Patents

Literature

50results about How to "Liquid level is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

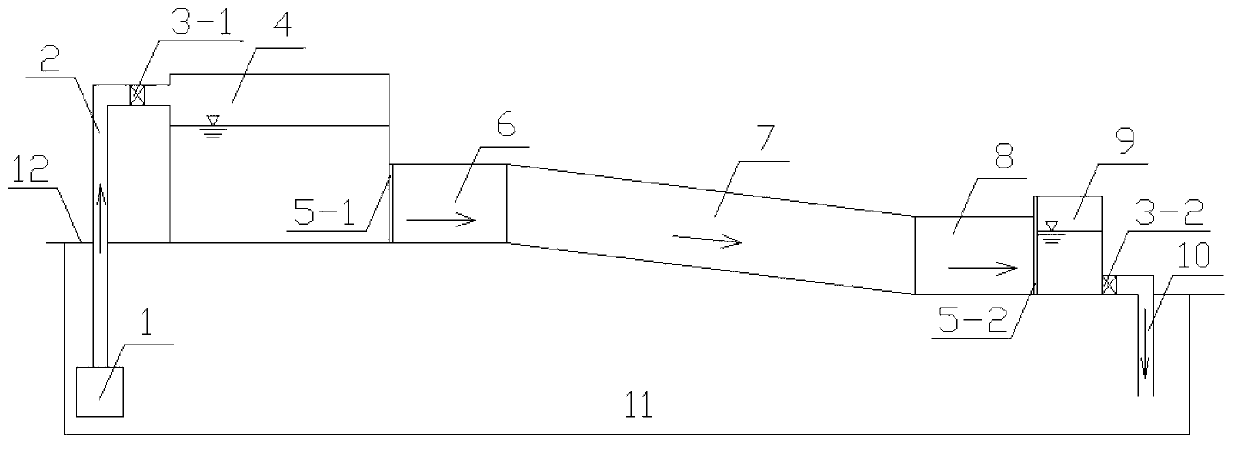

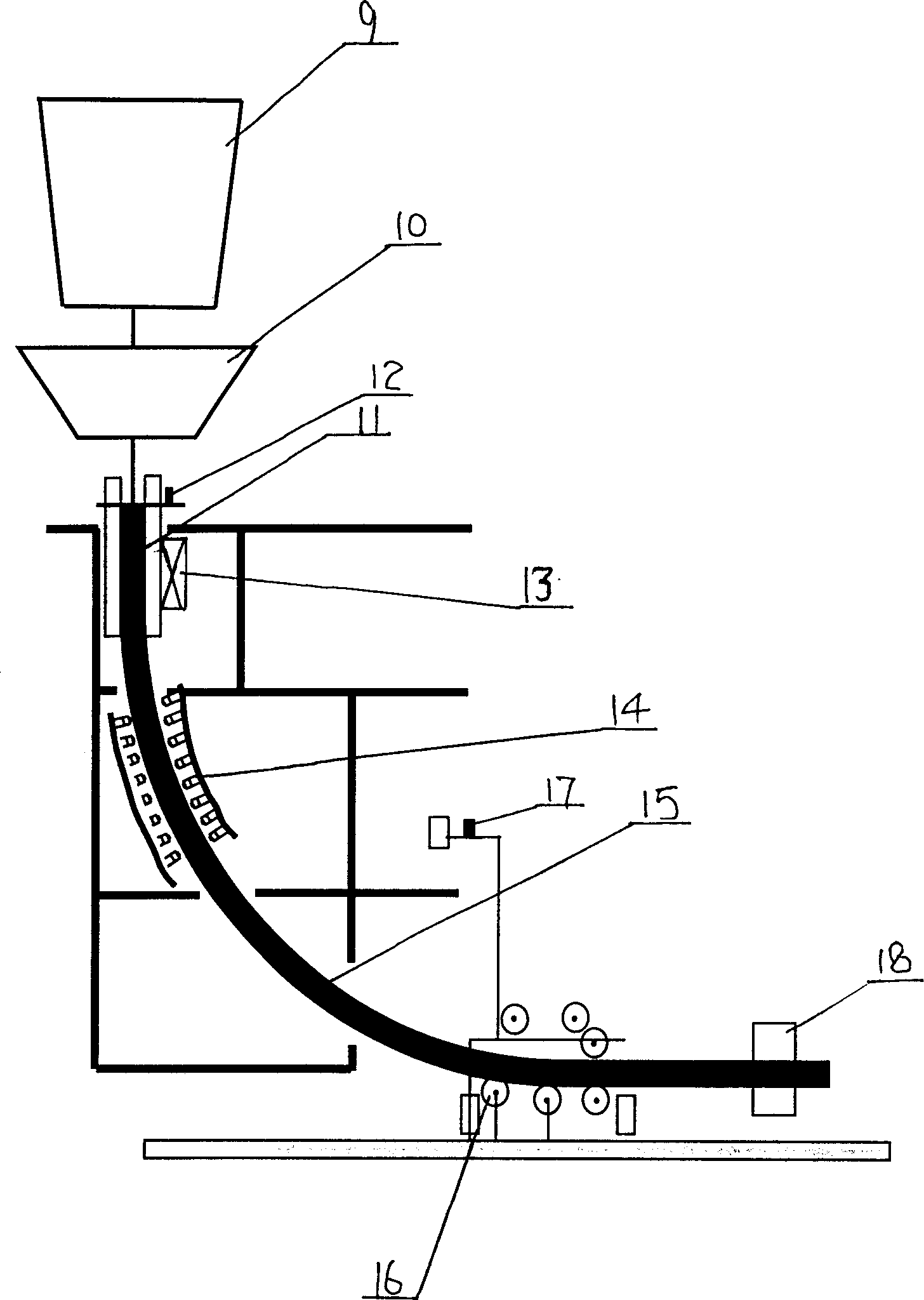

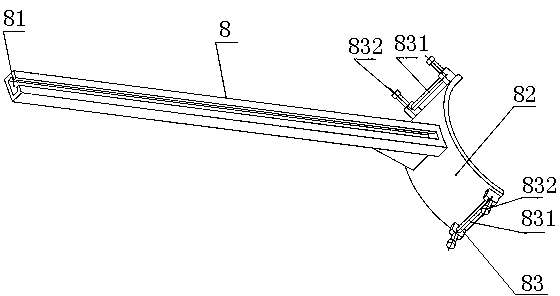

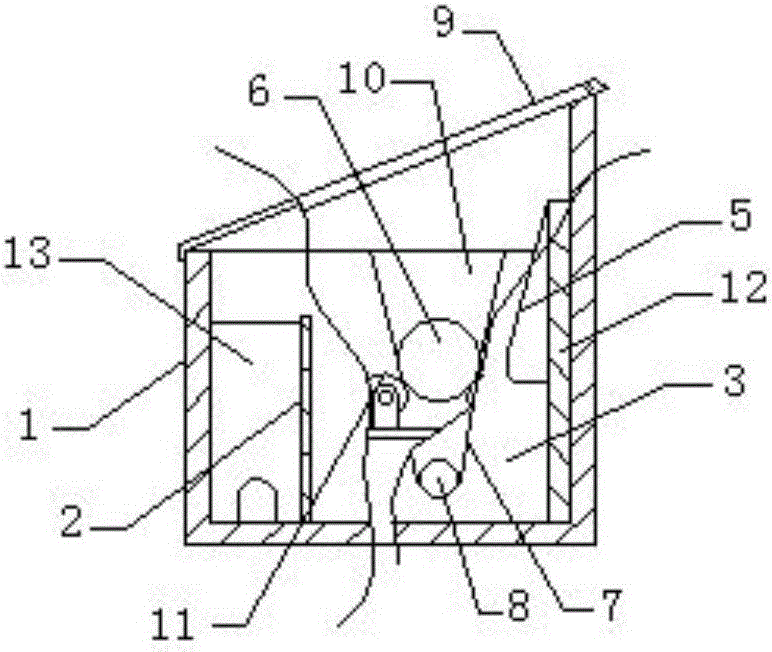

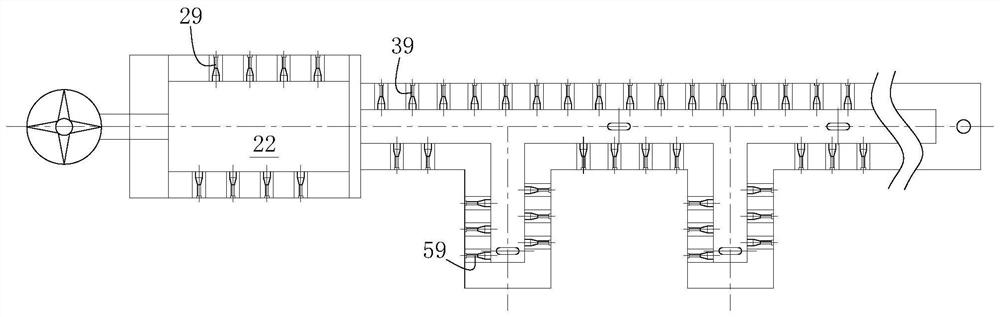

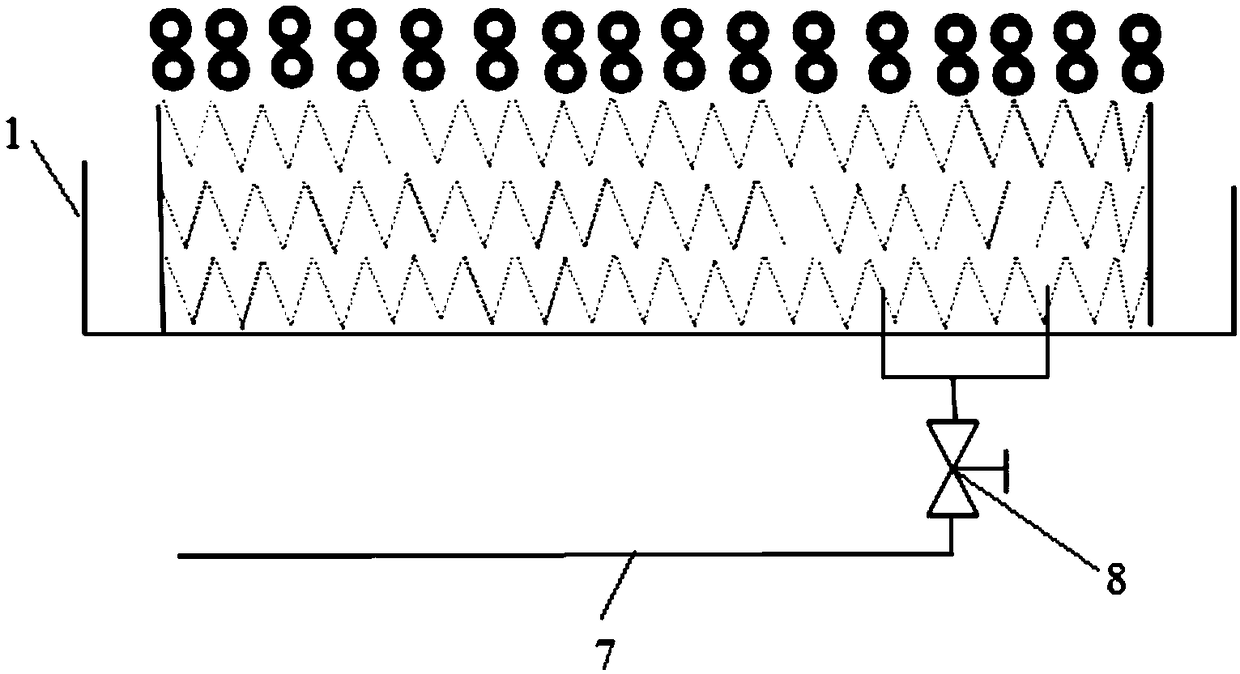

Slit type fishway experimental device with stages of falling sills and grooves

InactiveCN102176295AImprove applicabilityHigh degree of regulation automationHydrodynamic testingEducational modelsWater volumeThree stage

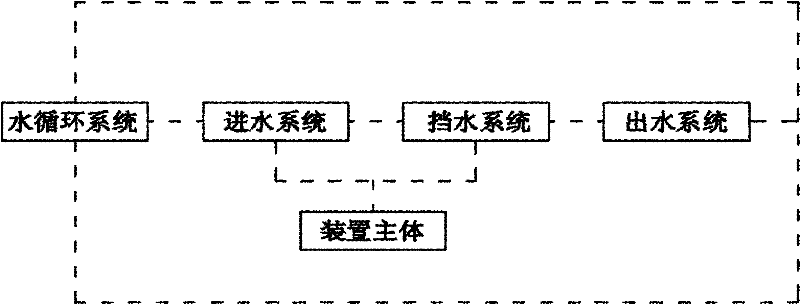

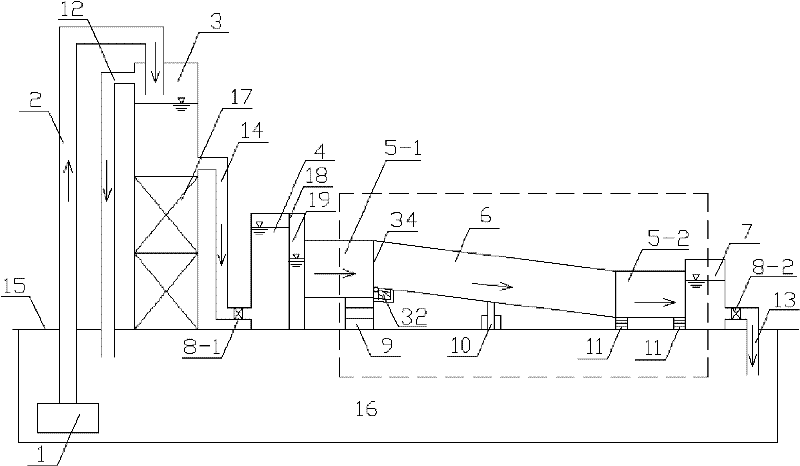

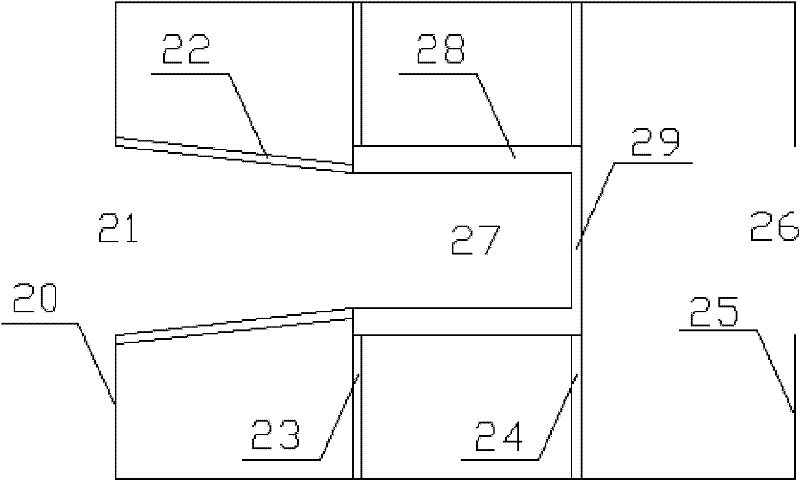

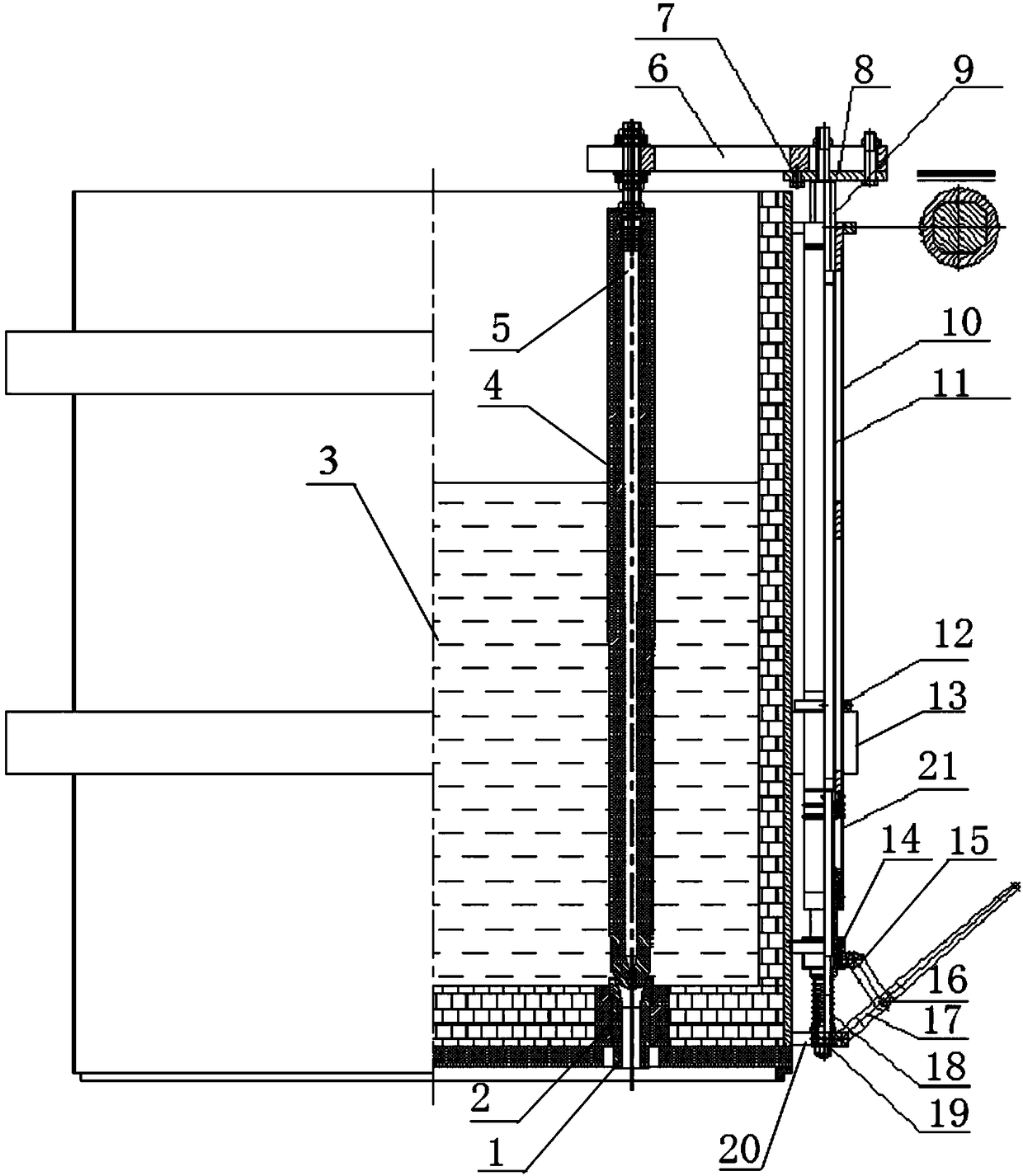

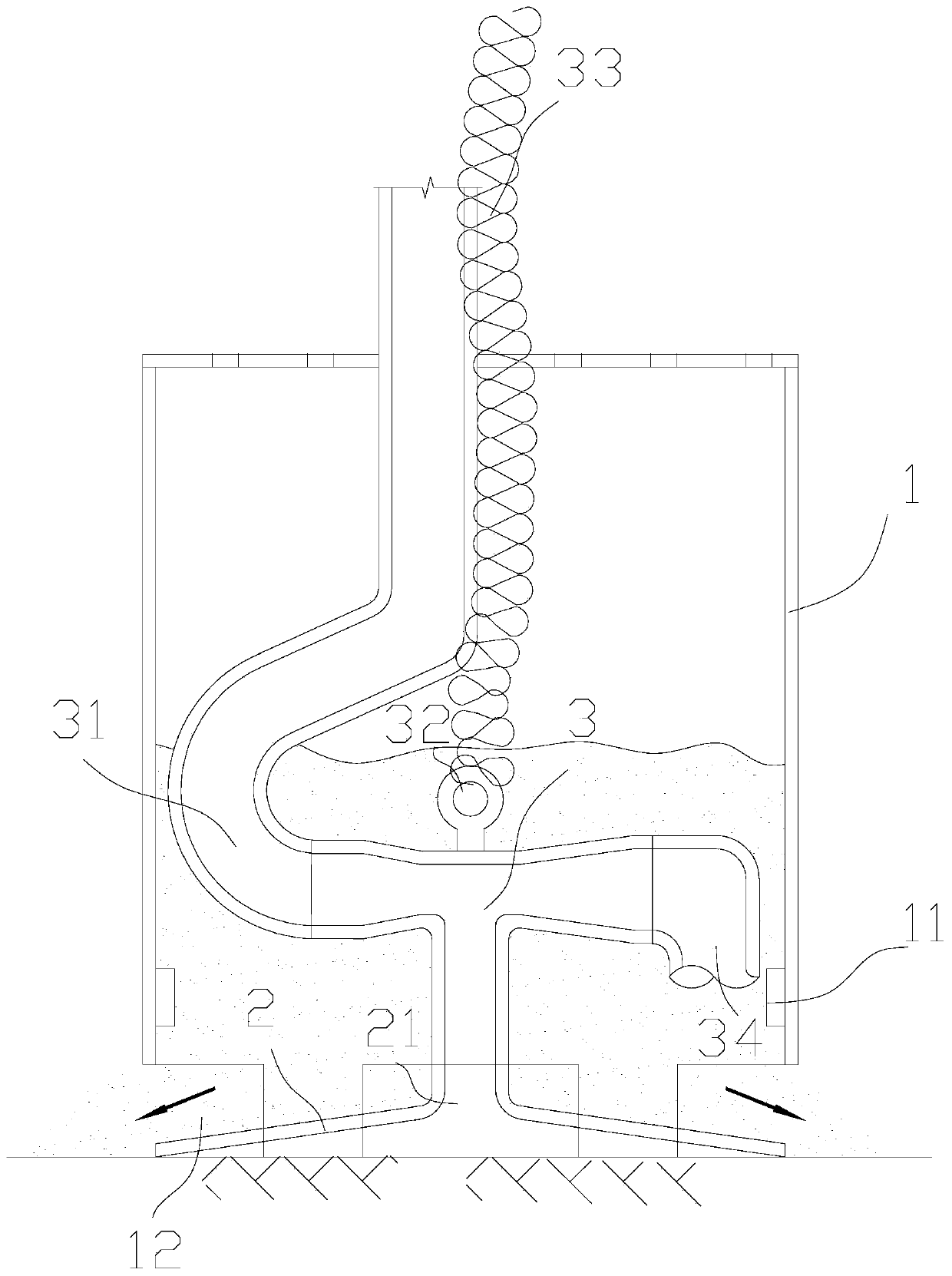

The invention relates to a slit type fishway experimental device with a plurality of stages of falling sills and grooves. The device mainly comprises a water inlet system connected with a water circulation system, a water retaining system connected with the water inlet system, and a water outlet system connected with the water retaining system. A water flow flows into the water inlet system through a ground water tank of the water circulation system, flows into a water tank of the water retaining system through a water flow buffer tank in the water inlet system, flows from a tail pond in the water inlet system into an underground pond through the water tank, and flows back into the ground water tank of the water circulation system through a draft tube.The water flow of the ground water tank is controlled by an upstream manual control valve, and the water flow of the tail pond is controlled by a downstream manual control valve. The device provided by the invention adopts the water circulation system, can recycle experimental water and reduces an experimental water volume and cost; three stages of falling sills are in fit with grooves so as to relatively more equally distribute energy dissipation to each energy dissipation part, improve the energy dissipation efficiency and reduce the degree of disorder of the water flow; and in a controllable range of the water flow, the flow rate and flow regime of the water flow are relatively closer to natural conditions, so a fish putting experiment meets actual conditions.

