Wet chain type etching groove liquid inlet structure

A technology for etching grooves and feeding liquid, which is applied in the direction of sustainable manufacturing/processing, climate sustainability, semiconductor devices, etc. It can solve problems such as slime and silicon wafer degradation, achieve uniform liquid feeding, stable liquid level, and increase process The effect of debugging stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

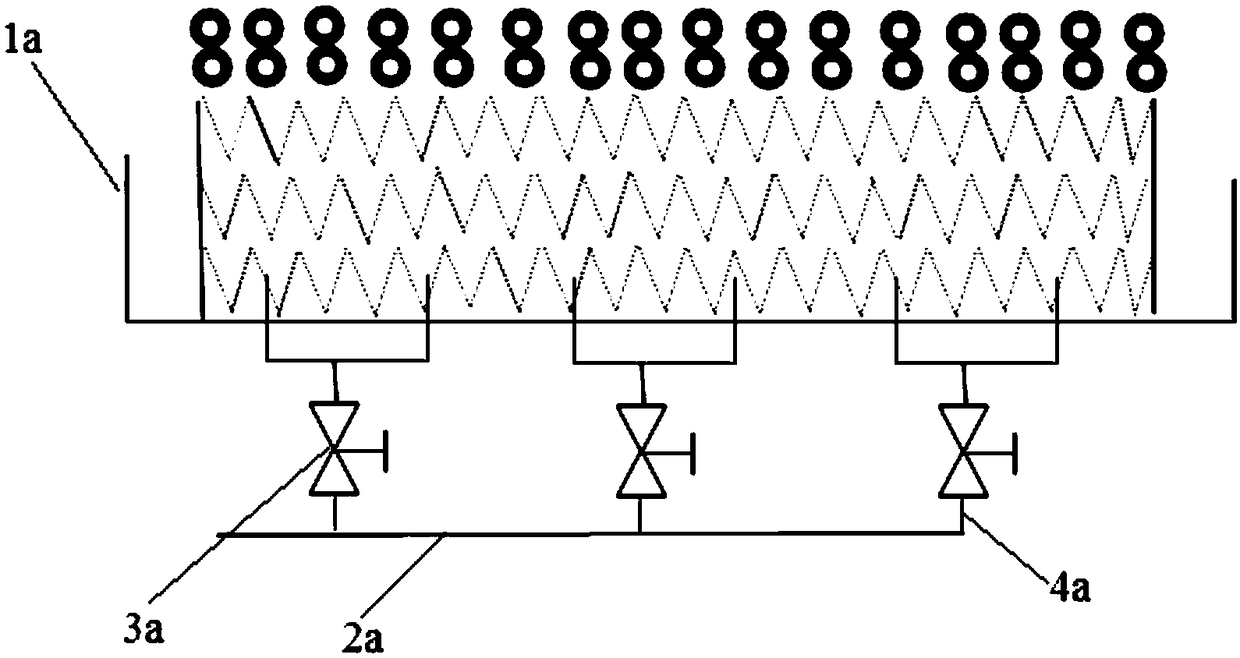

[0027] like figure 2 , image 3 As shown, the liquid inlet structure of the wet chain etching tank according to the present invention includes a liquid inlet box 2 arranged at the bottom of the wet etching tank body 1, and the liquid inlet box 2 is arranged on a side away from the feeding direction of the silicon wafer; Pic 4-1 , Figure 4-2 , Figure 4-3 As shown, a liquid discharge hole 3 is arranged on the side of the liquid inlet box 2 facing the feeding direction of silicon wafers, and an inner lining plate 4 is arranged inside the liquid inlet box 2, and the bottom of the inner lining plate 4 is connected with the liquid inlet The lower part of the box 2 is sealed and connected, and there is a liquid outlet gap 5 between the top of the inner lining plate 4 and the upper part of the liquid inlet box 2; the bottom of the liquid inlet box 2 is provided with a liquid inlet 6, and the liquid inlet box 2 passes through the liquid inlet 6 is connected with the liquid inlet...

