Patents

Literature

56results about How to "Increase fit clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

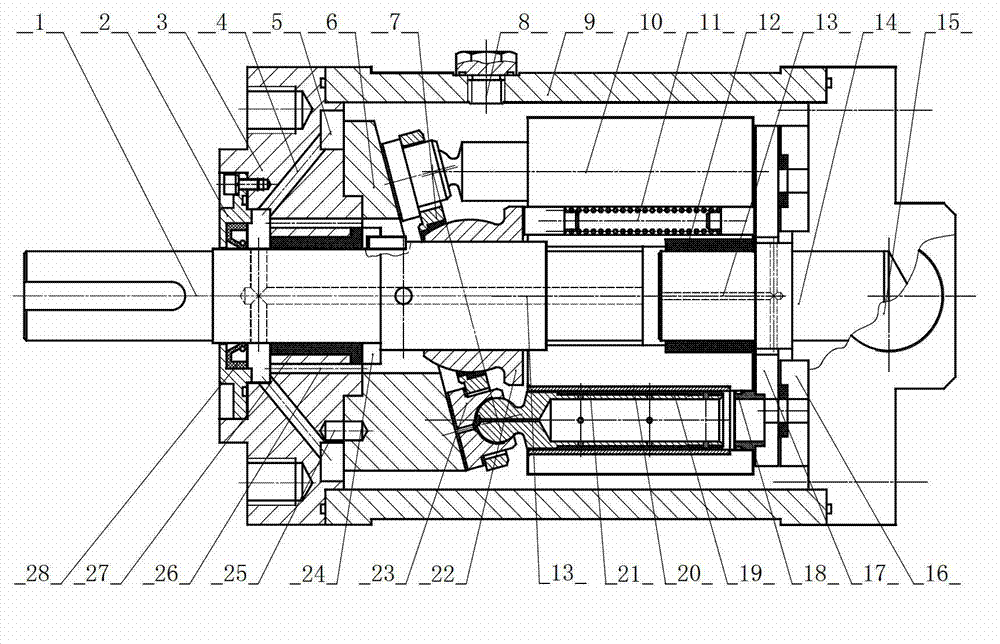

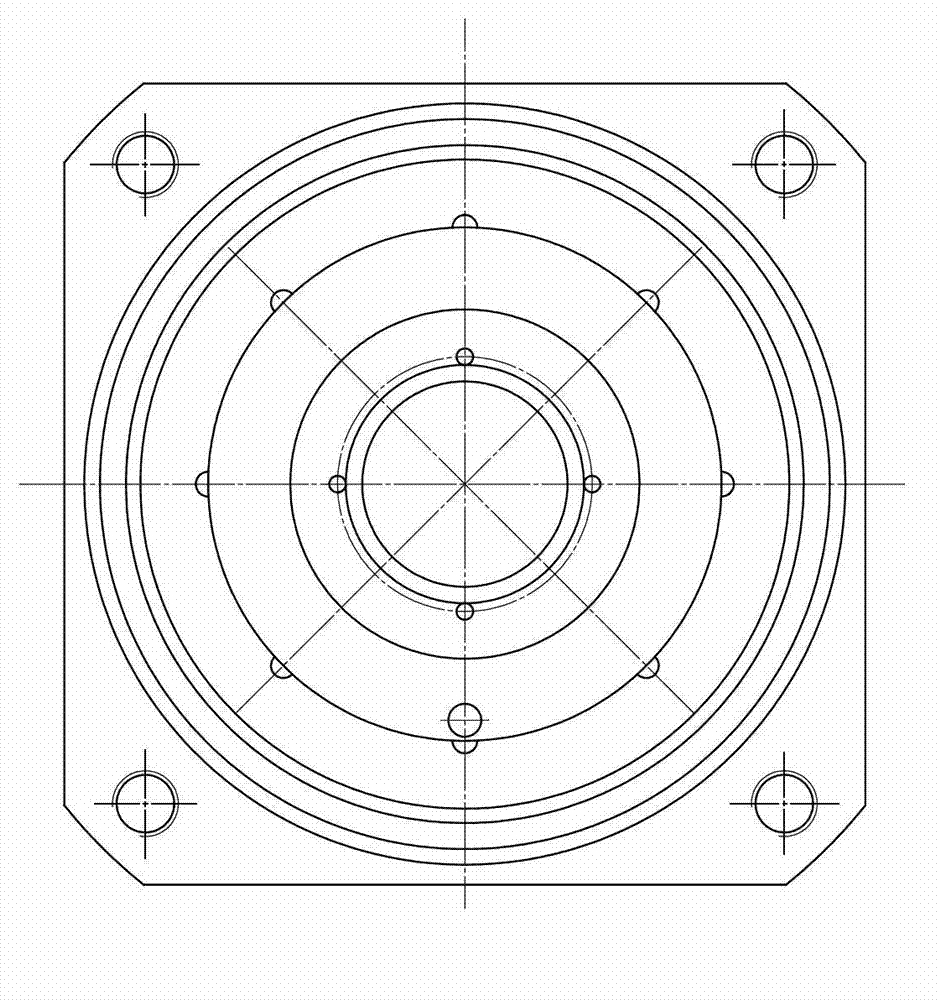

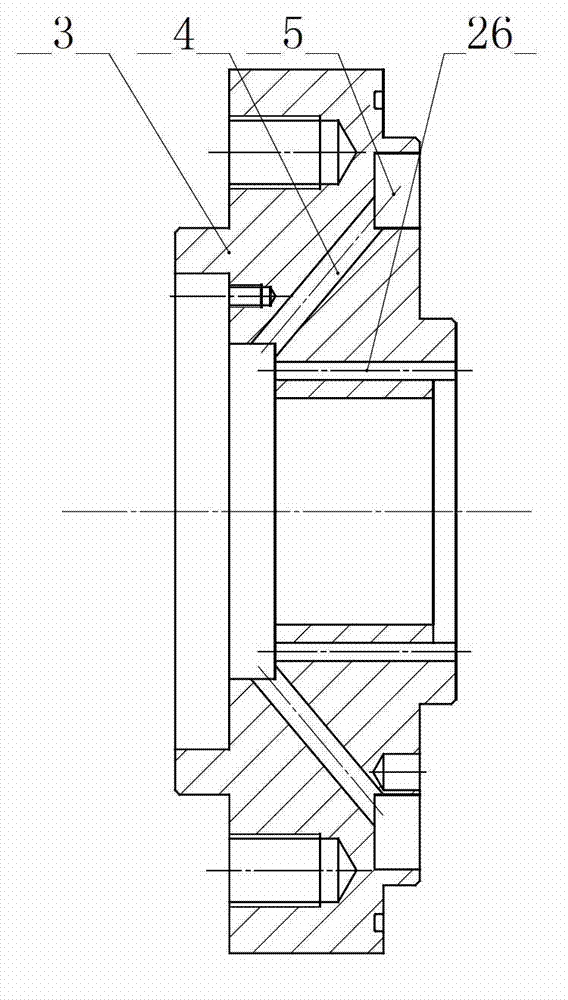

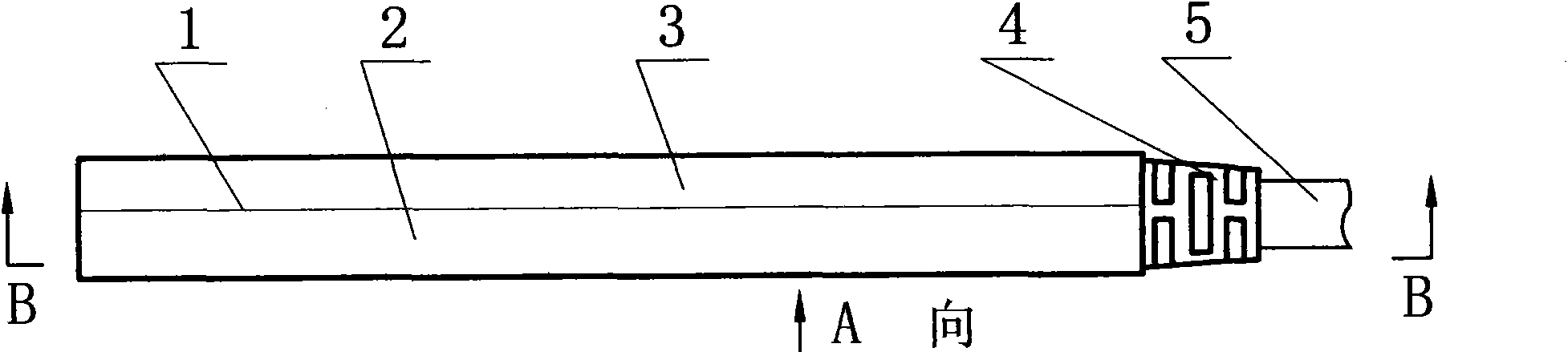

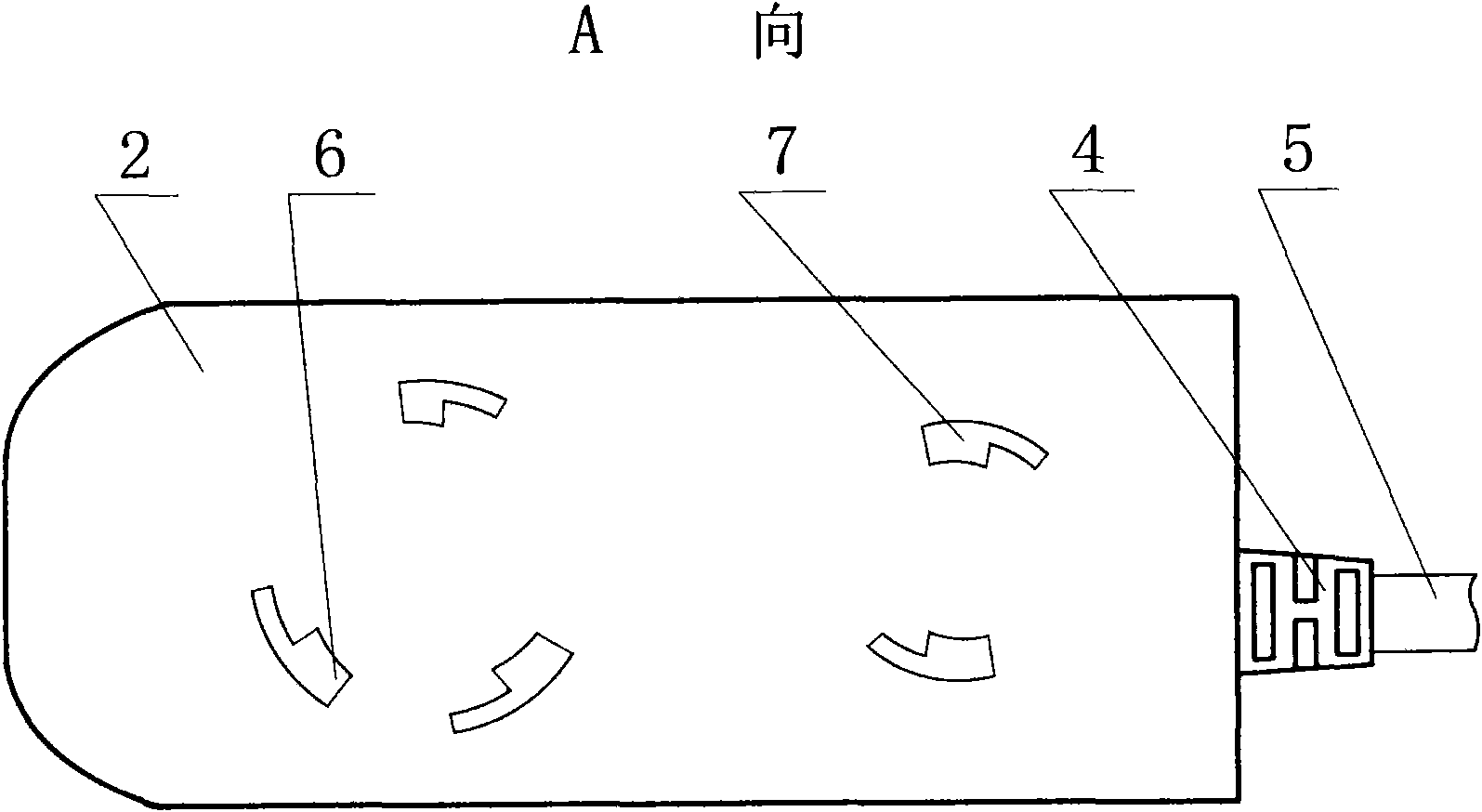

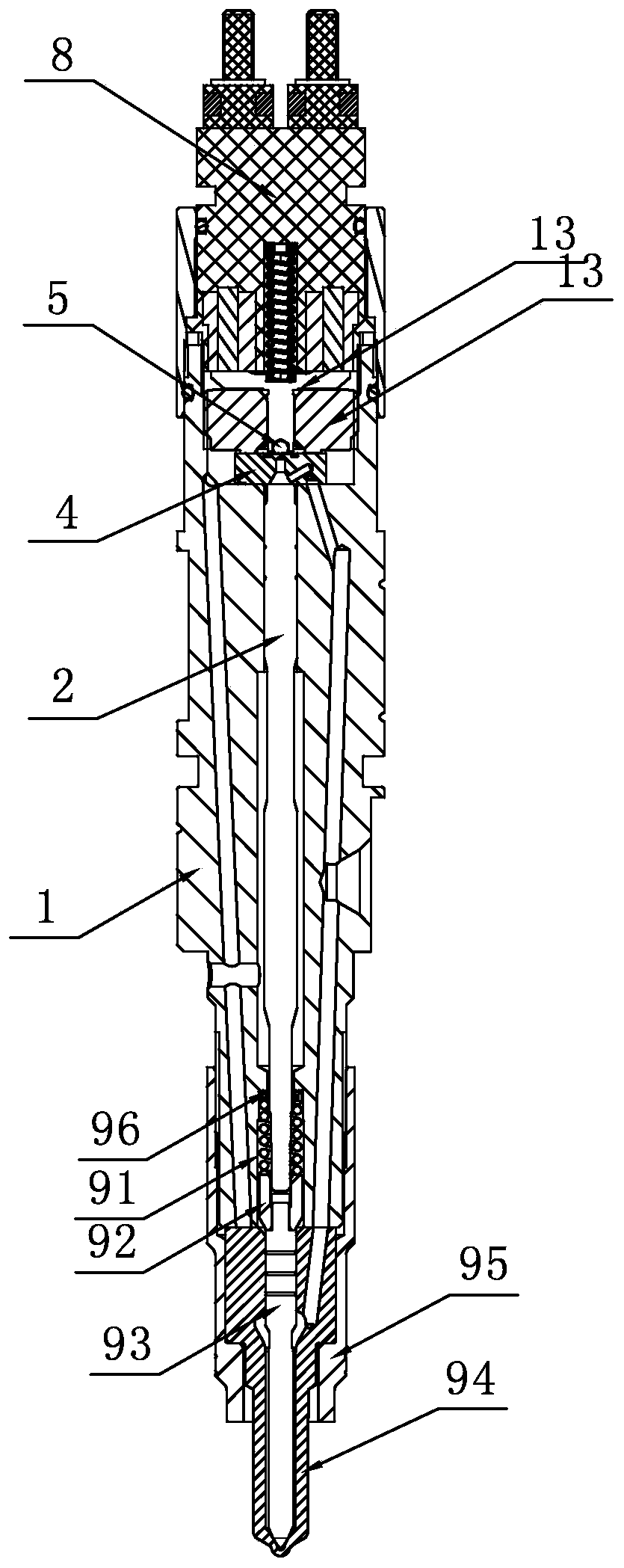

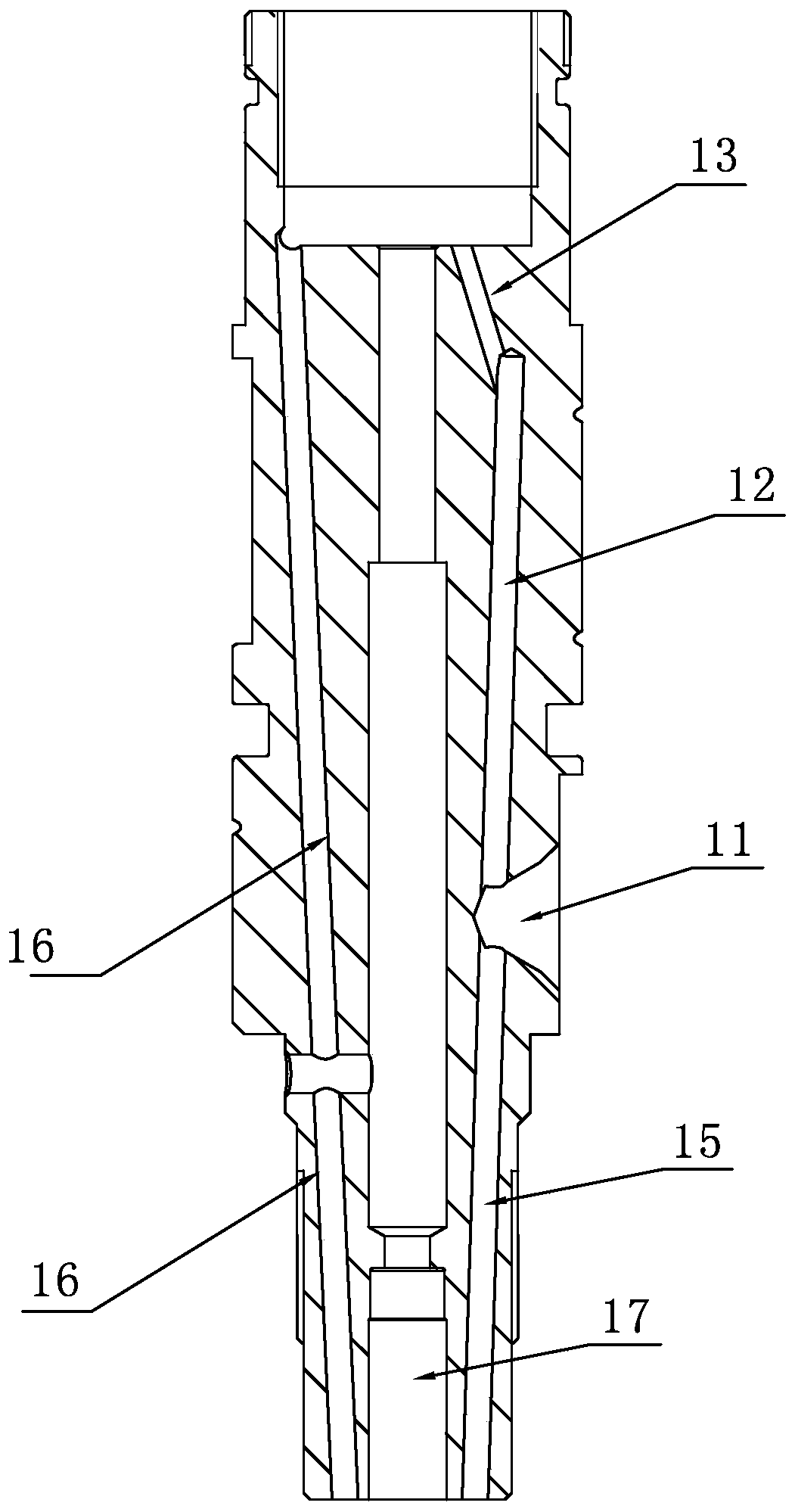

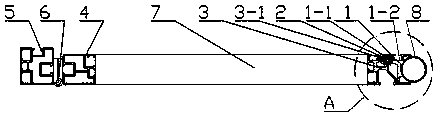

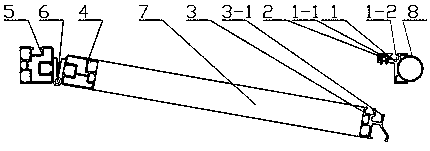

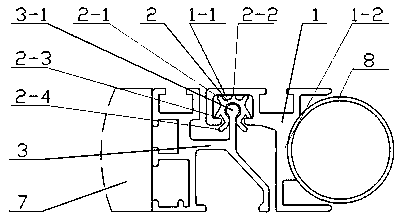

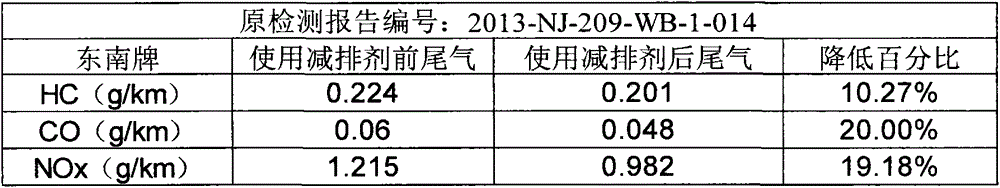

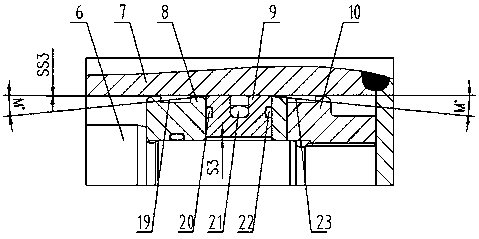

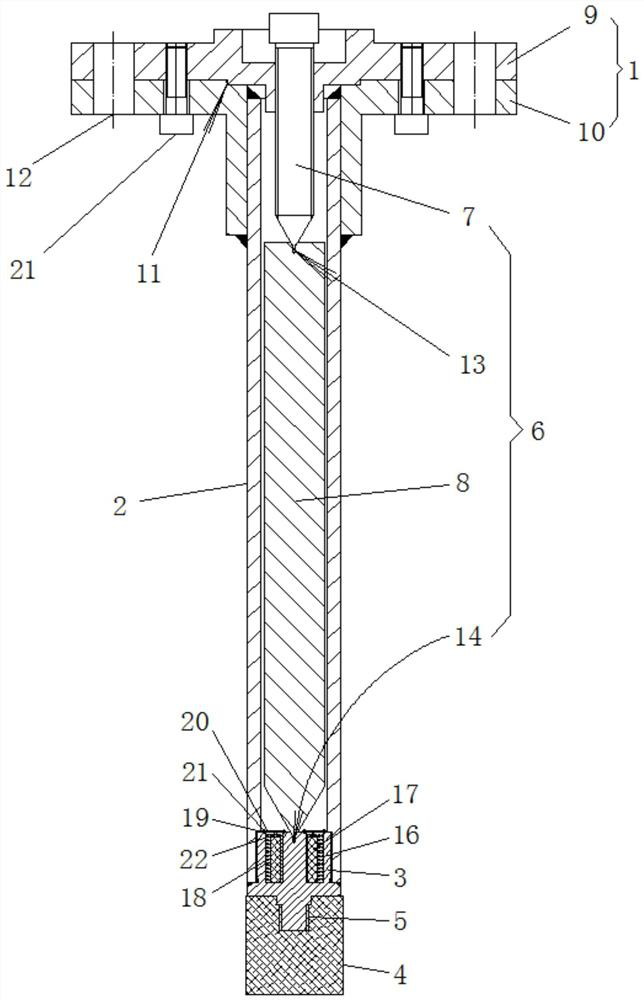

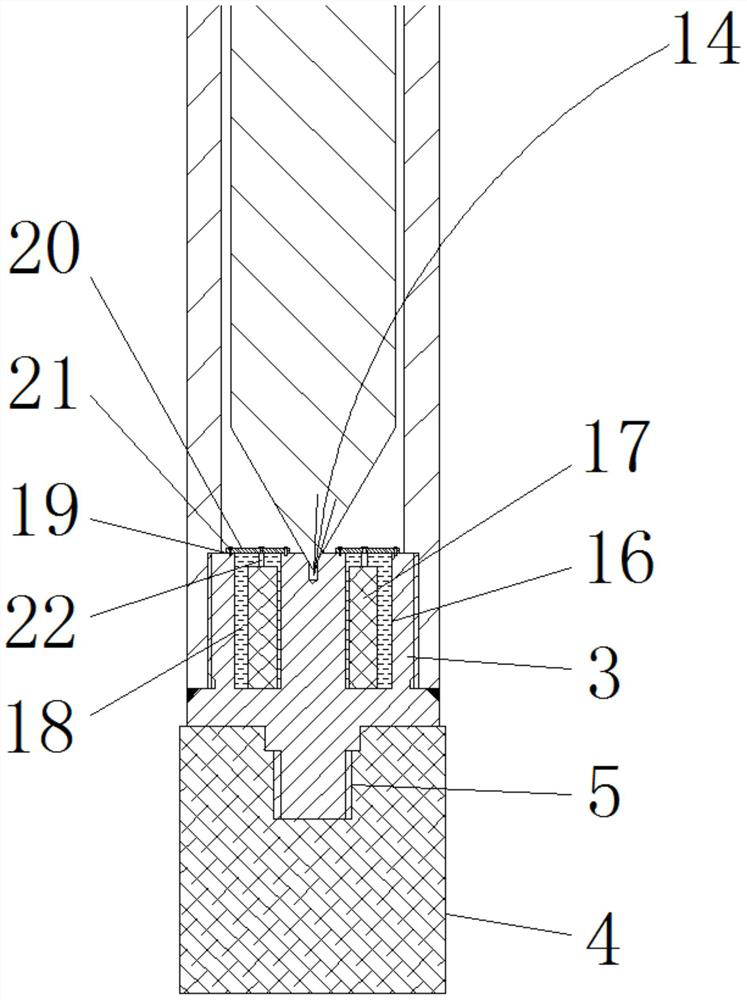

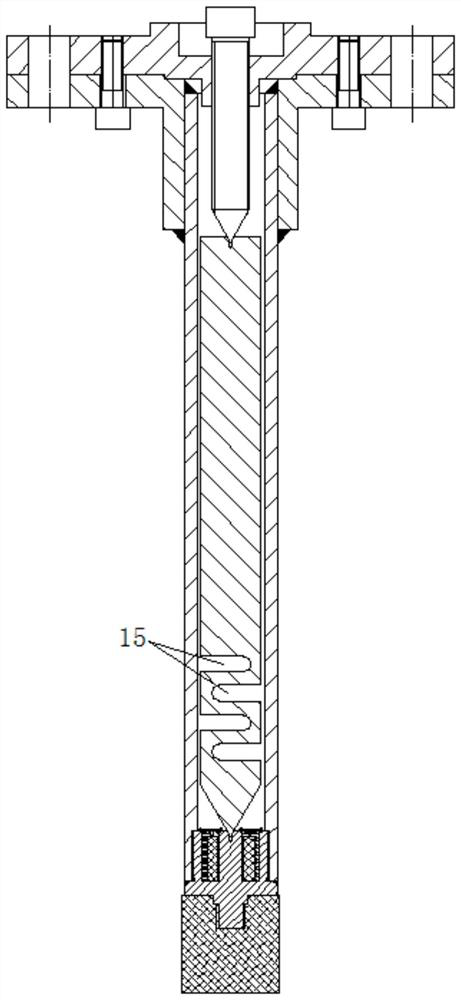

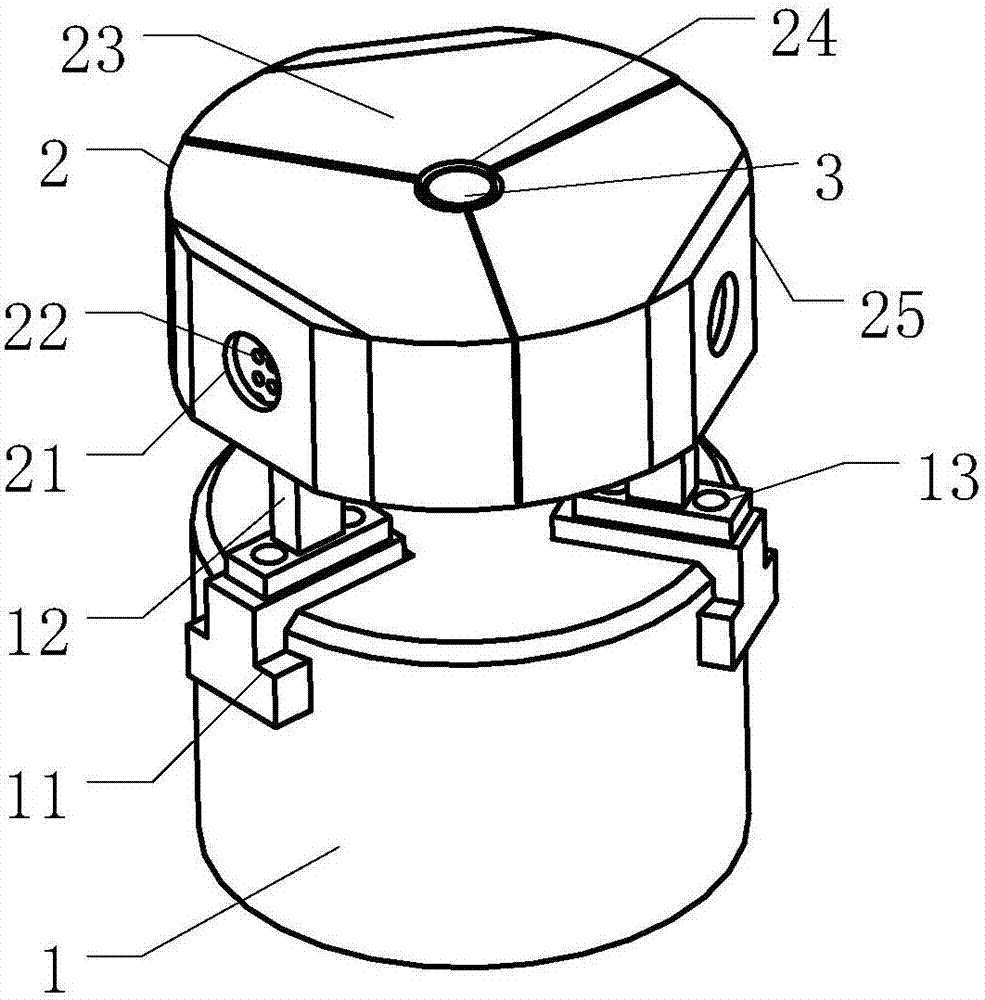

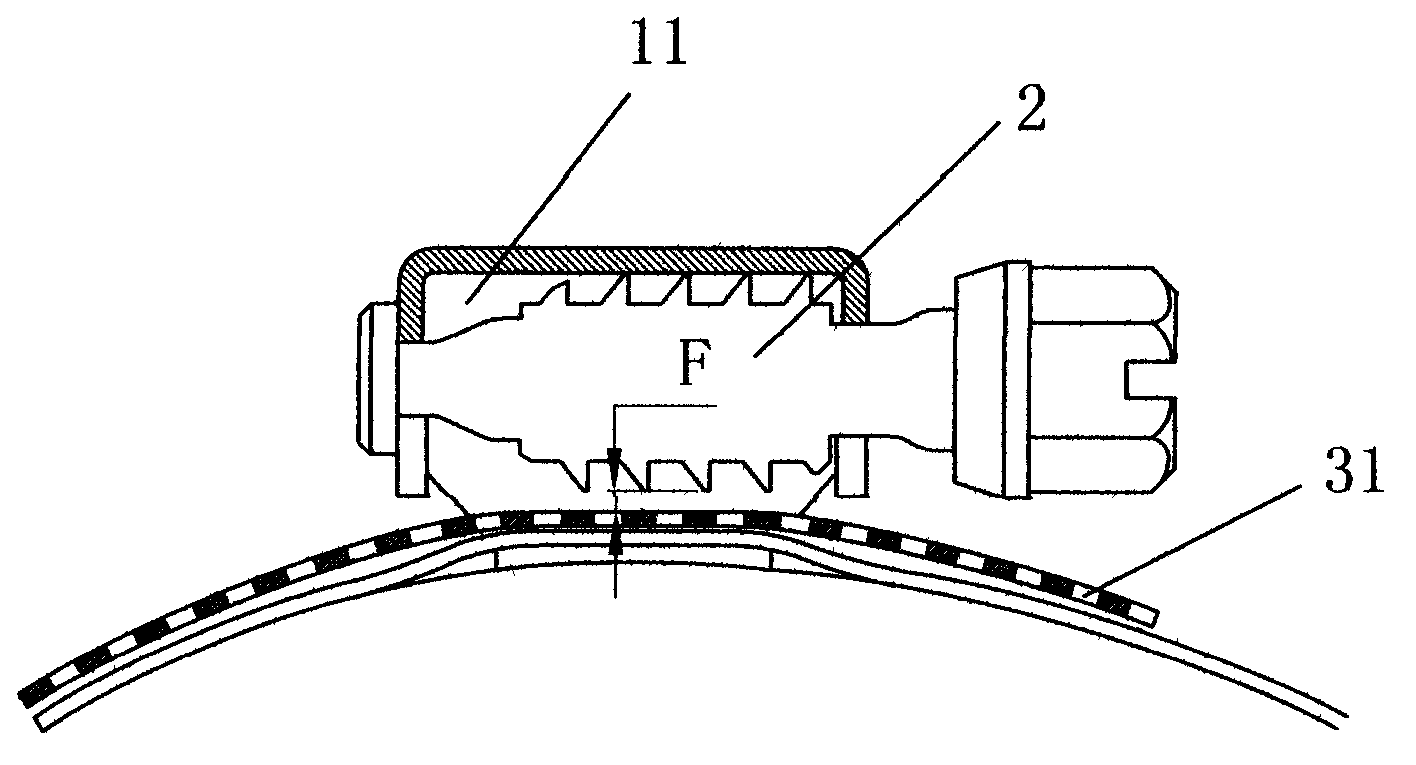

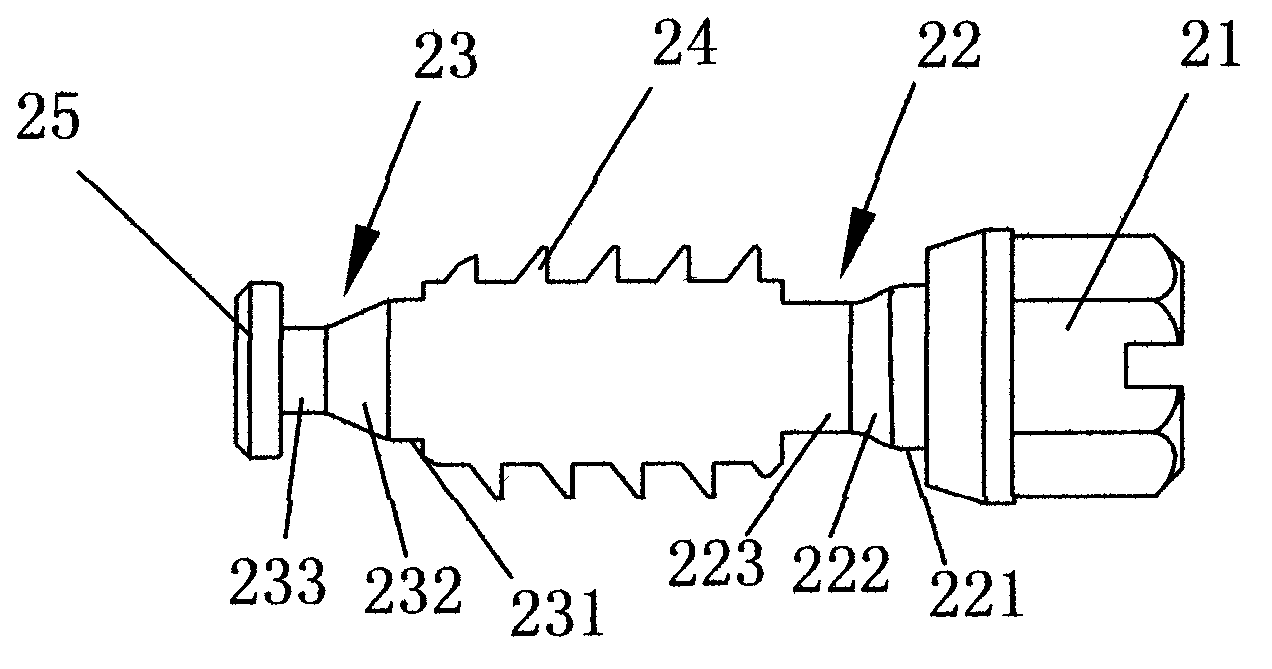

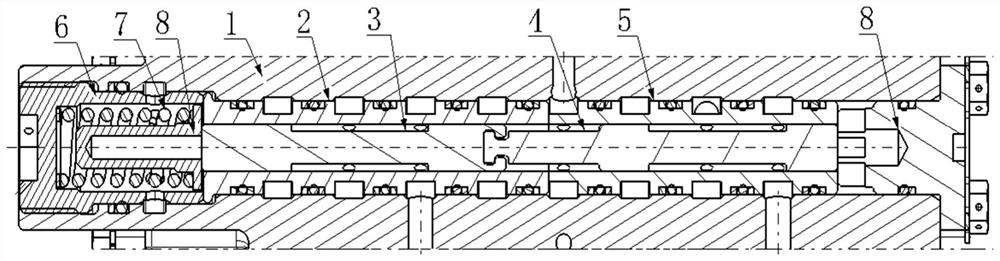

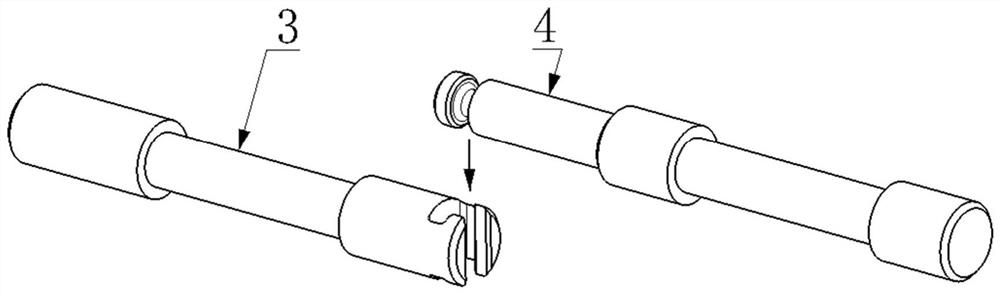

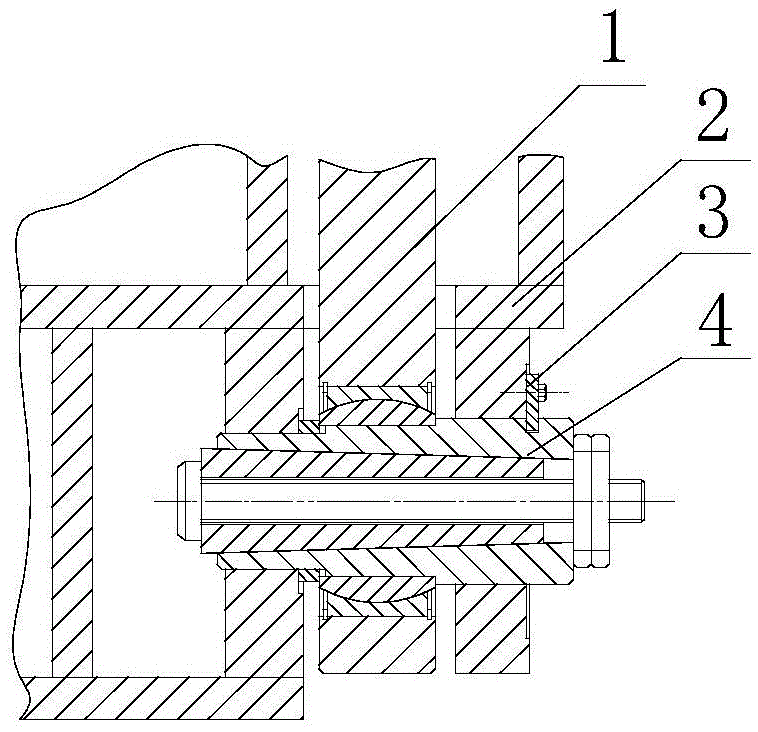

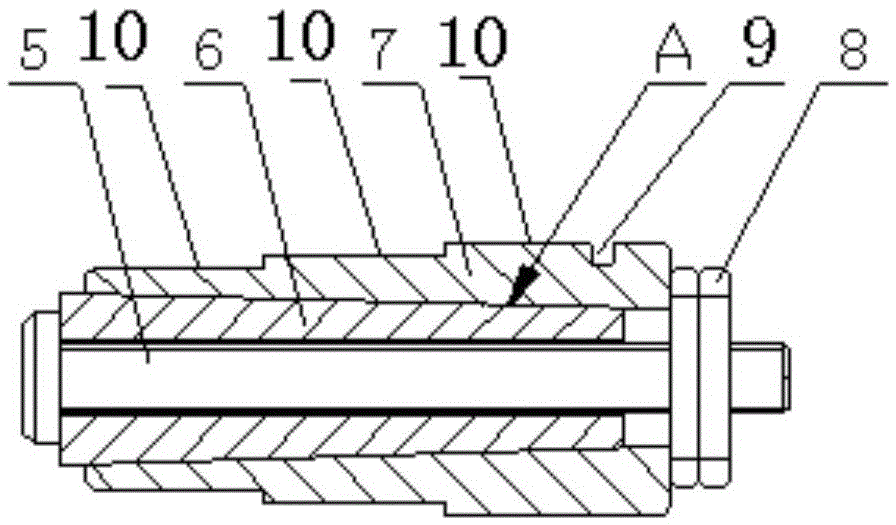

Semiaxis type pure-water hydraulic axial plunger pump supported by bearings in cylinder