Owner:SICHUAN UNIV

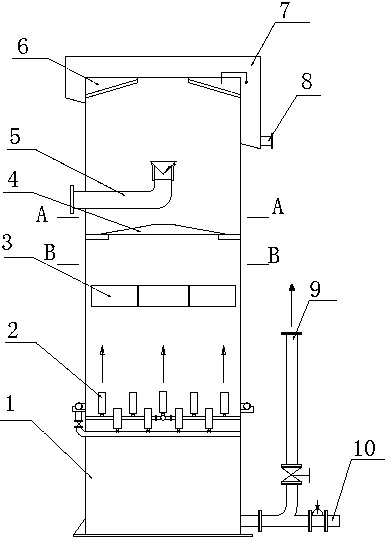

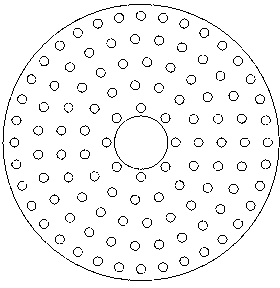

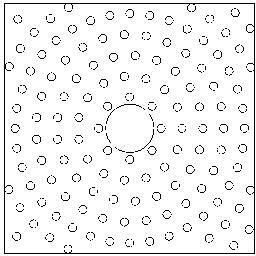

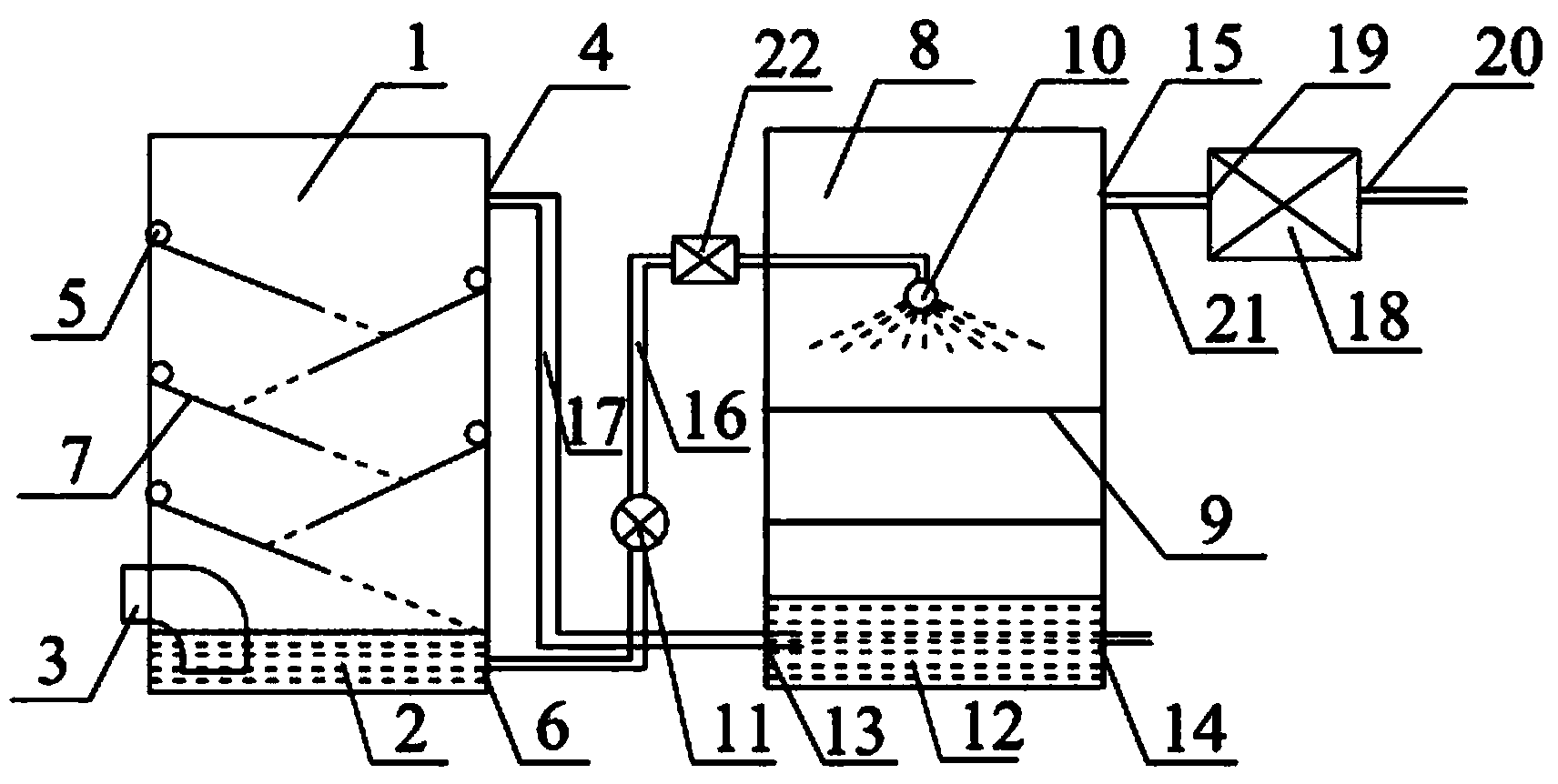

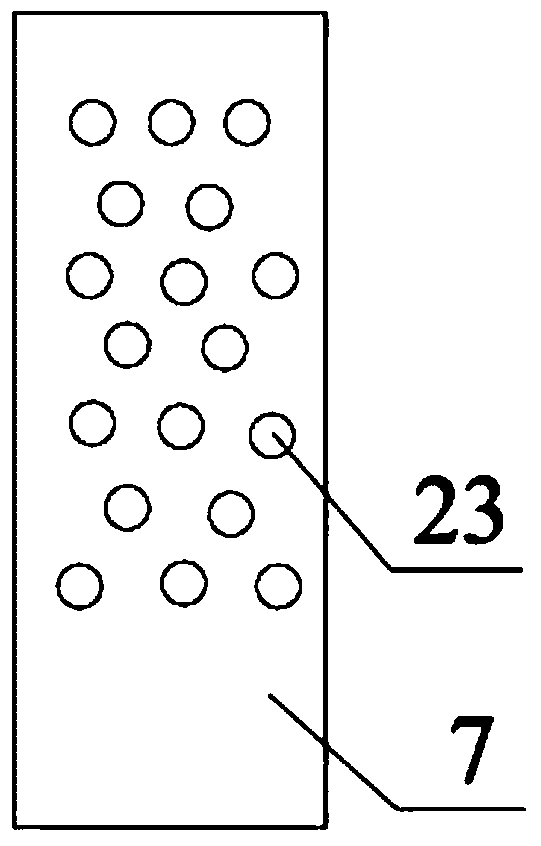

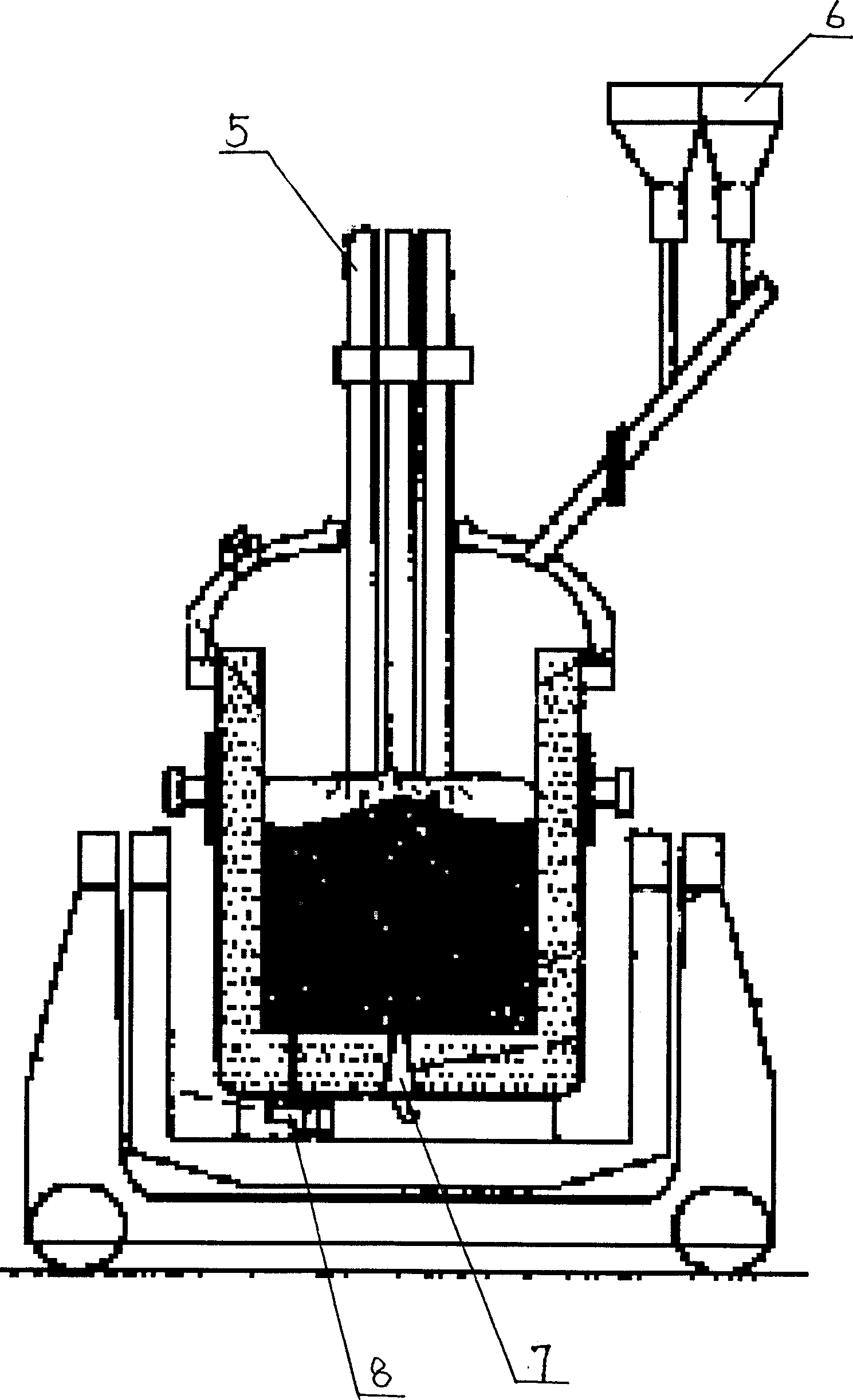

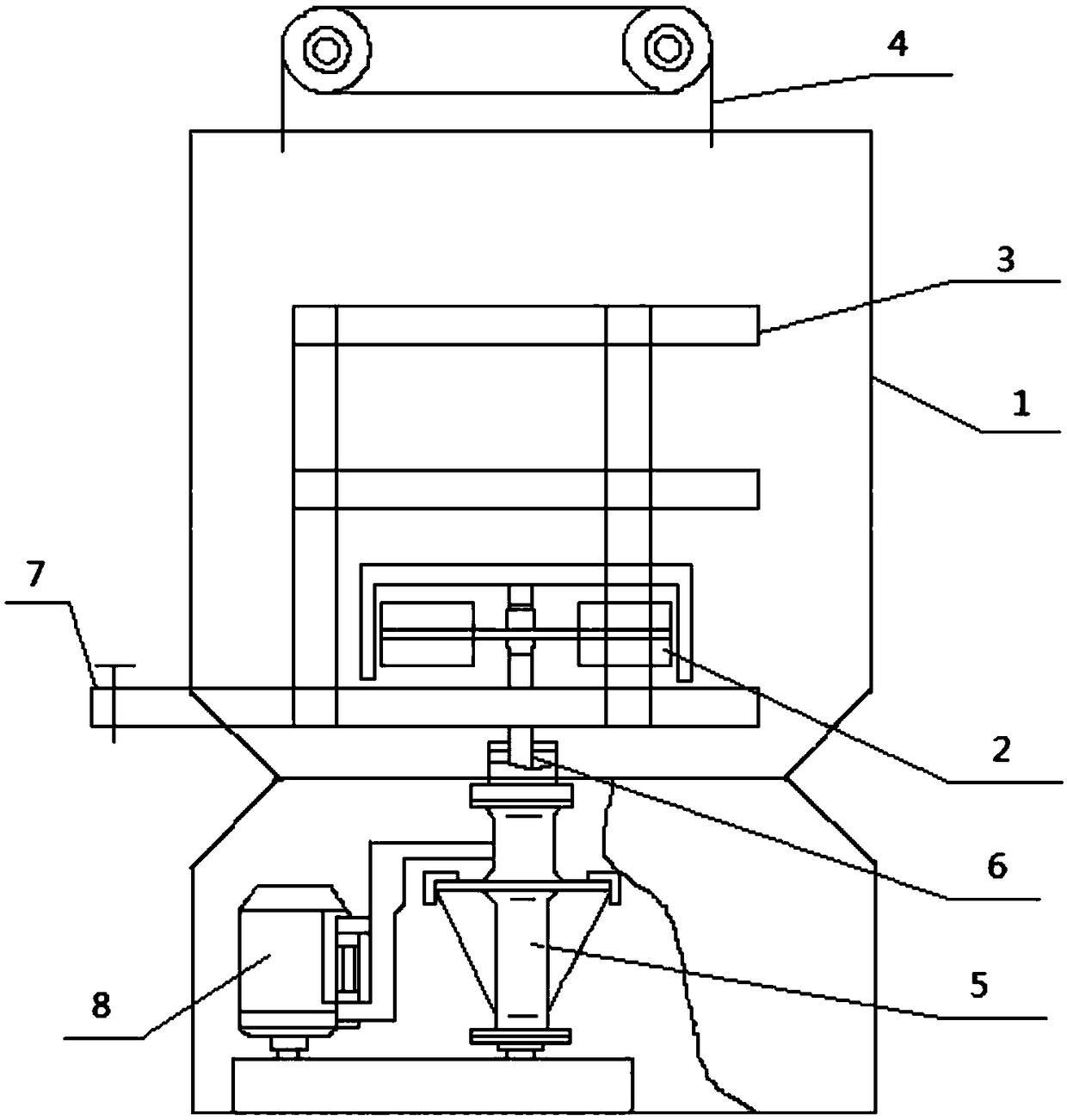

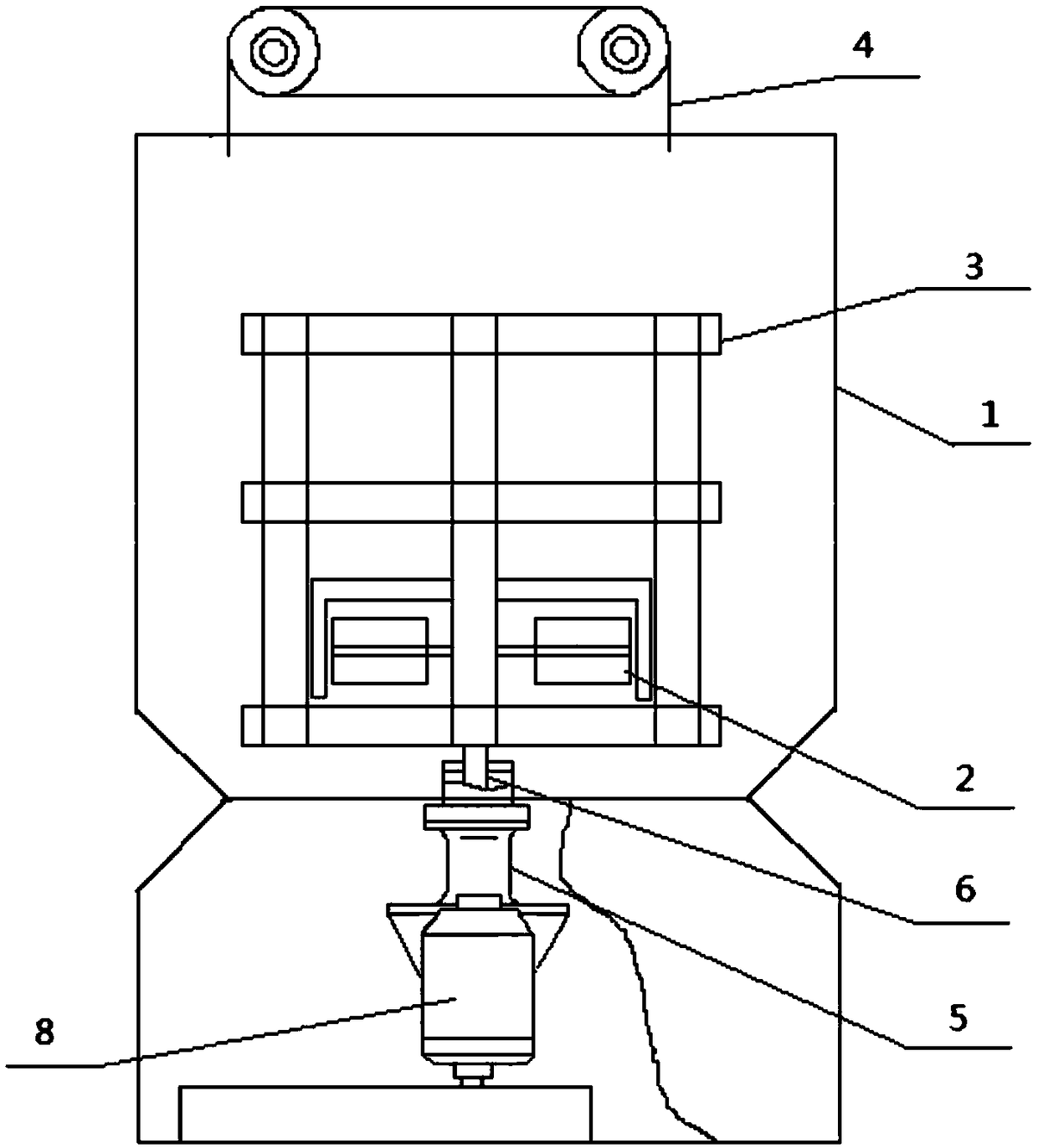

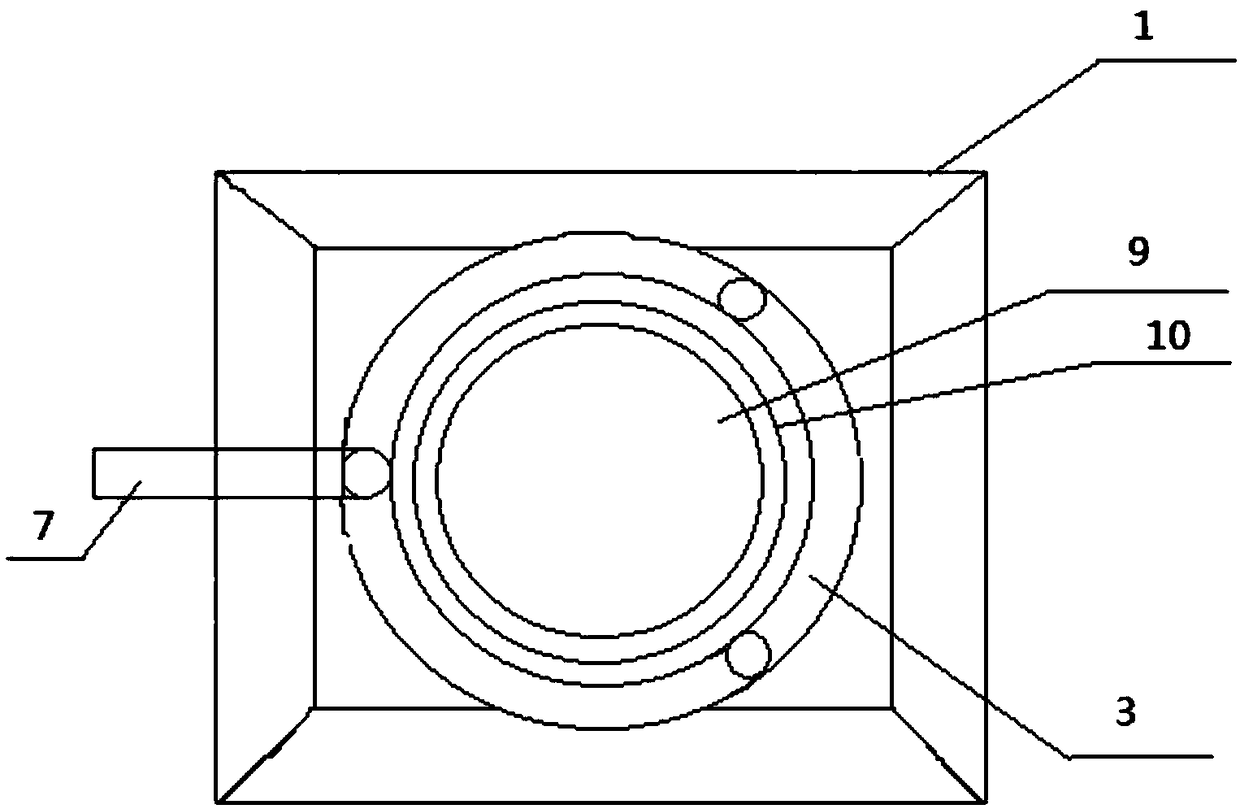

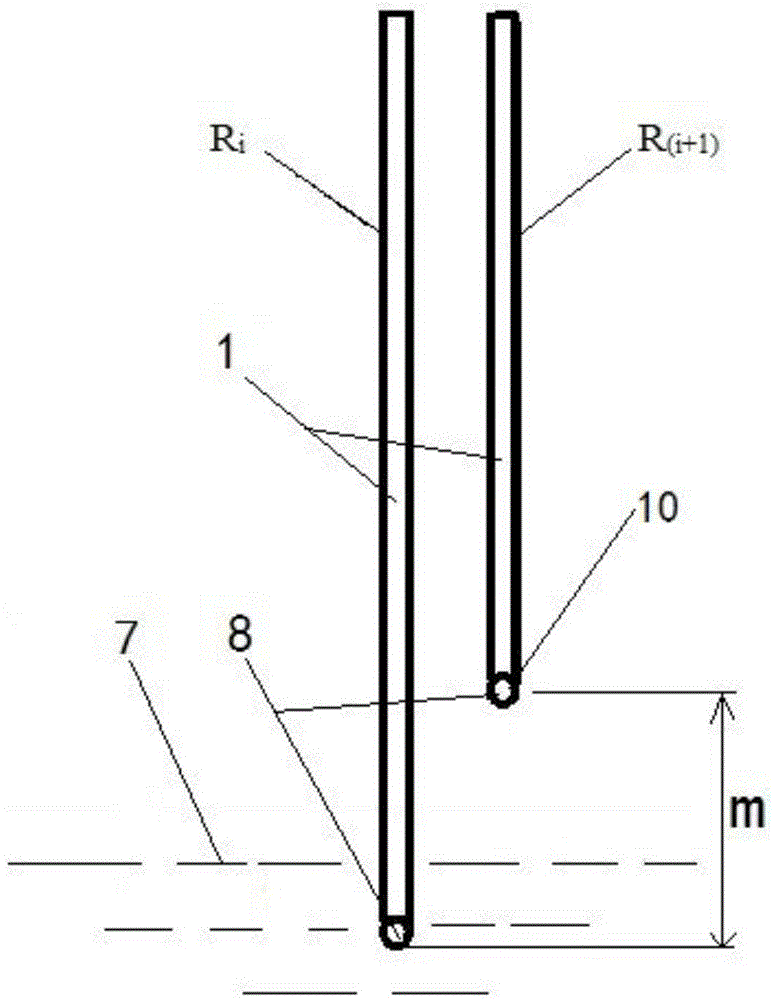

Short flotation column for selecting gold

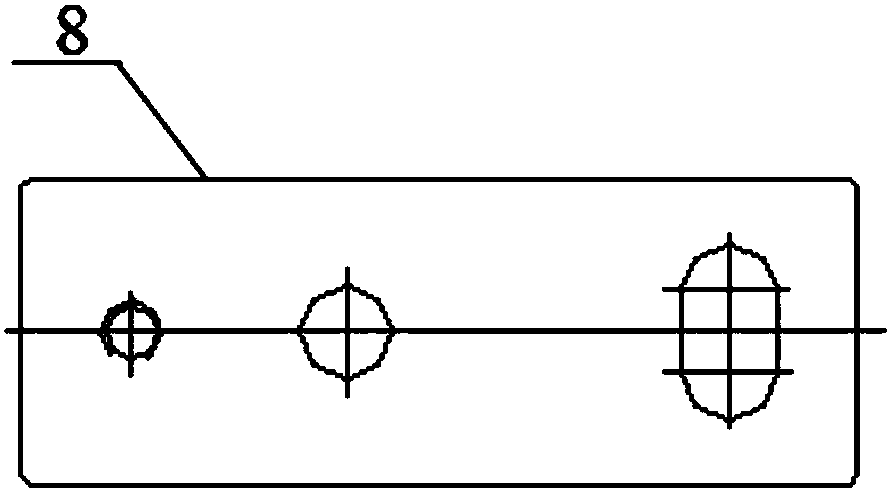

The invention discloses a short flotation column for selecting gold. The short flotation column comprises a flotation column body (1) with a hollow structure; a foam tank (6), a foam overflow groove (7), an overflow pipe (8) and a feeding device (5) are arranged on the upper part of the flotation column body (1); the lower part of an inner cavity of the flotation column body is provided with a foaming device (2); the bottom of the flotation column body is provided with a blow-down pipe (10) and a tailing discharge device (9); and a steady flow plate (3) and an ore pulp dispersion cover (4) are respectively arranged on the upper part of the inner cavity of the flotation column body. The flotation column is shortened, and the steady flow plate of a well and the ore pulp dispersion cover are added, thereby guaranteeing the stability of a liquid level, and being beneficial to improving the treatment capacity and beneficiation indexes of the flotation column.

