Liquid sampling device and density measuring method

A technology for liquid sampling and density measurement, which is applied in sampling devices, specific gravity measurement, measuring devices, etc., and can solve cumbersome, toxic, corrosive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

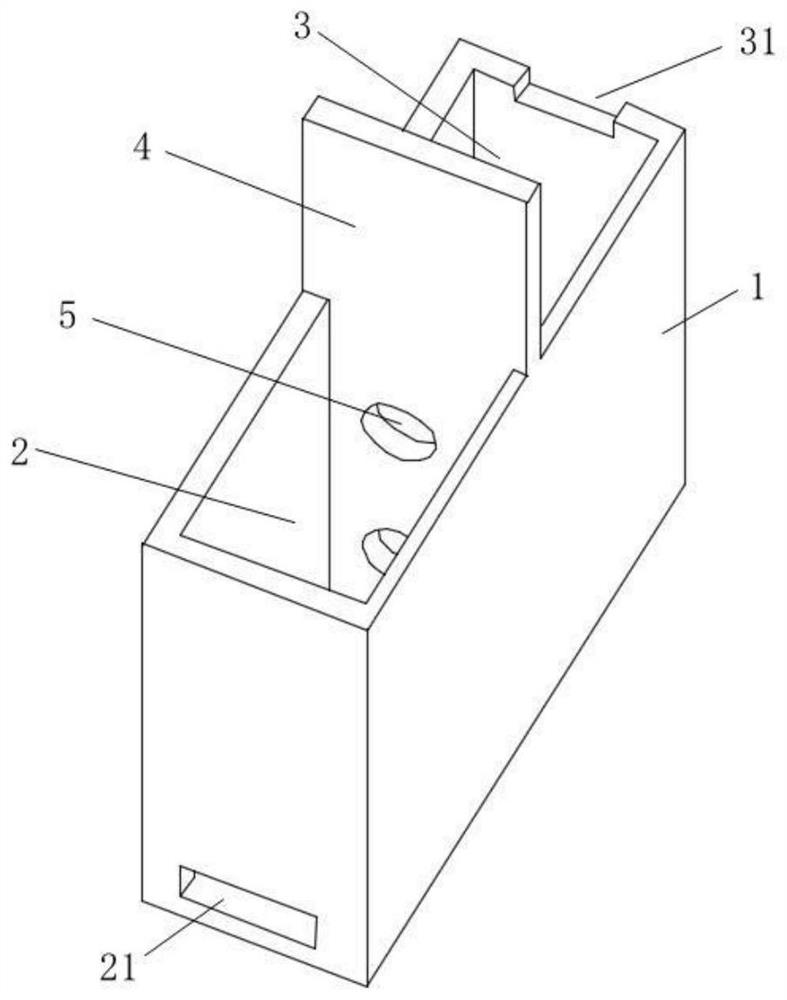

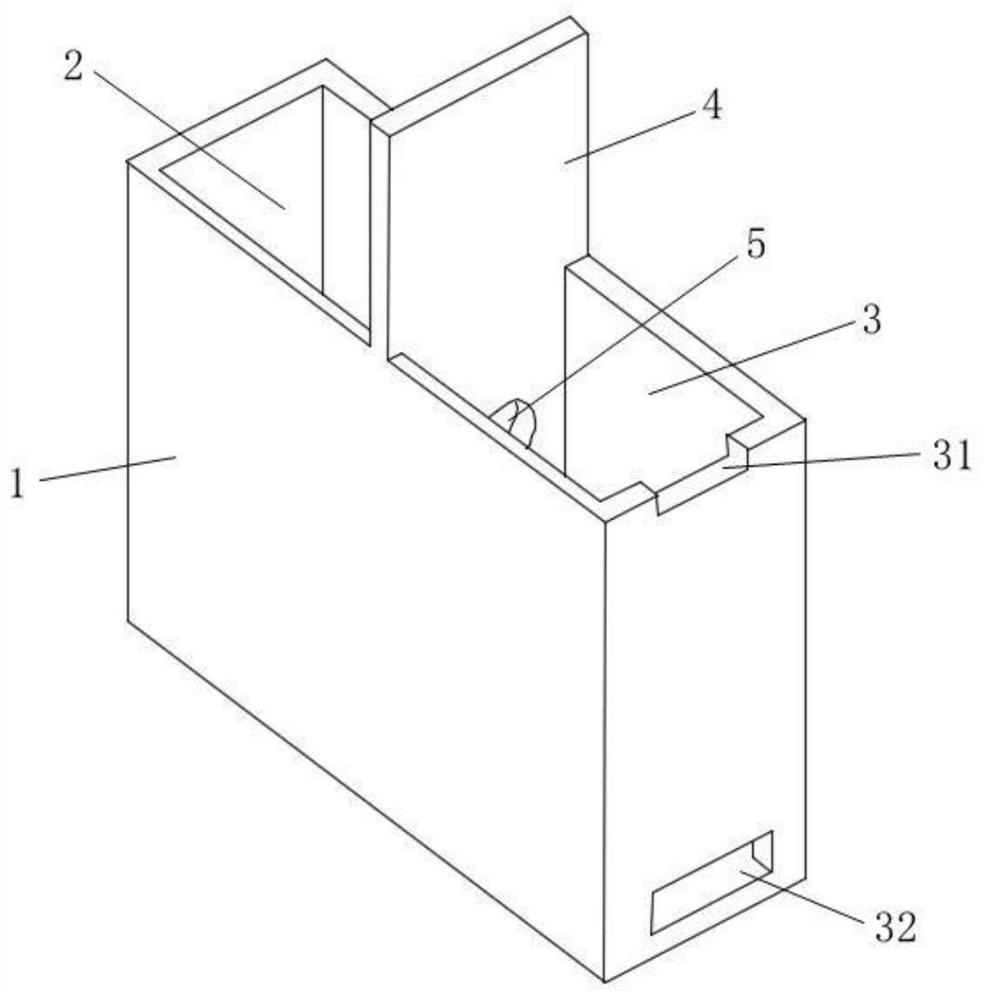

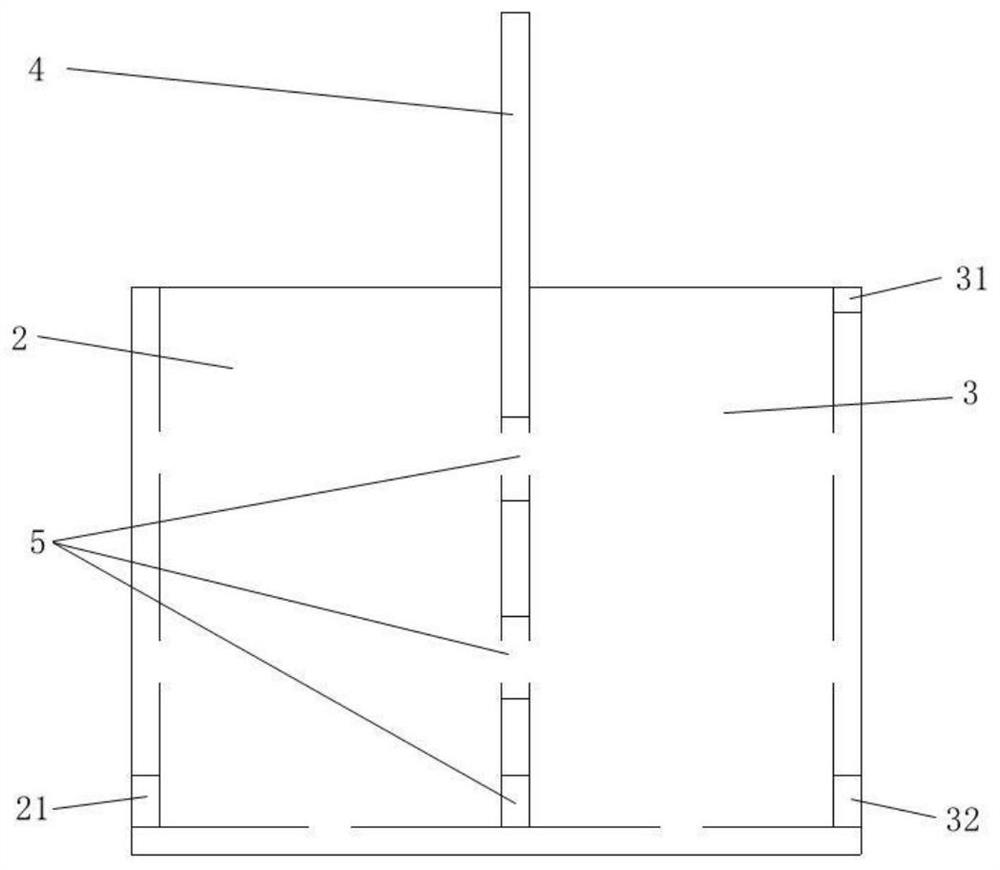

[0035] Such as Figure 4As shown, the liquid-taking tank 1 is made of transparent material, and the baffle 4 is detachably connected with the liquid-taking tank 1. When measuring the density, the baffle 4 is inserted into the liquid-taking tank 1 so that the liquid-taking tank 1 is divided into full flow Chamber 2 and observation chamber 3 are two parts. When cleaning the liquid-taking tank 1 after the measurement is completed, the baffle 4 is removed, and the baffle 4 and the liquid-taking tank 1 are cleaned separately.

[0036] In this embodiment, the baffle 4 is provided with a communication hole 5, the communication hole 5 is located at the bottom of the baffle 4, the communication hole 5 is a square hole 51, and the communication hole 5 is provided at the bottom of the baffle 4. 