Magnesium alloy continuous casting liquid level position detection device and detection method thereof

A liquid level position and detection device technology, which is applied in the configuration of casting equipment, metal processing equipment, indicating equipment/measuring equipment, etc., can solve the problems such as the inability to confirm the position of the liquid level of the magnesium alloy continuous casting liquid level, and achieve a stable liquid level , Improving the quality of billet and ensuring the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

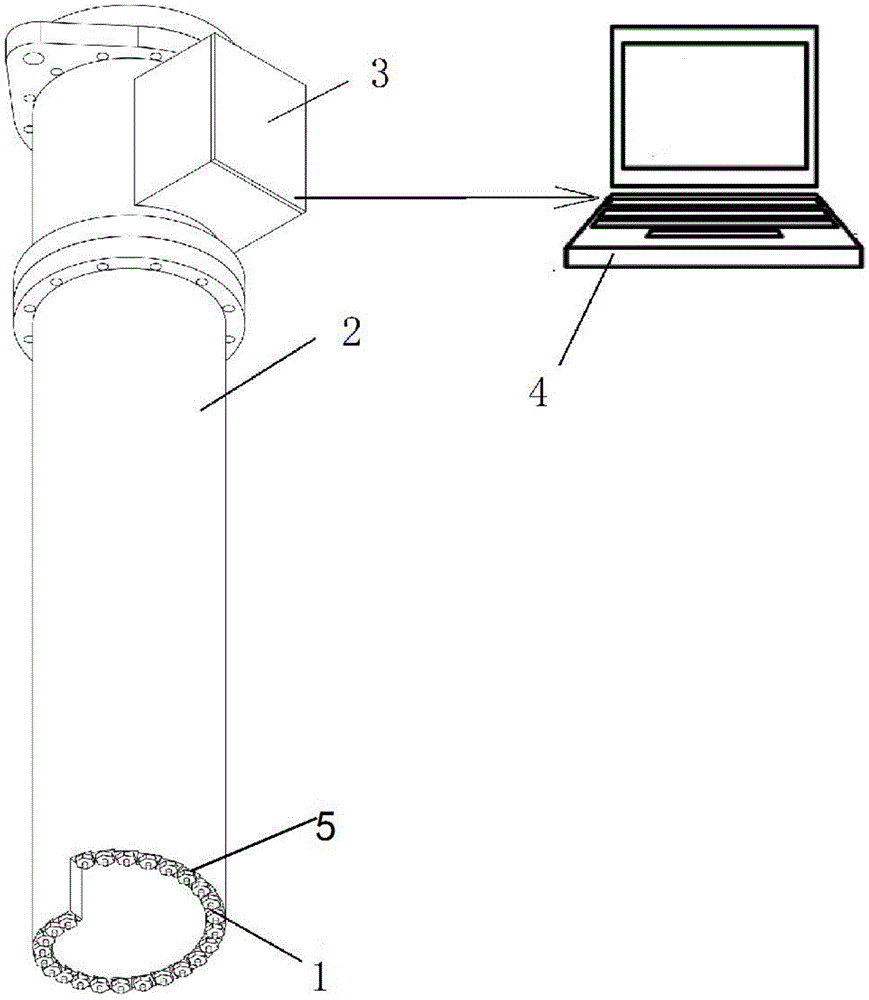

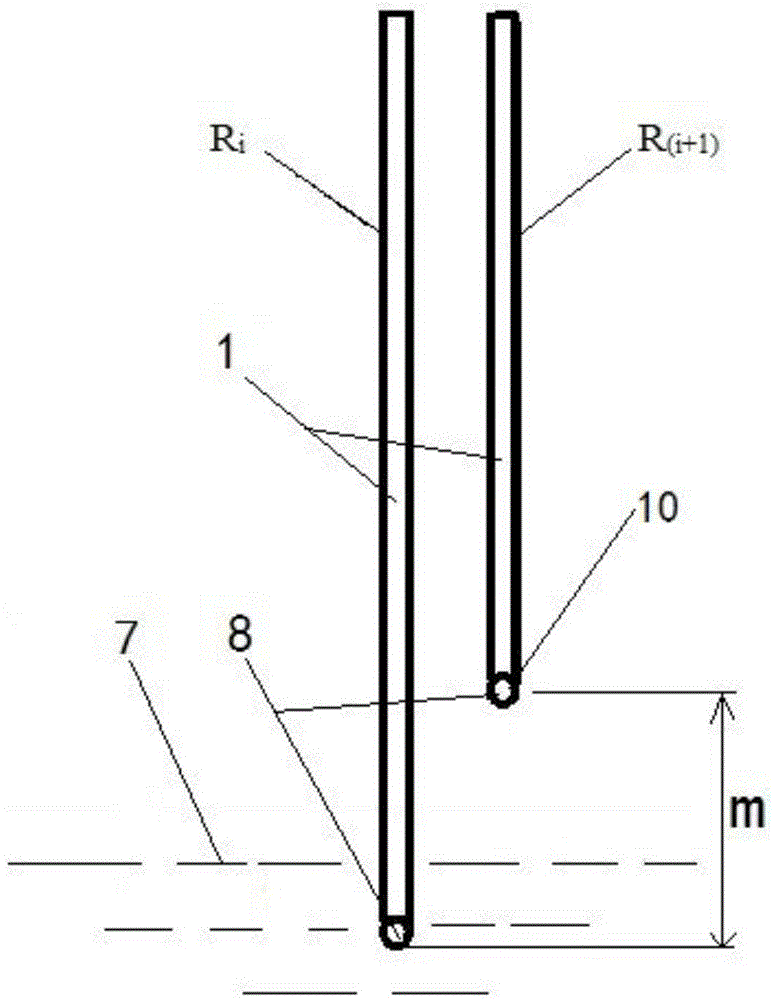

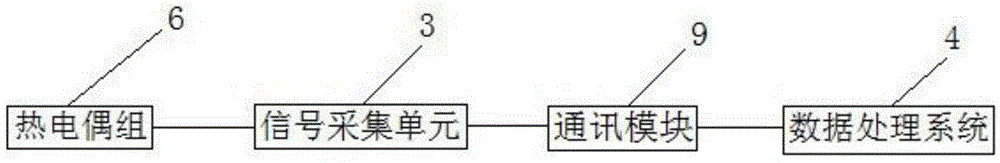

[0030] Such as figure 1 and image 3 As shown, the present invention provides a magnesium alloy continuous casting liquid level position detection device, which is characterized in that it includes a cylindrical detection housing 2, and there are multiple holes in the axial direction between the inner wall and the outer wall of the detection housing 2. through holes 5, and the through holes 5 are evenly arranged at equal intervals along the circumference of the detection housing 2, and a thermocouple 1 is installed in each through hole 5 to form a thermocouple group 6, and the measuring end group 8 of the thermocouple group 6 extends The bottom end of the outlet through hole 5 can be in contact with the detected liquid surface 7, and the measuring terminal group 8 forms a spiral shape, and the terminal group of the thermocouple group 6 is connected with the signal acquisition unit 3 installed on the top of the detection housing 2, and the signal acquisition The unit 3 is conn...

Embodiment 2

[0034] On the basis of Embodiment 1, specifically, the connection relationship between the measurement end 10 and the detection housing 2 is that the measurement end 10 and the detection housing 2 are fixedly connected by nuts.

Embodiment 3

[0036]On the basis of Embodiment 1, it should be noted that the communication module 9 is EtherCAT, LIGHTBUS, PROFIBUS, INTERBUS, MODBUS, CANopen, DeviceNet, ControlNet, CC-Link, IO-Link, PROFINET, RS232, RS485, WLAN , NFC, WIFI-Dircet, bump, 2G, 4G, bluetooth, wifi, zige-bee, GPRS, 3G, USB module any one. The signal acquisition unit 3 adopts the FM3332-B310 high-density thermocouple input module of German BECKHOFF company. The data processing system 4 adopts Siemens S7 series PLC control device or Siemens, Advantech, HP and other brand computers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com