Owner:洛阳昶威机械制造安装有限公司

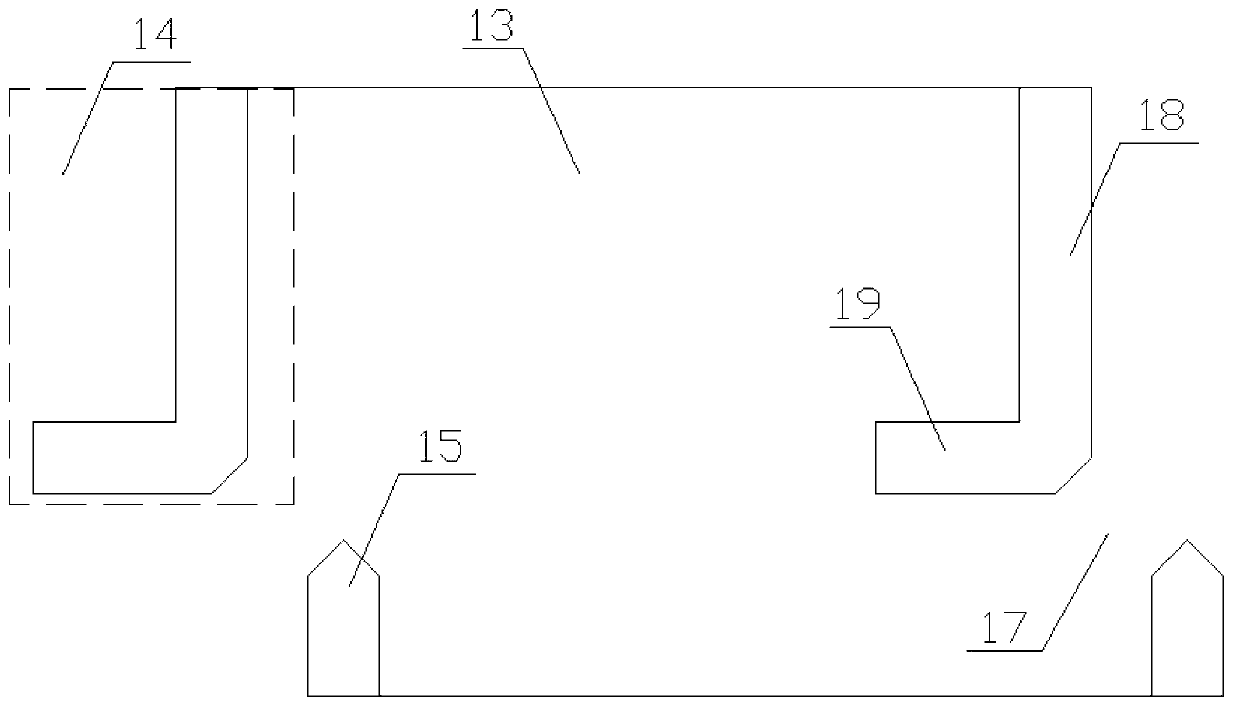

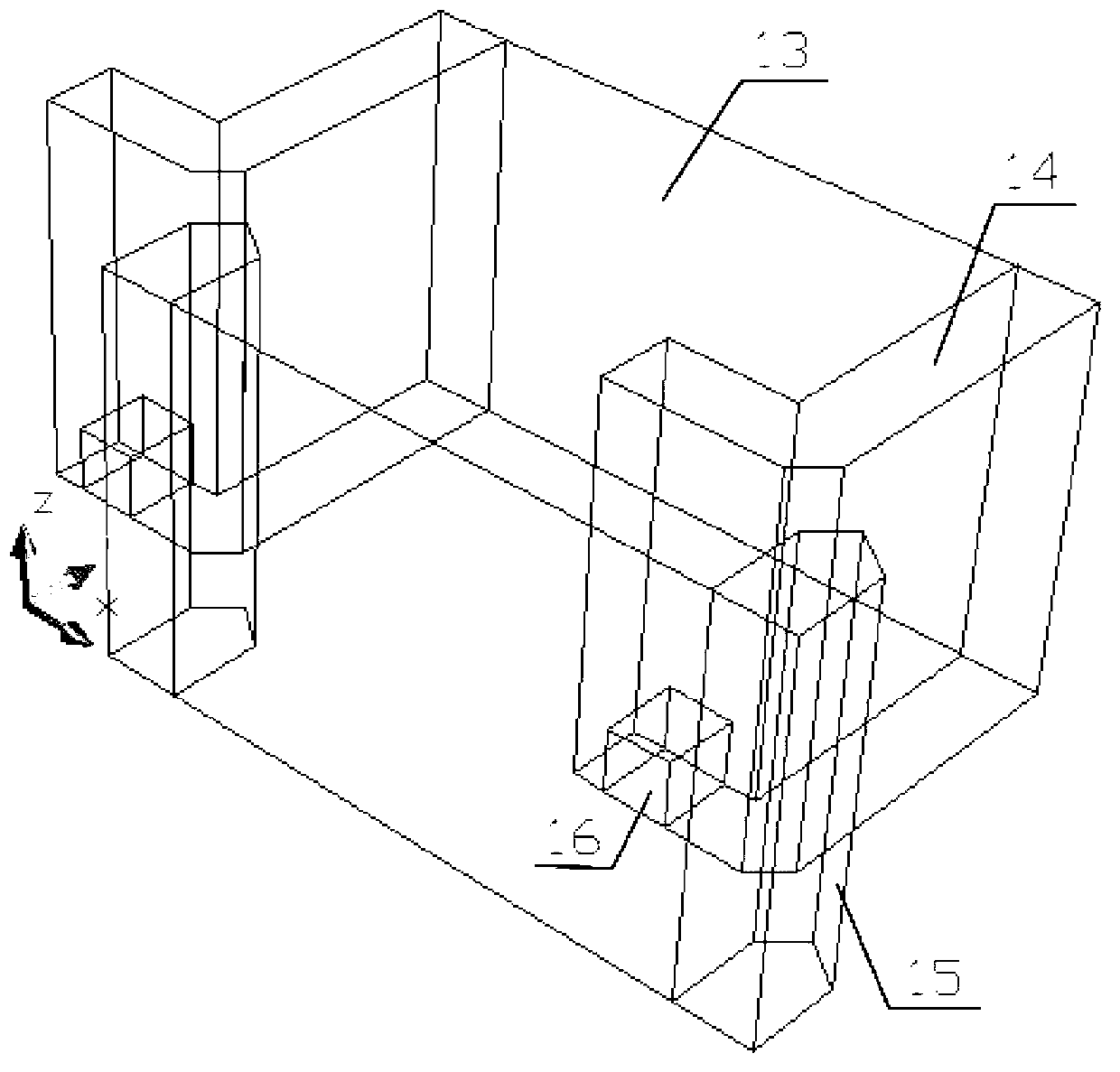

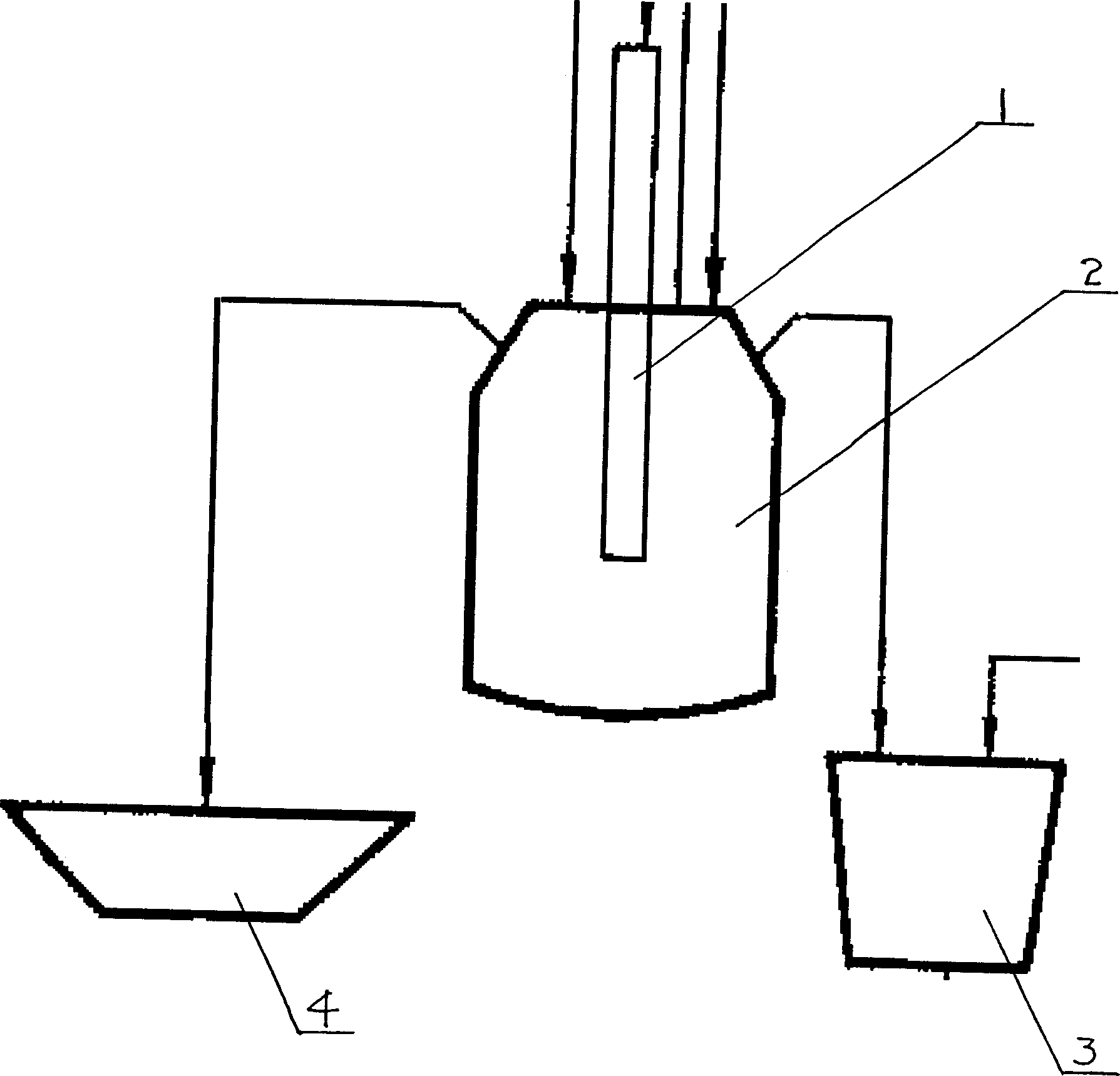

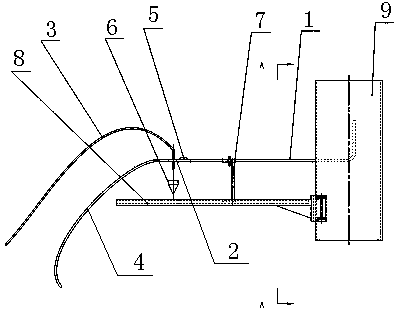

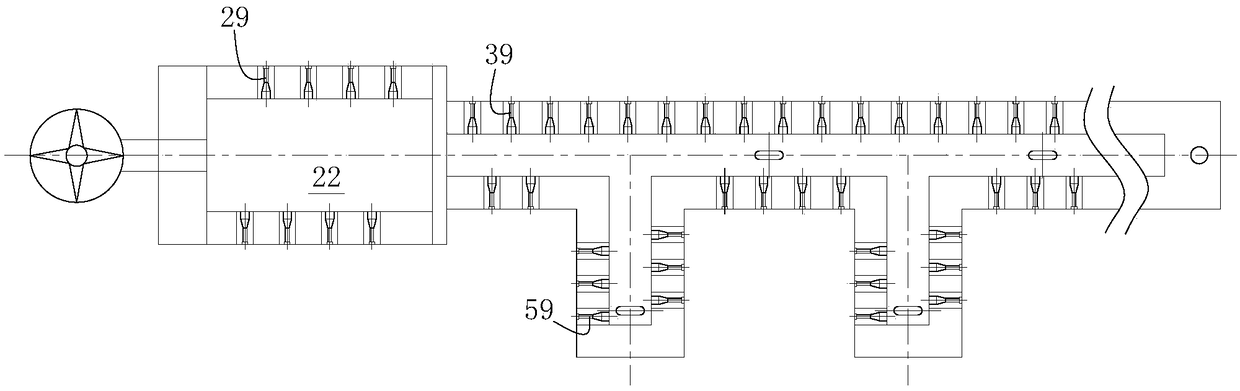

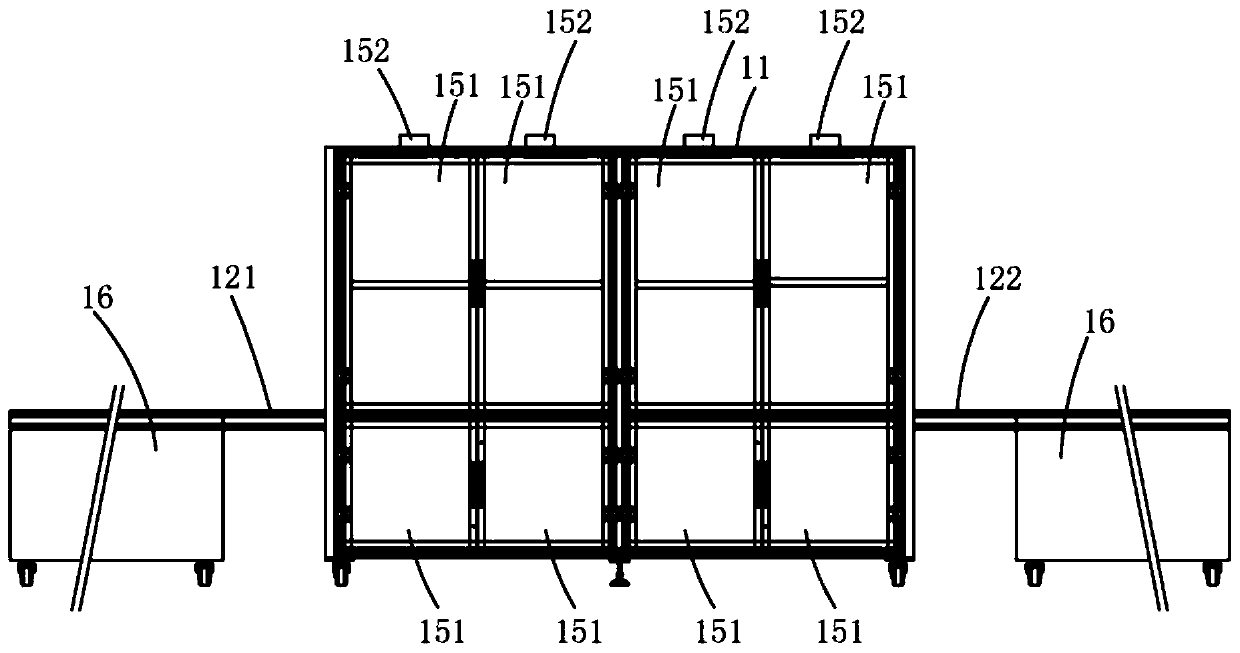

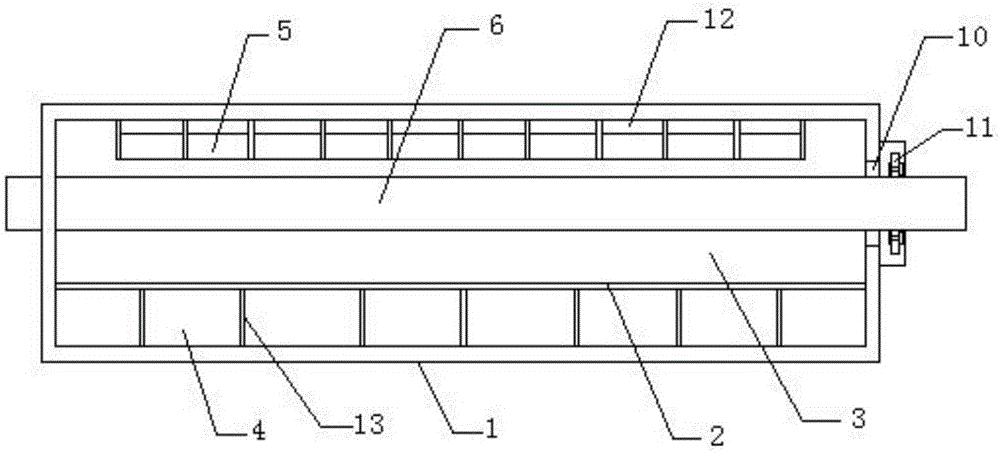

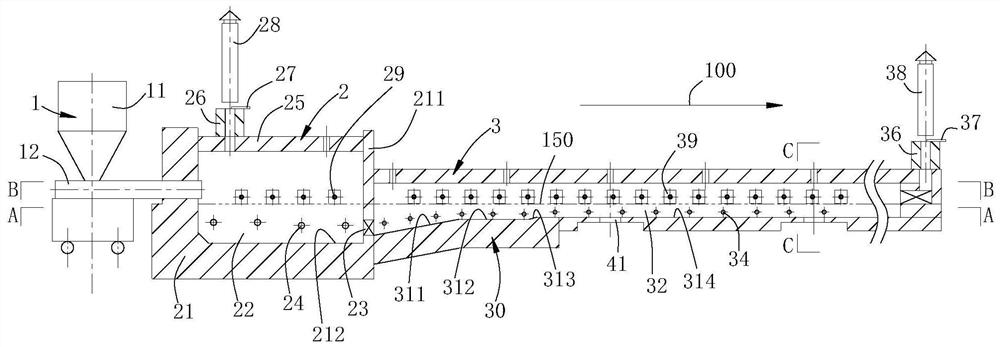

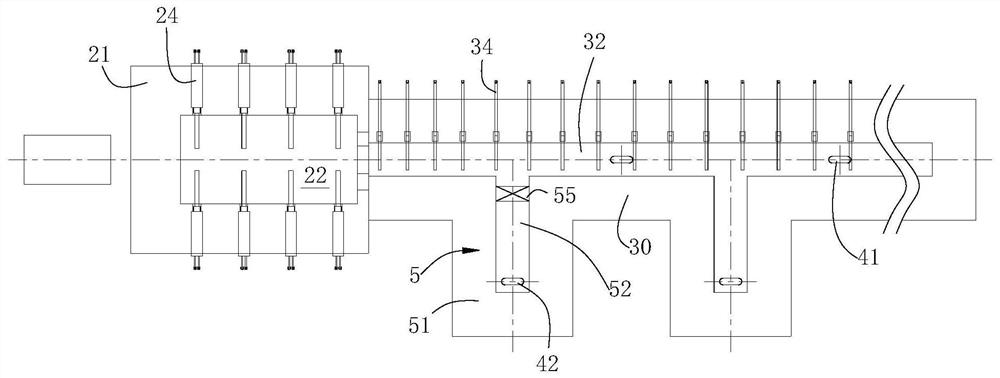

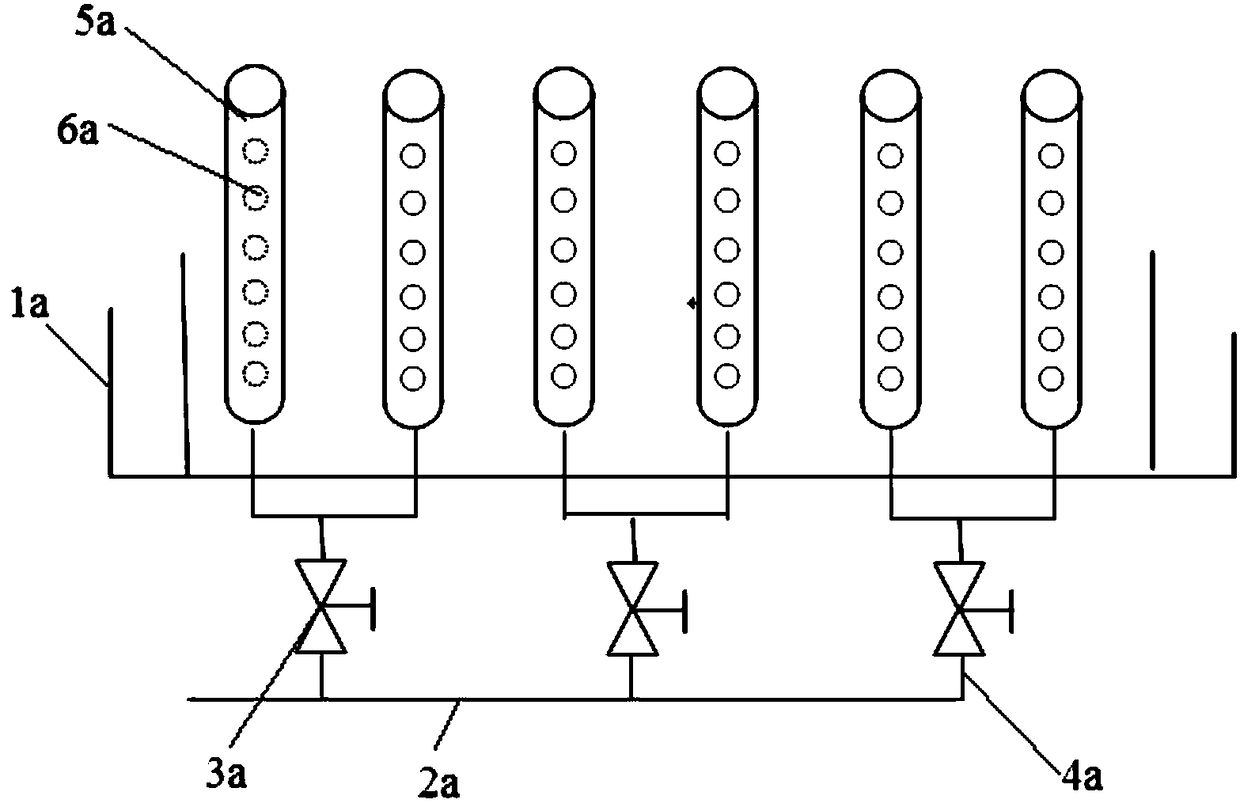

Vertical clearance type fish passing effect experimental system

InactiveCN103343524AReduce experimental water consumptionReduce experiment costHydraulic modelsWater flowEngineering

The invention relates to a vertical clearance type fish passing effect experimental system which comprises a water inlet system connected with a water circulation system, a water blocking system connected with the water inlet system and a water outlet system connected with the water blocking system. The water circulation system comprises a water suction pump, an overground water pool, an underground water pool, an upstream control valve and a downstream control valve. The water inlet system comprises an upstream flashboard and an upstream fish resting pool. The water blocking system is composed of a plurality of stages of fishponds. The water outlet system is composed of a downstream fish resting pool, a downstream water flow buffering box and an underground water pool. The vertical clearance type fish passing effect experimental system can be used for studying and analyzing hydraulics turbulent energy dissipation problem, a fish migration problem and hydraulics experimental model demonstration, due to the fact that the experimental system and an actual fishway partial project are built with a proportion of 1:1, the flow regime of the water flow in a fish passing facility is truly reflected, and the reliability and the accuracy of a water flow field in a fishway and the analysis of the fish passing effect are further guaranteed.

Owner:SICHUAN UNIV

Water curtain dust precipitator

ActiveCN104307278AImprove adsorption capacitySimple structureCombination devicesUsing liquid separation agentActivated carbonAlcohol

The invention discloses a water curtain dust precipitator. The water curtain dust precipitator comprises a water curtain dust precipitating mechanism, a sprinkling dust precipitating mechanism and a drying mechanism, wherein the water curtain dust precipitating mechanism comprises a water curtain dust precipitating box body and a first filtrate tank, and a molasses alcohol zymotic fluid is placed in the first filtrate tank; the sprinkling dust precipitating mechanism comprises a sprinkling dust precipitating box body, a sieve layer, a sprayer, a liquid pump and a second filtrate tank, and the molasses alcohol zymotic fluid is placed in the second filtrate tank; the drying mechanism comprises a drying box body, the box body is filled with activated carbon, and dust containing gas enters the water curtain dust precipitating box body from a first gas inlet, passes the sprinkling dust precipitating box body and the drying box body and is discharged from a third gas outlet. The creative use of the liquid-state molasses alcohol zymotic fluid raw material in water curtain dust precipitation is favorable for dust absorption and the reclamation of residual heat in smoke. The liquid raw material is preheated, and the molasses alcohol zymotic fluid used for scrubbing can be reutilized. The device can realize great dust precipitating effect and conform with current-stage environment-friendly and energy-conservative theories with simple structure and low cost.

Owner:湖南豫园(南宁)生物科技有限公司

Technological process of making flat spring steel for automobile

The flat spring steel for automobile is produced via converter smelting process. Compared with available technology, the present invention has the following advantages and positive effects: utilizing molten iron with less harmful elements as material to result in high flat spring steel quality; higher finished product rate and lower power consumption to result in lower cost than production in electric furnace; casting molten steel into small square billet to omit the billet cutting step and lower cost; and high size precision of the continuously cast small square billet to ensure high size precision of flat spring steel.