ActiveCN103075316AImprove the lubrication effectImprove cooling effectPositive displacement pump componentsPositive-displacement liquid enginesFresh waterCylinder block

The invention relates to a semiaxis type pure-water hydraulic axial plunger pump supported by bearings in a cylinder, which adopts a semiaxis type structure that a sliding bearing supports a cylinder body. The semiaxis type pure-water hydraulic axial plunger pump is characterized in that a front bearing supports an input shaft, and a rear bearing is the sliding bearing in the cylinder and is used for supporting the cylinder body. Due to reasonable bearing distribution, the stressing of the bearings is reduced, and the overturning moments of flow distribution discs are balanced. A distributed type return spring penetrates through the cylinder body and acts on a spherical hinge and a floating lining plate respectively, so that not only is the sealing of a sliding shoe pair and a flow distribution pair guaranteed, but also the abrasion of sliding shoes and the flow distribution discs can be automatically compensated. The flow distribution discs are fixedly arranged on a rear end cover and are sealed by adopting sealing rings so as to avoid leakage of the back surfaces of the flow distribution discs. A plunger pair adopts an automatic gap-compensating type sealing structure so as to reduce leakage of the plunger pair and improve the anti-pollution capability of the pump. The semiaxis type pure-water hydraulic axial plunger pump adopts filtered fresh water or seawater as a working medium, adopts all-water lubrication for all friction pairs, is high in power density, can be used for industrial cleaning, seawater freshening and underwater operation tools and the like and is wide in application prospect.

Owner:BEIJING UNIV OF TECH

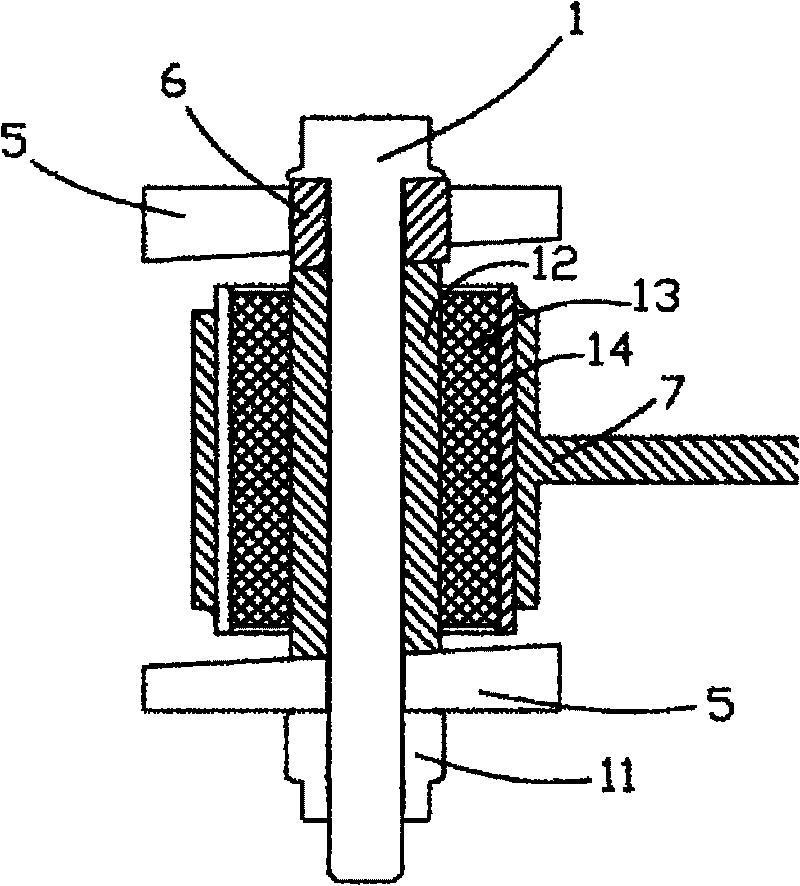

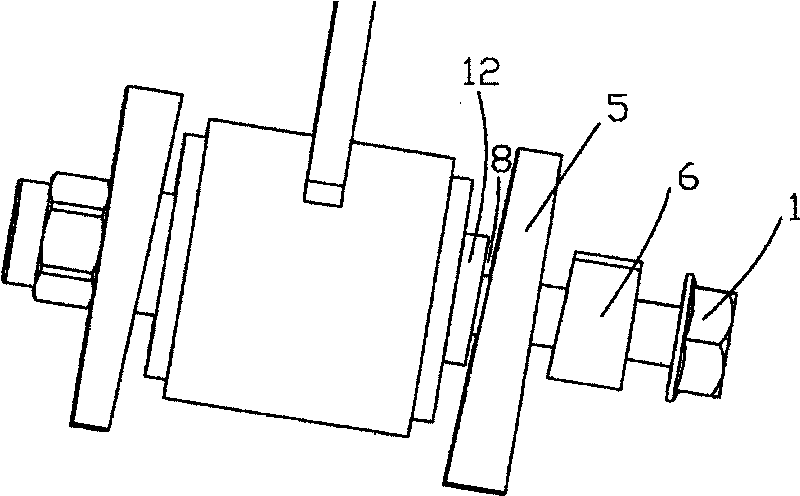

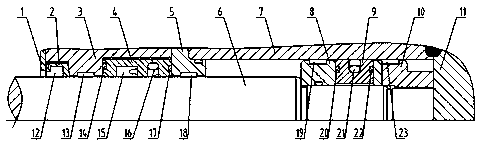

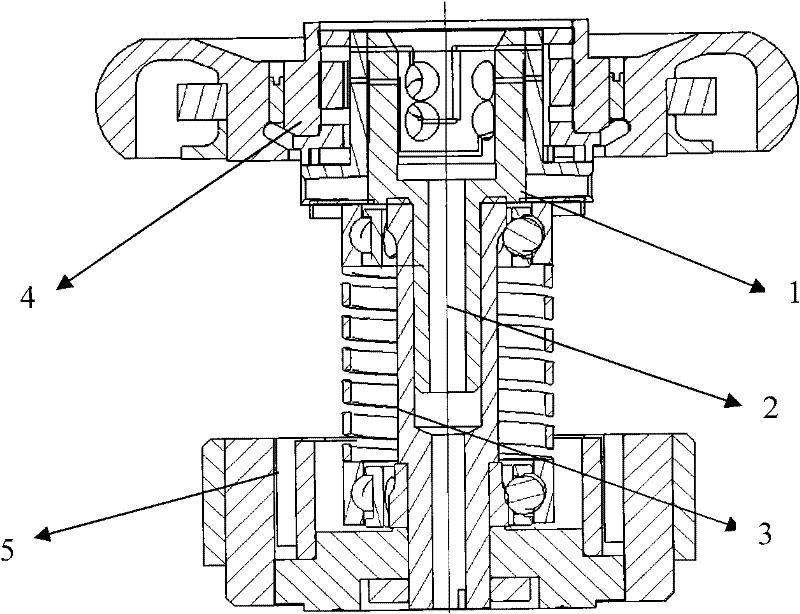

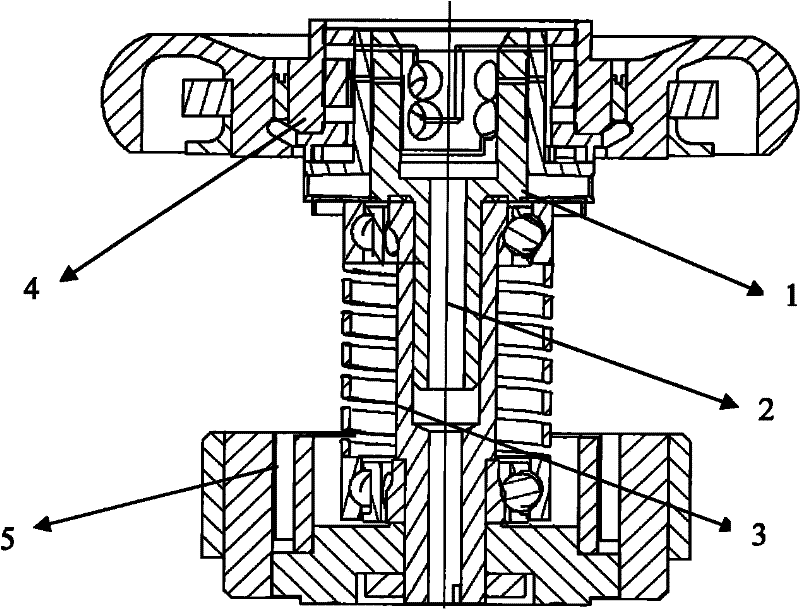

Rotary contact socket and plug

InactiveCN102655289AReduce space occupationIncrease contact surfaceCoupling contact membersTwo-part coupling devicesElectrical and Electronics engineeringElectrode

The invention relates to rotary contact socket and plug. A three-pole jack slide and a two-pole jack slide are arranged on a socket front housing, each jack slide comprises a jack and a narrow slide which are communicated, a horizontal electrode clamping spring is fixed in the front shell, and a rear cover is fixed on the front shell to form a housing. A three-pole cascade insert, a three-pole power lead jacket and a three-pole power lead are fixed on a three-pole plug; and a two-pole cascade insert, a two-pole power lead jacket and a two-pole power lead are fixed on the plug II. According to the rotary contact socket and plug, under the condition of reaching the rated load of the traditional socket and plug, the ultrathin structure is realized; after the pug is inserted into the socket, the plug is locked with the socket, the plug can not be vertically pulled out, no shaking exists between the socket and the plug, so that the socket and the plug can keep better contact for a long time; and the rotary contact socket and plug are safe in use and convenient for operation.

