Megawatt semi-direct driving wind-power generator group

A wind turbine and direct drive technology, applied in the direction of wind motor combination, wind engine, wind engine control, etc., can solve the problems of complex vector decoupling calculation, complex control implementation, and inconspicuous control target effect, and achieve system control High precision, good running stability and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

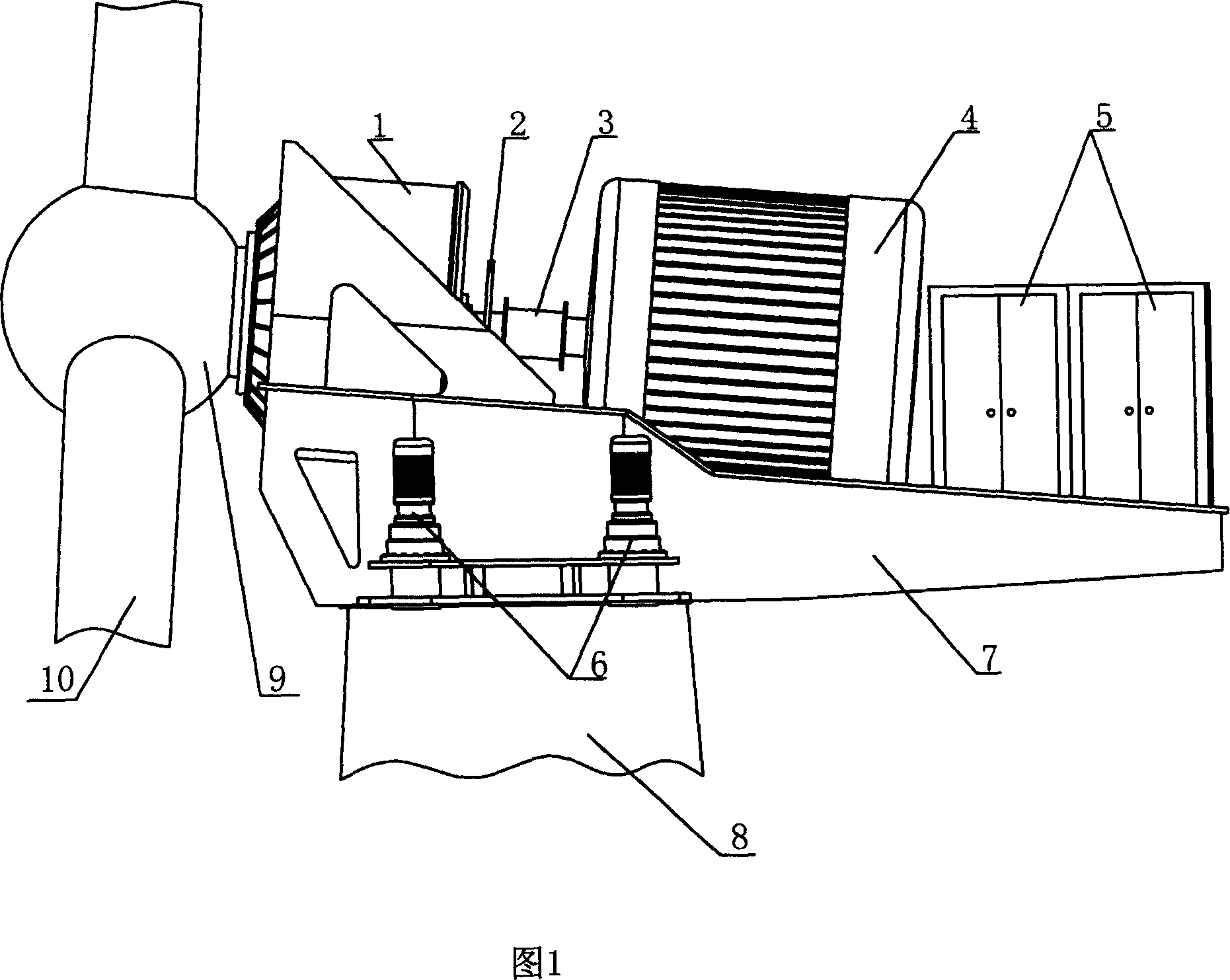

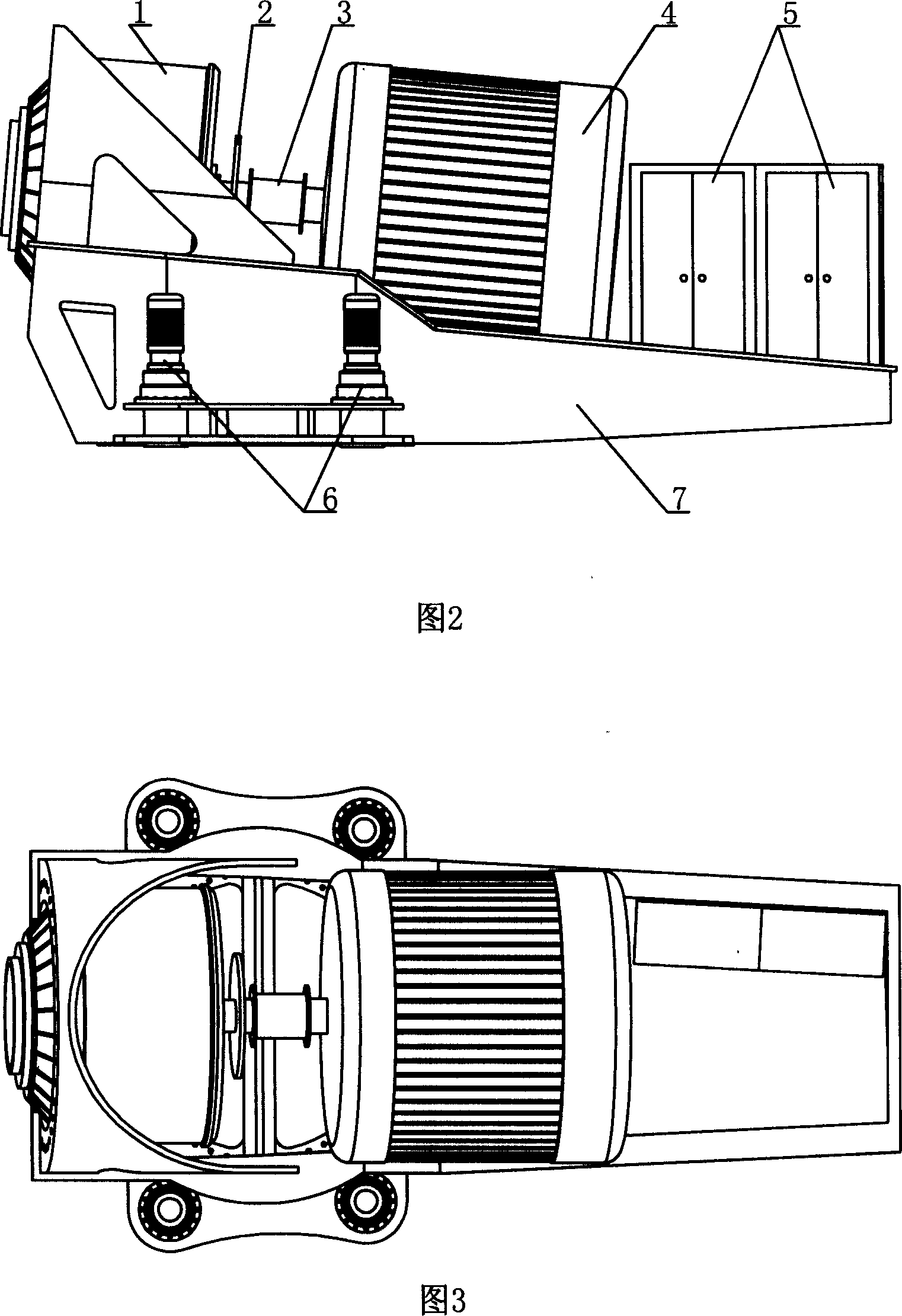