2, the sample liquid enters the observation chamber 3 through the communication hole 5 at the bottom of the baffle 4 at the same time.

[0037] Alternatively, the baffle plate 4 is provided with ...

Embodiment 2

[0040] Such as Figure 5 As shown, the liquid sampling tank 1 is made of transparent material, and the liquid sampling tank 1 is provided with a sampling cover 6, which is detachably connected with the liquid sampling tank 1, and the sampling cover 6 is provided with a density measurement through hole 62 and at least one sampling through hole 61, the density measurement through hole 62 is arranged directly above the observation chamber 3, the sampling through hole 61 is arranged directly above the full flow chamber 2, the density meter is inserted into the observation chamber 3 through the observation hole, and the sampling pipeline Inserted into the sampling through hole 61 and the sampling pipeline leads into the full flow cavity 2 .

[0041] Preferably, the sampling cover plate 6 is provided with two sampling through holes 61, which are respectively a first through hole and a second through hole. Connect the sampling pipeline of the liquid to be tested waiting for the subs...

Embodiment 3

[0044] On the basis of embodiment 1 or embodiment 2, such as Figure 6 As shown, the liquid taking tank 1 is made of transparent material, and the outer wall of the observation chamber 3 is provided with an overflow pipe, which is connected to the overflow port 31, and the outlet of the overflow pipe faces downward, and the overflow pipe can also be connected to the sample The recovery device is connected, and an overflow pipe is provided on the outer wall of the observation chamber 3 to prevent the sample liquid from polluting the outer wall of the liquid-taking tank 1 when it overflows.

[0045] The method for measuring density using a liquid sampling device is described in conjunction with the above-mentioned embodiments, and the steps are as follows,

[0046] Place the liquid sampling tank 1 in the sampling horn, open the valve of the emptying pipe under the sampling horn, and place the full flow cavity 2 of the liquid sampling tank 1 under the sampling point. The sampling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com