Owner:青岛钢铁控股集团有限责任公司

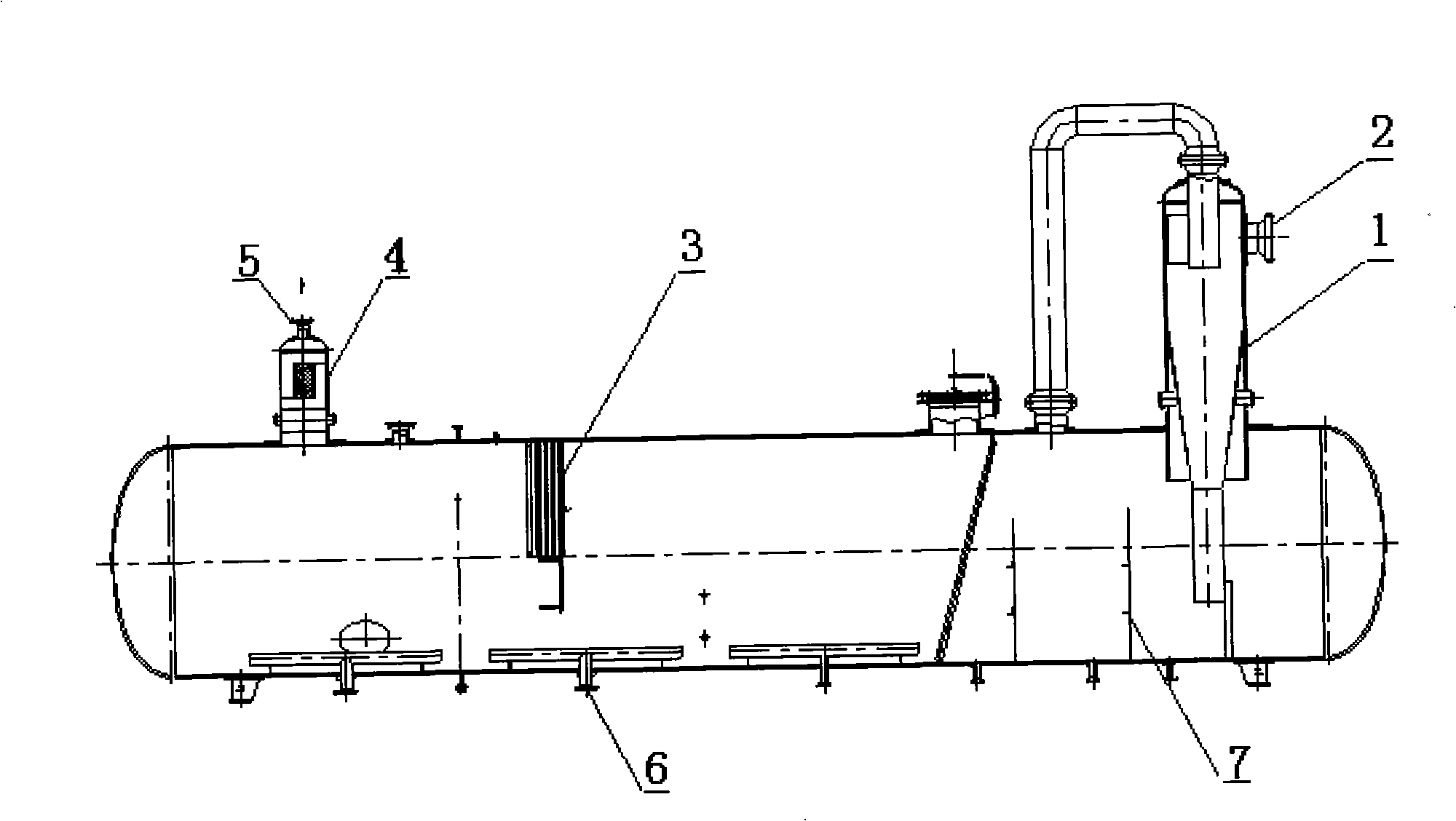

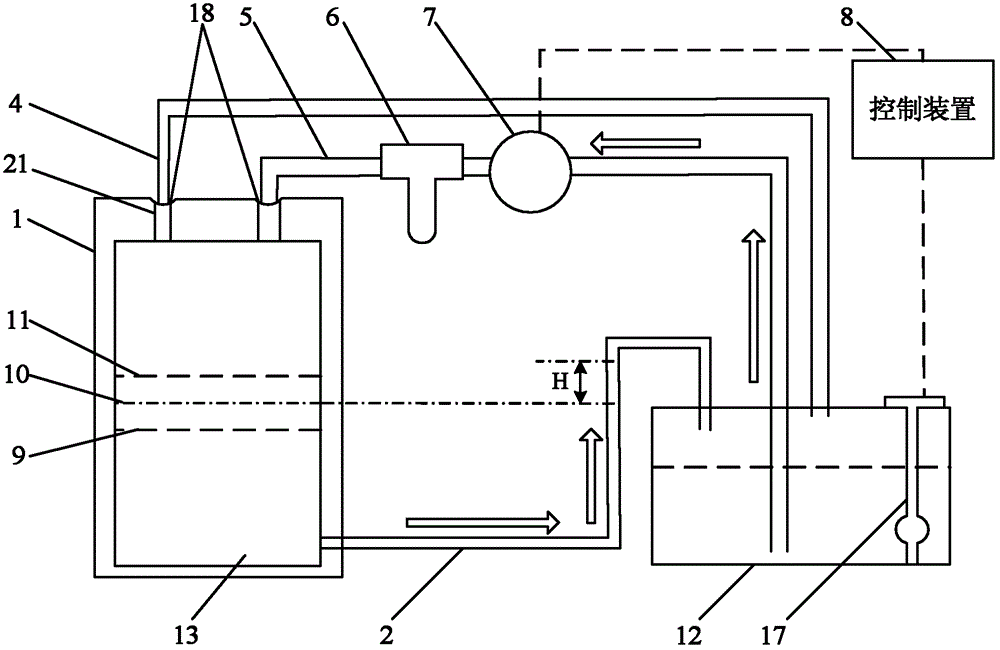

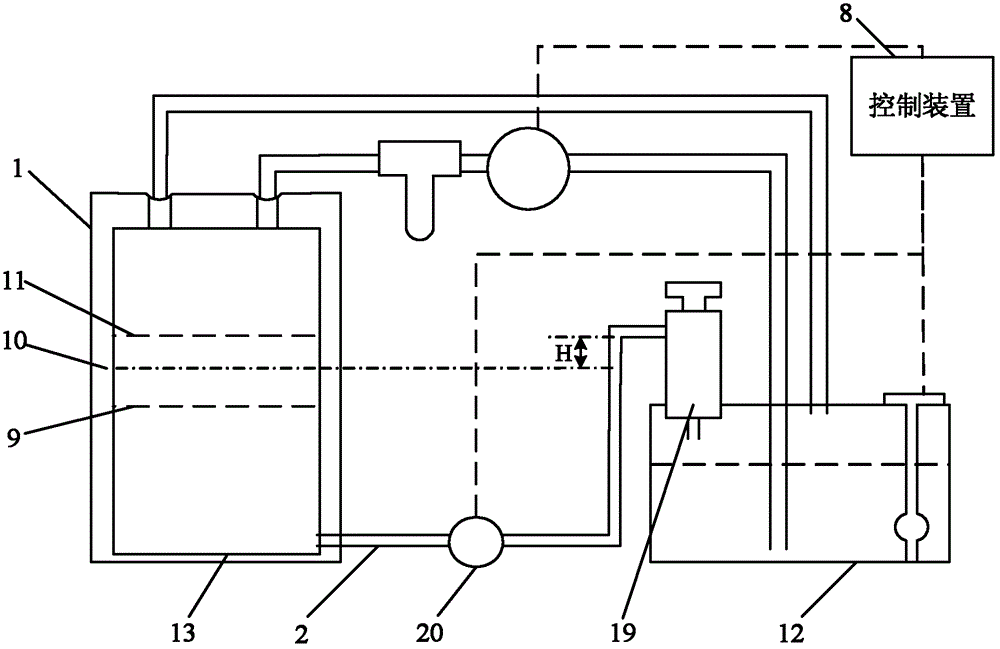

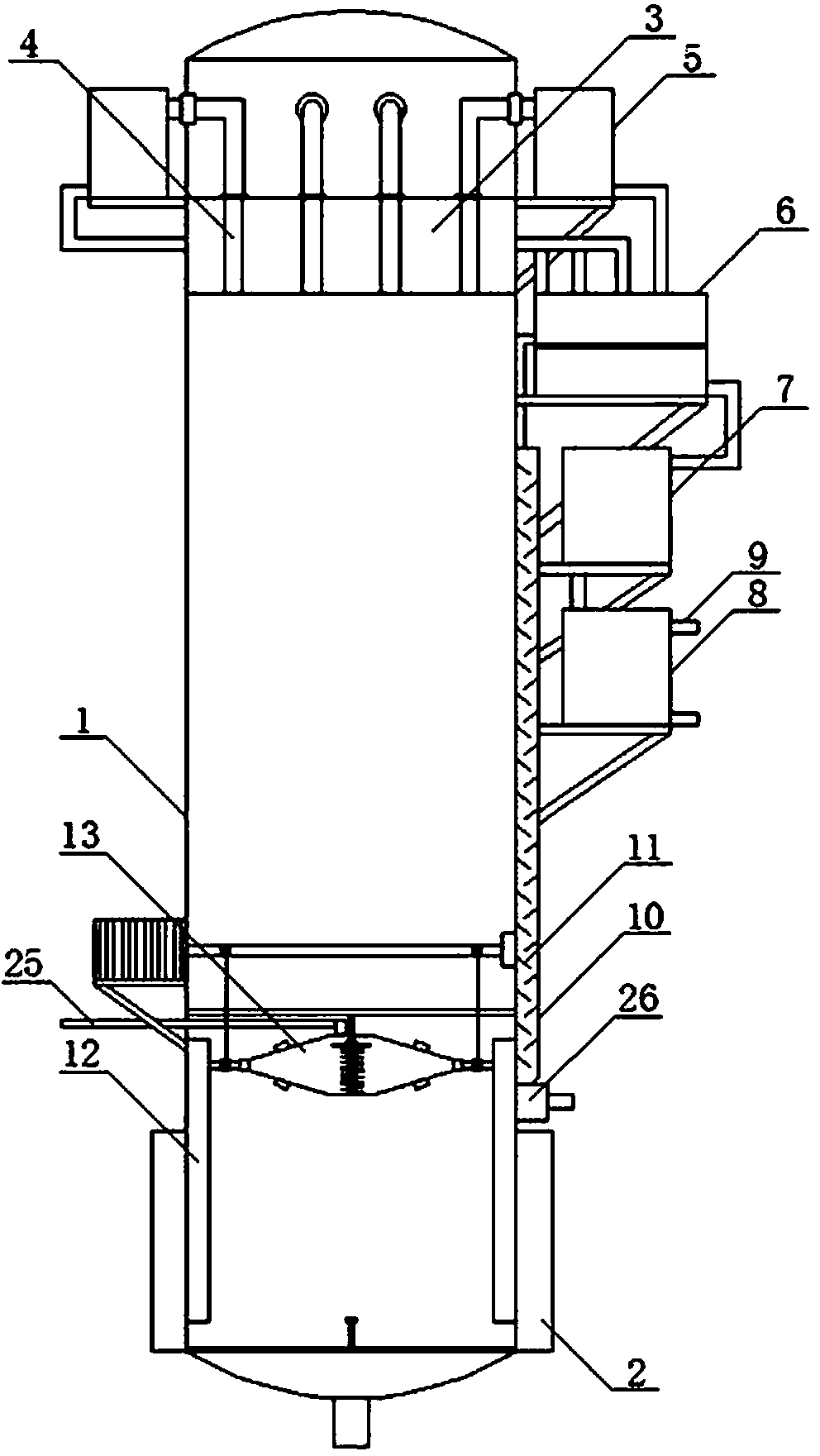

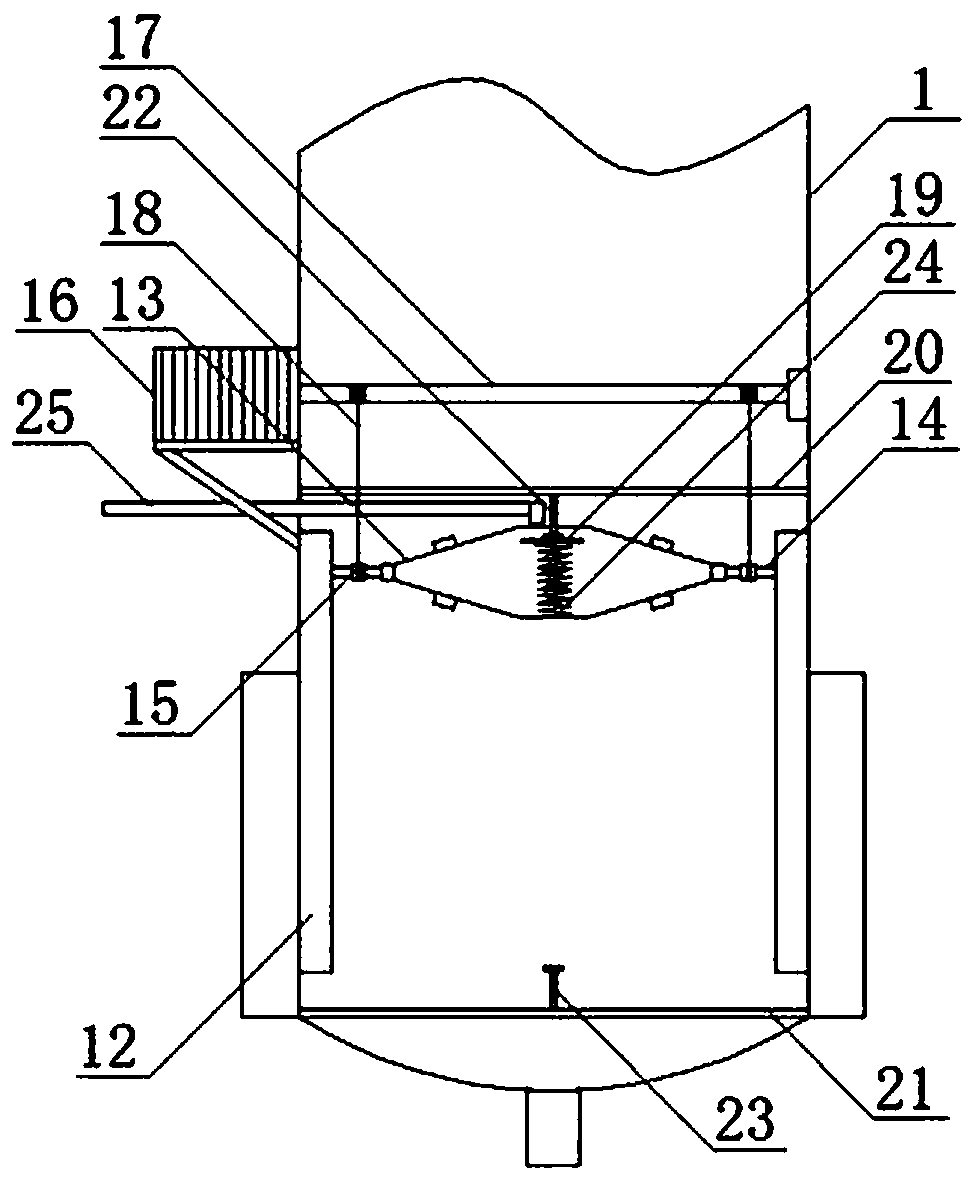

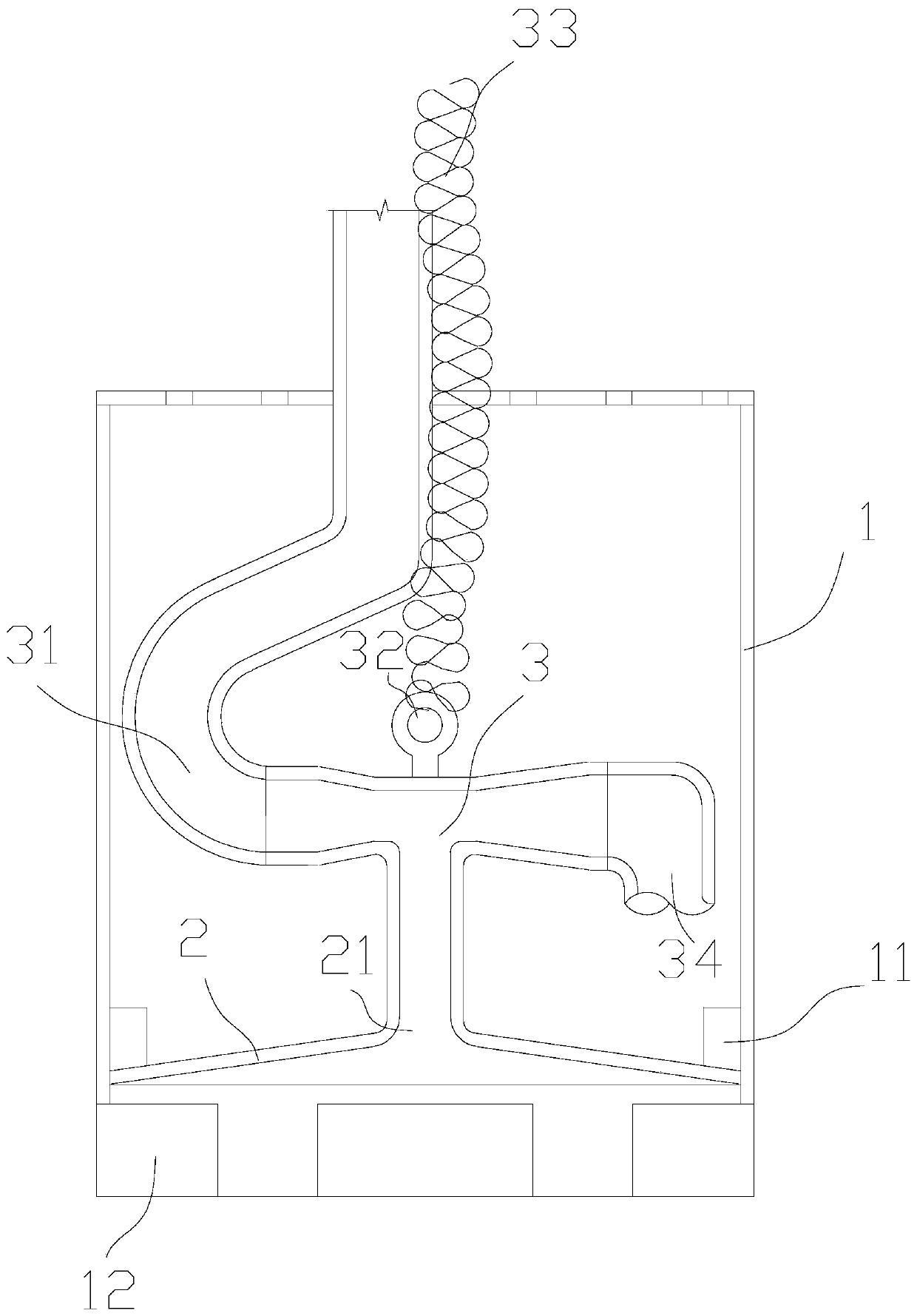

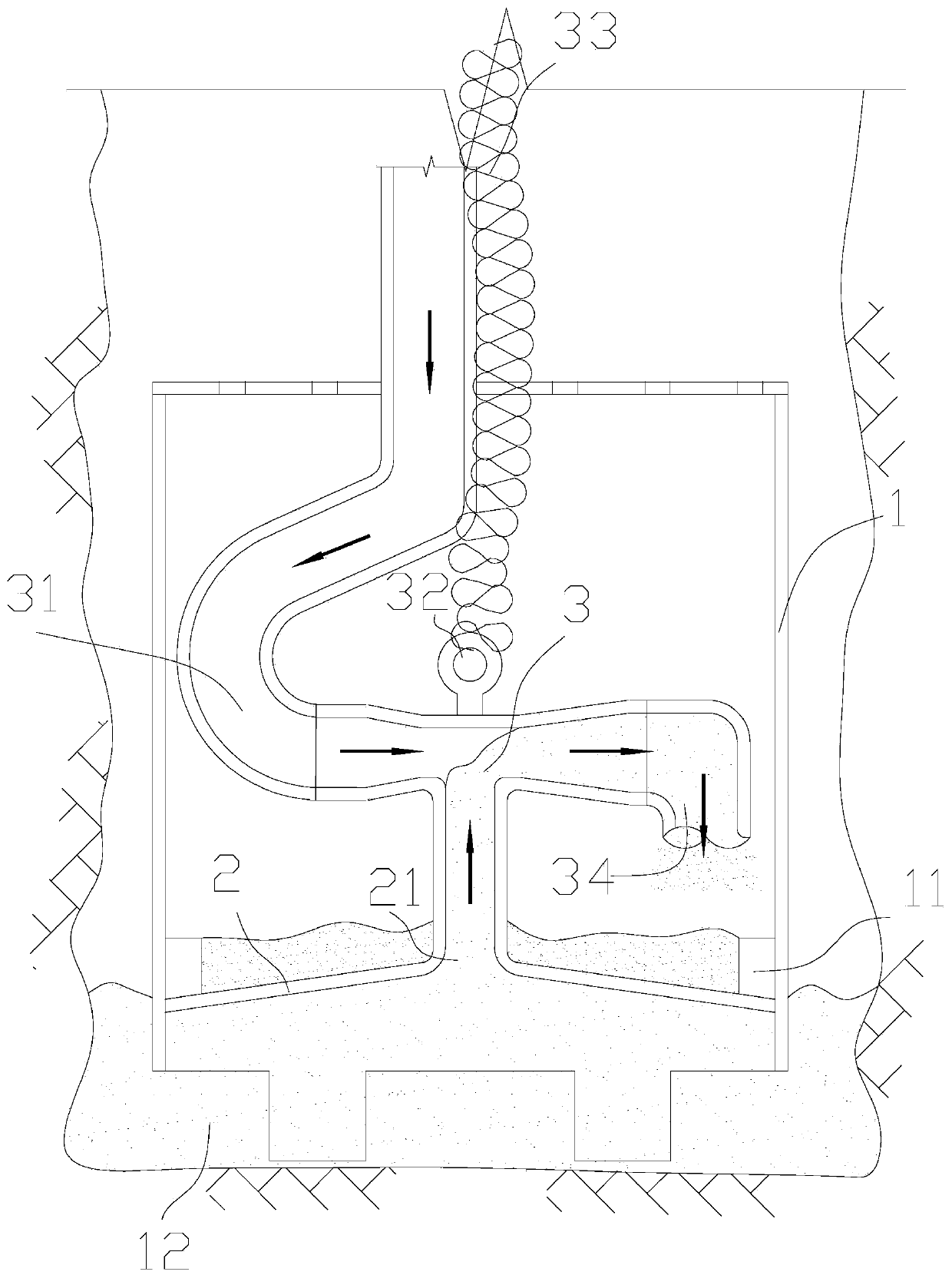

Slug catching system

InactiveCN101408280ASmall pressure fluctuationsLiquid level is stablePipeline systemsControl systemInstrument control

The invention belongs to oil and gas equipment, and particularly relates to a plug flow scheme collecting system during production and establishment processes of oil and gas field. The collecting system is characterized in that the system comprises a tank body, a rotation flow device (1), a gas rectifier device (3), a vertical fog-collecting separation device (4) and a damping baffle (7); the top end at the right side of the tank body is vertically provided with the rotation flow device (1); the lower cylinder of the rotation flow device (1) is internally provided with a two-step damping baffle (7), the left side of which on the top position close to the middle position of the tank body is provided with the gas rectifier device (3); and the top of the left end of the tank body is provided with the vertical fog-collecting separation device (4) and the lower part thereof is provided with an anti-vortex outlet (6). Therefore, under the impact force and pressure fluctuation generated by the plug flow scheme, the plug flow scheme collecting system ensures the normal running of the instrument control system and the safety of the equipment body.

