Water-shedding indoor wall mounted cabinet

a wall mounted cabinet and water-shedding technology, which is applied in the direction of electrical equipment casings/cabinets/drawers, substation/switching arrangement casings, casings/cabinets/drawers details, etc., can solve the problems of denying access to the general workforce, electrical shorts and/or other equipment failures, and unable to meet the needs of the general workforce, so as to prevent water ingress and heat egress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

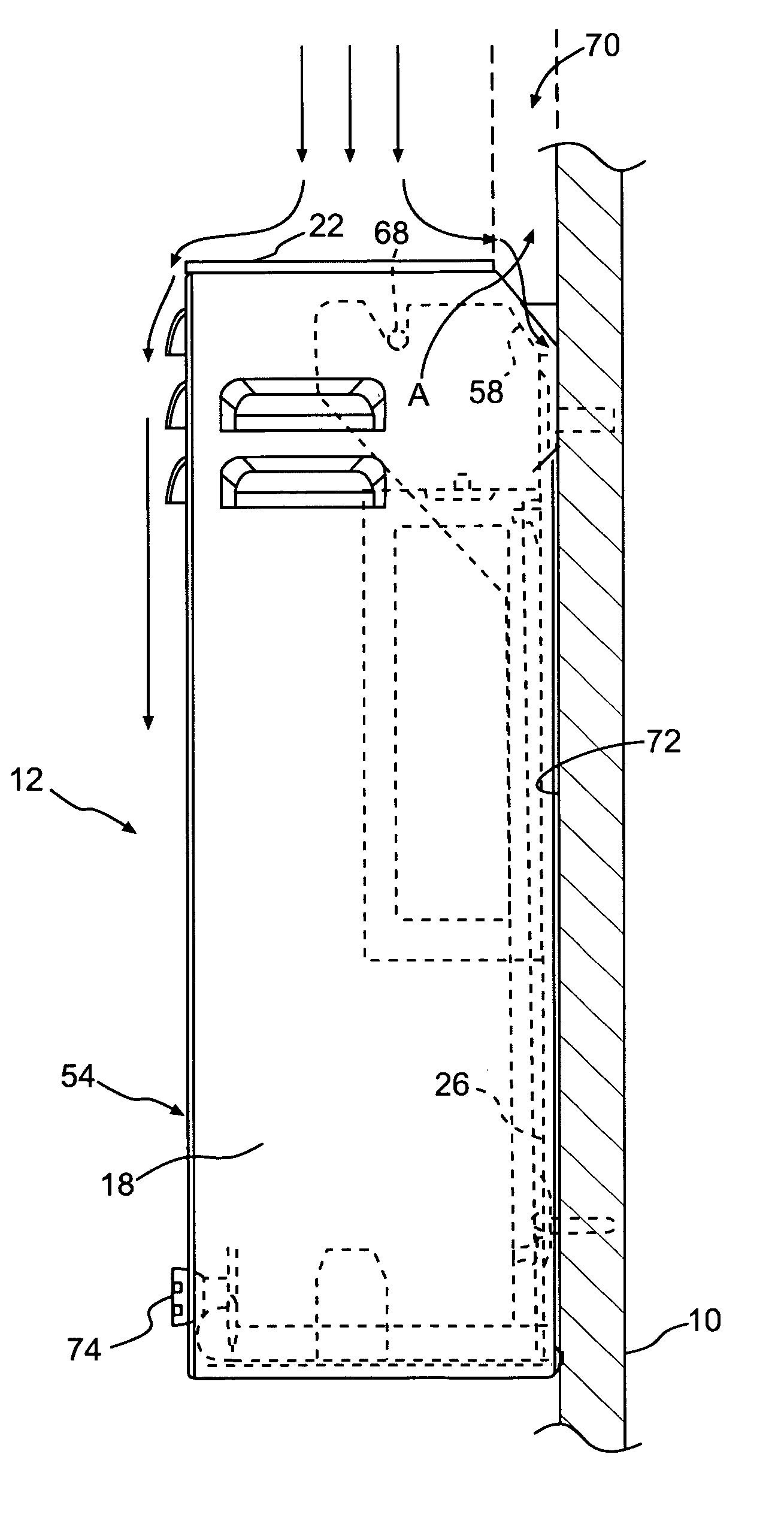