Embodiment 2

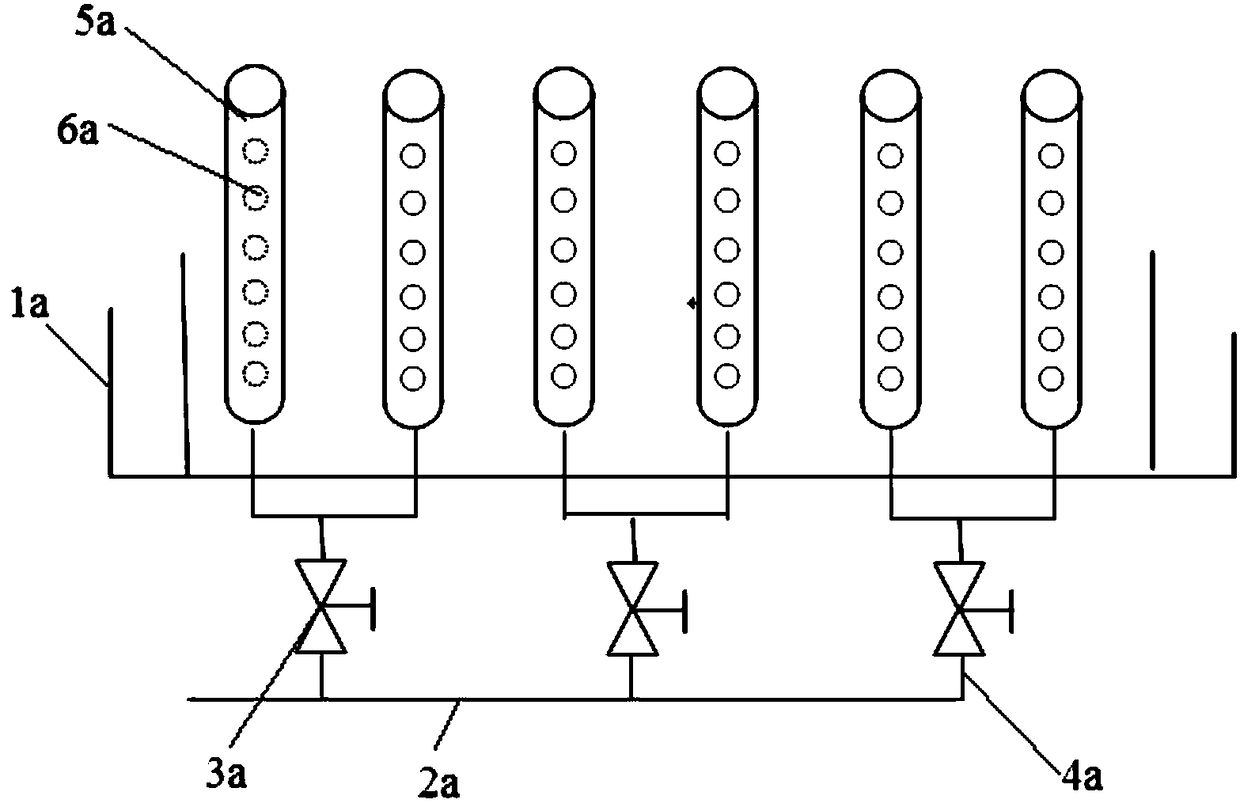

[0032] The liquid inlet structure of the wet chain etching tank of the present invention includes a liquid inlet box 2 arranged at the bottom of the wet etching tank body 1, and the liquid inlet box 2 is arranged on a side away from the feeding direction of the silicon wafer; The side of the liquid box 2 facing the feeding direction of the silicon wafer is provided with two or more rows of liquid discharge holes 3, and an inner lining plate 4 is arranged inside the liquid inlet box 2, and the bottom of the inner lining plate 4 is in contact with the liquid inlet. The lower part of the box 2 is sealed and connected, and there is a liquid outlet gap 5 between the top of the inner lining plate 4 and the upper part of the liquid inlet box 2; the bottom of the liquid inlet box 2 is provided with a liquid inlet 6, and the liquid inlet box 2 passes through the liquid inlet 6 is connected with the liquid inlet pipeline 7 to realize liquid inlet; a valve body 8 is arranged on the liquid...