Owner:XIAN CHANGQING TECH ENG

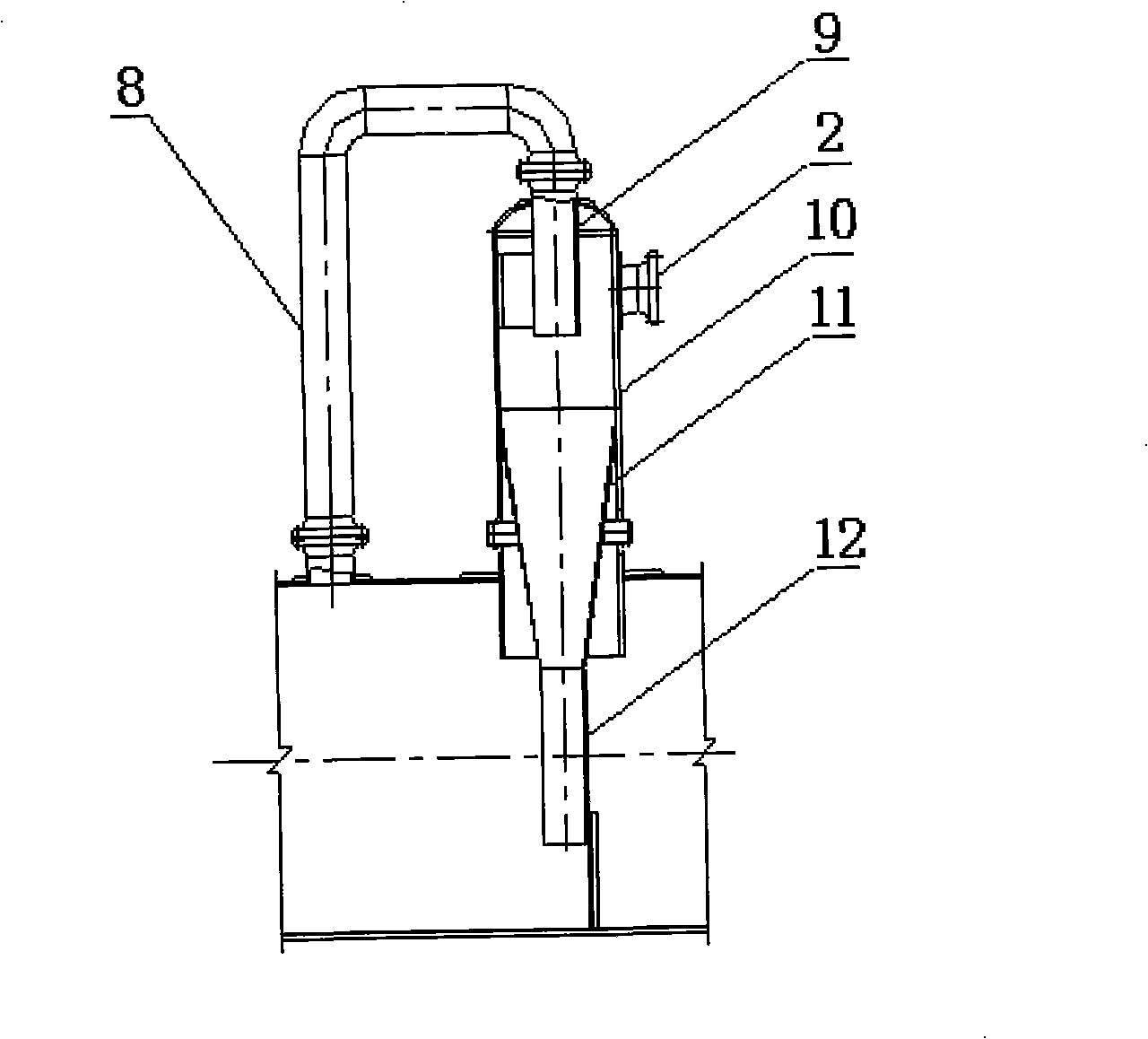

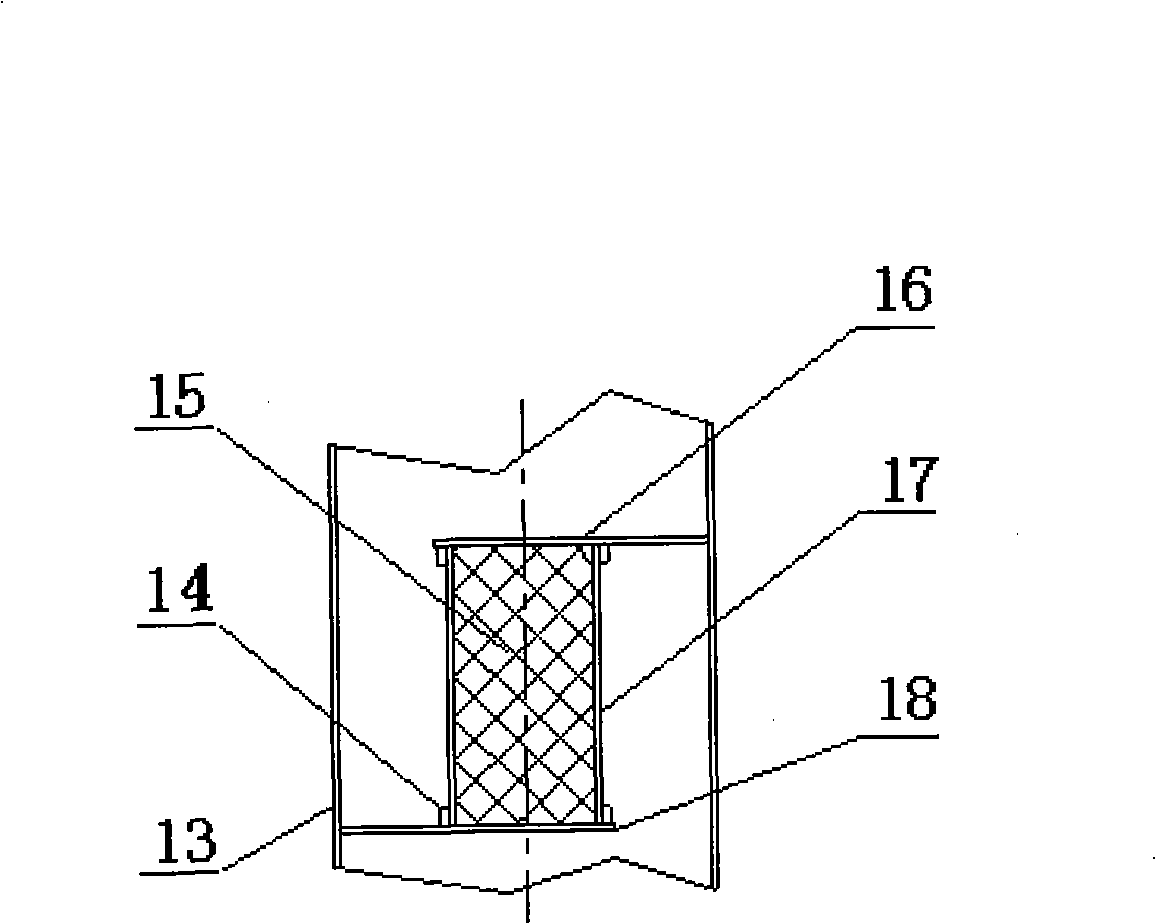

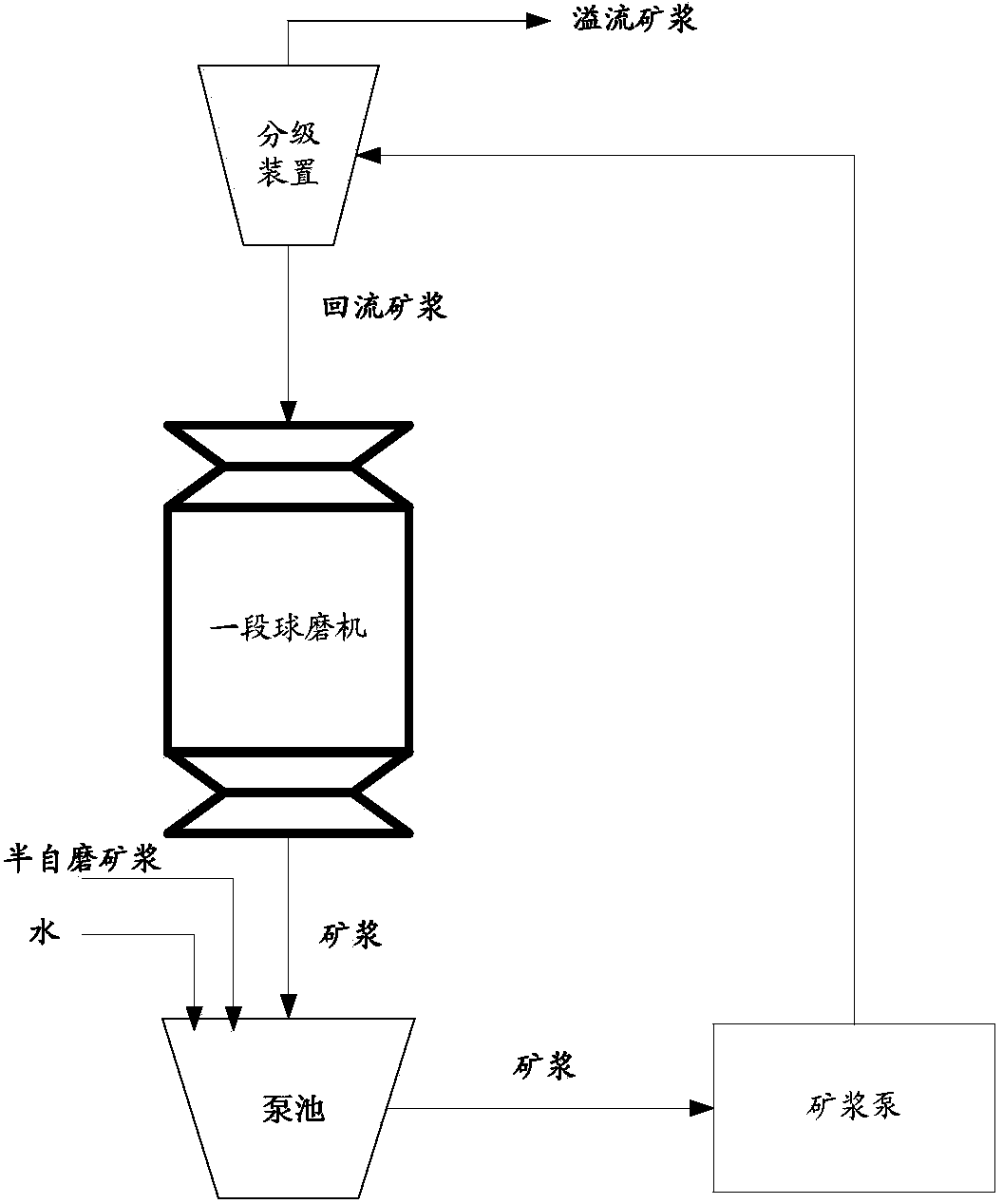

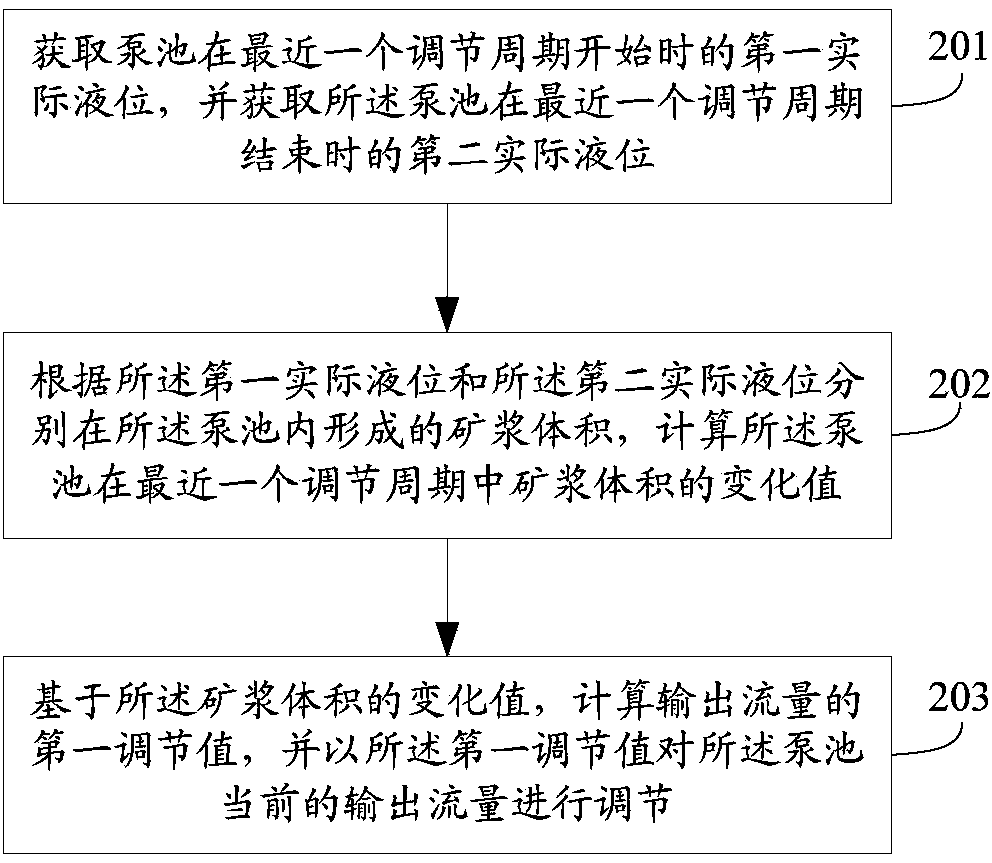

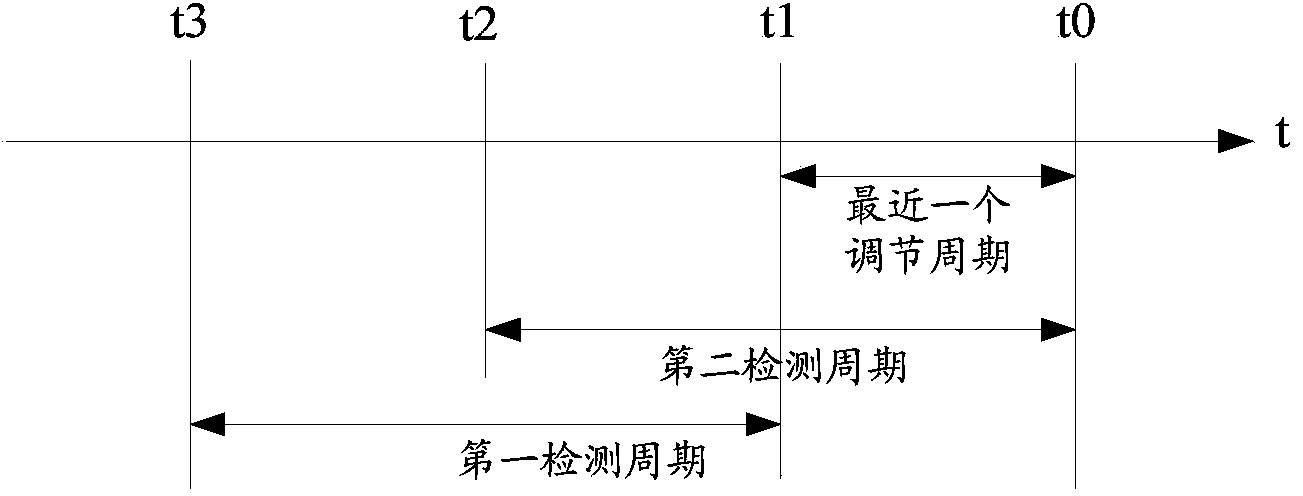

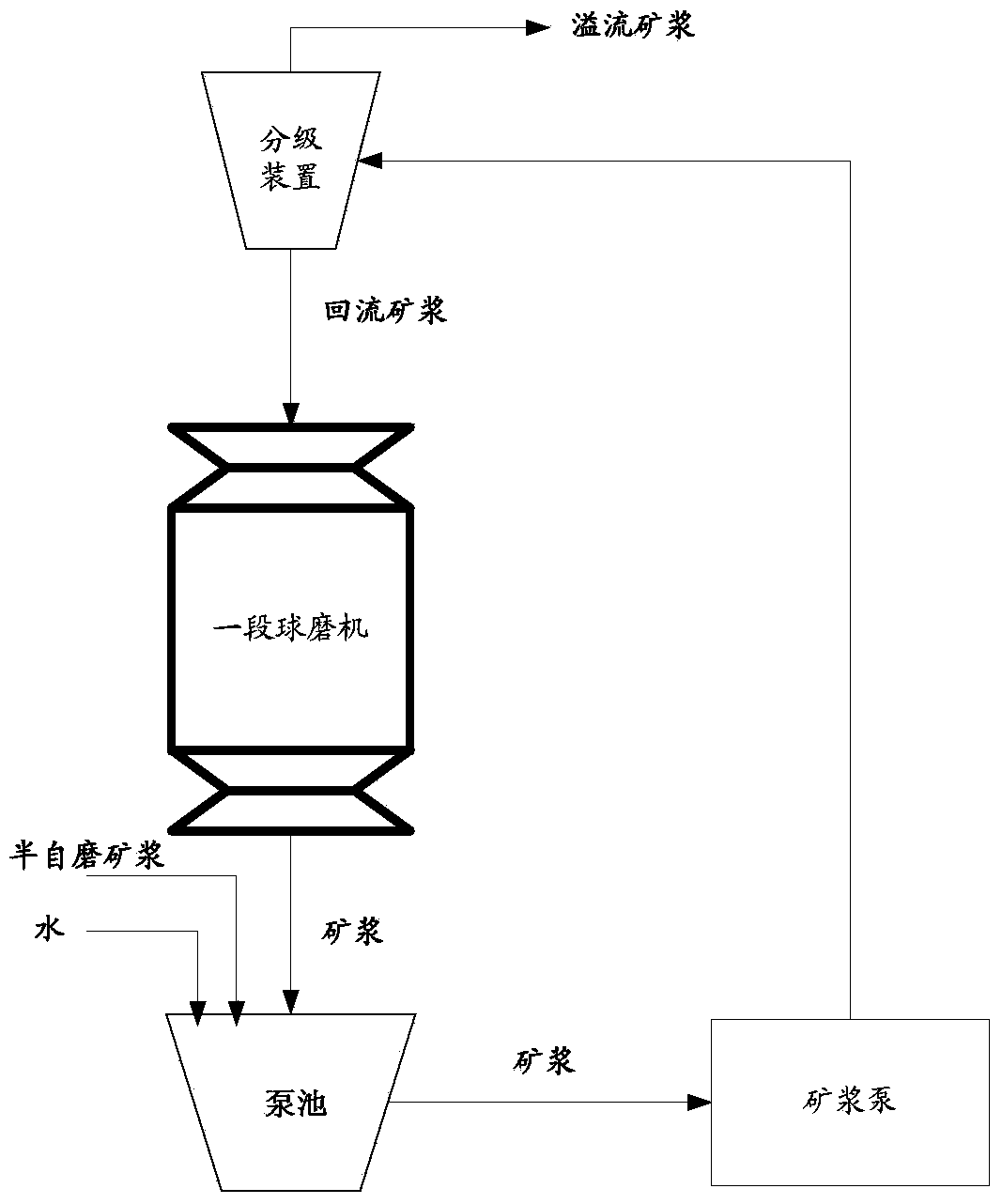

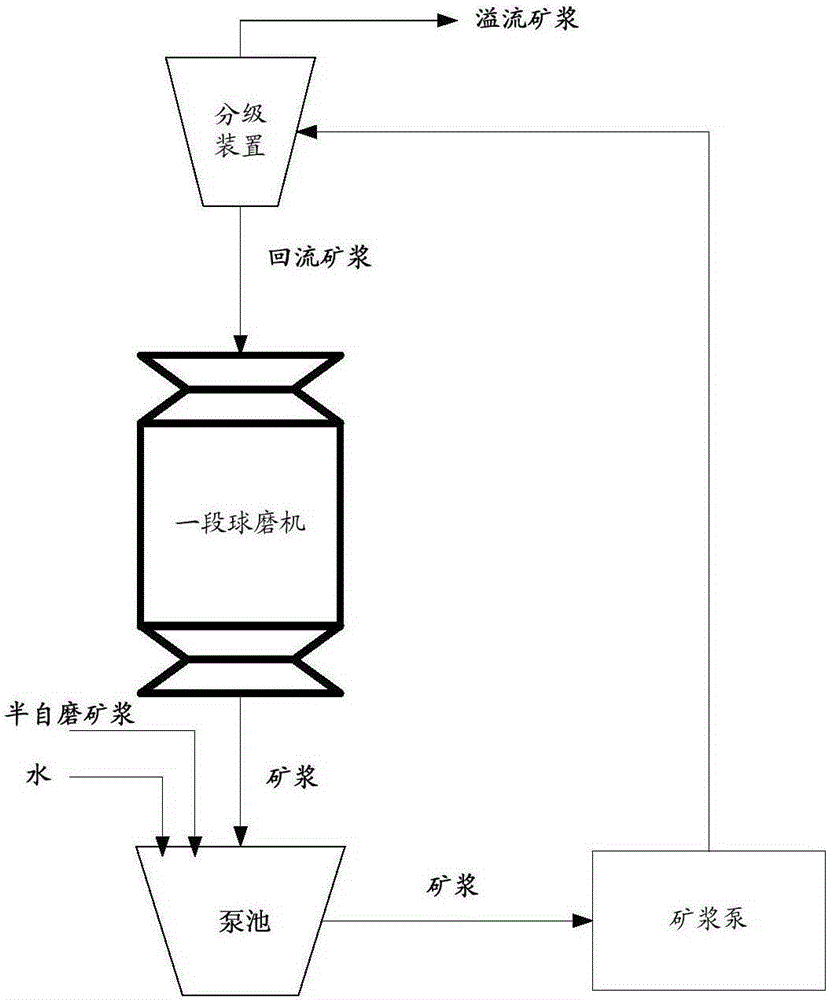

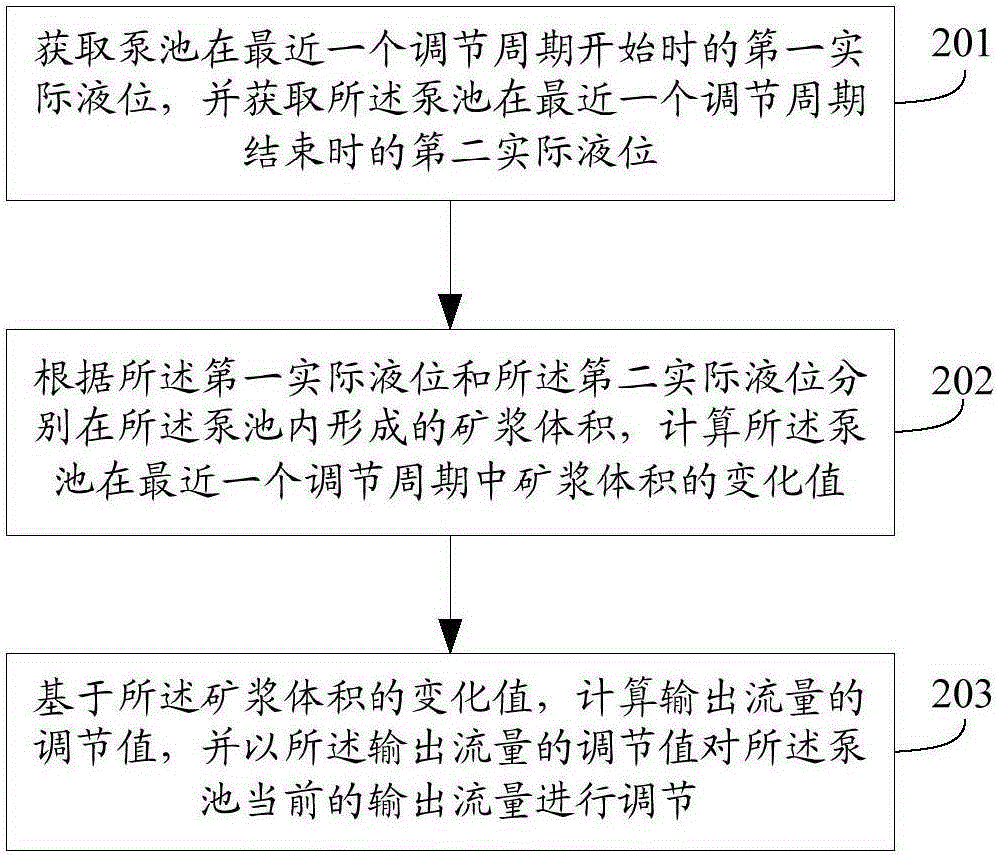

Method and device for controlling liquid level of ore pulp pump pool in ore grinding classification

The invention discloses a method and device for controlling the liquid level of an ore pulp pump pool in ore grinding classification. The method comprises the following steps of acquiring a first practical liquid level of the pump pool when the latest adjusting period starts and acquiring a second practical liquid level of the pump pool when the latest adjusting period finishes; calculating change values of the ore pulp volume in the latest adjusting period according to the ore pulp sizes formed by the first practical liquid level and the second liquid level in the pump pool respectively; calculating a first adjusting value of output flow based on the change values of the ore pulp volume and adjusting the current output flow according to the first adjusting value. By means of the technical scheme, the ore pulp flow output by the pump pool can be adjusted to meet the requirement for balancing the input and output of the ore pulp of the pump pool according to the first adjusting value obtained by calculating the change values of the ore pulp volume, so that stability of the height of the inner liquid face in the pump pool is more accurately maintained, and the effect of ore grinding classification is more stable.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

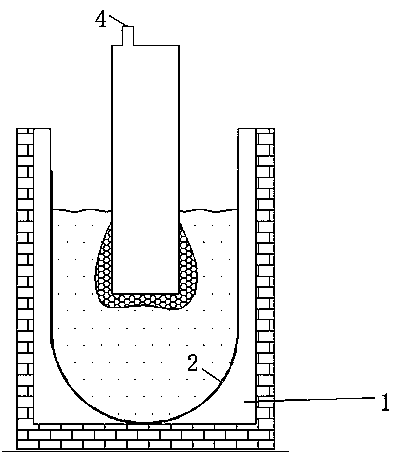

Ultra-pure aluminum purification crystallization method

ActiveCN109680159ALiquid level is stableAvoid contactProcess efficiency improvementAluminiumCrucible

The invention relates to an ultra-pure aluminum purification crystallization method. The method comprises the following steps that an aluminum raw material of which the purity is 3-5N is melted into molten aluminum in a crucible; a crystallization device is installed on the upper portion of the crucible, the lower end of the crystallization device stretches into the surface of the molten aluminum,and normal-temperature air at 50-100L / min is continuously injected into the crystallization device through an air feeding pipe arranged at the upper end of the crystallization device; a motor is started to drive the crystallization device to rotate continuously, the rotation speed of the motor is increased, it is kept that the surface of the molten aluminum is not influenced, high-purity part ofthe molten aluminum solidifies and stacks at the lower end of the crystallization device and forms a crystal substance; when the size of the crystal substance reaches half of the set size, the crystallization device is taken out and stopped rotating, the lower end of the crystallization device and the crystal substance are quickly cooled in the air to 280-320 DEG C, then, the crystallization device is inserted into the molten aluminum to continue rotating till the crystal substance cannot be increased, and the crystal substance is taken down; and 50-70 mm portions of the head and tail of the crystal substance are cut off, and a preliminary purification substance is obtained. The ultra-pure aluminum purification crystallization method is simpler and more efficient in technology, more practical, and more suitable for industrial production.

Owner:宁波锦越新材料有限公司

Improved air volume measuring device based on L-shaped pitot tube

InactiveCN104121958ALiquid level is stableCount stableVolume indication and recording devicesVolume/mass flow by differential pressureAir volumeMeasurement point

An improved air volume measuring device based on an L-shaped pitot tube comprises a pitot tube composed of a U-shaped tube and an L-shaped tube. A cross-shaped tube is arranged at the rear end of the L-shaped tube, the two adjacent ends of the cross-shaped tube are connected with the static pressure end and the total pressure end of the U-shaped tube respectively, the U-shaped tube is filled with liquid, a strip-shaped gradienter is arranged on the L-shaped tube, and the strip-shaped gradienter is parallel with the L-shaped tube. The upper end of the cross-shaped tube is connected with the static pressure end of the U-shaped tube, a plummet is hung to the lower end of the cross-shaped tube, the lower portion of the L-shaped tube is movably connected with a guide rail through a slider support, and the slider support moves in the guide rail to make the L-shaped tube keep horizontal. The improved air volume measuring device solves the personal error problem caused by the fact that the L-shaped tube is held by hand, and meanwhile relevant improvement is made for solving the measuring point positioning problem in the air volume measuring process, data measuring accuracy is guaranteed, workloads of personnel are reduced, and human resource cost is reduced.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

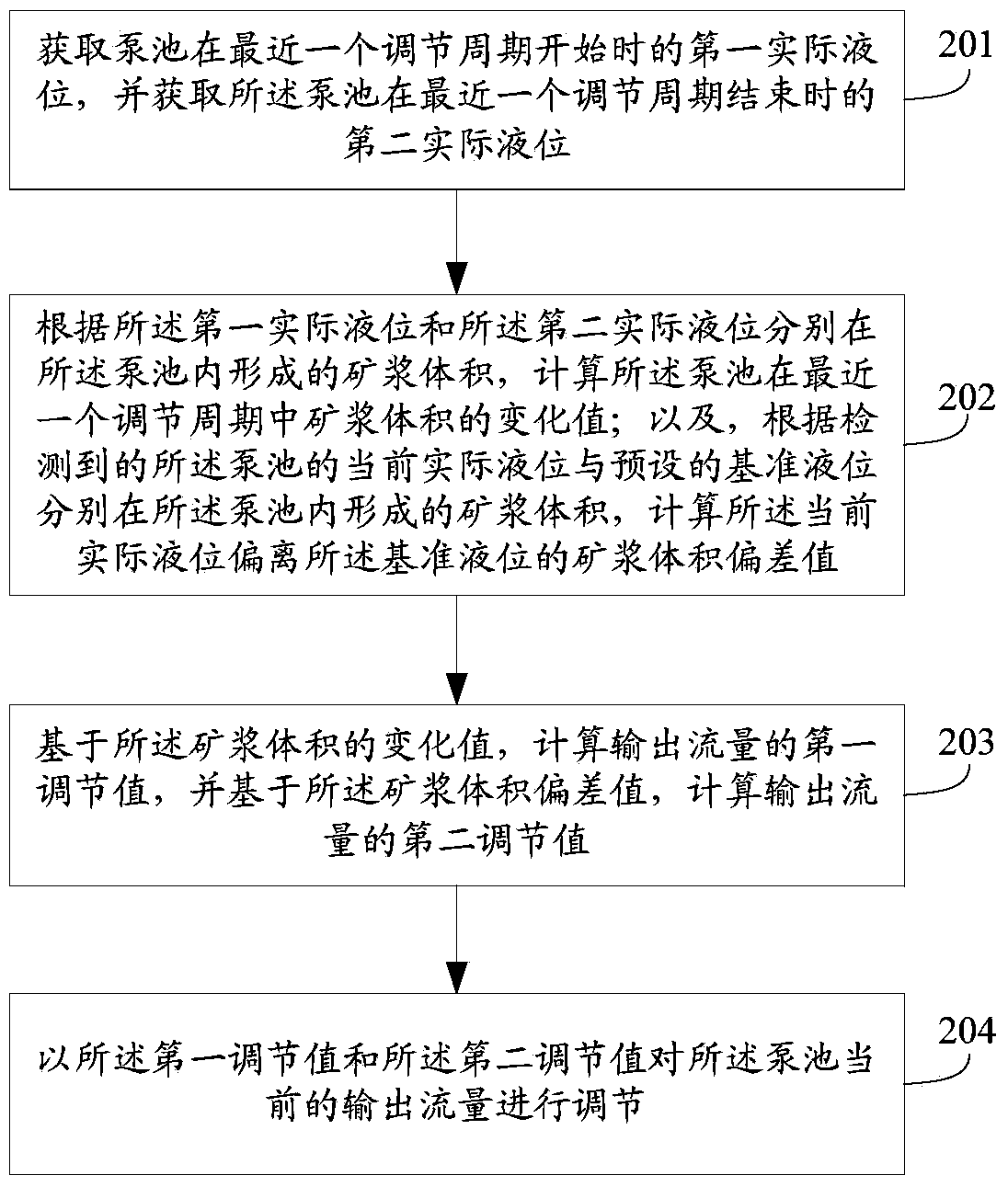

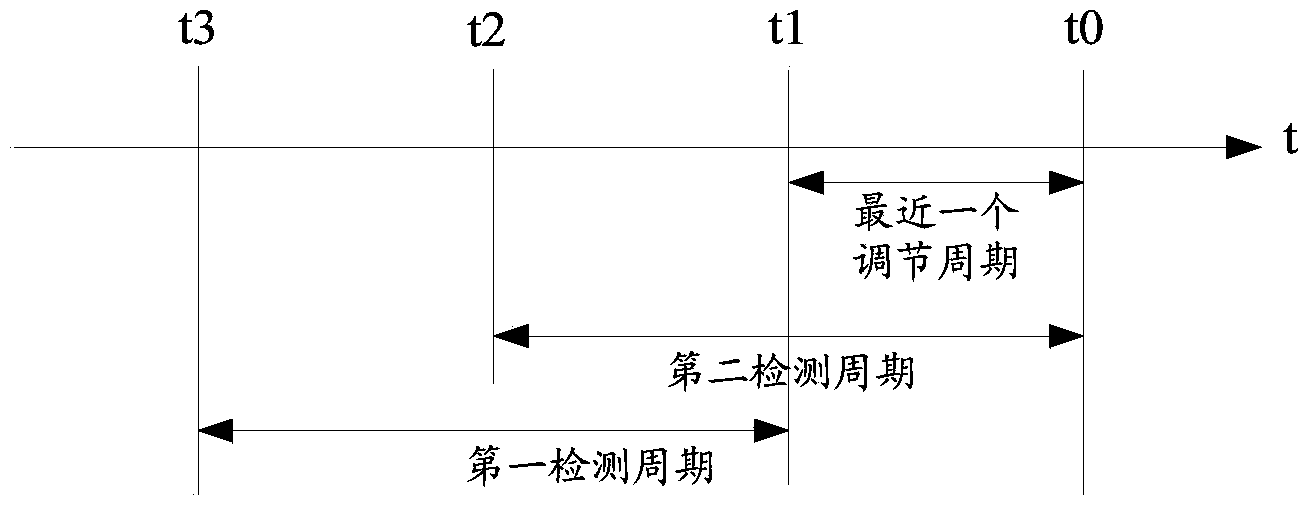

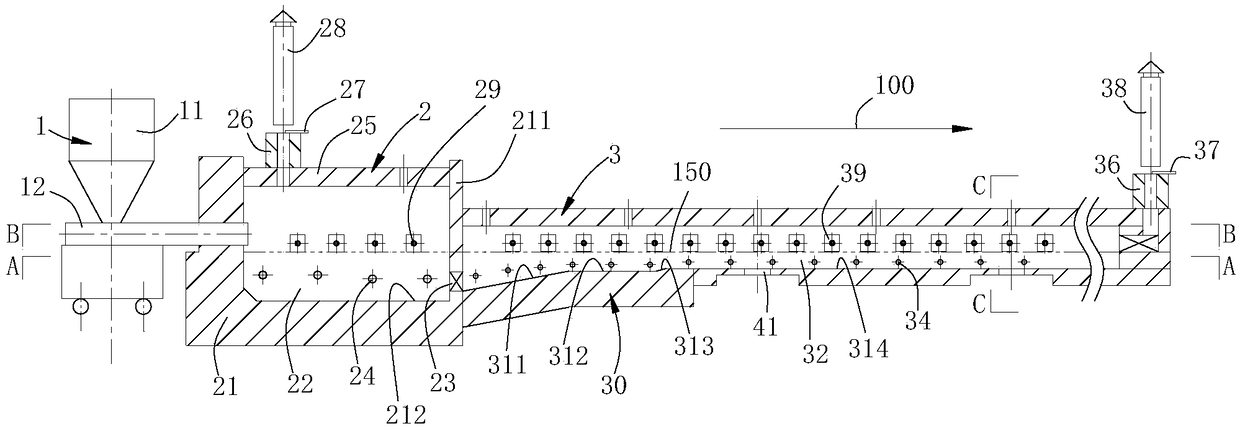

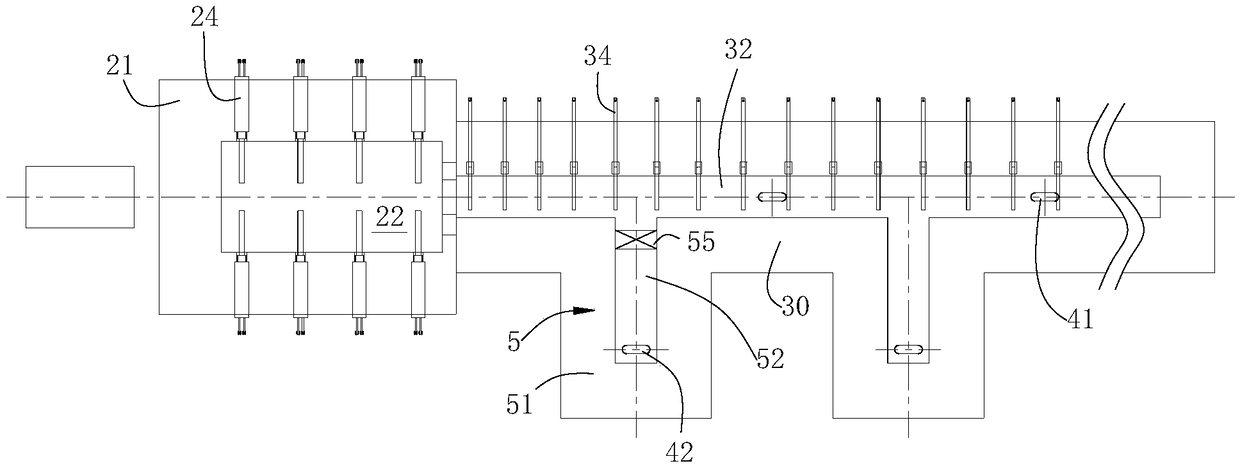

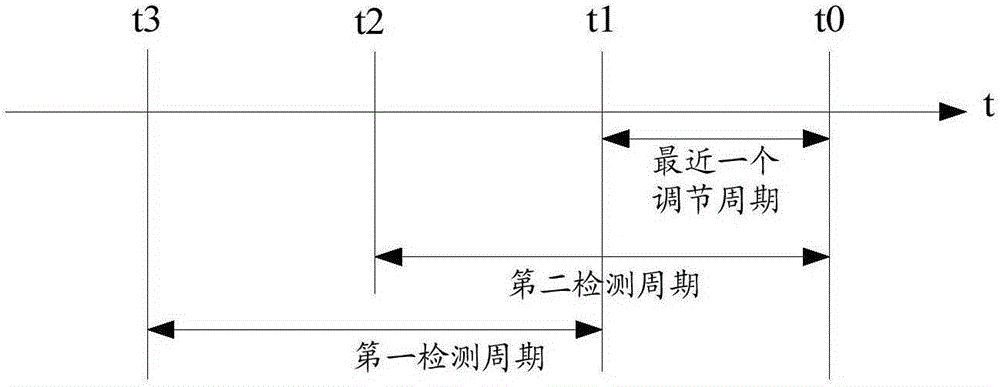

Method and device for controlling liquid level of pulp pump pool in process of ore grinding classification

ActiveCN103706469AEasy to adjustLiquid level is stableSolid separationPulp and paper industryEngineering

The invention discloses a method and device for controlling the liquid level of a pulp pump pool in the process of ore grinding classification. The method comprises the steps that a first actual liquid level at the start of a recent adjusting cycle of the pump pool is acquired, and a second actual liquid level at the end of the recent adjusting cycle of the pump pool is acquired; the variation value of the size of ore pulp in the recent adjusting cycle of the pump pool is calculated, and the pulp size deviation value that the current actual liquid level deviates from a reference liquid level is calculated; a first adjusting value of output flow is calculated based on the variation value of the pulp size, and a second adjusting value of the output flow is calculated based on the pulp size deviation value; the first adjusting value and the second adjusting value are used for adjusting the current output flow of the pump pool. According to the technical scheme, it is more accurately ensured that the liquid surface height in the pump pool is stably placed on the reference liquid level, and the classification effect is more stable in the ore grinding classification process.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD +1

Kiln for producing basalt fibers

ActiveCN109081599AIncrease the number of placementsExpand production scaleGlass making apparatusEngineeringBasalt fiber

The invention discloses a kiln for producing basalt fibers. The kiln comprises a forming area extending along a first direction in the length direction, the forming area is provided with a primary material channel for circulation of basalt melt, a lug tank is arranged on one side of the width direction of the forming area and provided with a secondary material channel communicated with the primarymaterial channel, a first leakage plate is arranged at the bottom of the forming area, a second leakage plate is arranged at the bottom of the lug tank, an electric heater is arranged is arranged onthe side wall of the width direction of the forming area and arranged on the lower portion of melt setting liquid level, and a first flame heater is arranged on at least one of the top or the side wall of the width direction of the forming area and arranged on the upper portion of the melt setting liquid level. By the aid of the kiln, part of basalt melt can enter the lug tank, the length of the forming area can be effectively decreased under the condition of the same number of leakage plates, the flow distance of the basalt melt is shortened, and the quality of the basalt fibers is ensured.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Synthesis method of N, N-dimethylacetamide

InactiveCN103524369ASame operationLiquid level is stableOrganic compound preparationCarboxylic acid amide separation/purificationAcetic acidPtru catalyst

The invention relates to a synthesis method of N, N-dimethylacetamide. The method adopts a catalytic reaction distillation technology to improve an acetic acid catalyzed condensation method, and includes: adding well metered glacial acetic acid and a catalyst in order into a four-neck flask equipped with a vent pipe, a thermometer, an external cooling bath and a rectification column, then introducing a dimethylamine gas into a reaction bottle through a flowmeter and a buffering bottle to undergo a neutralization reaction, then adding the neutralization solution into the rectification column bottom connected with cooling water, two-stage cooling, the thermometer and the vent pipe to undergo catalytic reaction-rectification, and then employing intermittent method and continuous method to carry out secondary rectification on a DMAC crude product collected from the reaction rectification. The method provided by the invention makes use of reaction heat, and the reaction process has low energy consumption. The reaction and product separation can be accomplished in a tower, the technological process is simplified, the reaction yield and selectivity are improved, and the product purity can reach 99.7%-99.9%. Also, fewer wastes are discharged in the preparation process, and the product entrainment loss is small.

