Automatic treatment agent coating equipment

A technology of treatment agent and automatic wiping, which is applied in the direction of coating and liquid coating device on the surface, etc. It can solve the problems of uneven application of treatment agent on coating rollers, large fluctuations, troublesome disassembly and installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

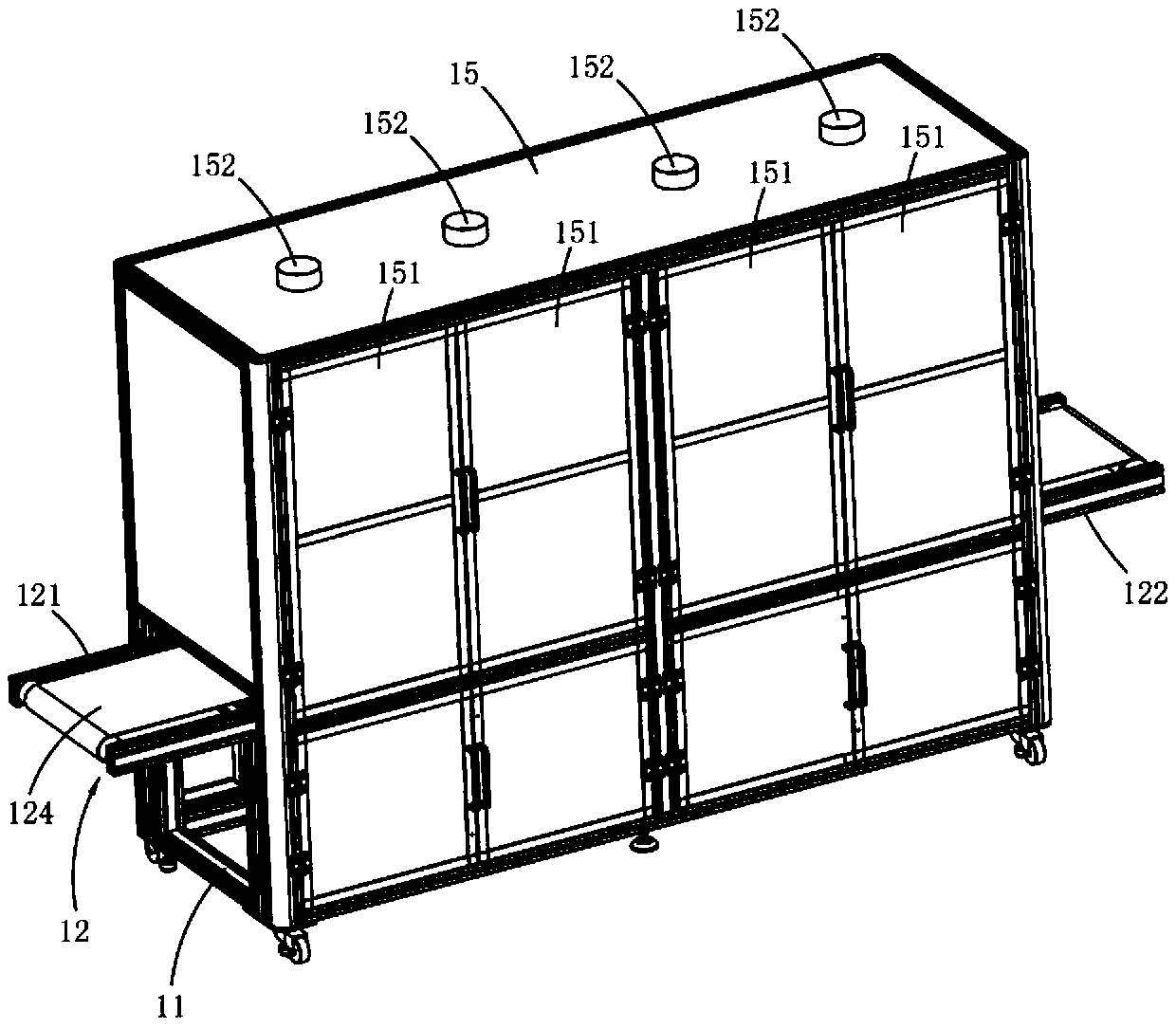

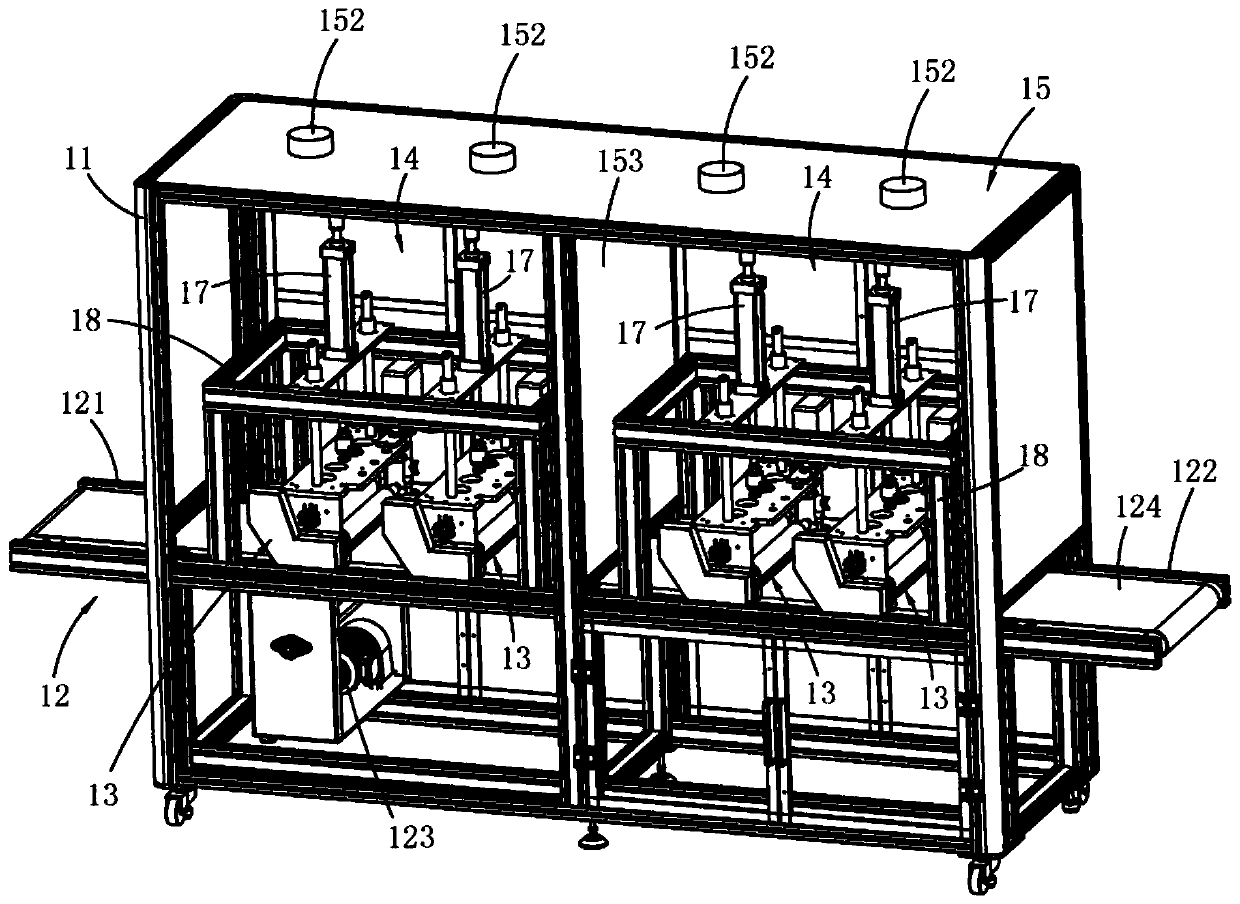

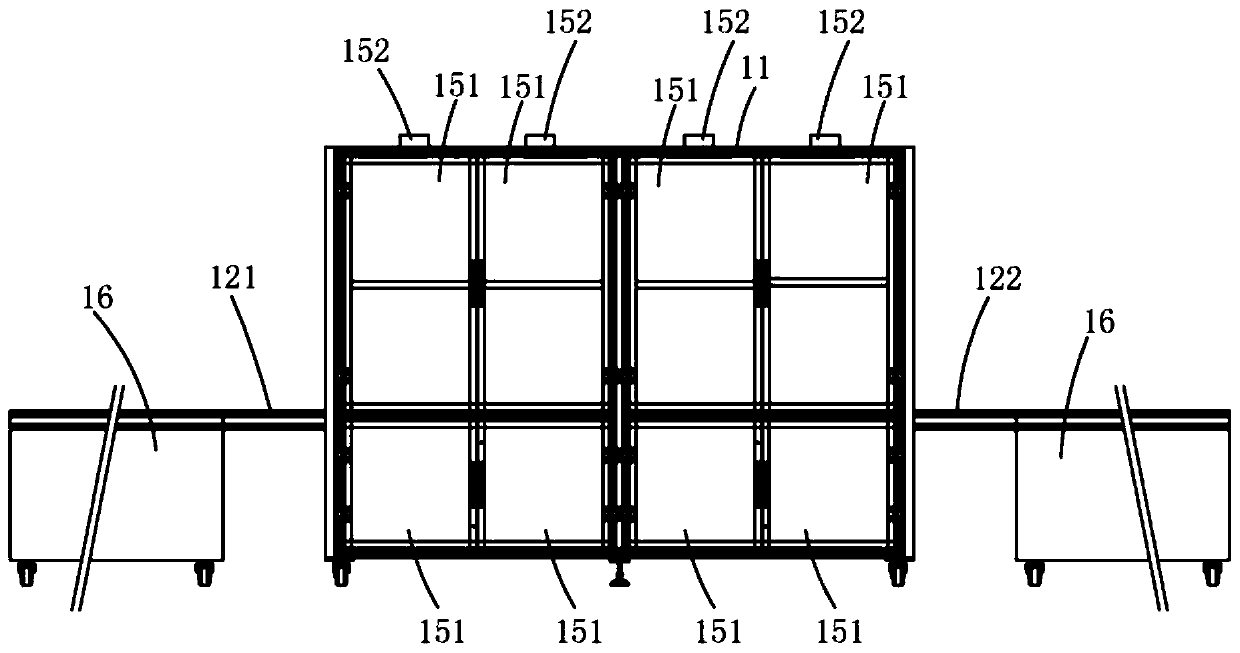

[0086] An automatic wiping agent device, Figures 1 to 9As shown, it includes a control device, a frame 11 and a shoe material conveying mechanism 12 installed on the frame 11. Along the conveying direction of the shoe material conveying mechanism 12, there are at least two sets of automatic wipers installed in the frame 11 and used alternately. For the treatment agent unit, each automatic rubbing treatment agent unit is provided with at least one group of smearing mechanisms 13 , and the smearing mechanisms 13 are located above the shoe material conveying mechanism 12 . Specifically, along the conveying direction of the shoe material conveying mechanism 12, there are two automatic wiping treatment agent units arranged adjacent to each other and used alternately, and each automatic wiping treatment agent unit is provided with a unit frame 18, two front and rear phase The smearing mechanism 13 and the two smearing lifting mechanisms 17 are arranged adjacently; each smearing lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com