Owner:侯永昌

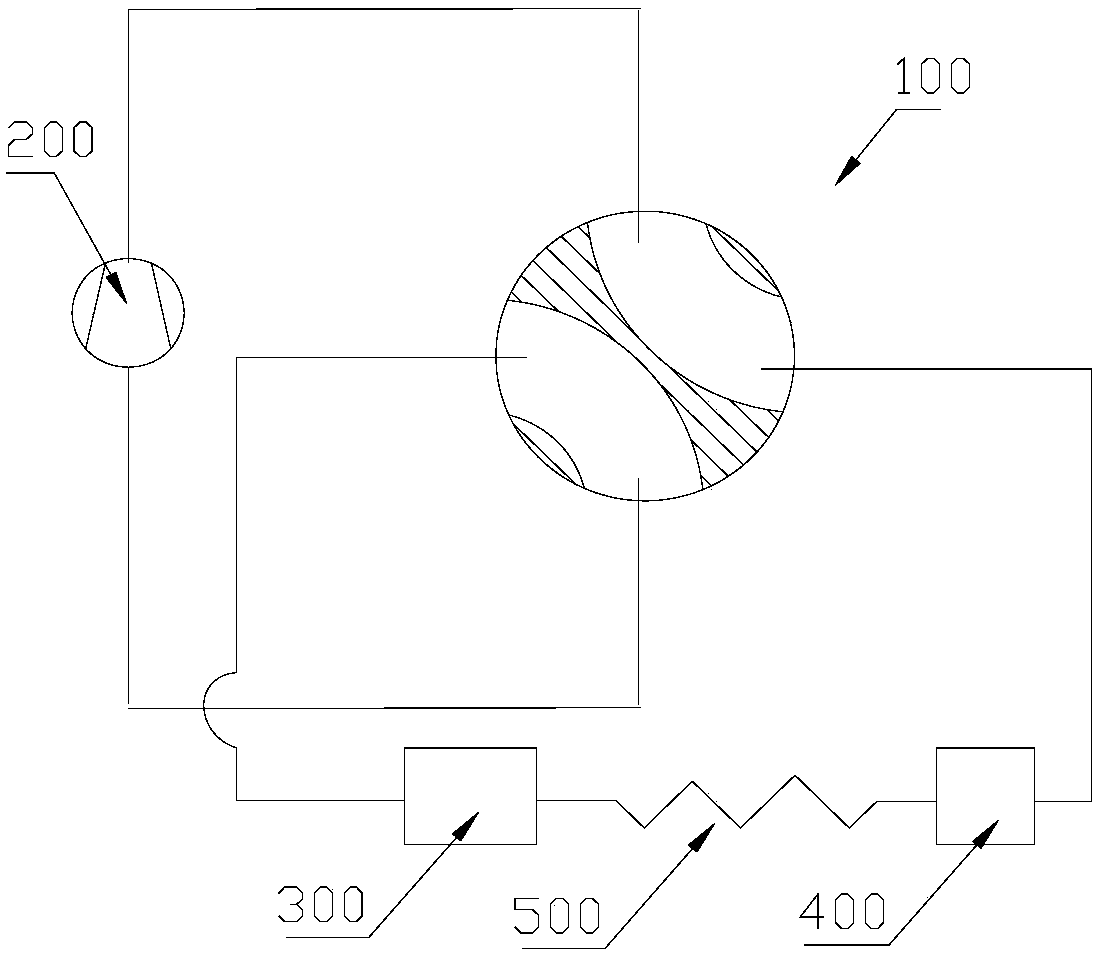

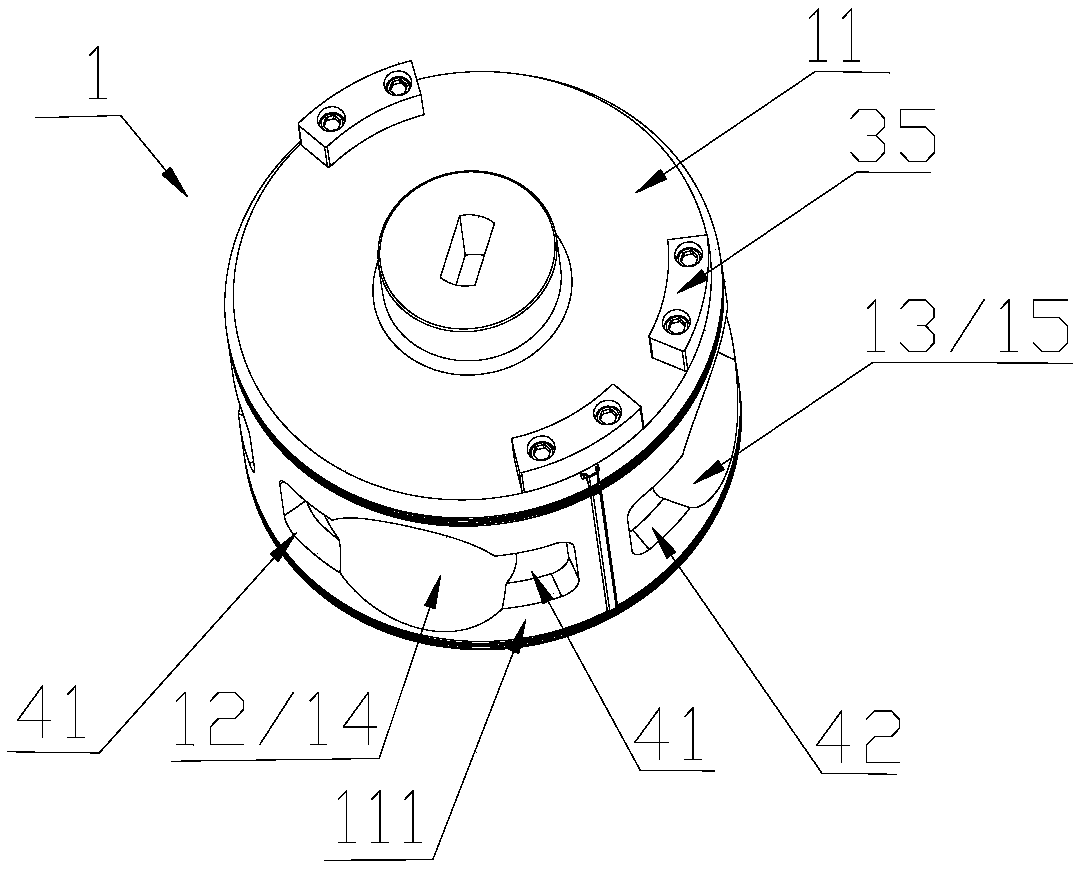

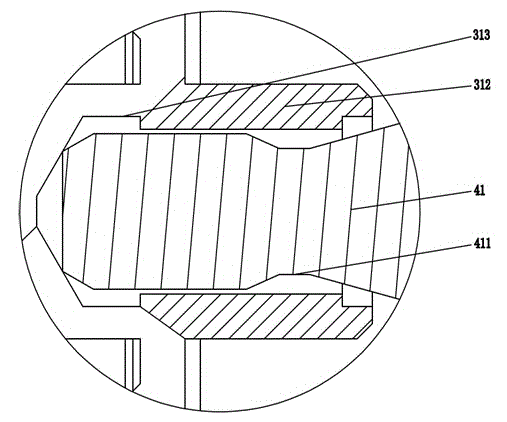

Rotary reversing valve

ActiveCN109424766ADoes not affect mutual sealing performanceIncrease fit clearancePlug valvesOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention discloses a rotary reversing valve. The rotary reversing valve comprises a valve core part, the valve core part comprises a valve core with a first flow channel and a second flow channel, the first flow channel is provided with two first valve port portions on a circumferential outer edge portion of the valve element, the second flow channel is provided with two second valve port portions on the circumferential outer edge portion of the valve element, and axial containing grooves are formed in the portions, wherein the second valve port portions are opposite to the first valve port portions, of the circumferential outer edge portion; and the rotary reversing valve further comprises an axial sealing part, the axial sealing part comprises an elastic component and a sealing component, the elastic component is arranged in the containing groove, and the sealing part is arranged in the containing grooves and partially protrudes out of the circumferential outer edge portion. According to the rotary reversing valve, the impurity compatibility of products can be improved, and then the valve element and a valve body are not prone to be clamped.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

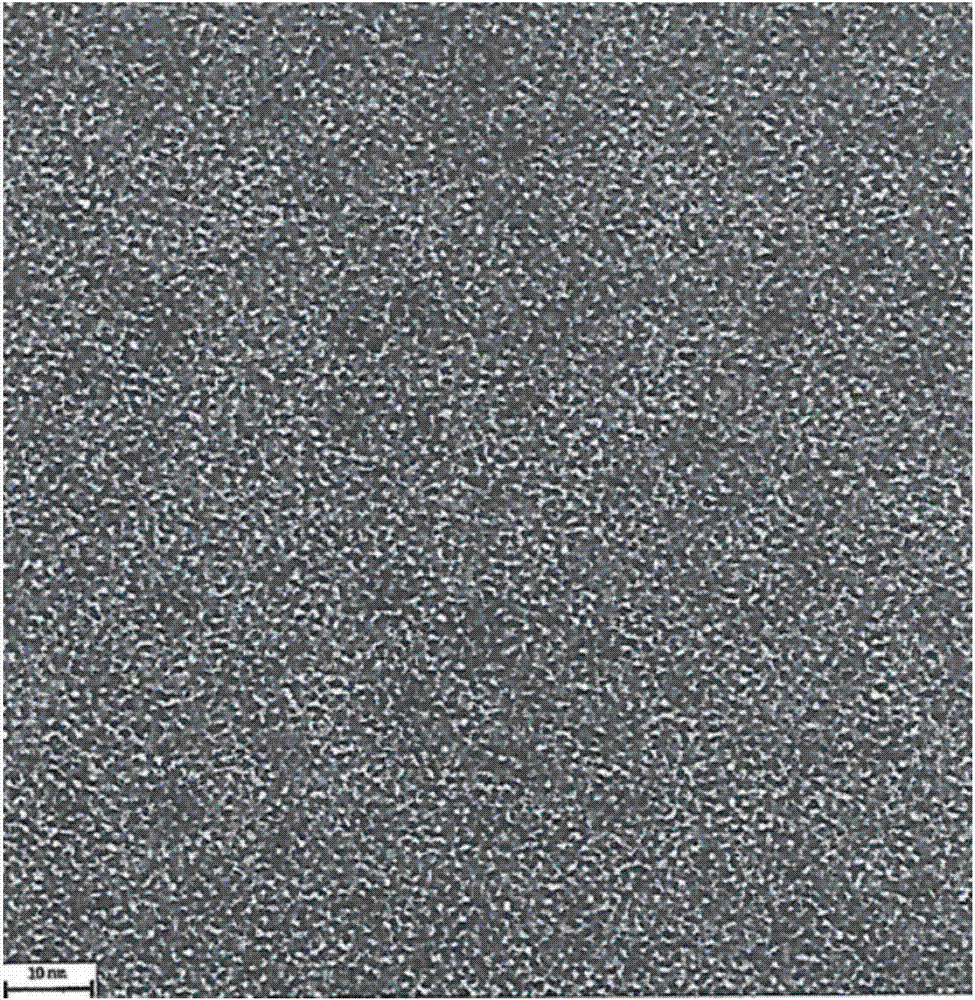

Energy-saving and environment-friendly lubricating oil capable of self-repairing wear for internal combustion engine and preparation method of energy-saving and environment-friendly lubricating oil

ActiveCN107488491AWon't fall offWork effectively for a long timeLubricant compositionExternal combustion engineAntioxidant

The invention discloses energy-saving and environment-friendly lubricating oil capable of self-repairing wear for an internal combustion engine and a preparation method of the energy-saving and environment-friendly lubricating oil, and belongs to the field of lubricating materials. The energy-saving and environment-friendly lubricating oil is prepared from the following components in percentage by weight: 87 to 90 percent of base oil and 10 to 13 percent of additive, wherein the additive is prepared from the following components in percentage by weight: 1.2 to 2.5 percent of a calcium-containing clearing agent, 1.3 to 2 percent of a dispersing agent, 0.5 to 1.4 percent of an anti-wear agent, 1.5 to 2.5 percent of an antioxidant, 0.5 to 0.8 percent of a corrosion inhibitor, 1.5 to 2 percent of a viscosity index improver and 1.1 to 3.5 percent of a friction improver; the friction improver is polytetrafluoroethylen high-molecular compound ultramicro nano-powder and the particle size of the powder is 2 to 12 nm. According to the energy-saving and environment-friendly lubricating oil disclosed by the invention, the problem that existing lubricating oil for the internal combustion engine cannot repair friction and wear of internal parts in the engine is solved; in addition, the design tolerance gap can be automatically compensated and non-disassembly in-situ repair can be carried out, thereby improving the sealing property of a cylinder, a piston and other parts; in addition, a compression ratio and an air-fuel ratio of the engine are improved, fuel oil is combusted more sufficiently, the discharge of exhaust pollutants is reduced and the frictional resistance is reduced.

Owner:安徽游能润滑新技术有限公司

Inclined plane slide block type control arm bush structure

ActiveCN101695895AWith stableMeet angle installation requirementsPivoted suspension armsInterference fitWhole body

The invention discloses an inclined plane slide block type control arm bush structure, which comprises a control arm body, an outer liner tube, rubber, an inner liner tube, bolts and nuts, wherein the outer liner tube is in clearance fit through press mounting and is fixed in a control arm lining; the rubber connects the outer liner tube and the inner liner tube into a whole body; and two end faces of the inner liner tube are inclined planes. The number of restrictions of the control arm bush structure formed by matching two groups of inclined planes is 5 and has 2 restrictions more than that of plane matching, the extra restrictions can ensure that the matching is firmer, so the control arm bush structure effectively solves the problem of bolt fracture caused by bolt torque losses or matching surface relative sliding in the connection between the inner liner tube of a control arm rubber sleeve and a car body, and can satisfy the assembly with angle mounting requirements.

