FPSO (Float Production Storage and Offloading) ship

A stern and bow technology, which is applied to the field of offshore floating production and storage ships, can solve problems such as poor adaptability of the hull and mooring system, and reduce the probability and severity of collision damage, large oil storage, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

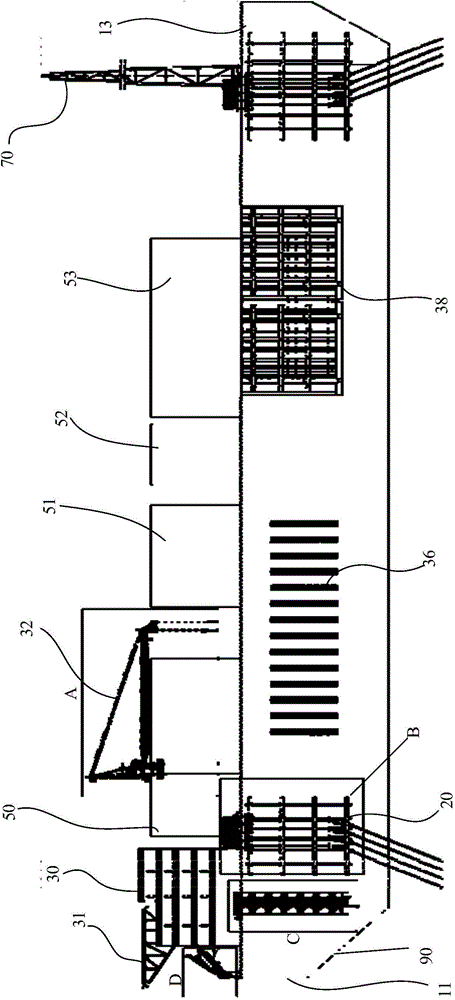

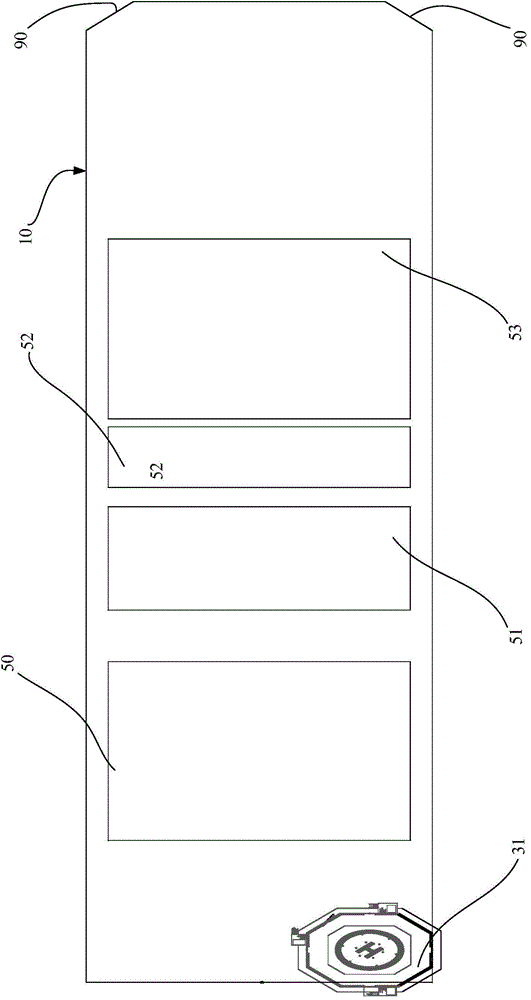

[0074] Figure 1-Figure 9 An FPSO vessel is shown. Such as figure 1 As shown, the FPSO ship of the present embodiment includes a hull 10, the total length of the hull is 310-330 meters, the molded width is 60-65 meters, the molded depth is 30-35 meters, and the maximum draft is 20-25 meters; from the stern 11 to the ship Bow 13 includes in turn:

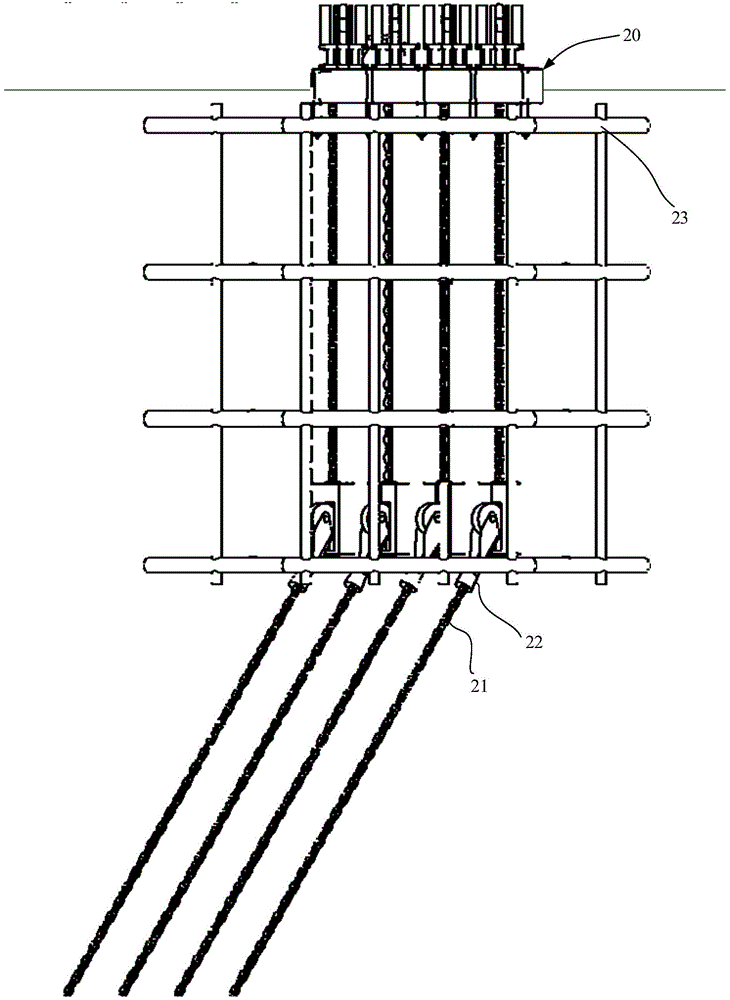

[0075] Such as Figure 1-4 As shown, the living building 30, the main power station and power distribution module 50, the thermal station module 51, the process system module 52, the oil and gas treatment and metering module 53, and the flare tower 70; the stern 11 and the bow 13 of the FPSO ship are symmetrical on the left and right sides A total of four mooring points 20 are arranged on the ground; the bow 13 of the FPSO ship, and a set of external oil delivery devices 40 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com