Embodiment 3

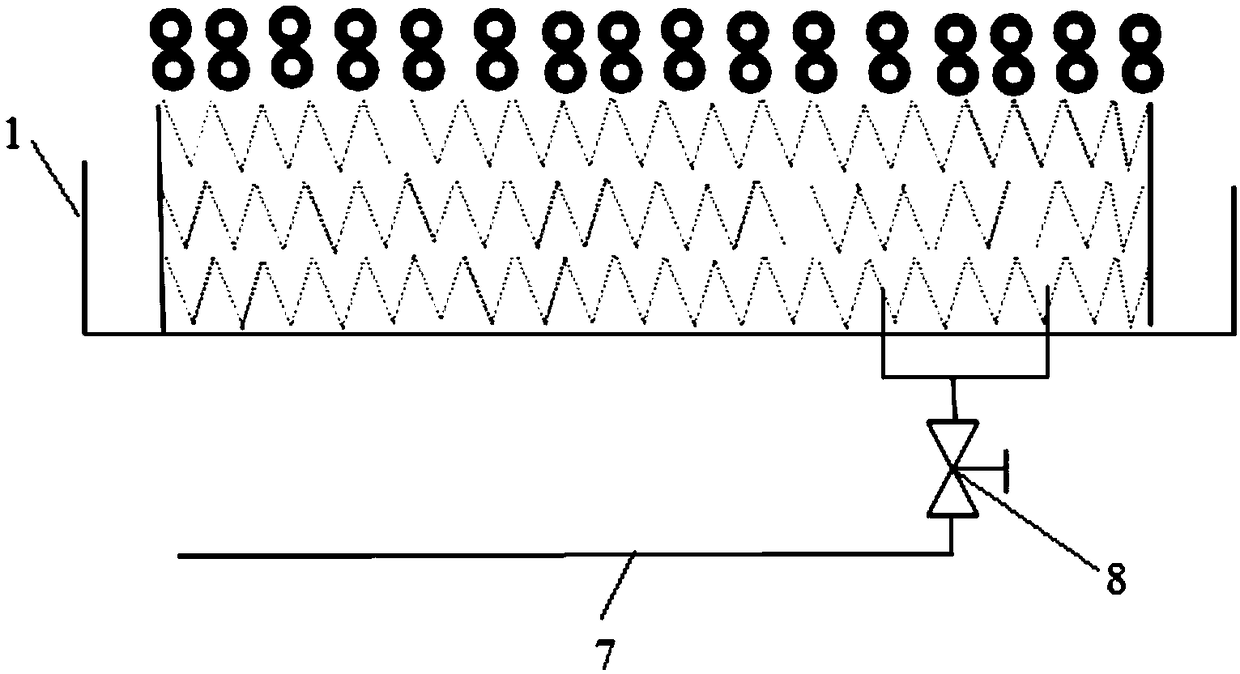

[0037] The liquid inlet structure of the wet chain etching tank of the present invention includes a liquid inlet box 2 arranged at the bottom of the wet etching tank body 1, and the liquid inlet box 2 is arranged on a side away from the feeding direction of the silicon wafer; The side of the liquid box 2 facing the feeding direction of the silicon wafer is provided with two or more rows of liquid discharge holes 3, and an inner lining plate 4 is arranged inside the liquid inlet box 2, and the bottom of the inner lining plate 4 is in contact with the liquid inlet. The lower part of the box 2 is sealed and connected, and there is a liquid outlet gap 5 between the top of the inner lining plate 4 and the upper part of the liquid inlet box 2; the bottom of the liquid inlet box 2 is provided with a liquid inlet 6, and the liquid inlet box 2 passes through the liquid inlet 6 is connected with the liquid inlet pipeline 7 to realize liquid inlet; a valve body 8 is arranged on the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com