Owner:CHERY COMML VEHICLE ANHUI

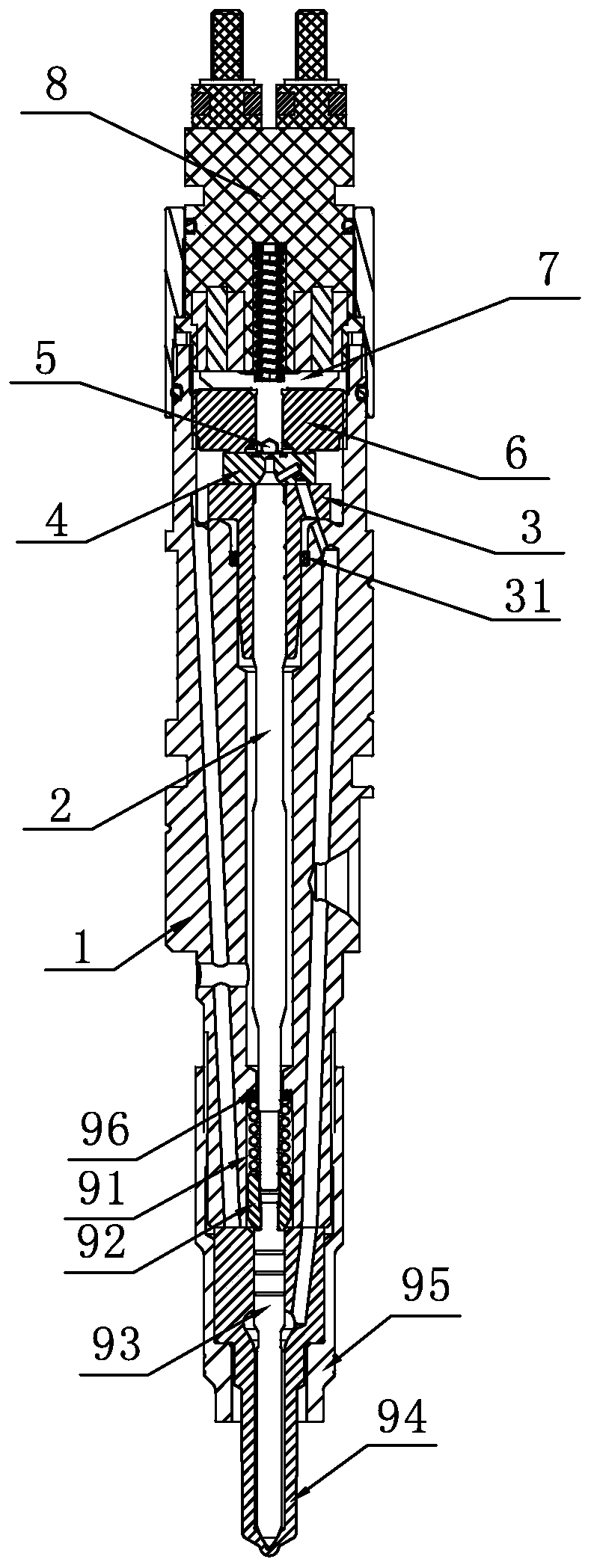

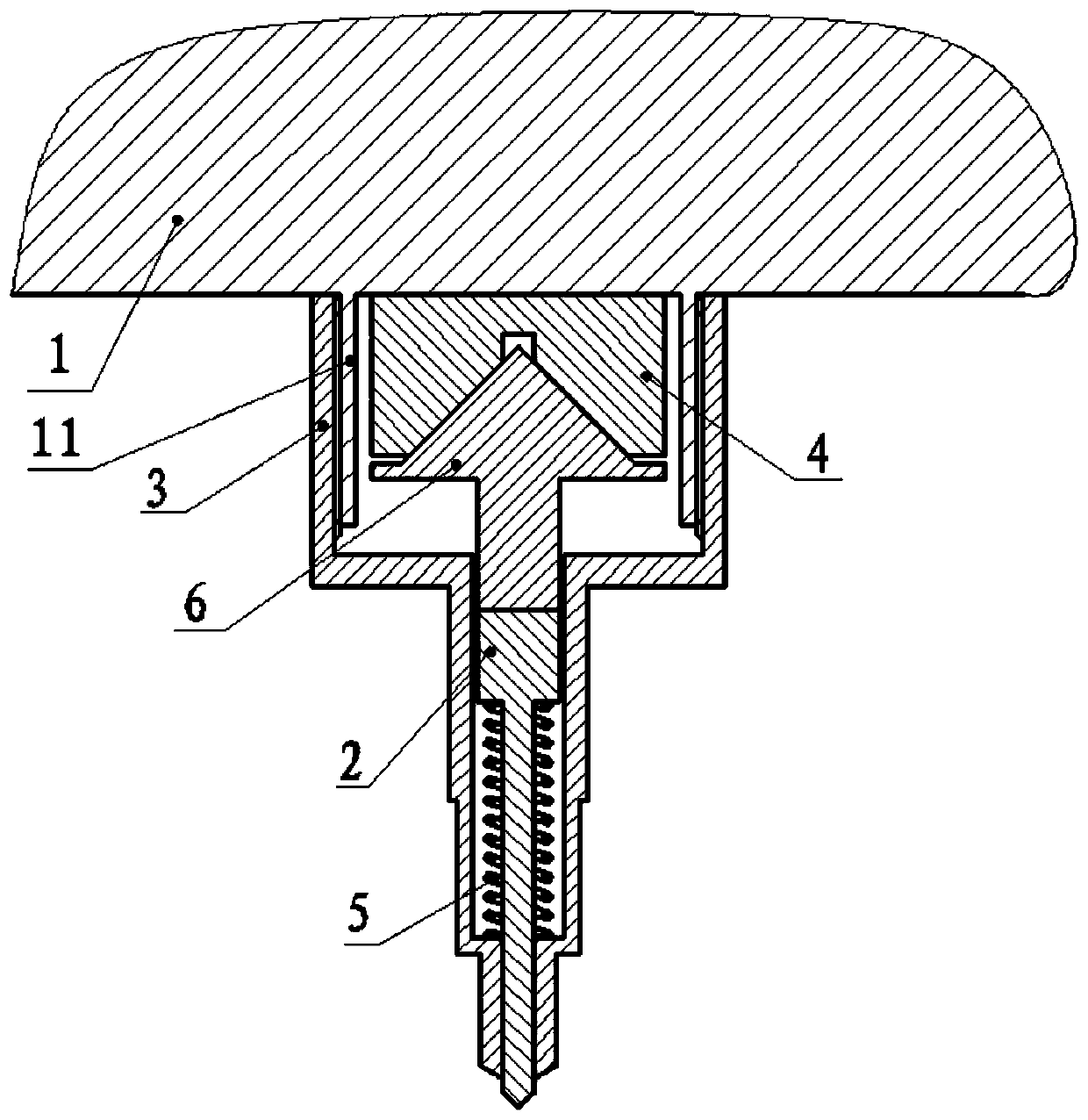

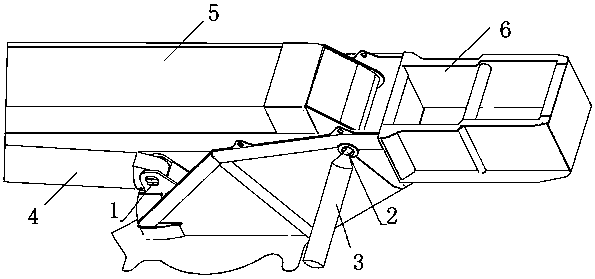

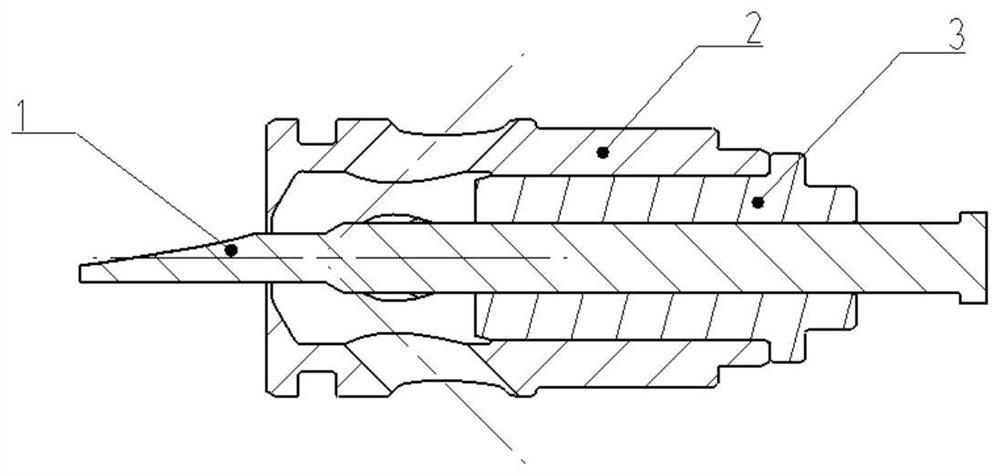

Valve stem coupled high-pressure common rail injector

PendingCN110131084AReduce use and maintenance costsPrevent leakageFuel injection apparatusMachines/enginesValve stemBiomedical engineering

A valve stem coupled high-pressure common rail injector comprises a valve body, a valve stem and a valve stem sleeve. A pressure balance hole and a valve stem sleeve seat hole are arranged on the valve body, and the valve stem sleeve is installed in the valve stem sleeve seat hole through a matching sleeve. A shaft shoulder seat is in contact with the upper end surface of the pressure balance hole, and the diameter of the pressure balance hole is larger than the outer diameter of the matching sleeve. The lower end of an oil inlet hole communicates with the pressure balance hole. The inner holeand the valve stem sleeve is in coupled precise clearance fit with the valve rod, and a seal ring is arranged between the pressure balance hole and the outer diameter of the valve stem sleeve. According to the valve stem coupled high-pressure common rail injector, the valve stem and the valve stem sleeve are coupled, and a replaceable matched structure is adopted between the valve stem sleeve andthe valve body; in this way, when the fit clearance between the valve stem and the valve stem sleeve is out of tolerance due to wear, the valve stem sleeve and the valve stem can be directly replaced, and the use and maintenance cost of the injector can be greatly lowered. The arranged pressure balance hole can eliminate the situation that pressure deformation of the inner hole of the valve stemsleeve causes the fit clearance between the valve stem and the matching hole to be enlarged; and the seal ring is arranged between the pressure balance hole and the outer diameter of the valve stem sleeve to prevent leakage.