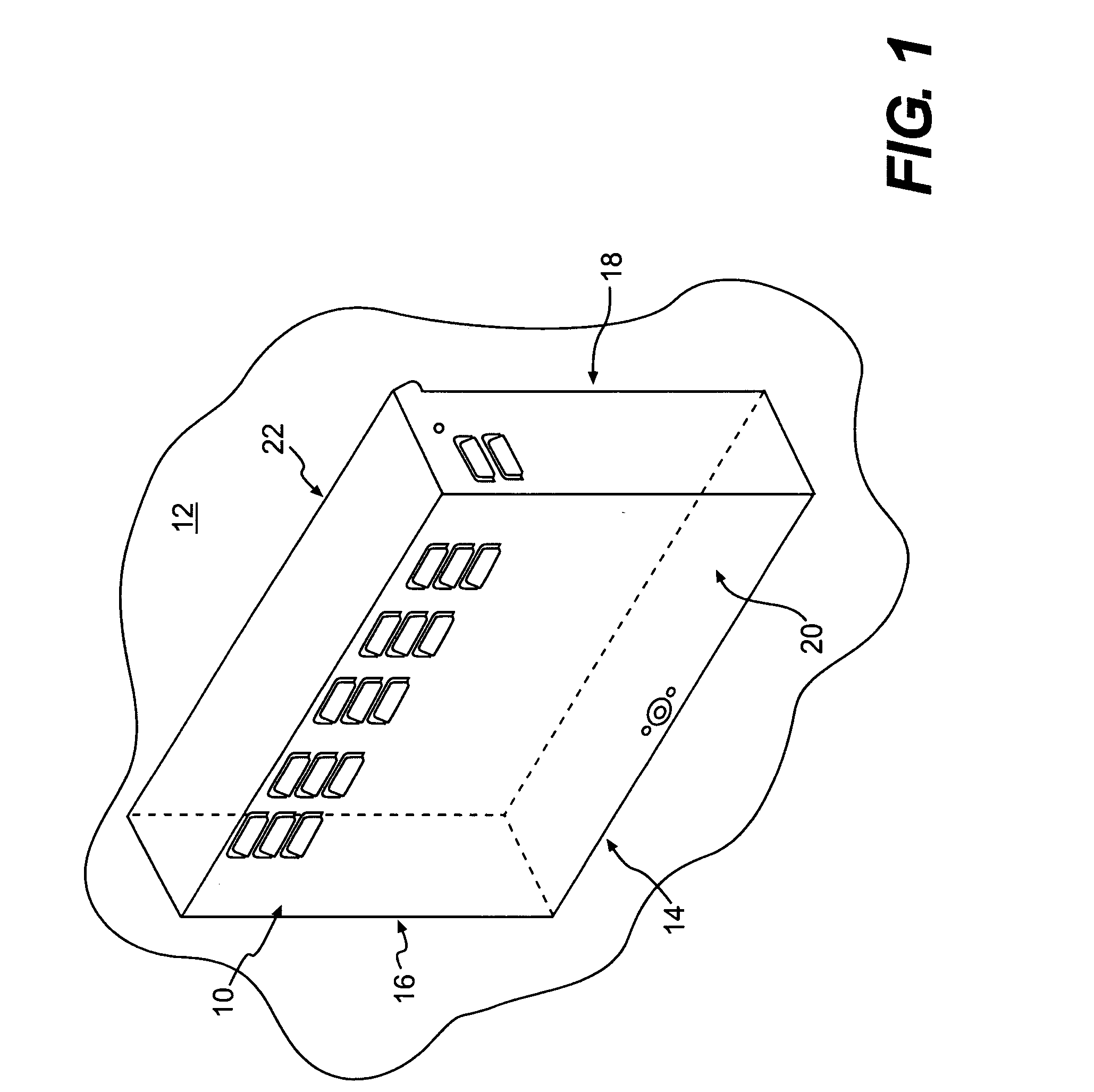

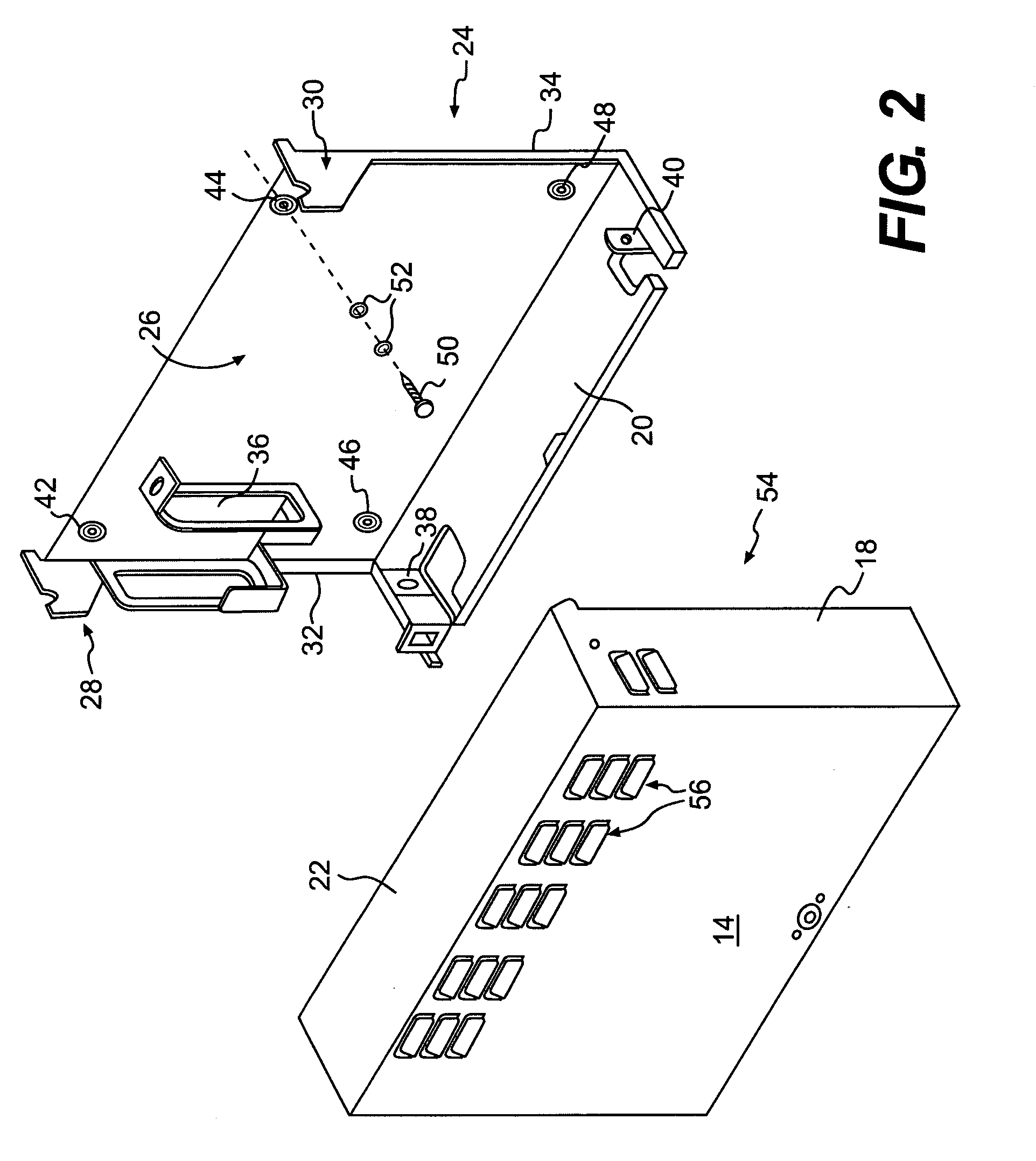

[0021] Referring to FIG. 1, a wall mounted cabinet 10 is mounted on a wall 12. The wall 12 is preferably an interior wall within a room that is may be designated as an equipment room to contain electrical, telecommunications, and / or computer equipment. While the cabinet 10 is preferably located in such a room, it is also possible that the cabinet is mounted on a wall of other interior spaces that are less confined and perhaps designated for multiple uses. It is also possible that the cabinet could be located on a wall that is semi-enclosed but covered. Thus, the term “interior” could encompass building structures that are not confined by four walls, a ceiling and a floor. The term “interior” denotes a space that is not directly exposed to the elements, although the preferred location of the cabinet 10 is in an interior space defined in the traditional sense.

[0022] Moreover, the cabinet 10 of the present invention is intended to be mounted on a vertical wall, rather than horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com