Grease stain resistance separation-type high-speed energy-saving spinning spindle

A separate, spindle technology, applied in textiles and papermaking, etc., can solve the problems of upper bearing wear, inability to ensure the waste oil in the waste oil tank, clean oil pollution in the fuel tank, etc., achieve small structural changes, avoid insufficient cleaning, and refueling The effect of cycle extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

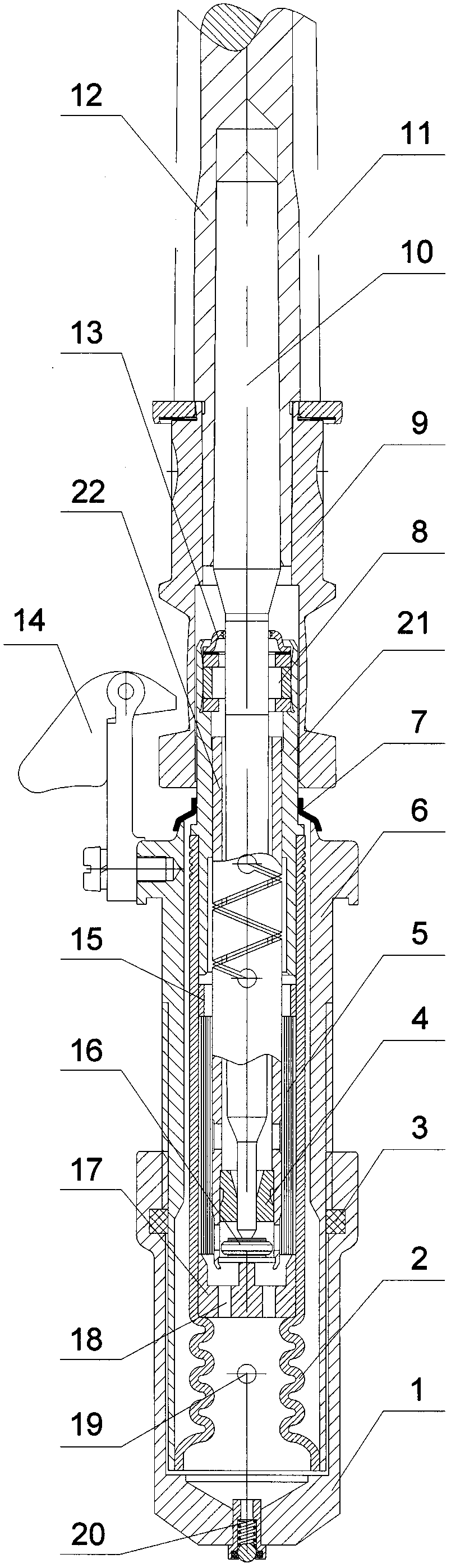

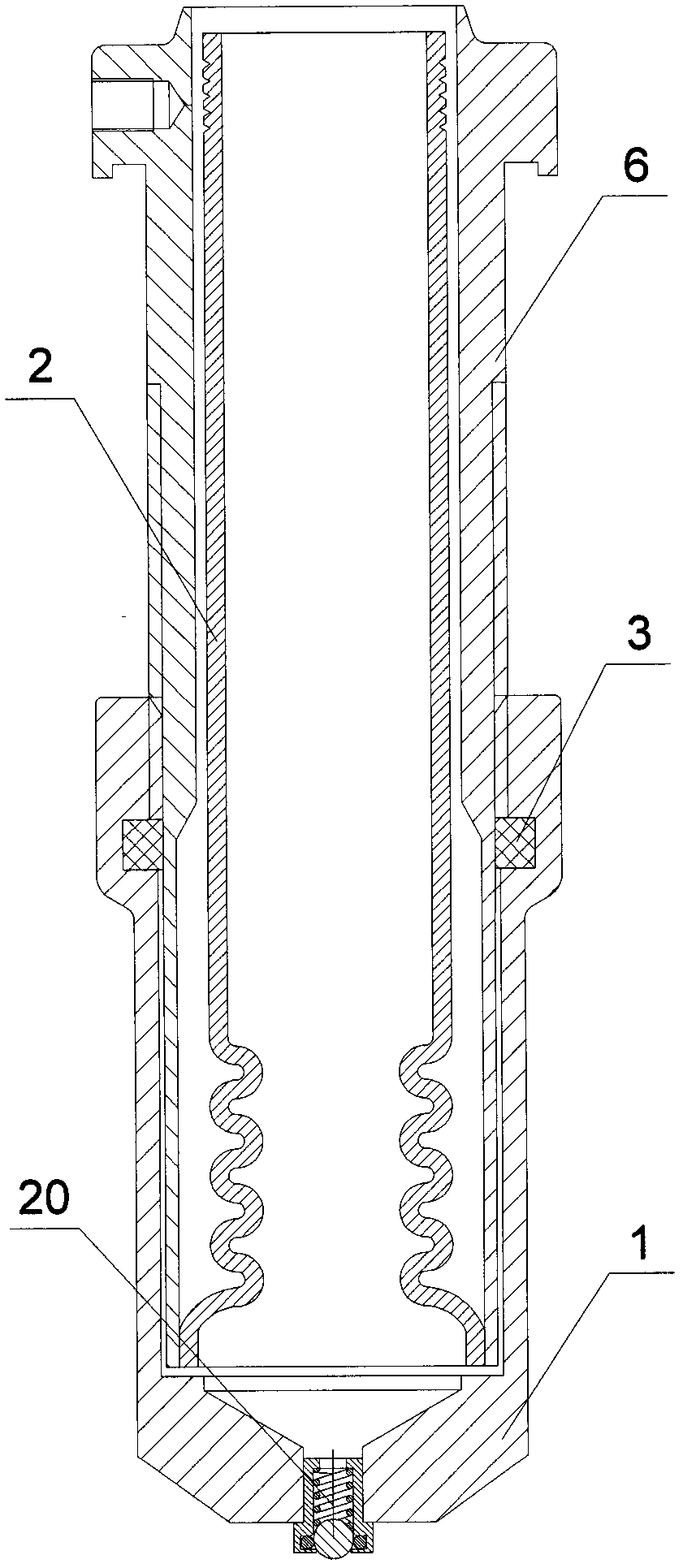

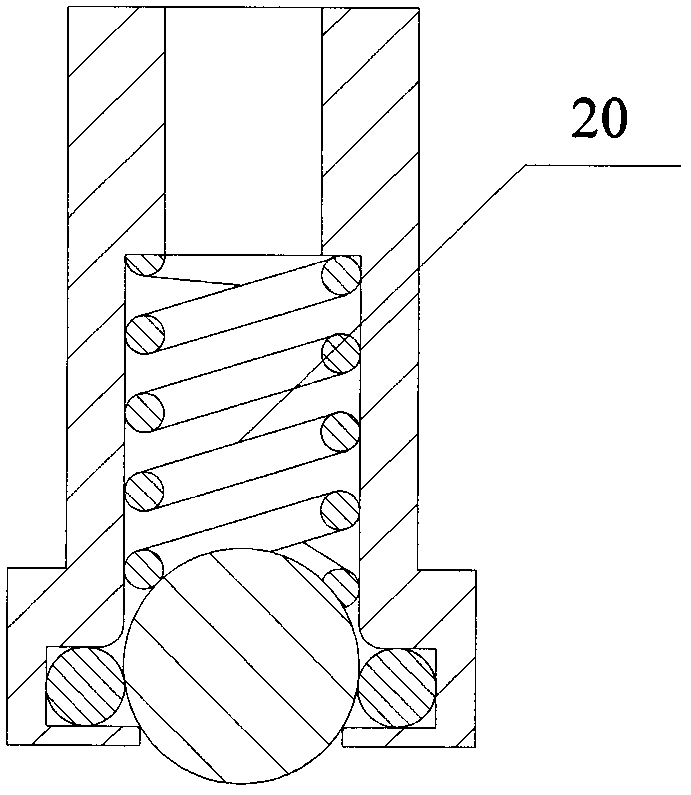

[0030] Embodiments of the present invention are described with reference to the accompanying drawings, below in conjunction with Figure 1-Figure 5 The present invention will be specifically described.

[0031] Such as figure 1 , figure 2 , image 3 As shown, a high-speed energy-saving textile spindle with anti-greasy dirt separation includes a spindle base 1, an inner spindle tube 2, a sealing ring 3, an outer spindle tube 6, a sealing cover 7 for the inner and outer spindle tubes, a support block 17, and a Hole 18, outer spindle foot oil valve 19, spindle bottom oil valve 20.

[0032] The inner spindle leg tube 2, the outer spindle leg tube 6, and the spindle leg base 1 are three separate structures, and the three together constitute a new type of separated spindle leg, wherein the lower end of the inner spindle leg tube 2 and the outer spindle leg tube 6 They are tightly matched, and the two are filled with damping oil. The oil filling work is completed by the outer sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com