Owner:无锡格林鲍尔科技有限公司

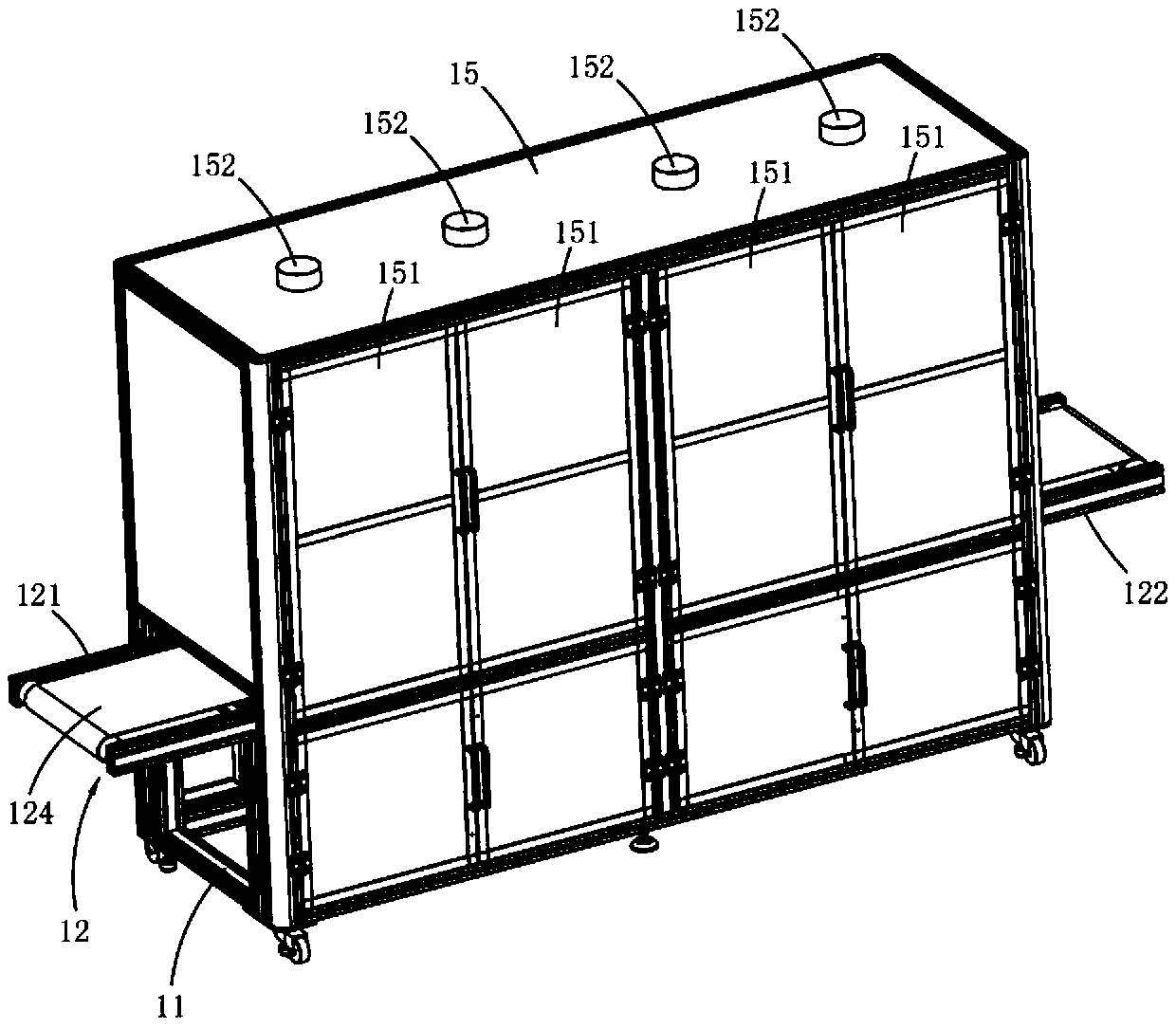

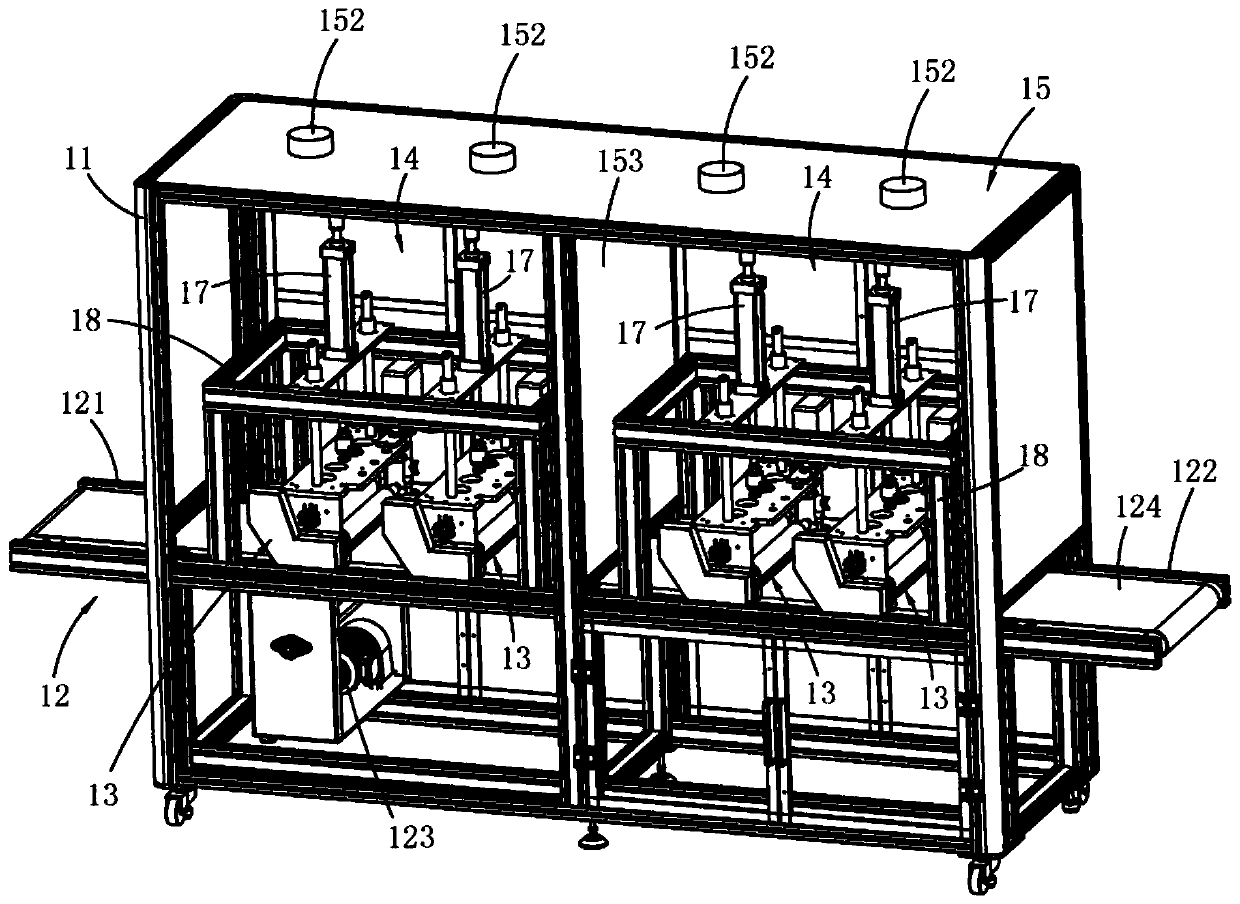

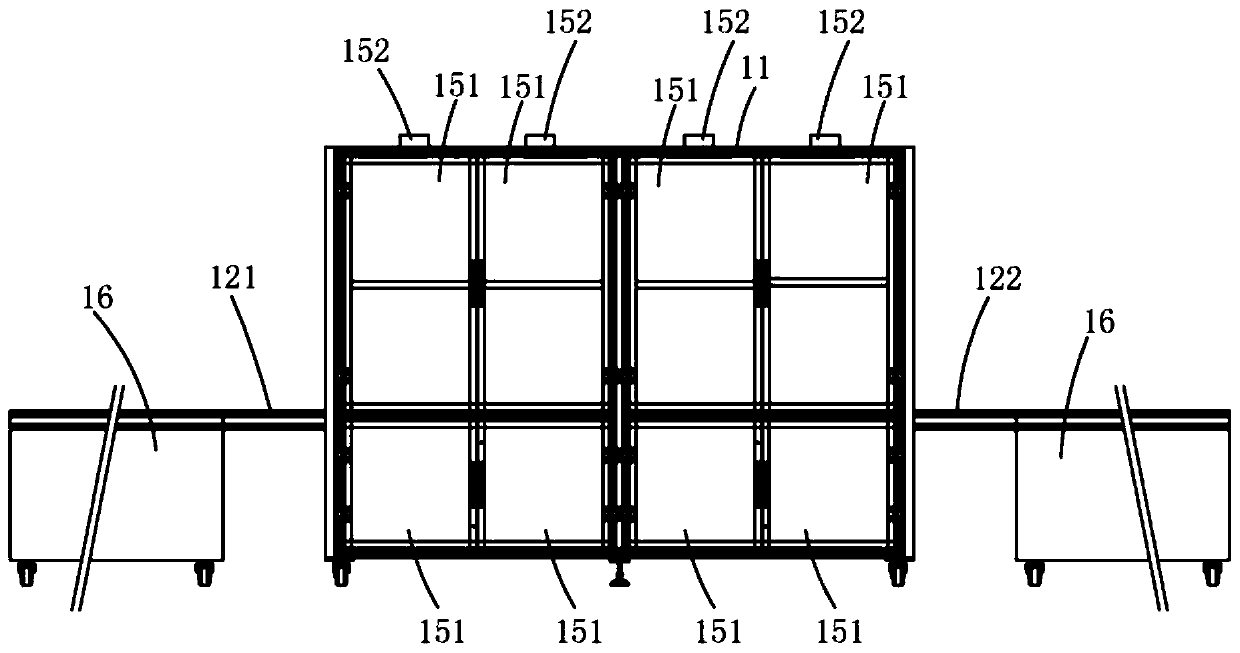

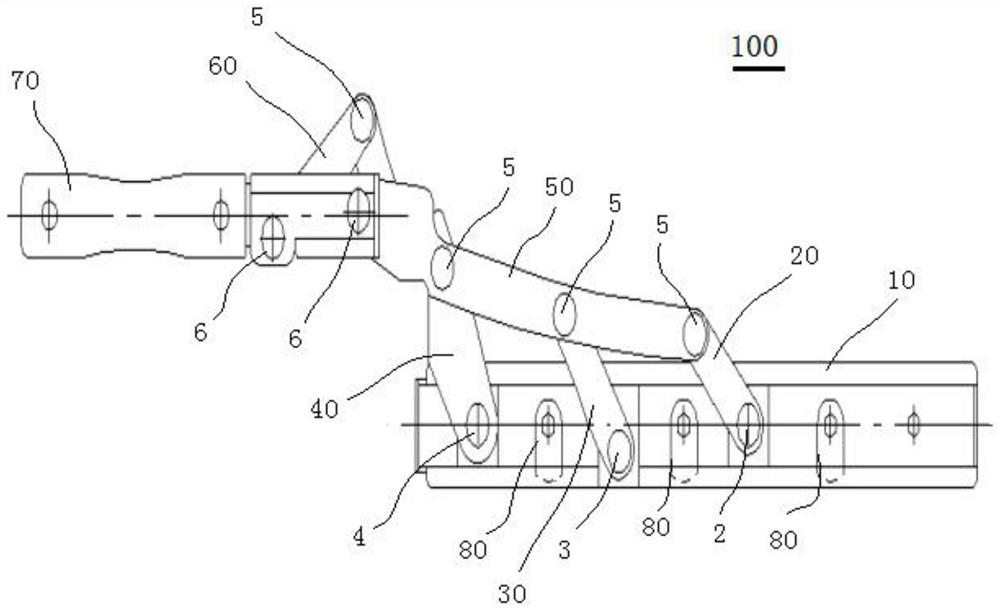

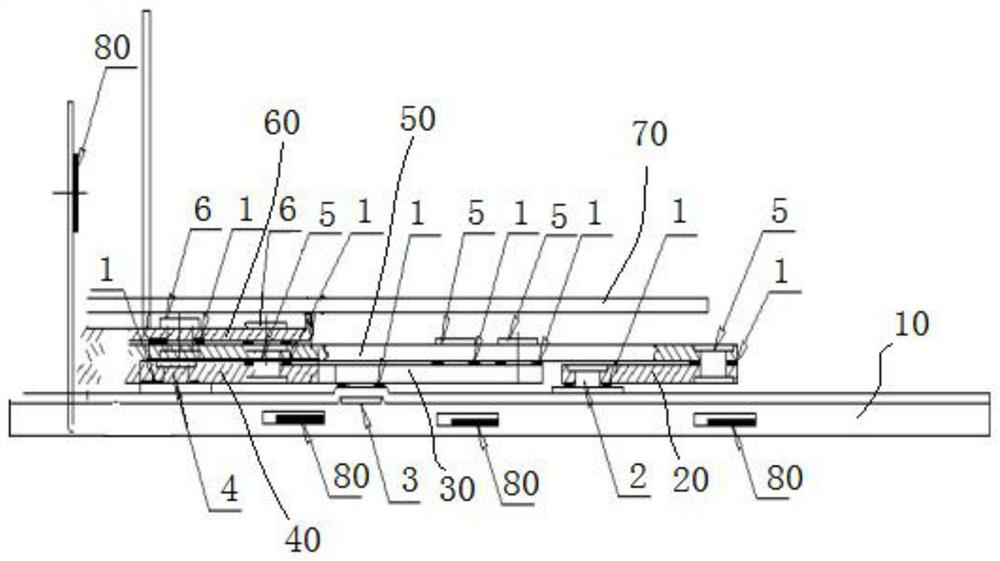

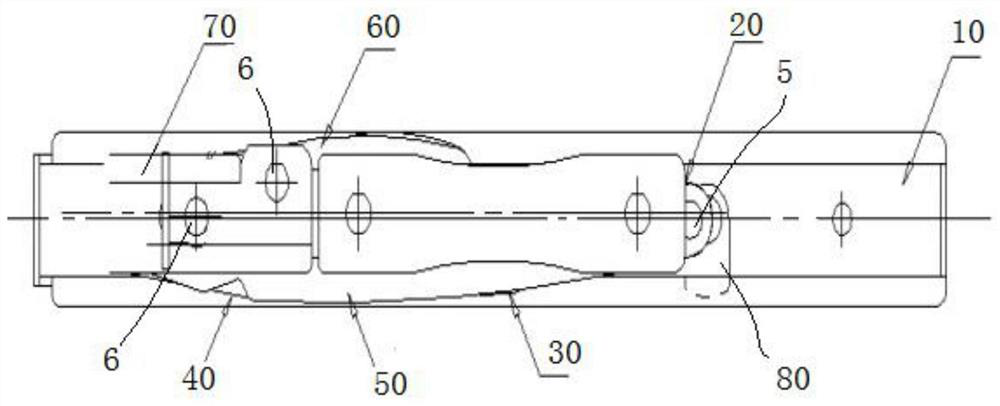

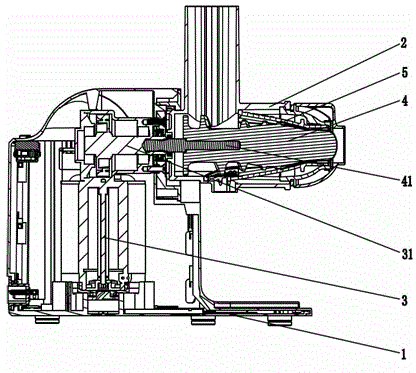

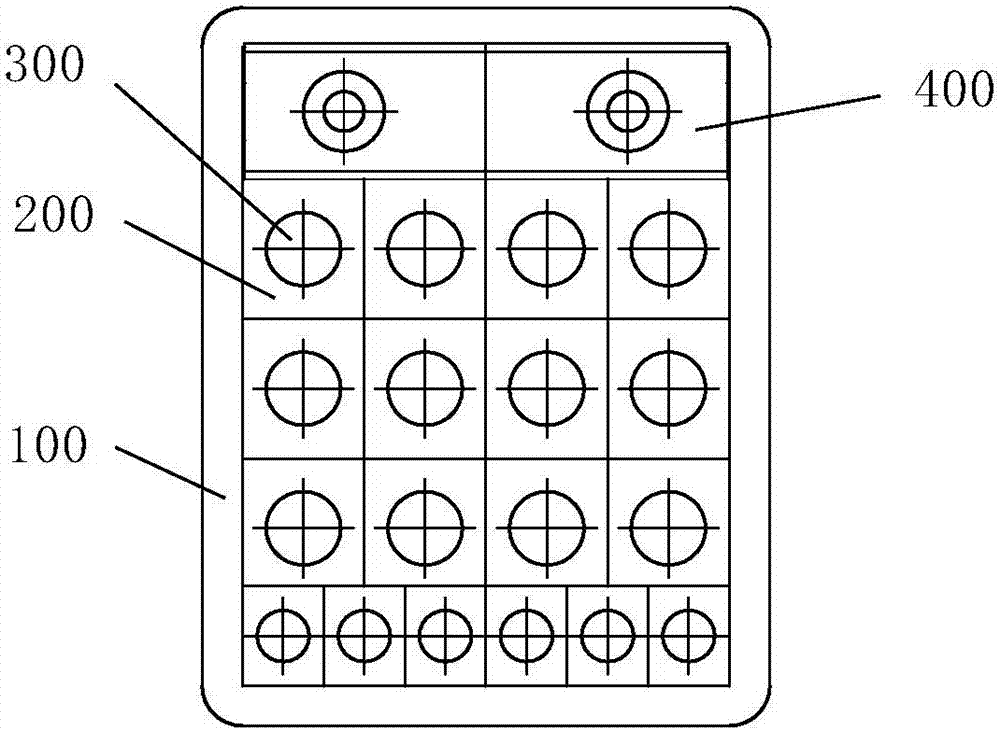

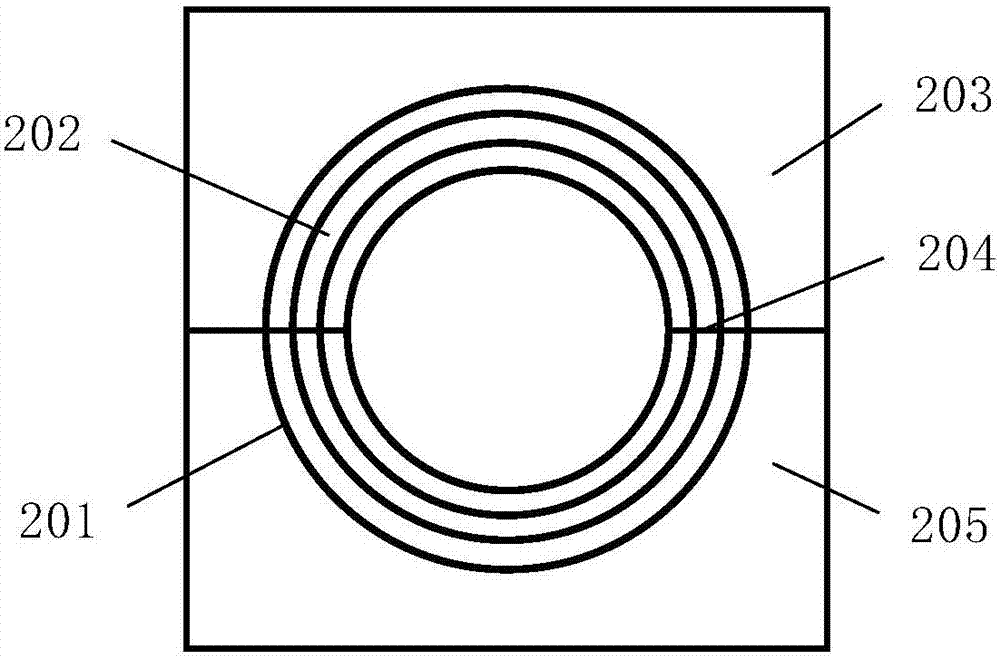

Automatic treatment agent coating equipment

PendingCN110918370AAvoid drippingAvoid uneven applicationLiquid surface applicatorsCoatingsStructural engineeringProcess engineering

The invention discloses automatic treatment agent coating equipment. The automatic treatment agent coating equipment is characterized in that at least two automatic treatment agent coating units, wherein the two automatic treatment agent coating units are arranged on a machine frame along the conveying direction of a shoe material conveying mechanism and are used alternately; each automatic treatment agent unit coating is provided with at least one coating mechanism correspondingly; a control device is connected with a dose adjusting