrated technology, applied in liquid fuel engines, parts of pumping devices for elastic fluids, machines/engines, etc., can solve problems such as damage to sliding bearings and rotor chambers, single-sided wear of sliding bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

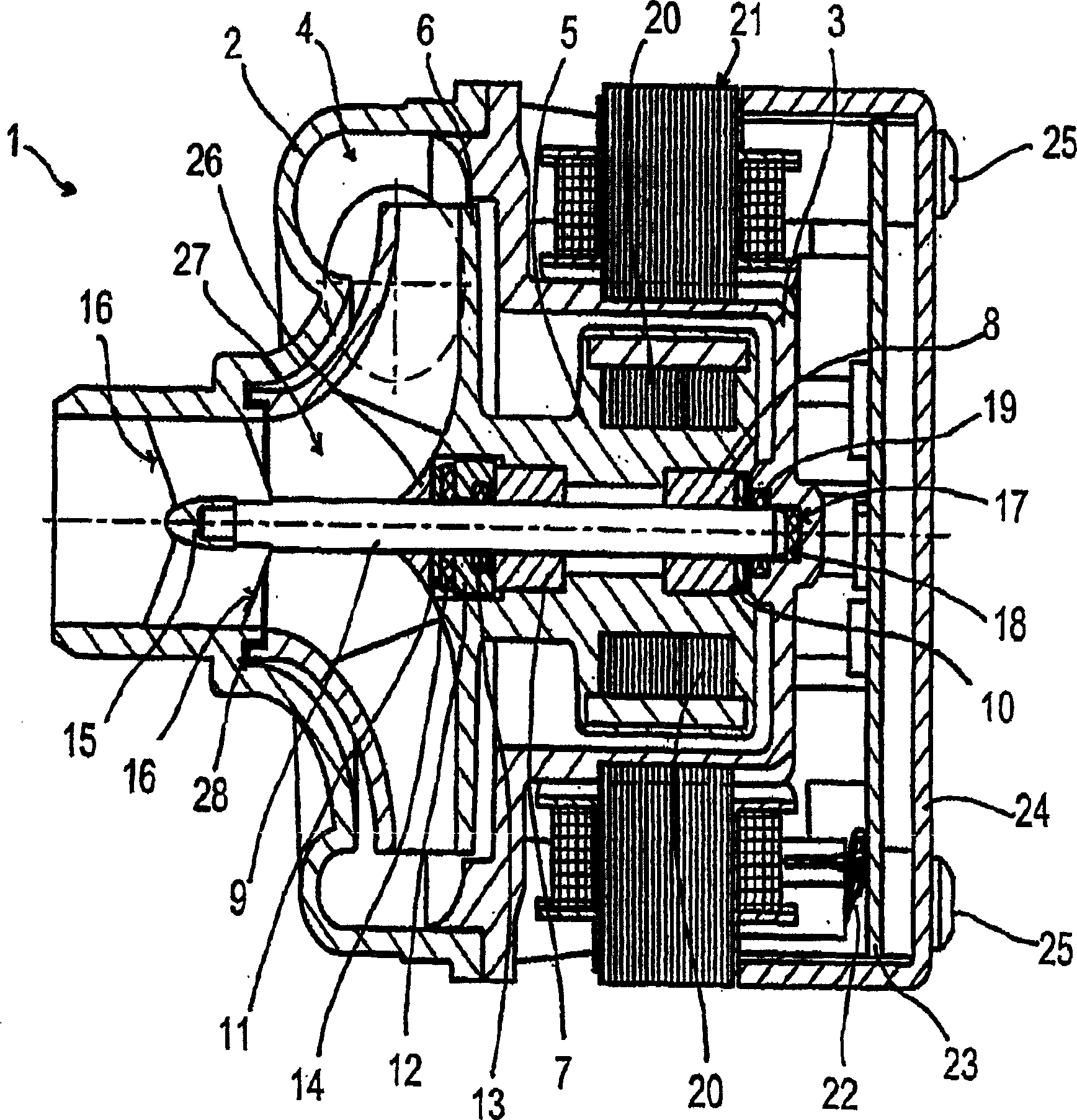

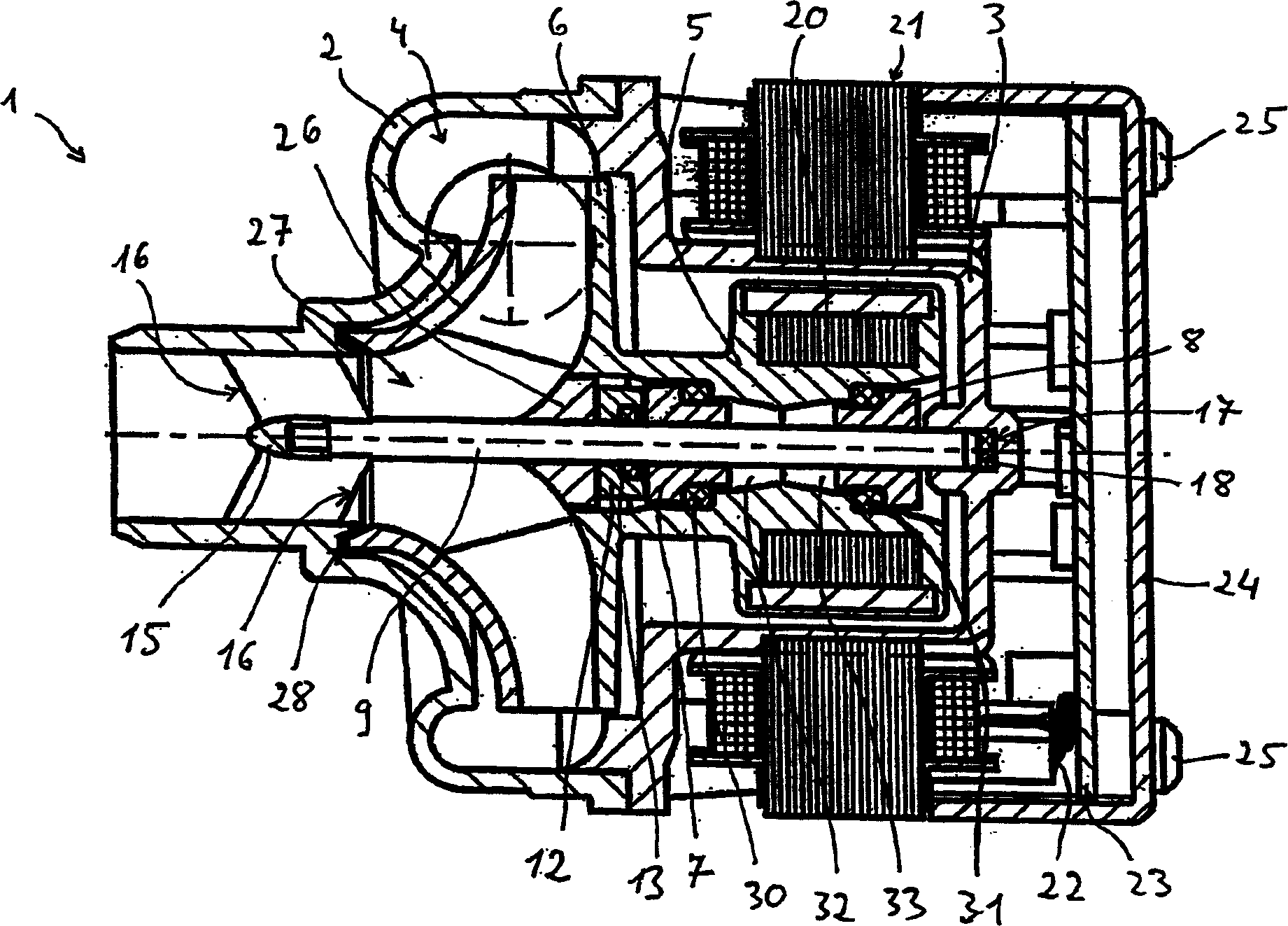

[0017] in accordance with figure 1 and figure 2 , The housing of the pump 1 is composed of a front housing shell 2 and a pot-shaped end cover 3, which are connected in a form-fitting manner. The casing of the pump 1 forms an integral pump chamber 4 in which a rotor 5 and an impeller 6 are included. The impeller 6 is preferably integrally formed on the rotor 5 .

[0018] The rotor 5 is rotatably supported on the shaft 9 via a front sliding bearing 7 adjacent to the impeller 6 and via a rear sliding bearing 8 adjacent to the end cover 3 . In order to prevent the rotor 5 from moving axially on the shaft 9, according to figure 1 , the rotor 5 is positioned at each of its ends by a locking ring 10 , 11 . In addition, the rotor 5 has an end bearing 12 at its front end close to the impeller 6 to reduce axial displacement, which has a seat for an O-ring 13 between the end bearing 12 and the slide bearing 7 . The sliding bearing 7 is sealed against the liquid inlet, in particular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com