Owner:连云港阳方催化科技有限公司

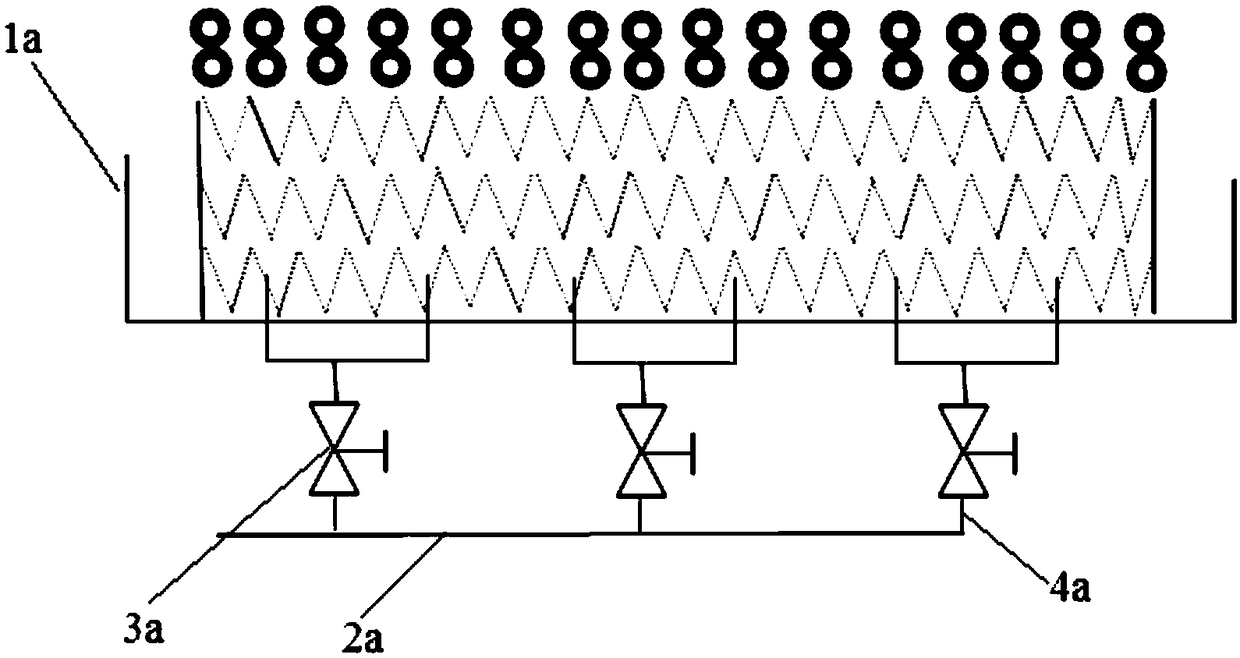

Continuous bubble scraping type multilayer inflatable bottom transmission type flotation machine

The invention discloses a continuous bubble scraping type multilayer inflatable bottom transmission type flotation machine. The flotation machine comprises a flotation groove; a mechanical stirring device, an annular column type micro-bubble generator and a bubble scraping device are arranged inside the flotation groove; the mechanical stirring device is located below a mineralized bubble foam layer; the annular column type micro-bubble generator is arranged on the periphery and the upper part of an impeller in a three-layer annular column type mode, air is transversely led into a bottom circular ring of the micro-bubble generator through an opening in the side part of the bottom of the flotation groove, and the purpose of inflation is achieved; the bubble scraping operation adopts two scraping plates for continuous scraping alternatively, and a long-stroke transmission belt wheel is matched. According to the flotation machine, the existing flotation machine mechanical stirring deviceis arranged at the bottom, the problems of middle foam stagnation and secondary sedimentation of mineralized particles are solved, so that the flotation index is improved; the annular column type micro-bubble generator is used as an air inflation device so that the diameter of the bubbles can be reduced, the sedimentation area is reduced, and the foam layer is stable and controllable; and the scraping plates of the flotation machine are two alternative scraping plates, and the belt wheel transmission is adopted, so that the mineralized foam can be timely and continuously scraped, the secondarysedimentation is prevented, and the flotation recovery rate is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

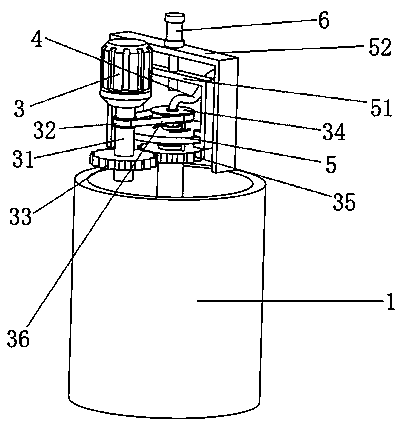

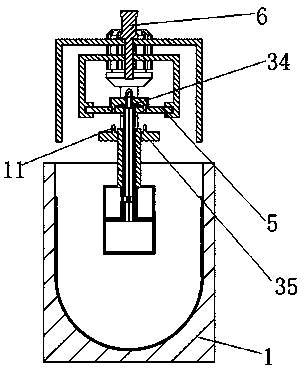

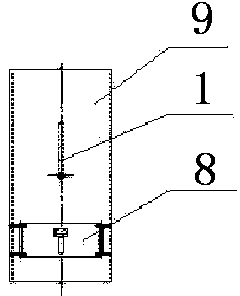

Device for aligning stopper rod precisely and aligning process for intermediate stopper rod

InactiveCN108568515AControl and adjust the opening and closing degreeLax closeMelt-holding vesselsHydraulic cylinderAutomatic control

The invention provides a device for aligning a stopper rod precisely. The device is composed of a mechanical automatic control system and a refractory material system. The mechanical automatic controlsystem comprises a cross beam, an angle adjusting bolt, a supporting plate, a guide positioning rod, an outer casing, a sliding core rod, a lifting adjusting loop, a hollow hydraulic cylinder, a pullrod, a shock absorbing spring and a spring compression adjusting nut; the refractory material system comprises an adjusting core rod, a stopper rod, a stopper rod head, a nozzle brick and a seat brick. The device is improved based on an existing stopper rod lifting device. Matched with an aligning process for an intermediate stopper rod, the aligning position of the stopper rod is adjusted by means of the angle adjusting bolt, the length of the stopper rod is adjusted by means of the adjusting core rod, and the central position of the sliding core rod is fixed by means of a positioning rod embedded to the outer casing to achieve precise alignment. The device has the advantages that the stopper rod which is aligned is unlikely to shift and is convenient to detach and debug.

Owner:刘中原

Rolling method of Cu-Cr series alloy plates and strips

ActiveCN111621666ALiquid level is stableConfiguration ratio is easy to controlTemperature control deviceMetal rolling arrangementsSolution treatmentCopper

The invention discloses a rolling method of Cu-Cr series alloy plates and strips. Alloy comprises the chemical components of 0.5-1.5% of Cr, 0.03-1.8% of Zr, <=0.08% of Fe, <=0.1% of Si and the balance of copper and unavoidable impurities. The rolling method comprises the steps of (1) proportioning; (1) upward-drawing continuous casting; (3) hot continuous rolling of a square billet; (4) solutiontreatment; (5) surface milling; (6) rough rolling; (7) aging treatment; (8) surface treatment; (9) finish rolling; (10) take-up; and (11) slitting. The method can lower production cost and improve product quality and the percent of pass of finished products, thereby greatly meeting market demands.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

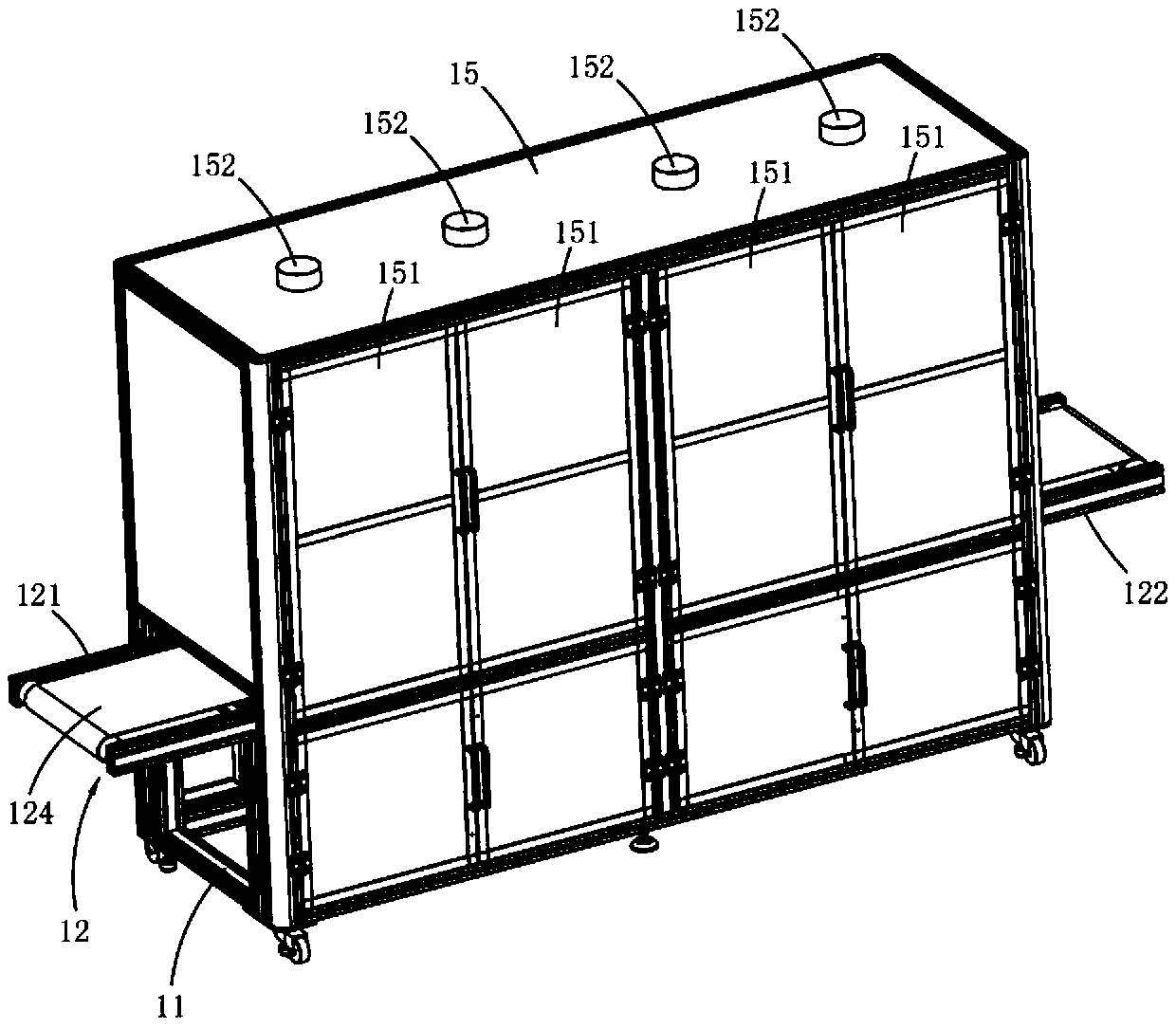

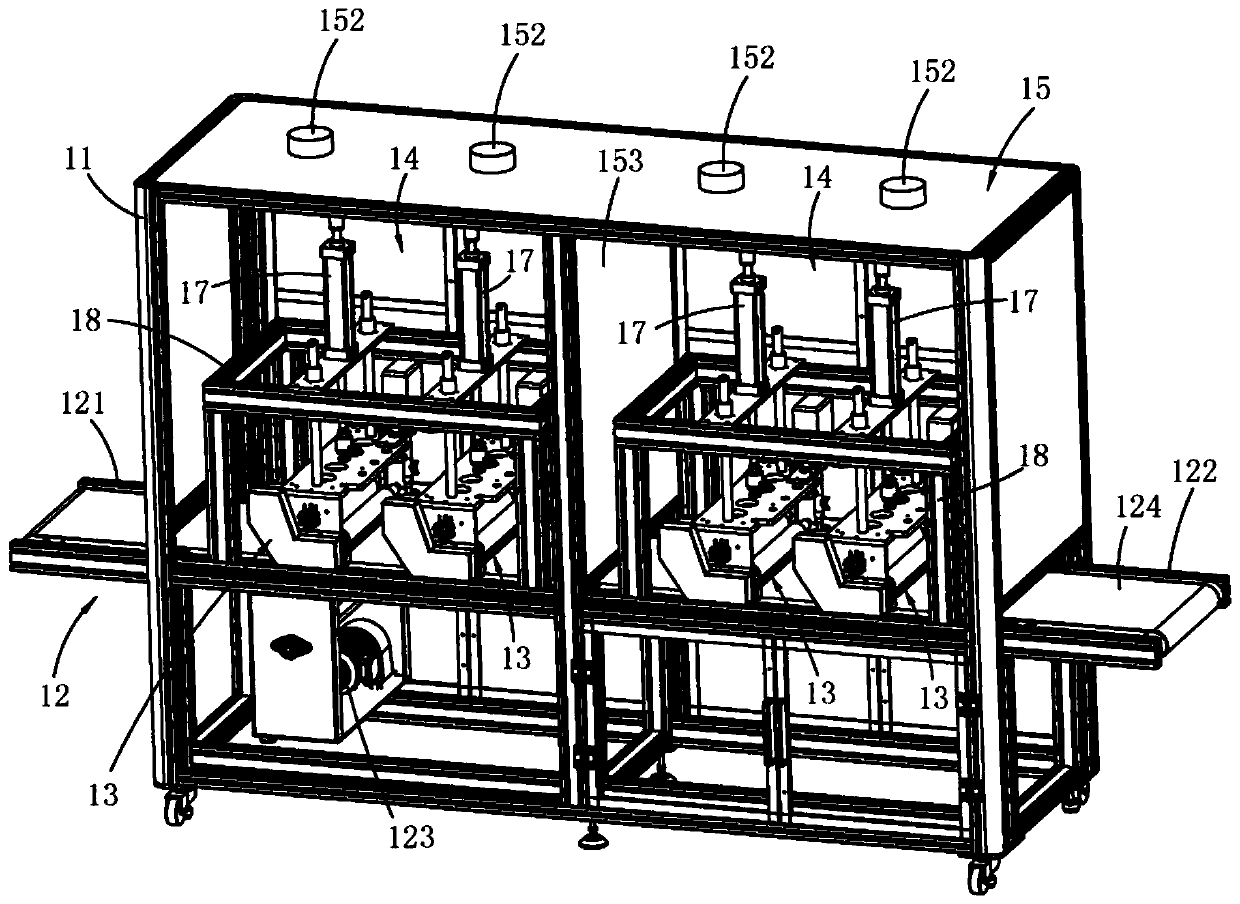

Automatic treatment agent coating equipment

PendingCN110918370AAvoid drippingAvoid uneven applicationLiquid surface applicatorsCoatingsStructural engineeringProcess engineering

The invention discloses automatic treatment agent coating equipment. The automatic treatment agent coating equipment is characterized in that at least two automatic treatment agent coating units, wherein the two automatic treatment agent coating units are arranged on a machine frame along the conveying direction of a shoe material conveying mechanism and are used alternately; each automatic treatment agent unit coating is provided with at least one coating mechanism correspondingly; a control device is connected with a dose adjusting driving mechanism arranged on each coating mechanism; when the equipment works, a transition roller is intermittently driven by the dose adjusting driving mechanism to leave a feeding roller and a coating roller at set time intervals, so that the transition roller respectively stays at a treatment agent coating device and the coating working position for corresponding stay time, and the dosage of the treatment agent transferred to the transition roller isautomatically adjusted in the working process; a roller body in the treatment agent coating device can be quickly disassembled, and a cushion sleeve on the surface of the roller body can be conveniently cleaned and replaced and installed; and the treatment agent can be automatically coated continuously without stopping, the production is accelerated, and the use is convenient.

Owner:东莞云展智能装备有限公司

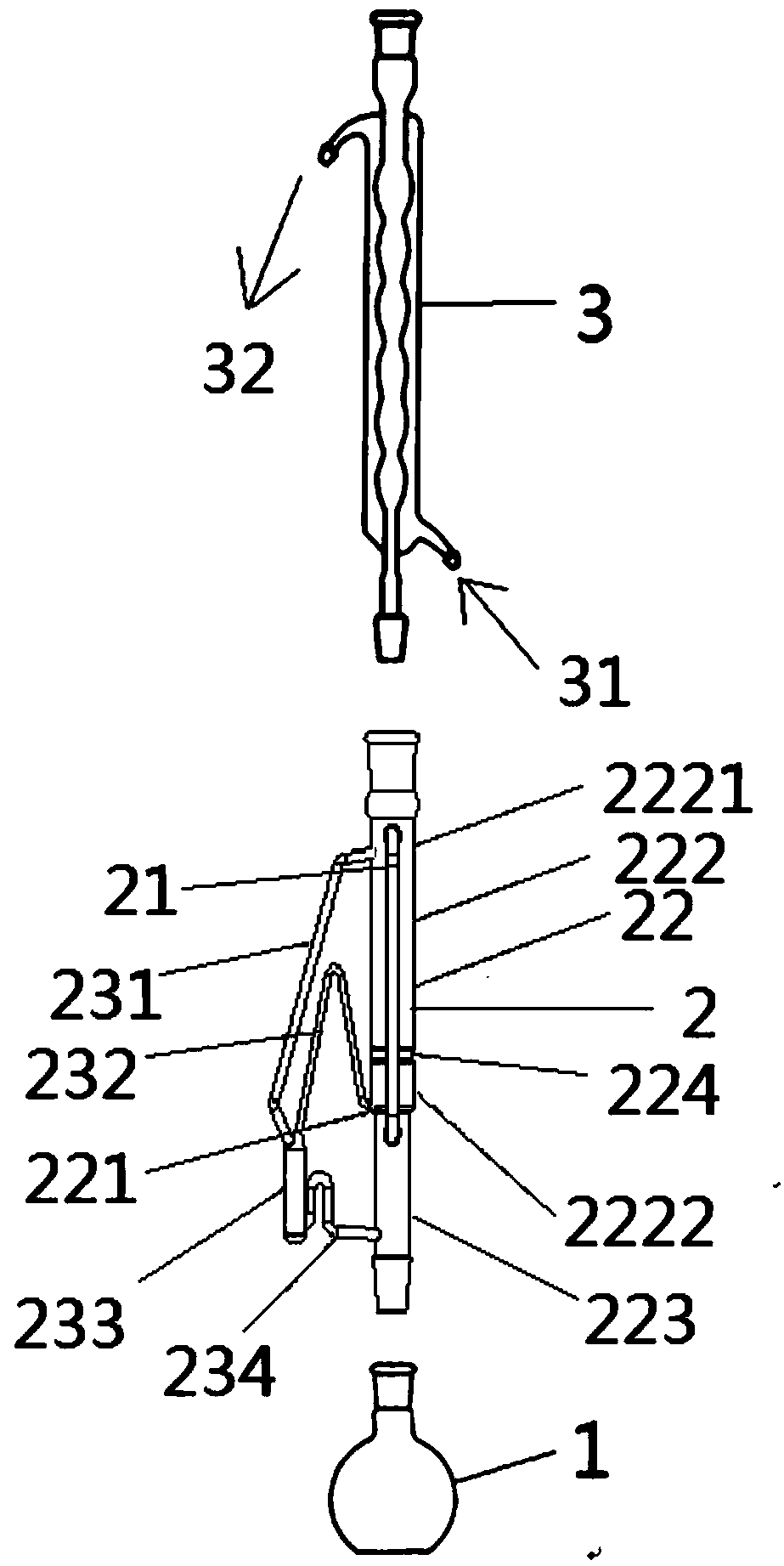

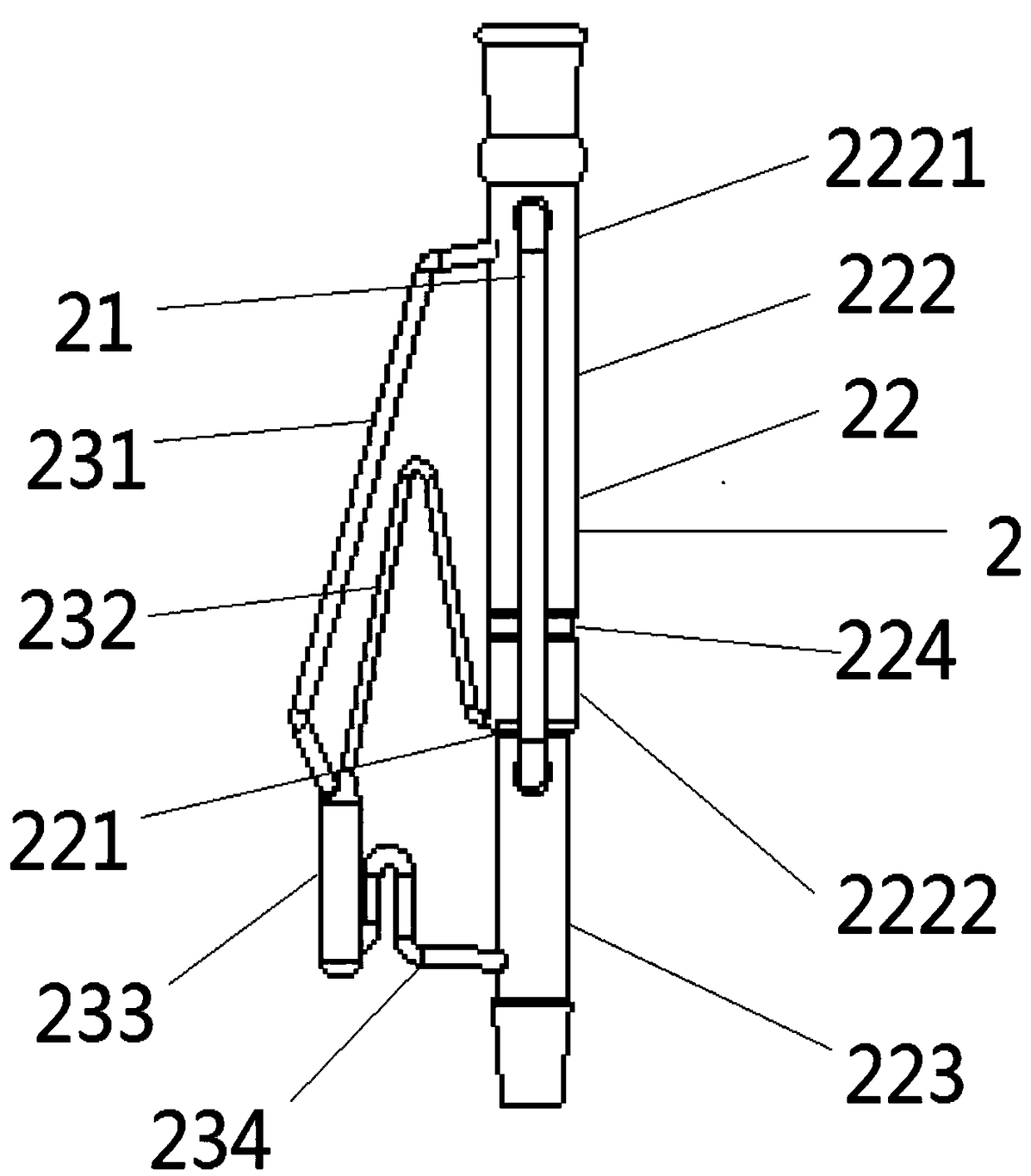

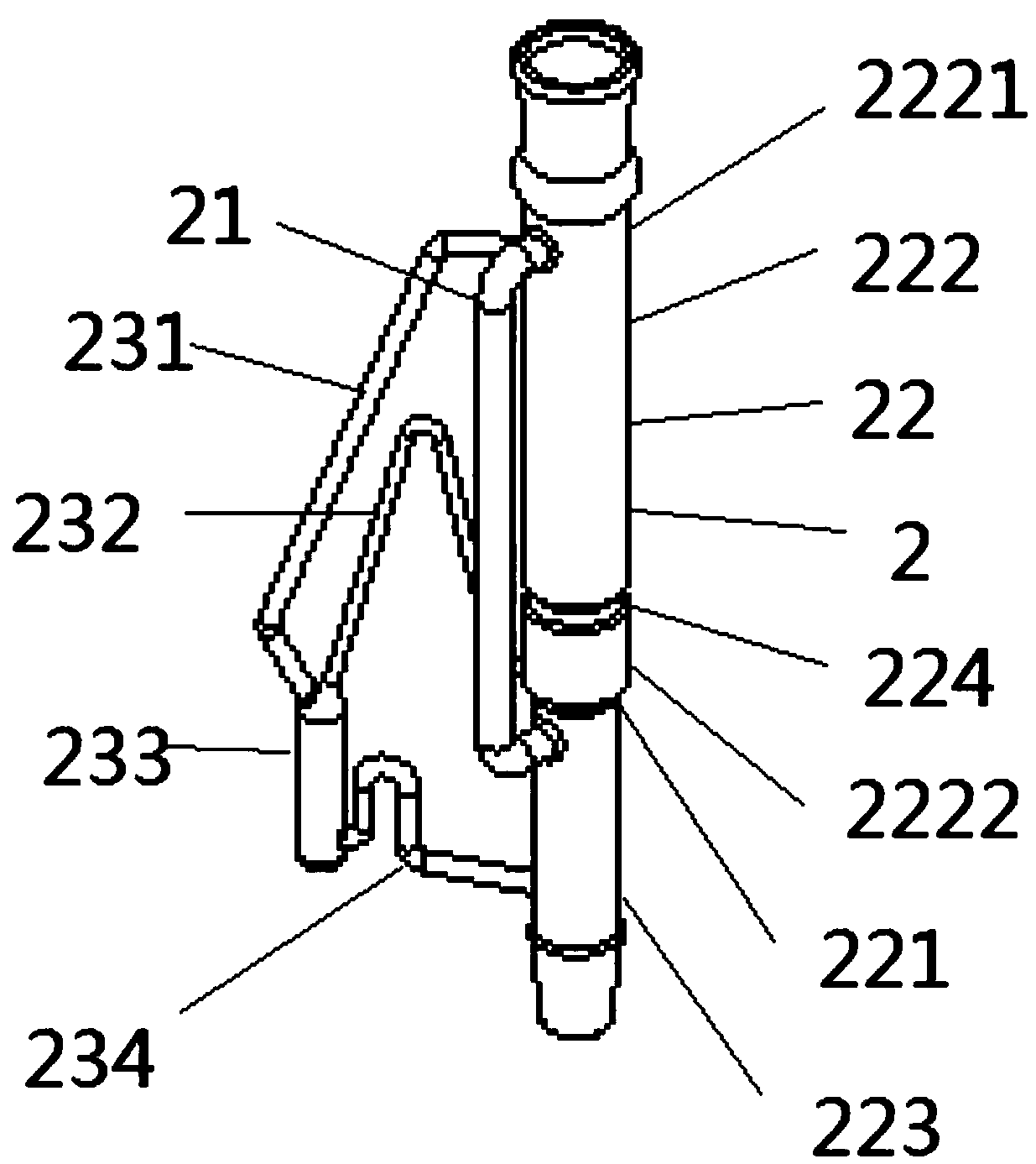

Reflux extraction device and extraction tube

PendingCN109107222ASolve the problem of low extraction efficiency and long extraction timeLiquid level is stableSolid solvent extractionReflux extractionSiphon

The invention relates to the field of separation reflux extraction devices and particularly relates to a reflux extraction device and an extraction tube. The reflux extraction device comprises an extraction flask, an extraction tube located above the extraction flask and in sealing fit with the extraction flask and a condensation tube located above the extraction tube and in sealing fit with the extraction tube, wherein a partition is arranged in an extraction tube body; a sand core arranged in the lower part of the extraction tube and used for limiting flow is located above the partition; a steam tube and an extraction siphon are arranged on the side of the extraction tube. Compared with the existing reflux extraction device, the problems of low extraction efficiency and long extraction time caused when solid samples are not in soaked and extracted state all the time during extracting are solved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Nano-boiling solar multifunctional cup and heating method thereof

InactiveCN104776411ALiquid level is stableSteam generation heating methodsWater/sewage treatmentWater storageThermodynamics

The invention discloses a nano-boiling solar multifunctional cup and a heating method thereof. The nano-boiling solar multifunctional cup comprises a cup cover, a cup body, a cup base, a tee-joint diversion pipe, porous water adsorption materials, a light adsorption nano layer, a bracket, a water storage cavity and an annular runner. According to the nano-boiling solar multifunctional cup, the efficient light absorption performance and the hydrophilia of light adsorption nano layer materials are utilized, solar energy is efficiently adsorbed and converted into high-temperature steam in a process that the temperature is quickly risen by the light adsorption of nano-particles in the light adsorption nano layer, surrounding water is boiled by the heating of the nano-particles and high-temperature steam generates, so that the photo-thermal conversion efficiency of a solar device is improved, and the generated high-temperature steam realizes various applications in the multifunctional cup.

