Rigid pavement construction on steel deck and construction method thereof

A construction method and steel bridge deck technology, which can be applied to cohesive pavement paved on site, bridges, bridge parts, etc., can solve the problems of threatening driving safety and easy loosening of gravel, so as to achieve good integrity and improve driving safety , Improve the effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Pavement structure and materials

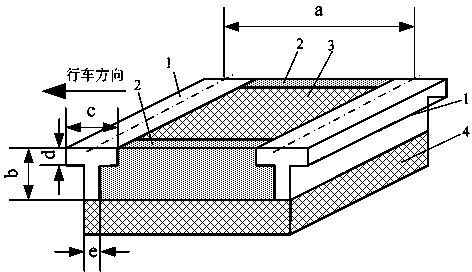

[0022] Such as figure 1 , the components of the pavement structure include: a grid piece formed by a steel grid laid on the bridge deck steel plate 4 and a rigid filler 3 filling the internal gap of the steel grid. The upper surface of the steel grid is flush with the upper surface of the rigid packing, and jointly bear the driving load.

[0023] Among them, the steel mesh is a regular quadrilateral. The grid side length a is 100 mm. The grid height b is the thickness of the pavement layer, which is 25mm. The raw material of the steel grid is Q345qC grade steel specified in GB / T714-2008 "Structural Steel for Bridges". The cross-section of the beam 1 perpendicular to the driving direction is T-shaped; the width e of the lower surface is 10mm; the width c of the upper surface is 1.5 times of the width of the lower surface. The section of the longitudinal beam parallel to the driving direction is rectangular, and the section w...

Embodiment 2

[0033] (1) Pavement structure and materials

[0034] The components of the pavement structure include: a grid piece formed by a steel grid laid on the bridge deck steel plate 4 and a rigid filler 3 filling the internal gap of the steel grid. The upper surface of the steel grid is flush with the upper surface of the rigid packing, and jointly bear the driving load.

[0035] Among them, the steel mesh is a regular quadrilateral. The grid side length a is 1000mm. The grid height b is the thickness of the pavement layer, which is 50mm. The raw material of the steel grid is Q345qC grade steel specified in GB / T714-2008 "Structural Steel for Bridges". The cross-section of the beam 1 perpendicular to the driving direction is T-shaped; the width e of the lower surface is 20 mm; the width c of the upper surface is twice the width of the lower surface. The section of the longitudinal beam parallel to the driving direction is rectangular, and the section width is 20mm.

[0036] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com