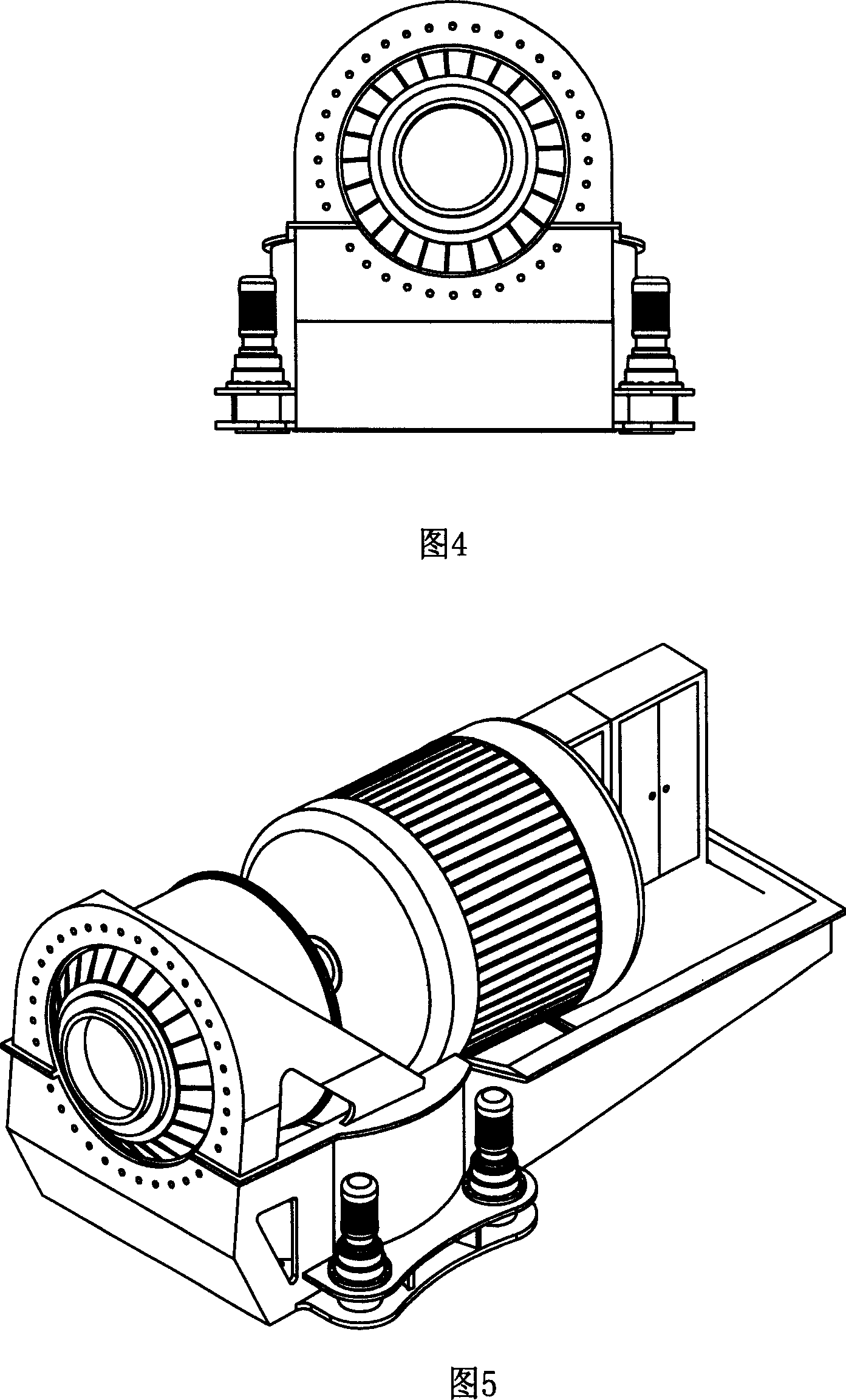

[0044]Embodiment: As shown in Figure 1, the speed-up gearbox 1 of this example adopts a one-stage planetary speed-up gearbox structure, the speed ratio is 1:8, and the motor uses a low-speed permanent magnet three-phase synchronous generator with a power of 1 megawatt. . The present invention includes a wind wheel 19, a variable pitch device, a main shaft, a nacelle chassis 7, a yaw motor 6, a speed increaser 1, a coupling 3, a generator 4 and a control system 5, and the wind wheel 19 includes a wind wheel blade 10 and a hub 9. The wind rotor blade 10 is connected to the wheel hub 9 through the variable pitch bearing 15, the wheel hub 9 is connected to the outer ring of the variable pitch bearing 15, the wind rotor blade 10 is connected to the inner ring of the variable pitch bearing 15, and a deflector is fixed on the chassis 7 of the nacelle. Aeromotor 6, generator 4, generator 4 is connected to speed-up box 1 through coupling 3, brake 2 is installed on the output shaft of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com