Owner:ZHEJIANG UNIV

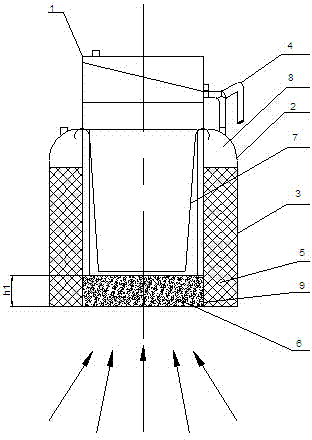

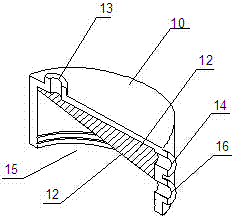

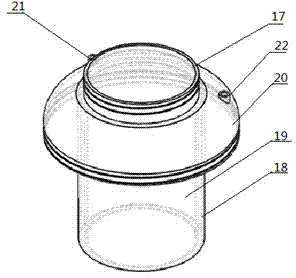

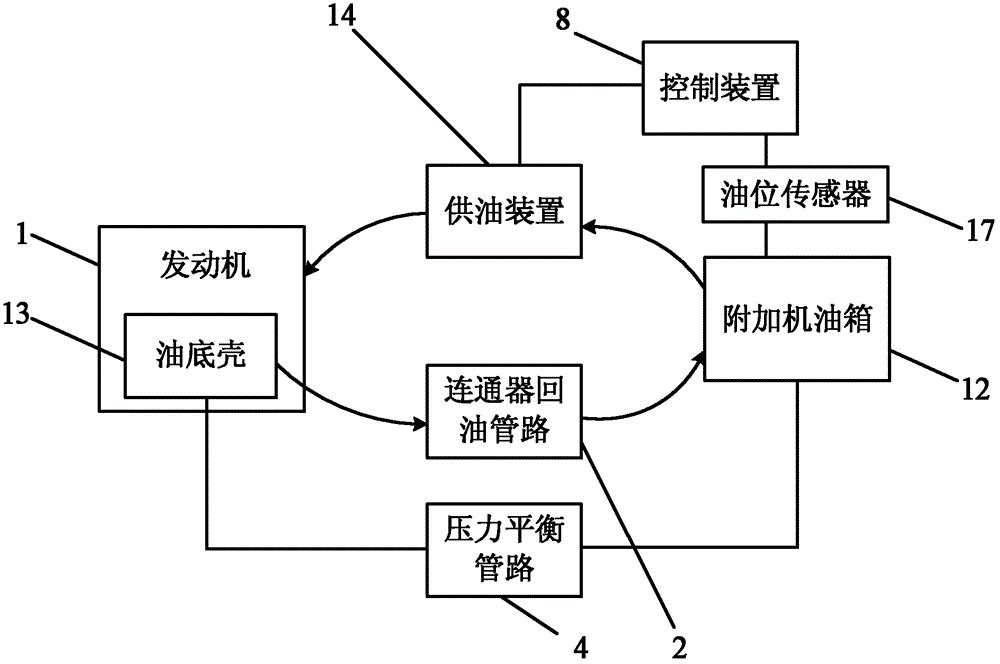

Automatic machine oil cleaning system, oil return pipeline of communicating vessel, and engine system

ActiveCN102536379BLiquid level is stableImprove reliabilityLubricant conduit arrangementsLubricant mounting/connectionCombustionFuel tank

The embodiment of the invention provides an automatic machine oil cleaning system, relates to the technical field of internal combustion engines lubrication, and is used for prolonging the replacing period of machine oil in an engine, reducing the cost of a machine oil cleaning system, and improving the reliability of the machine oil cleaning system. The automatic machine oil cleaning system comprises an auxiliary machine oil box, an oil supply device connected with the auxiliary machine oil box and the engine respectively, and an oil return pipeline of a communicating vessel, wherein two ends of the oil return pipeline are communicated with the bottom end of an oil pan and the top end of the auxiliary machine oil box respectively; the peak of the oil return pipeline is higher than the set machine oil level of the oil pan; the set machine oil level of the oil pan is lower than the accessible uppermost level and the accessible bottommost level of the engine; the height difference between the set machine oil level of the oil pan and the accessible uppermost level or the accessible bottommost level is set according to the pressure in the oil pan during the operation of the engine and the atmospheric pressure, so that when the machine oil level in the oil pan is higher than the set machine oil level, machine oil can flow back to the auxiliary machine oil box along the oil return pipeline.

Owner:HUAWEI TECH CO LTD

Esterification reaction tower for producing glyceryl triacetate

PendingCN111298725ASolve the problem of long waiting time for recyclingGood dispersionOrganic compound preparationCarboxylic acid esters preparationPtru catalystReboiler

The invention discloses an esterification reaction tower for glyceryl triacetate production. The esterification reaction tower comprises a tower body, a reboiler, a gas distribution plate, a first condenser, a pervaporation membrane separator, a second condenser, a buffer tank, a reflux channel, a gear rack mechanism, a mesh cylinder and a gear motor. According to the invention, water generated bya reaction and a gas-phase azeotrope of a water-carrying agent are rapidly and efficiently dehydrated at the tower top, the removed water is intensively recycled in the buffer tank, and the recycledwater-carrying agent can be sent back to the tower as required and can also be discharged, so that the use is flexible; active carbon in a catalyst in a material can be directly intercepted in the mesh cylinder, so that the filtering difficulty of subsequent procedures is reduced; the mesh cylinder can reciprocate up and down in the tower and continuously rotate, so that the effect of stirring feed liquid is achieved, and the active carbon is dispersed so as to facilitate the reaction; and the feeding door of the mesh cylinder is matched with the reset spring, the upper pressing head and the lower pressing head, so that the functions of automatic feeding, cleaning and discharging can be achieved, and the esterification reaction tower has the advantages of being convenient to operate and maintain.

Owner:MILE KANGHE GLYCERIDE CO LTD

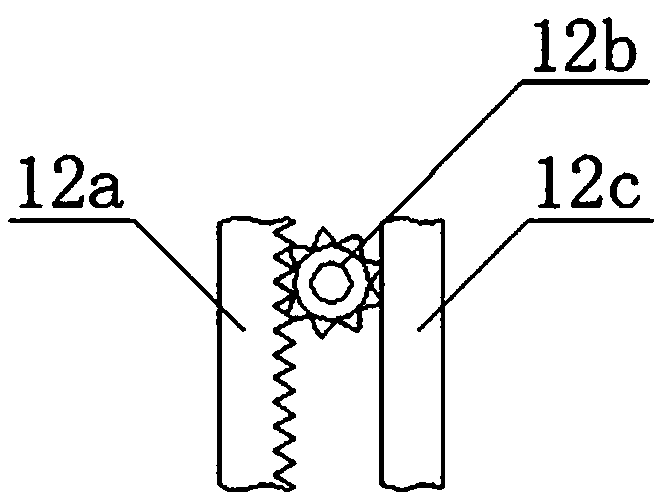

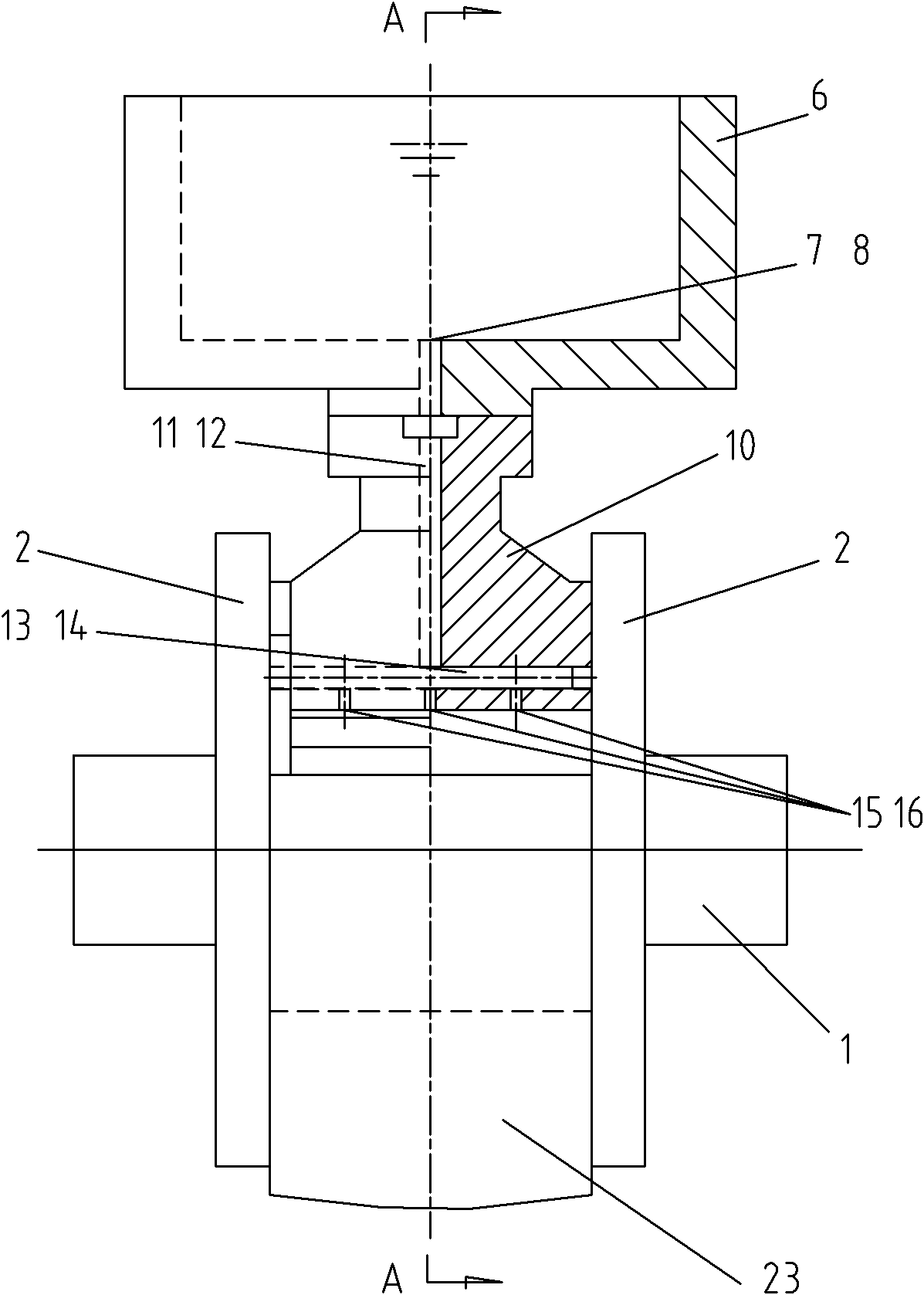

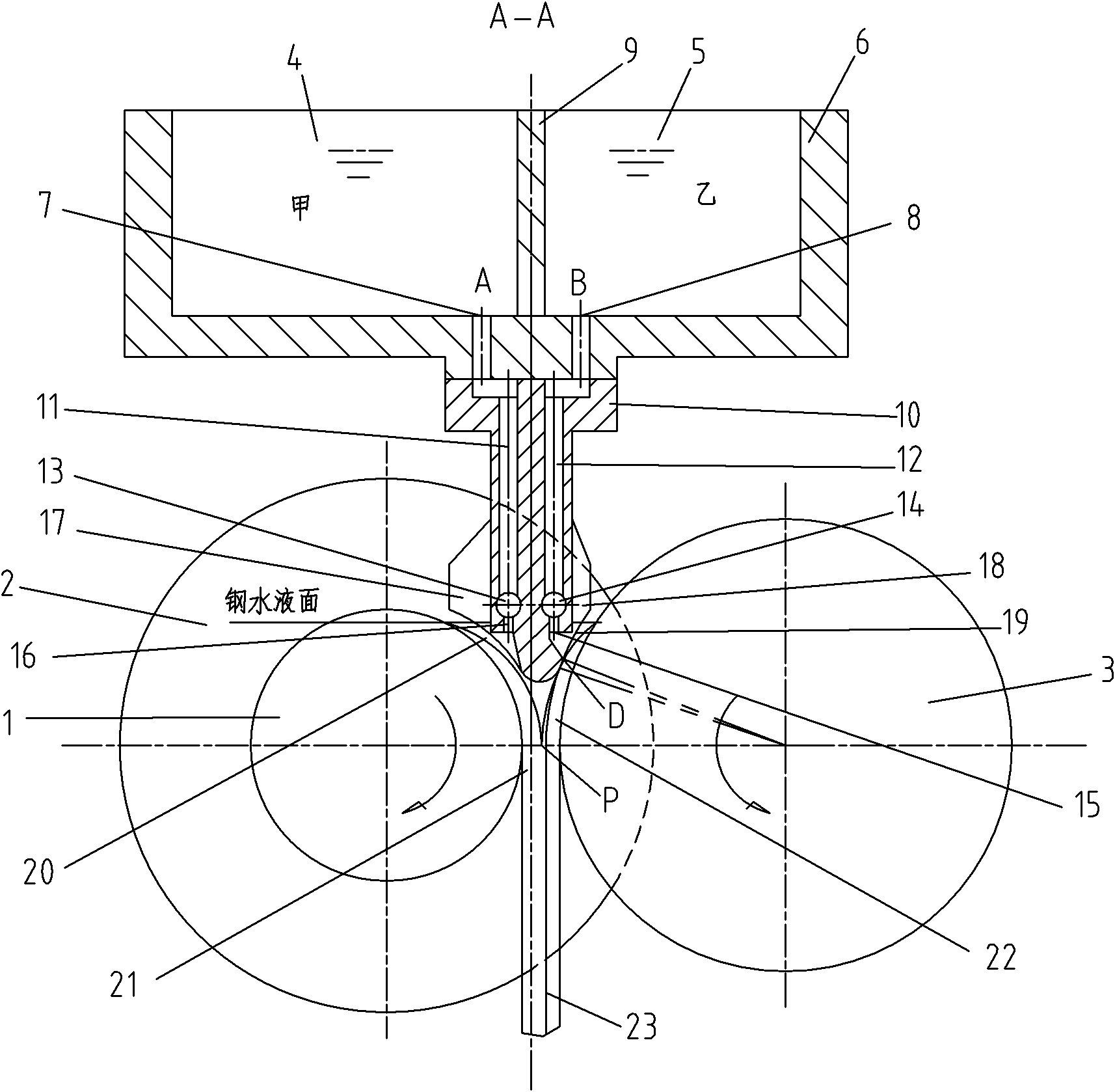

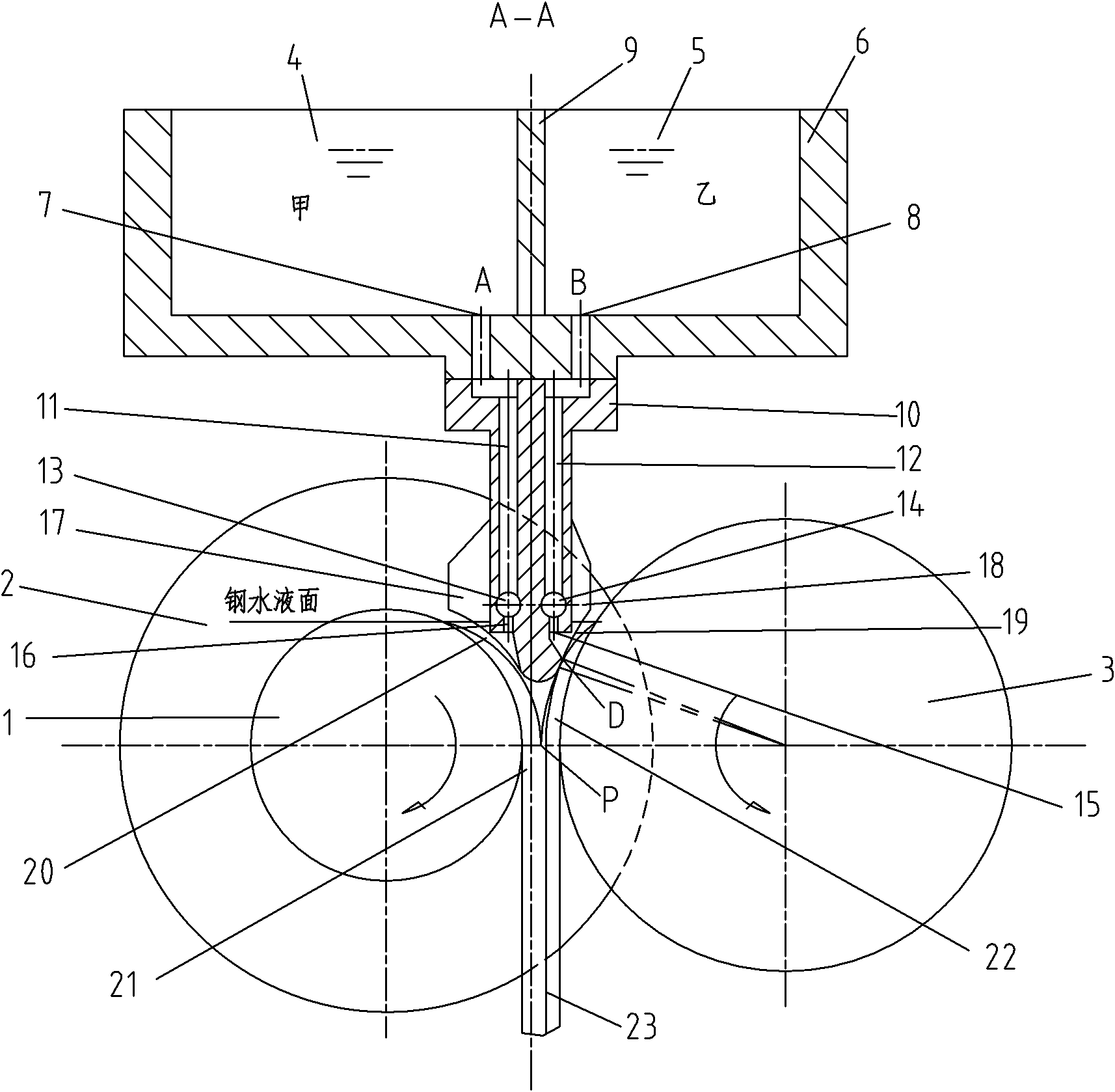

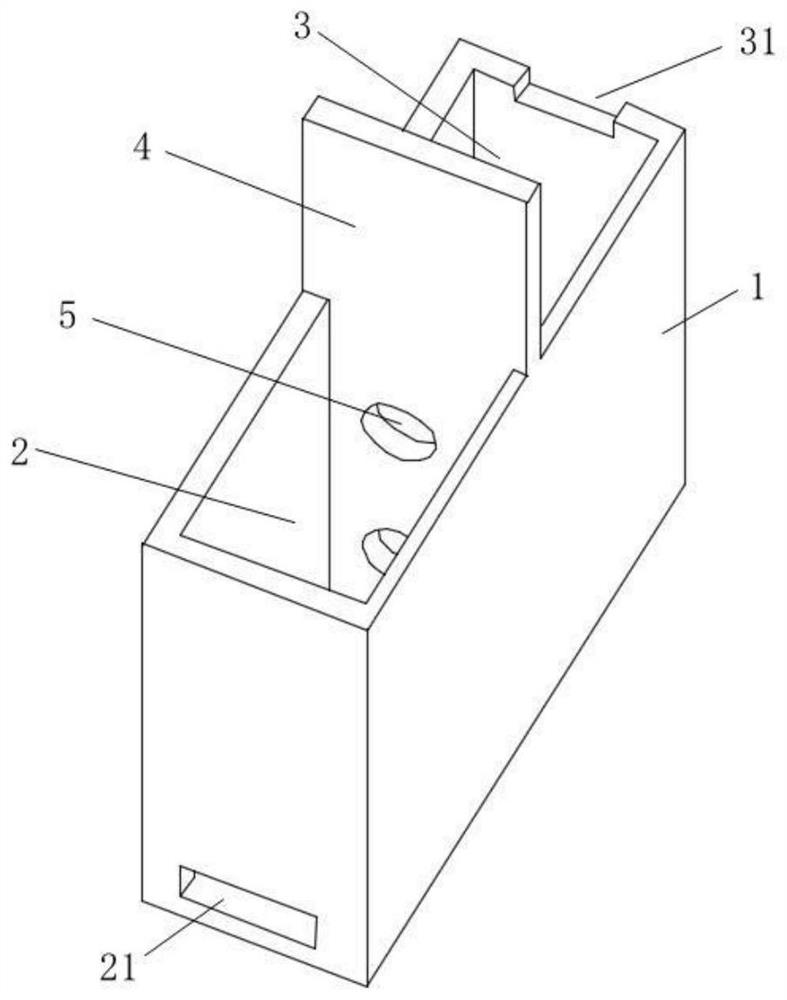

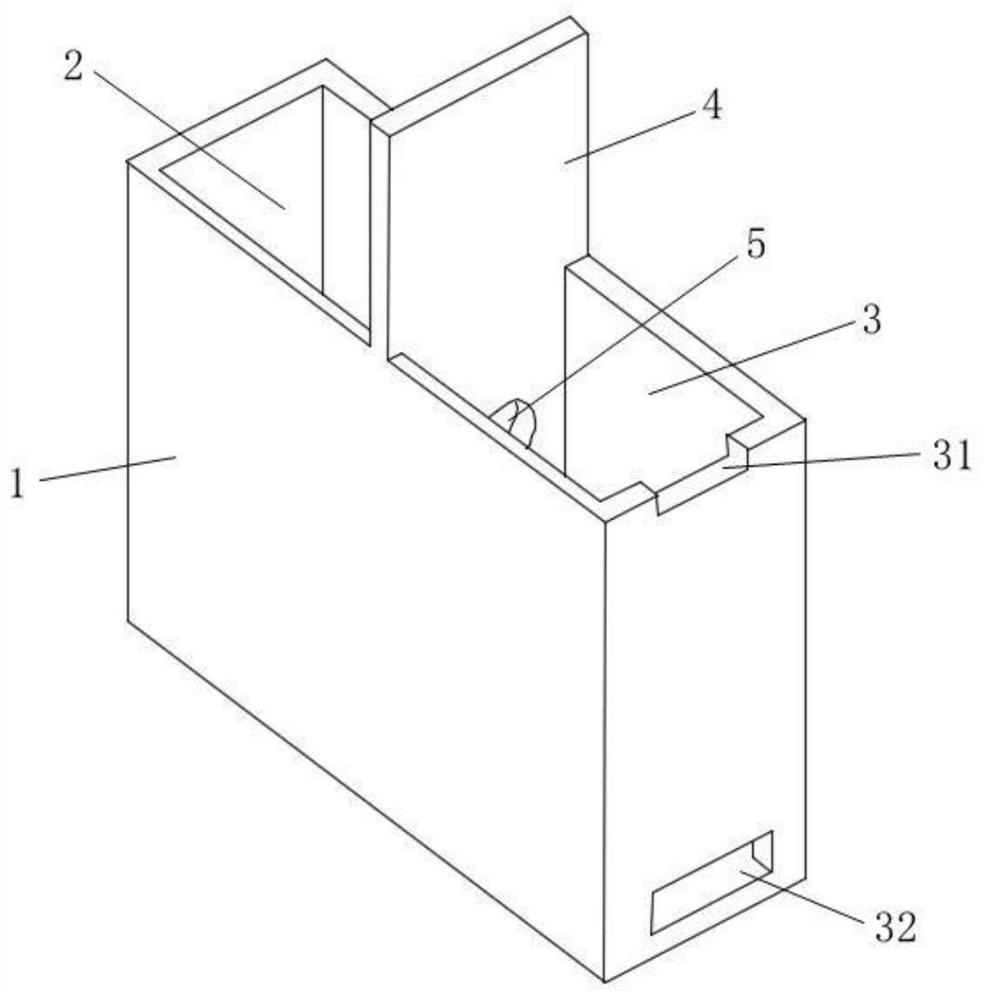

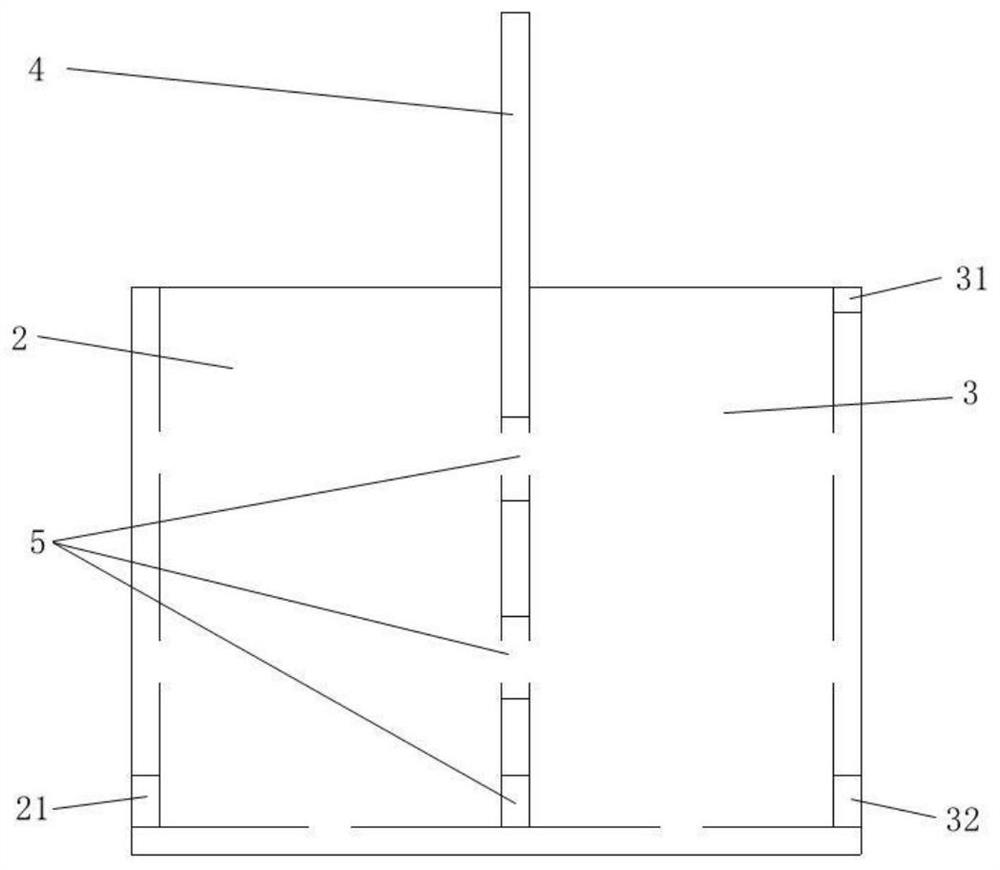

Partition plate device of casting system of double-roller continuous casting machine

The invention discloses a partition plate device of a casting system of a double-roller continuous casting machine. The partition plate device comprises a partition plate, a tundish, a tundish casting passage A, a tundish casting passage B, a tundish partition wall, a partition plate casting passage A, a partition plate casting passage B, a collecting hole A, a collecting hole B, a shunting hole A, a shunting hole B, a lateral wing plate A and a lateral wing plate B, wherein the tundish casting passage A, the partition plate casting passage A, the collecting hole A and the shunting hole A form a molten steel casting passage A; and the tundish casting passage B, the partition plate casting passage B, the collecting hole B and the shunting hole B form a molten steel casting passage B. Underthe condition that the molten steel is not mixed when two kinds of molten steel are solidified on crystallization rollers respectively, the two casting passages and the partition plate are combined together to form a whole; the head can be dipped into the molten steel of a melt bath so as to effectively prevent secondary oxidation of the molten steel; and the collecting holes and the shunting holes are added in the structural design, so impact of the molten steel is reduced, the molten steel is uniformly distributed and the liquid level is stable.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Nickel mesh coating bath

InactiveCN106435657AImprove space utilizationEasy to assemble and disassembleCellsTanksAperture ratioNickel coating

The invention discloses a nickel mesh coating bath, and relates to the technical field of nickel mesh production. The nickel mesh coating bath comprises a bath body, a longitudinal partition plate is arranged in the bath body and divides the bath body into an inner bath and an overflow bath, a cloth bag is arranged on the bath wall of one side of the inner bath and is far away from the overflow bath, nickel beads or nickel blocks are placed in the cloth bag, a mesh winding roller is arranged at two ends of the inner bath, a coating film is sleeved on the mesh winding roller, a pressure rod is arrange don the coating film, the bath wall of one side of the bath body is higher than that of the other side of the bath body, a bath body sealing cover is hinged at the top of the bath wall of the high side of the bath body, and a pumping pipeline is arranged on the bath wall of the high side of the bath body and communicated with an acid mist washing tower. According to the nickel mesh coating bath, utility rate of spaces is high, acid mist generated by bath solution in the nickel coating process is pumped by the aid of a side induced draft mode and recovered and treated, production safety is improved, environmental pollution is avoided, the aperture ratio of a nickel mesh is increased, and mesh openings are uniform.

