Multi-stream reducer tube wound heat exchanger

A coiled tube heat exchanger, multi-flow technology, applied in the direction of indirect heat exchangers, heat exchanger types, fixed tubular conduit components, etc., can solve the need for improvement in the coiled tube structure and layout, shell side fluid flow resistance Large, shell-side fluid turbulence effect and reduced convective heat transfer effect, etc., to improve the comprehensive heat transfer effect, reduce the total weight, enhance turbulence and convective heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

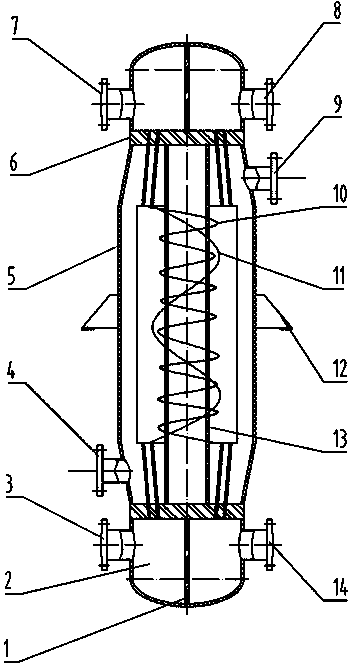

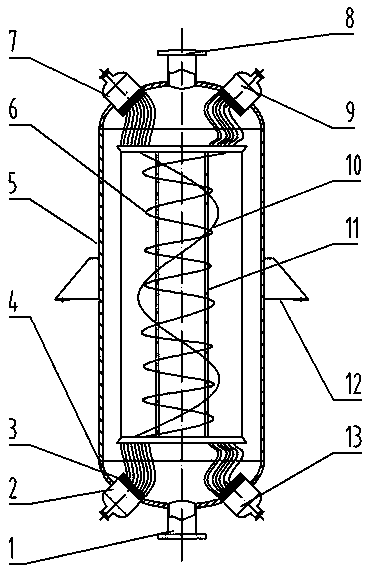

[0014] The assembly process of the multi-flow reducer tube-wound heat exchanger will be further described below with reference to the accompanying drawings.

[0015] Taking the double-tube-sheet double-flow reducer tube-wound heat exchanger as an example, first, the core tube and the tube sheets at both ends are welded and fixed, and then each layer of winding tubes is made of winding tubes of various diameters according to the The designed helix angles are wound outside the core barrel in turn, and then, the two ends of all the wound pipes are divided into two tube bundles according to the diameter of the tubes, and the two tube bundles at one end penetrate into the two areas of the same tube sheet respectively, and the two tube bundles at the other end The two tube bundles respectively penetrate into the two areas corresponding to another tube sheet.

[0016] For the four-tube-sheet double-flow reducer tube-wound heat exchanger, firstly, the core tube and the circular frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com