Oil bearing

A technology of bearings and oil storage holes, applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of high cost, limited, small assembly space, etc., and achieve the effect of avoiding the increase of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

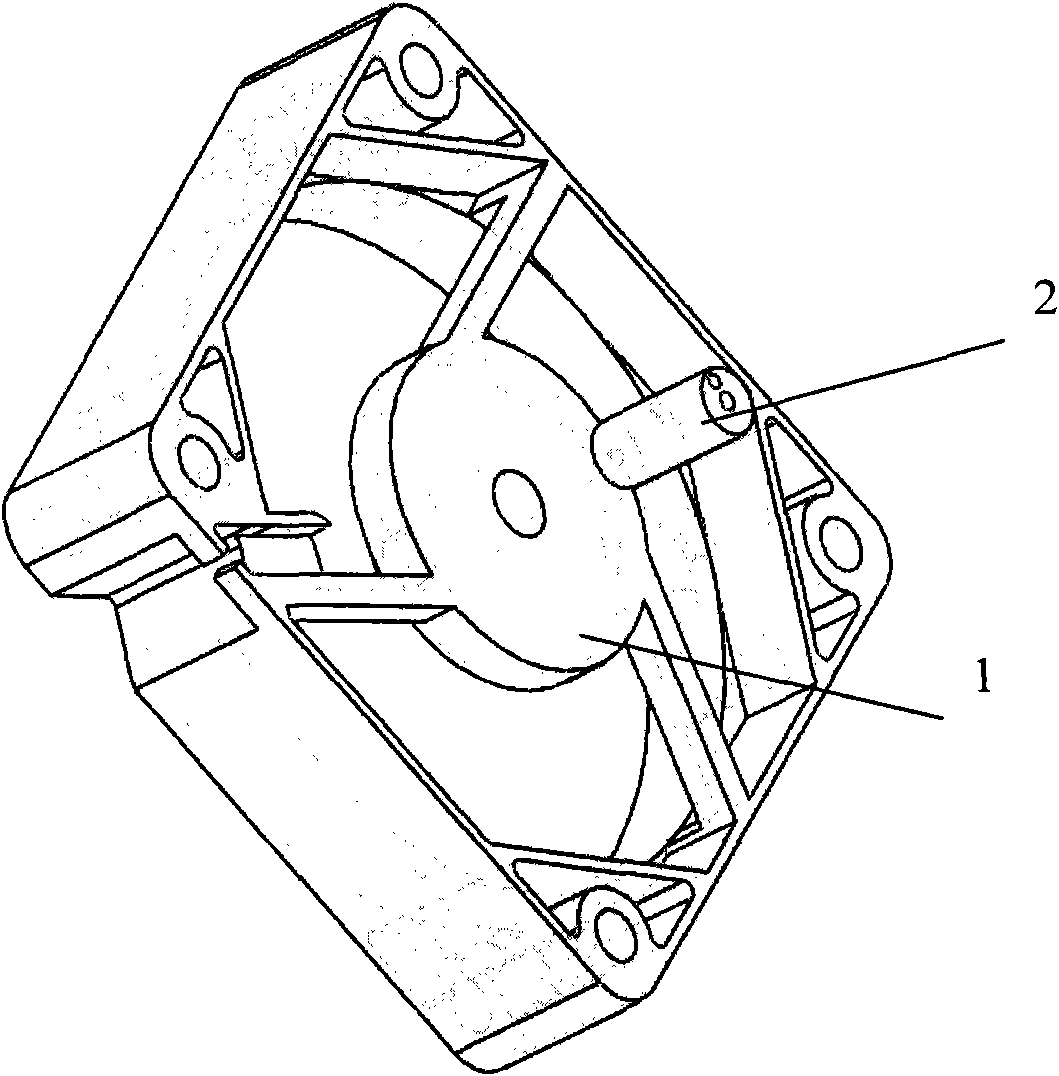

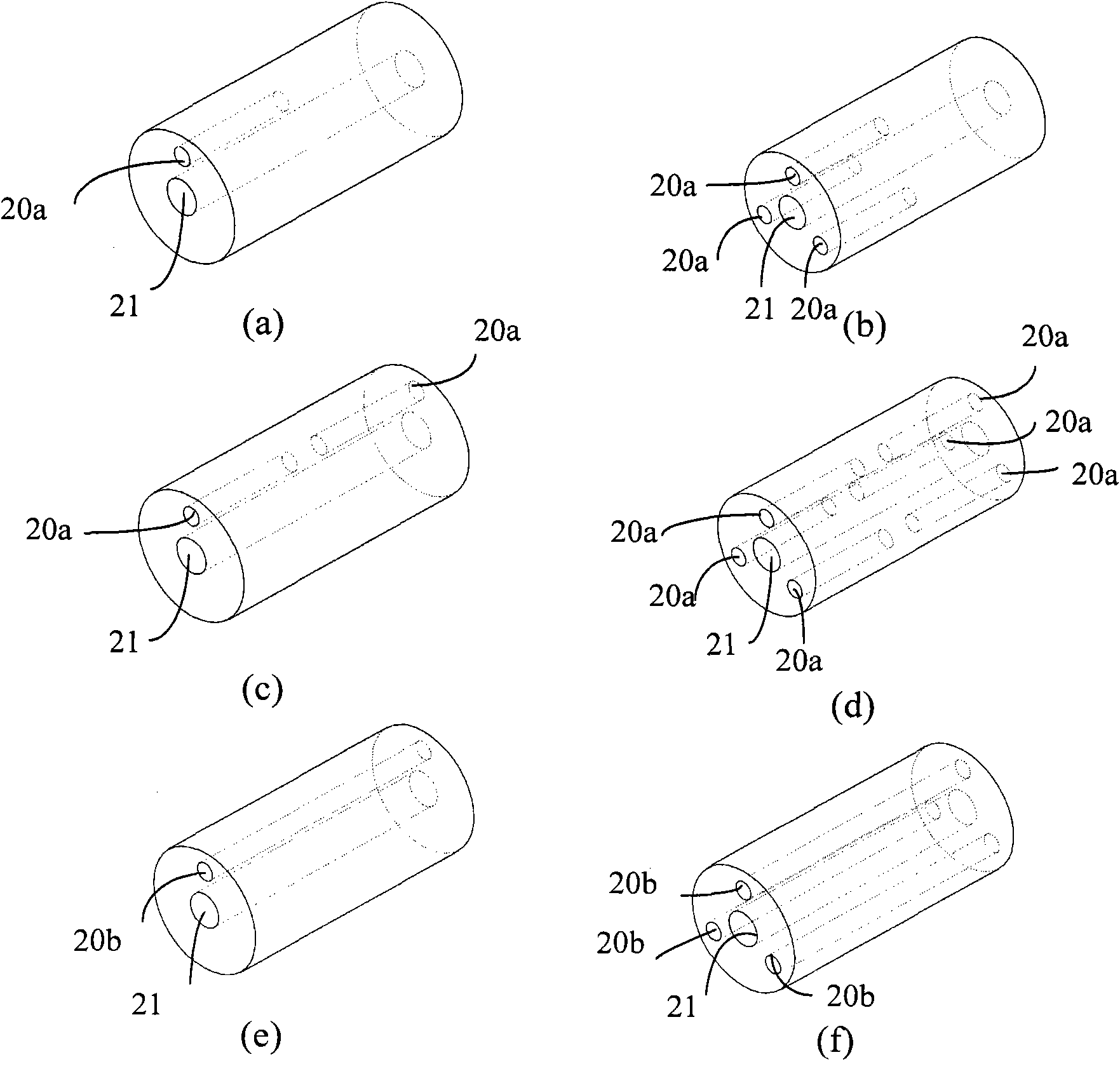

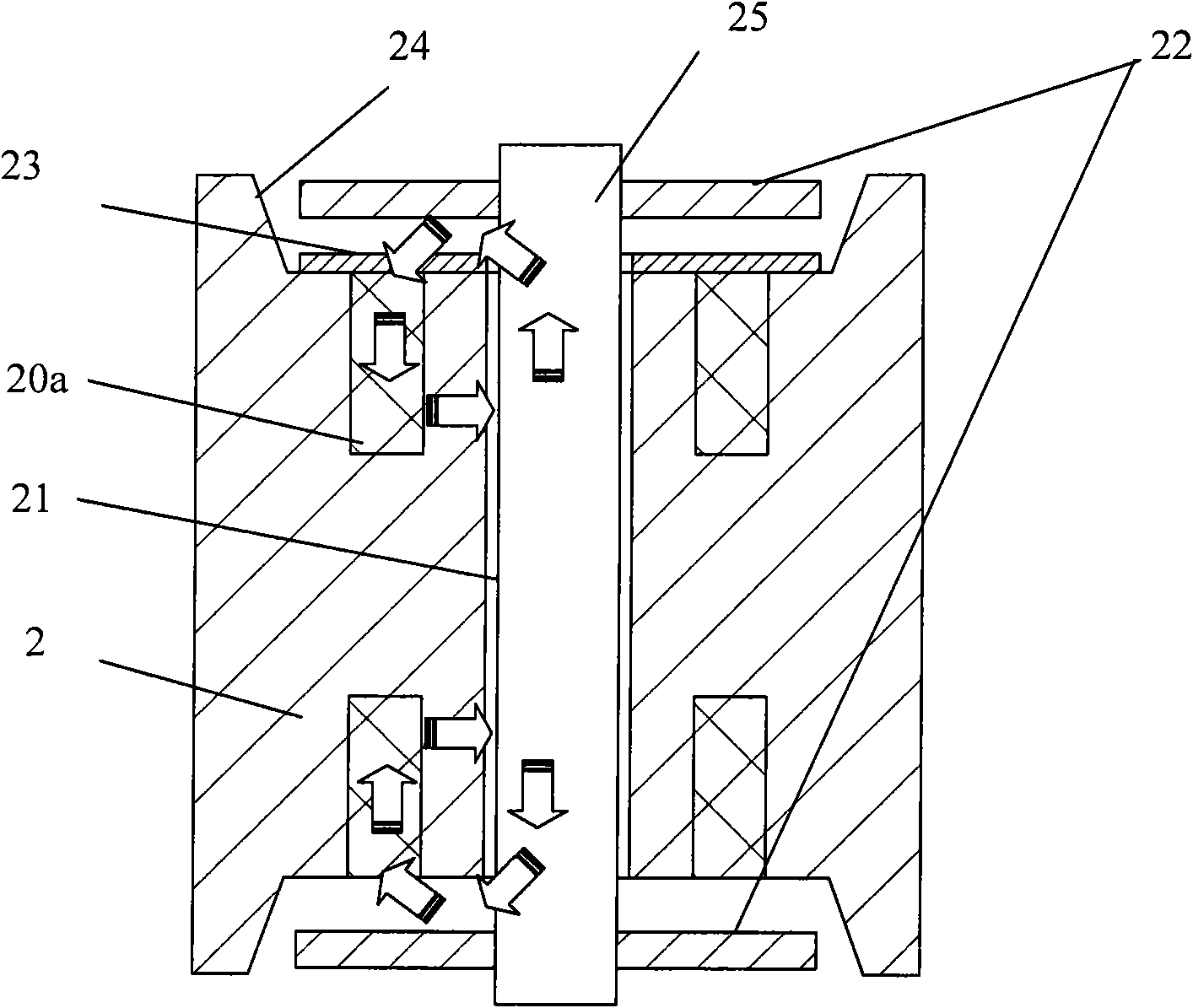

[0046] Please refer to figure 1 and figure 2 , the first embodiment of the present invention will be described below. Motor 1 uses the bearing structure of 1 oil-impregnated bearing 2, offers oil storage hole 20a or 20b on one end side or both sides, and the quantity of oil storage hole 20a or 20b can be single respectively (such as figure 2 (a) shown), can also be multiple (such as figure 2 (b) shown). The size and depth of the oil storage hole 20a or 20b can be changed and specifically adjusted according to actual needs, combined with the size and precision requirements of the bearing itself, and other aspects. The oil storage hole of the oil bearing 2 can have various structural changes as follows:

[0047] Such as figure 2 As shown in (a), the oil bearing 2 is provided with a single hole 20a on one side (the hole does not pass through);

[0048] Such as figure 2 As shown in (b), the oil bearing 2 is provided with holes 20a on one side (the holes are not connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com