Owner:湖北海富镍网科技股份有限公司

A slag pumping device for cleaning holes in underground piles and walls

The invention relates to a slag pumping device for an underground pile and a wall cleaning hole. The slag pumping device comprises a barrel, and the barrel is internally provided with a slag suction plate which is matched with the inside wall of the barrel and can be moved up and down; the part, above the slag suction plate, in the barrel is provided with a T type communicating pipe, and the middle part of the slag suction plate is provided with a slag suction inlet communicating with the bottom end of the T type communicating pipe; and one end of the T type communicating pipe is connected toa high-speed fluid pipe, and the other end of the T type communicating pipe is provided with a slag outlet. Sediments are sucked into the barrel only, and the lifting height is small; and the requiredslag removal power is low. Slurry is circulated in a hole, and the stability of the liquid level can be ensured effectively; and the slurry disturbance in the hole can be reduced, and hole collapse is avoided effectively.

Owner:GUANGDONG FOUND ENG GRP CO LTD

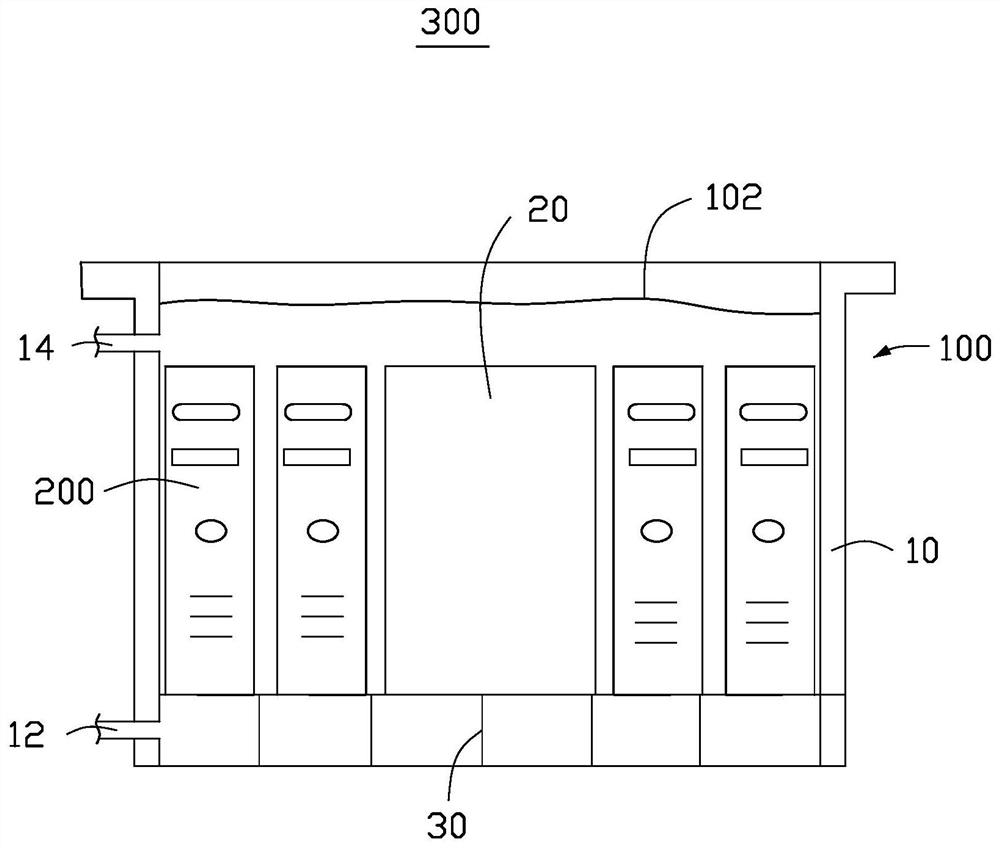

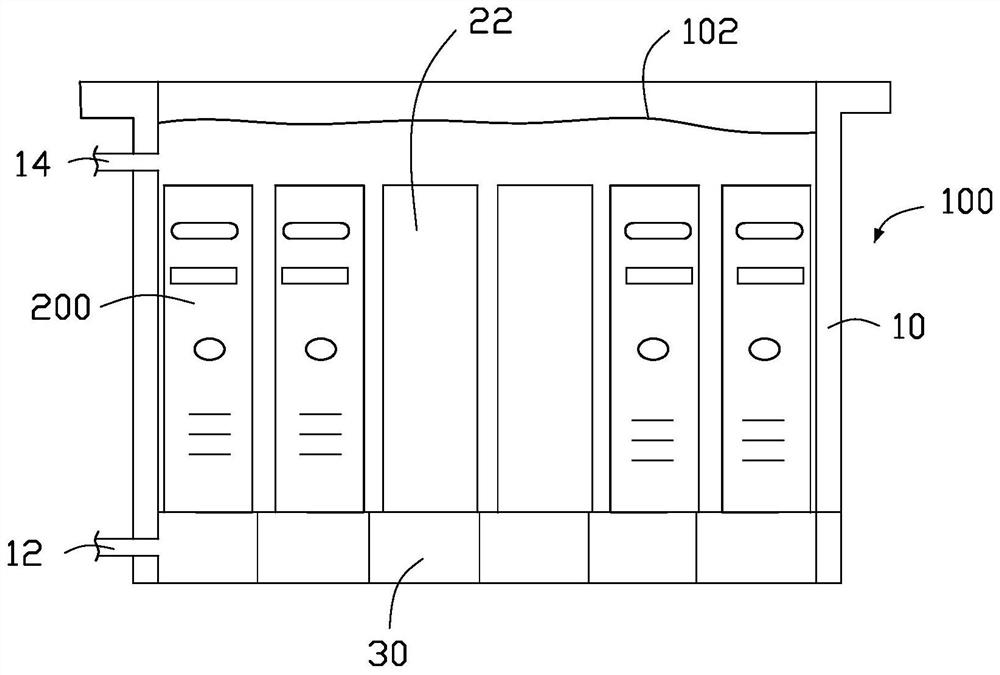

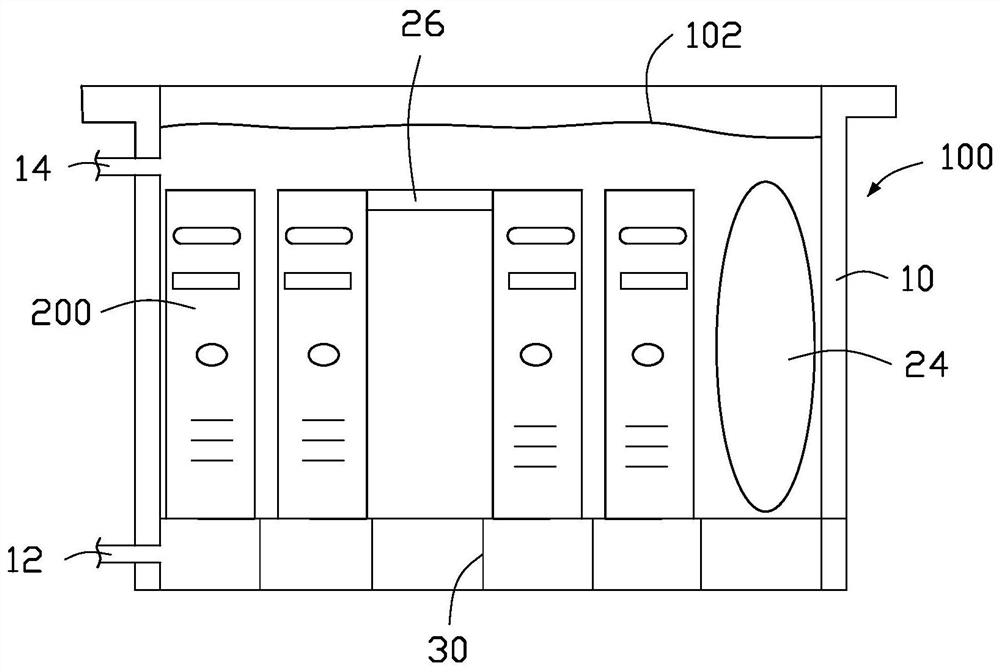

Heat dissipation device and heat dissipation system applying same

PendingCN111836506ALiquid level is stableImprove cooling effectDigital data processing detailsCooling/ventilation/heating modificationsThermodynamicsEngineering

The invention provides a heat dissipation system, which comprises a heat dissipation device and a plurality of electronic devices, wherein the heat dissipation device is used for heat dissipation of the plurality of electronic devices, and comprises a heat dissipation groove and a filling module, the heat dissipation groove is used for accommodating a cooling liquid and the plurality of electronicdevices, the plurality of electronic devices are immersed in the cooling liquid, the cooling liquid is used for heat dissipation of the plurality of electronic devices, and when the electronic deviceis taken out from the heat dissipation groove, the filling module is used for filling the same volume of the electronic device taken out from the heat dissipation groove, so that the heat dissipationeffect is good.

Owner:WARECONN TECH SERVICE (TIANJIN) CO LTD

A kiln for the production of basalt fiber

ActiveCN109081599BIncrease the number of placementsExpand production scaleGlass making apparatusPhysical chemistryEngineering

The invention discloses a kiln for producing basalt fibers. The kiln comprises a forming area extending along a first direction in the length direction, the forming area is provided with a primary material channel for circulation of basalt melt, a lug tank is arranged on one side of the width direction of the forming area and provided with a secondary material channel communicated with the primarymaterial channel, a first leakage plate is arranged at the bottom of the forming area, a second leakage plate is arranged at the bottom of the lug tank, an electric heater is arranged is arranged onthe side wall of the width direction of the forming area and arranged on the lower portion of melt setting liquid level, and a first flame heater is arranged on at least one of the top or the side wall of the width direction of the forming area and arranged on the upper portion of the melt setting liquid level. By the aid of the kiln, part of basalt melt can enter the lug tank, the length of the forming area can be effectively decreased under the condition of the same number of leakage plates, the flow distance of the basalt melt is shortened, and the quality of the basalt fibers is ensured.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Wet chain type etching groove liquid inlet structure

PendingCN108447805AImprove inflow stabilityReduce outflowFinal product manufactureSemiconductor/solid-state device manufacturingEtchingChain type

The invention relates to a wet chain type etching groove liquid inlet structure. The wet chain type etching groove liquid inlet structure is characterized by comprising a liquid inlet box arranged atthe bottom of a wet etching groove body; the liquid inlet box is arranged on one side, far from the feeding direction, of a silicon wafer; a row of liquid outlet draining holes are formed in one side,towards the feeding direction of the silicon wafer, of the liquid inlet box; a liquid inlet is formed in the bottom of the liquid inlet box; and the liquid inlet box is connected with a liquid inletpipeline through the liquid inlet. By virtue of the wet chain type etching groove liquid inlet structure, the groove body liquid inlet stability can be improved, generation of air bubbles on the surface of the silicon wafer can be avoided, and generation of unqualified wafers can be reduced or eliminated.

Owner:WUXI SUNTECH POWER CO LTD

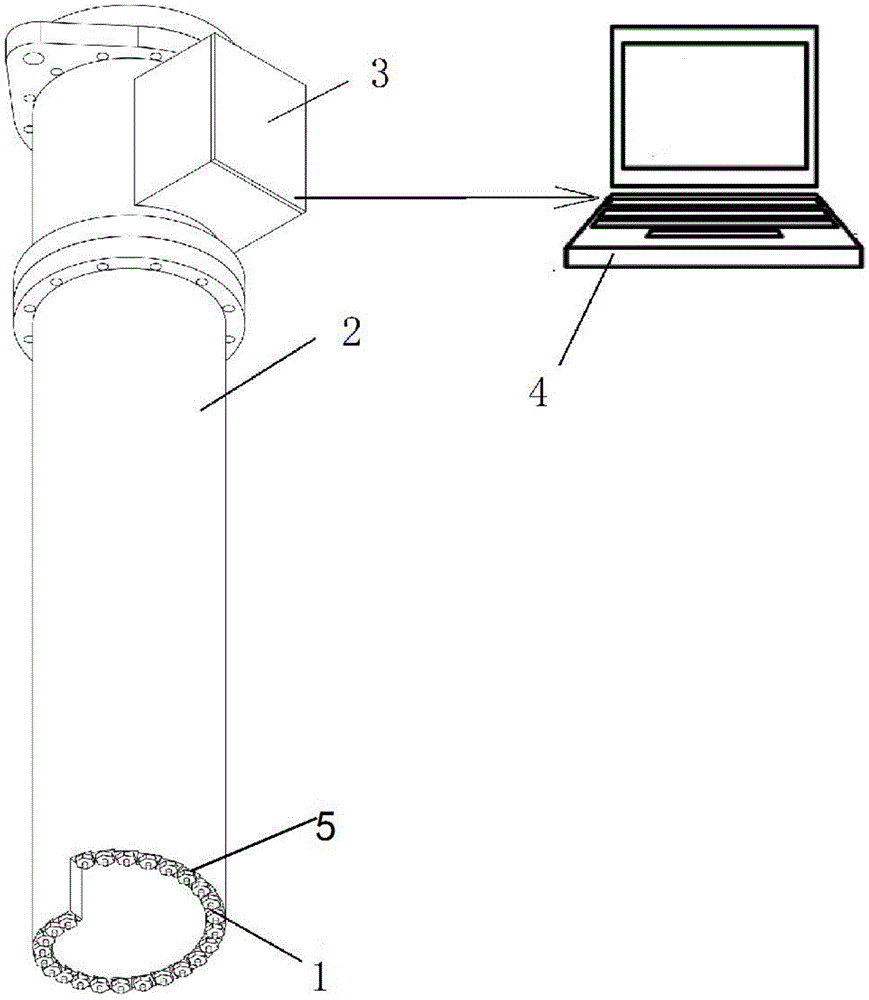

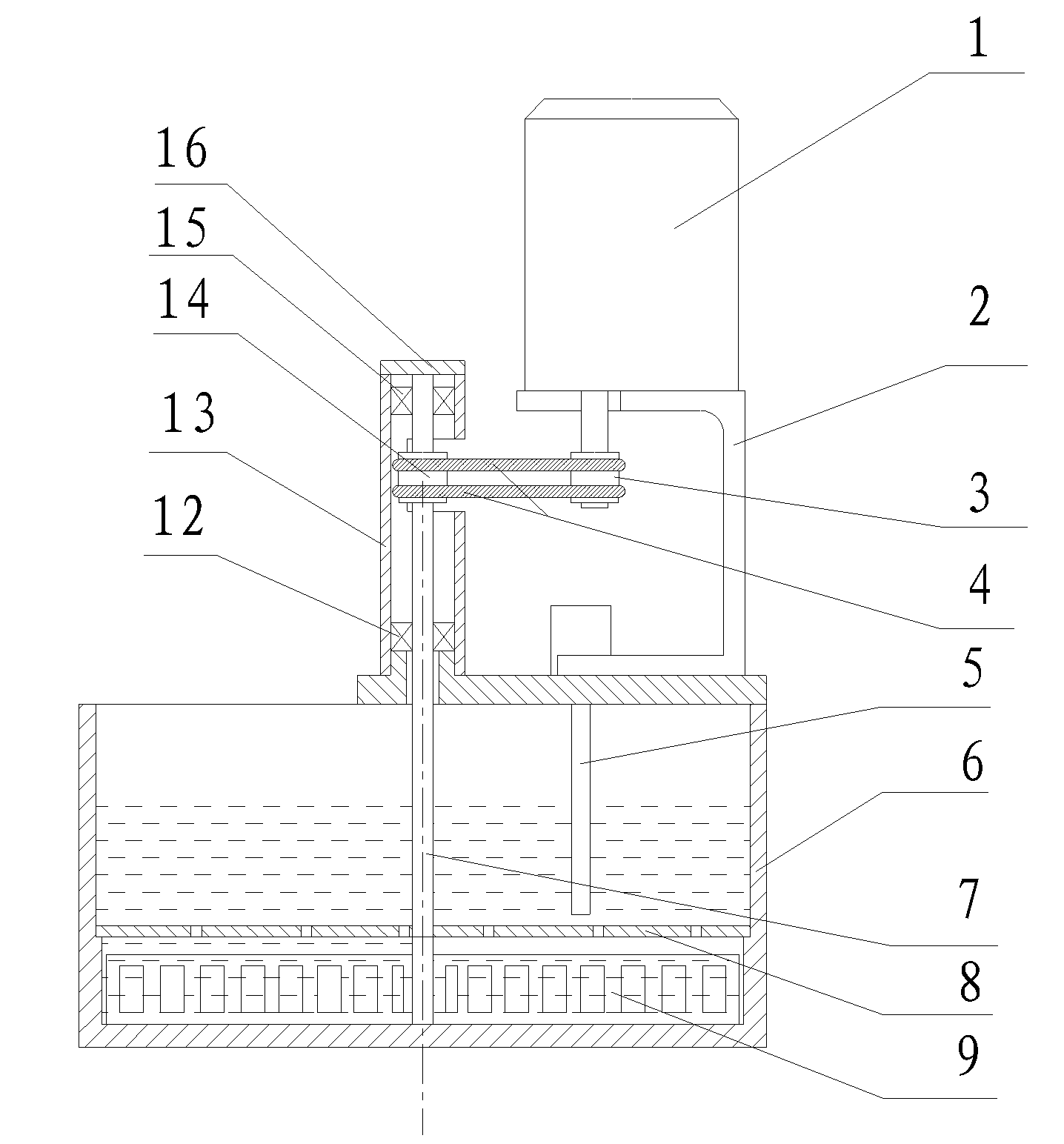

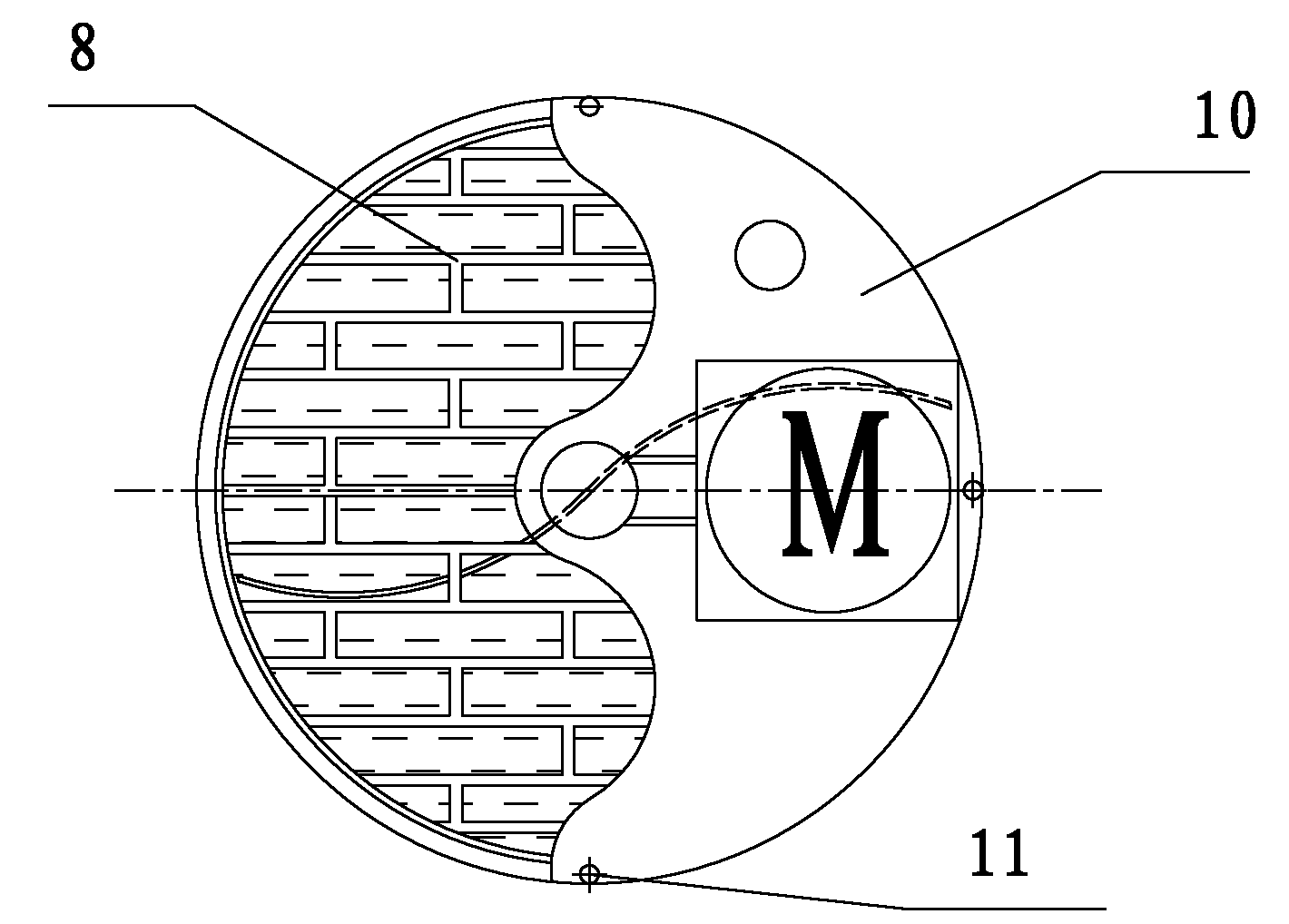

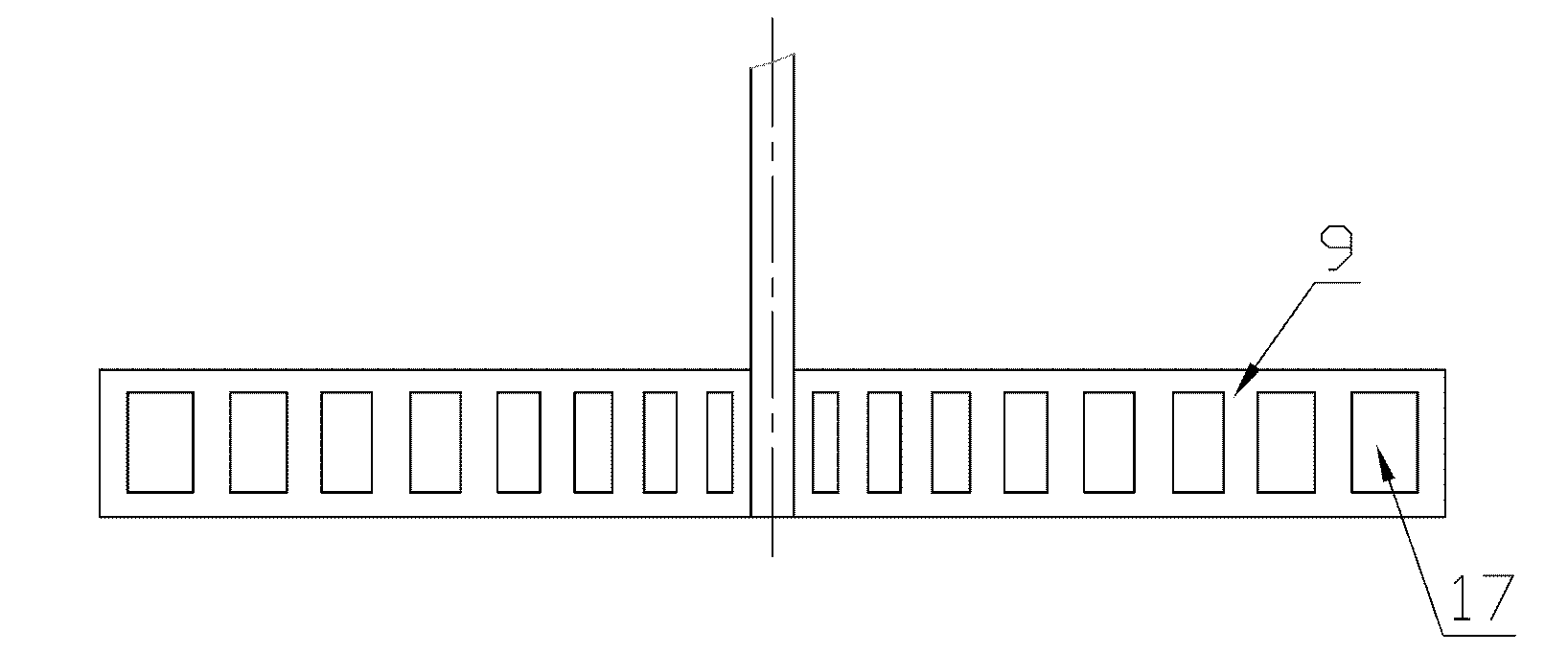

Magnesium alloy continuous casting liquid level position detection device and detection method thereof

ActiveCN104923749ALiquid level is stableEnsure safe productionCasting parameters measurement/indication devicesTemperature jumpThermocouple

The invention provides a magnesium alloy continuous casting liquid level position detection device and a detection method thereof. The magnesium alloy continuous casting liquid level position detection device comprises a cylindrical detection shell, a plurality of through holes are axially formed between the inner wall and the outer wall of the detection shell and equidistantly and uniformly arranged along the circumferential direction of the detection shell, a thermocouple is mounted in each through hole to form a thermocouple group, a measuring end group of the thermocouple group extends out of the bottom ends of the through holes, contacts with liquid level to be detected and forms a spiral, a terminal group of the thermocouple group is connected with a signal acquisition unit mounted at the top end of the detection shell, the signal acquisition unit is connected with a data processing system outside the detection shell through a communication module, the device judges between which thermocouples the liquid level to be detected is positioned according to temperature jump searched by the thermocouples positioned above and below the liquid level to be detected, the relative position of the liquid level to be detected is obtained, the liquid level position of the liquid level to be detected is timely adjusted, the liquid level of magnesium alloy melt is maintained stable, safety production of a magnesium alloy is ensured, and the quality of a cast billet is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Continuous stirring and dipping device for flux

InactiveCN102126100ALiquid level is stableIncrease temperatureWelding/cutting auxillary devicesAuxillary welding devicesImpellerMotor shaft

The invention discloses a continuous stirring and dipping device for a flux, which comprises a tank body. A motor is arranged above the tank body through a motor bracket, and is connected with one end of an impeller shaft through a transmission device; the other end of the impeller shaft is provided with an impeller extending to the bottom of the tank body; a permeable interlayer is arranged above the impeller in the tank body; the transmission device is a motor pulley connected with a motor shaft, a belt and a pulley; the opening of the tank body is provided with an upper cover plate on which the motor bracket is arranged; an impeller shaft support is arranged on the upper cover plate; an upper bearing and a lower bearing are arranged at two ends in the impeller shaft support; the upper part of the impeller penetrates the upper cover plate to be sleeved on the upper and lower bearings; the upper part of the impeller is connected with the pulley; the tank body is provided with a solution temperature measuring and overtemperature alarm device; and the impeller is provided with a wave reducing hole. By arranging the motor, when the flux is dipped, the flux is stirred, and a stable speed meeting the actual requirement can be achieved; by arranging the permeable interlayer, blades perform stirring at the bottom of the tank, so that the whole solution is uniform; moreover, the blades cannot contact workpieces and can perform continuous stirring.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

Liquid sampling device and density measuring method

InactiveCN113125204ACleaningSelf-rinsingWithdrawing sample devicesSpecific gravity measurementEngineeringMechanical engineering

Owner:SGIS SONGSHAN CO LTD

A method and device for controlling the liquid level of the slurry pump pool during the grinding and grading process

The invention discloses a method and a device for controlling a liquid level in an ore pulp pump sump during ore grinding and classification. The method comprises the steps of acquiring a first actual liquid level of the pump sump in the beginning of a latest adjustment cycle, and a second actual liquid level of the pump sump at the end of the latest adjustment cycle, calculating a variation value of an ore pulp volume of the pump sump in the latest adjustment cycle according to ore pulp volumes formed by the first actual liquid level and the second actual liquid level in the pump sump respectively, calculating an adjustment value of an output flow based on the variation value of the ore pulp volume, and adjusting the current output flow of the pump sump with the adjustment value of the output flow. With the adoption of the technical scheme, the ore pulp flow output by the pump sump can be adjusted to the flow required to balance ore pulp input and output of the pump sump more precisely according to the adjustment value calculated by the variation value of the ore pulp volume, so that the stable liquid level in the pump sump can be kept more precisely, and an ore grinding and classification effect is more stabilized indirectly.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com