driving mechanism arranged on each coating mechanism; when the equipment works, a transition roller is intermittently driven by the dose adjusting driving mechanism to leave a feeding roller and a coating roller at set time intervals, so that the transition roller respectively stays at a treatment agent coating device and the coating working position for corresponding stay time, and the dosage of the treatment agent transferred to the transition roller isautomatically adjusted in the working process; a roller body in the treatment agent coating device can be quickly disassembled, and a cushion sleeve on the surface of the roller body can be conveniently cleaned and replaced and installed; and the treatment agent can be automatically coated continuously without stopping, the production is accelerated, and the use is convenient.

Owner:东莞云展智能装备有限公司

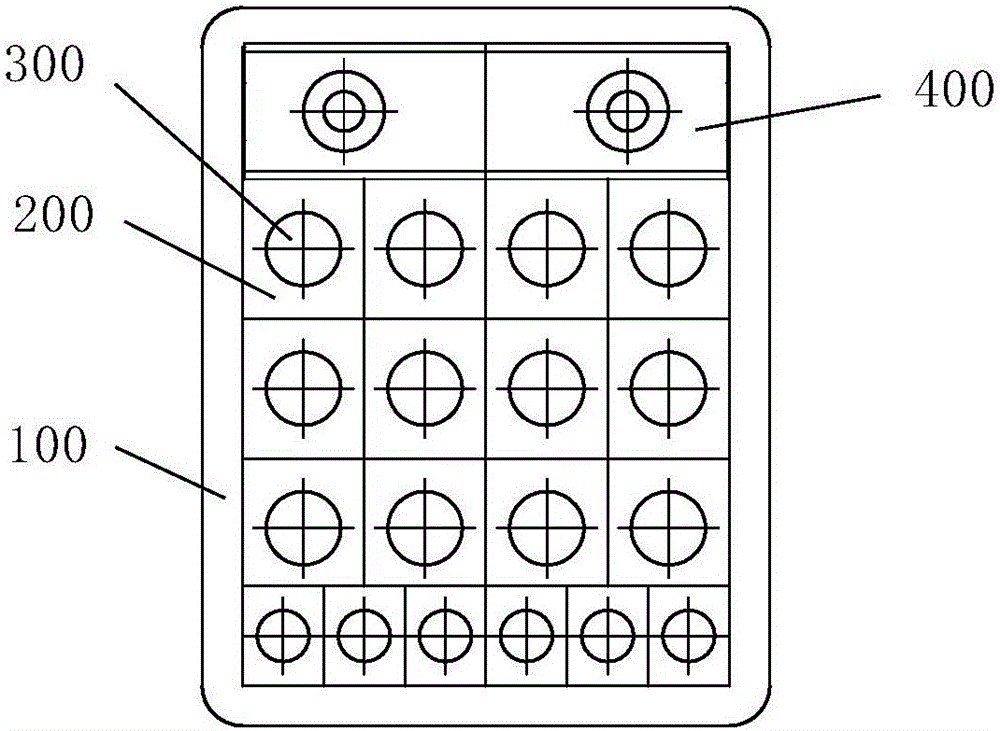

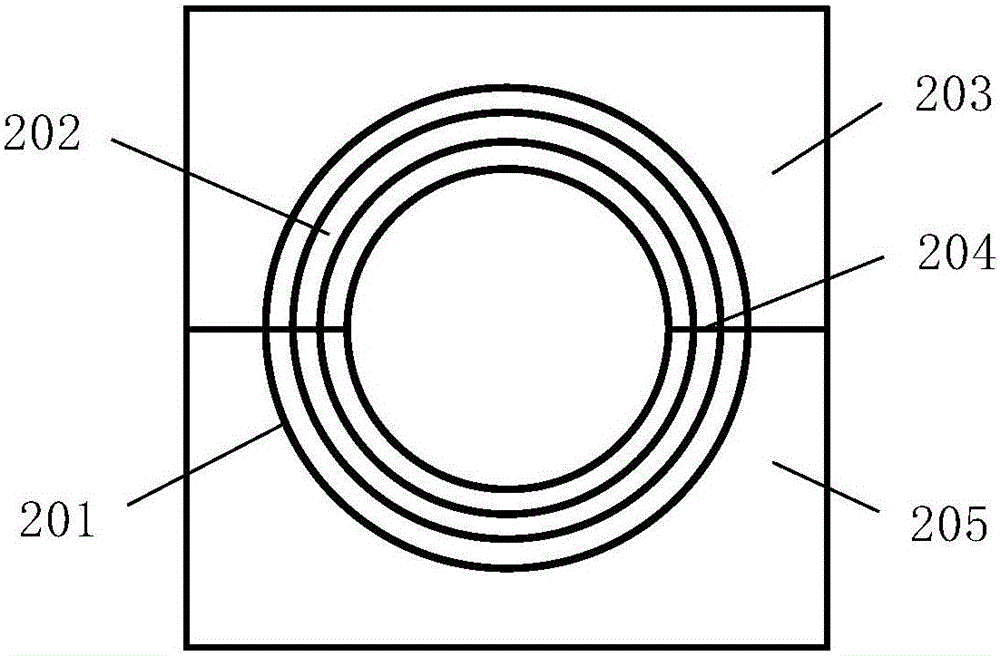

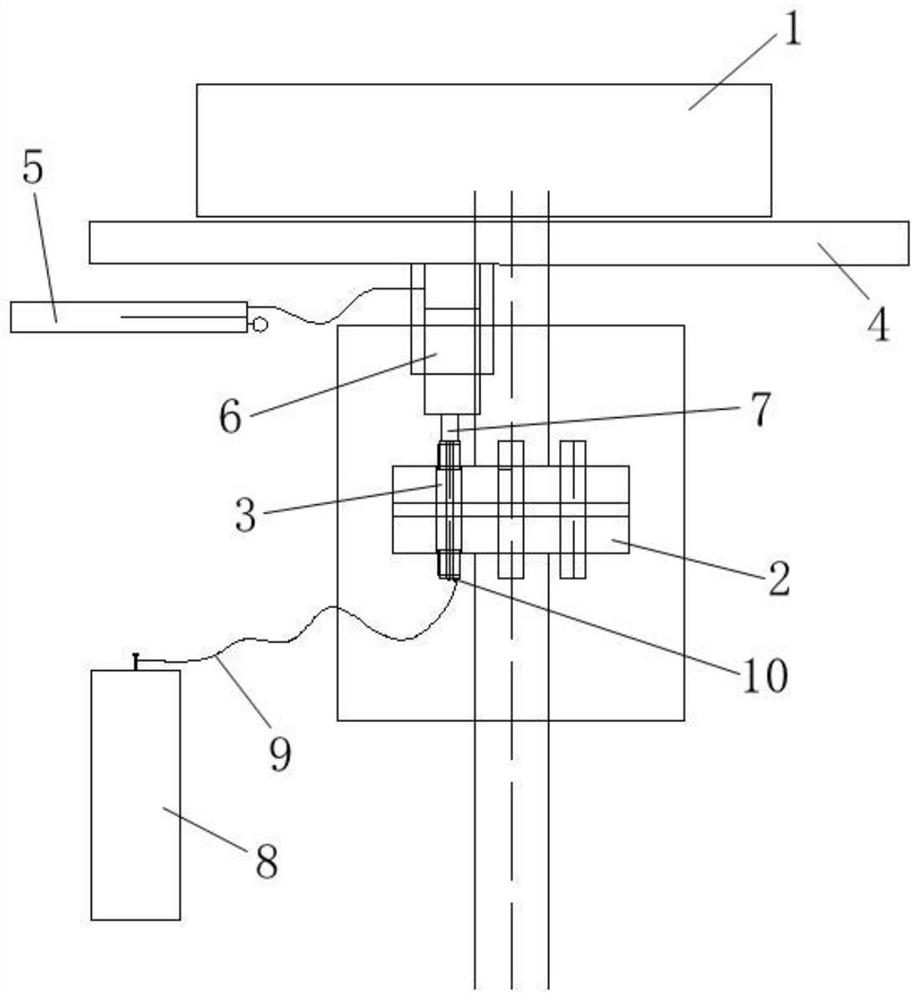

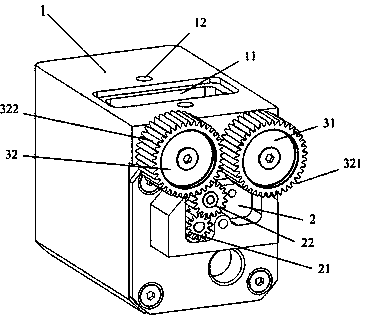

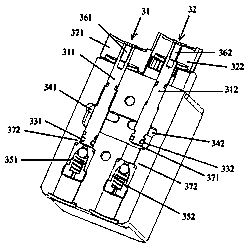

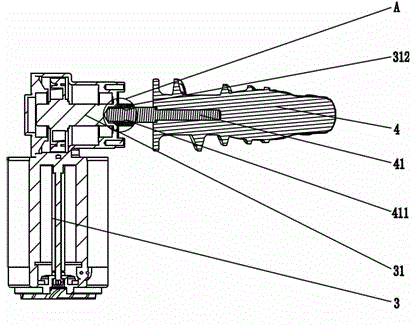

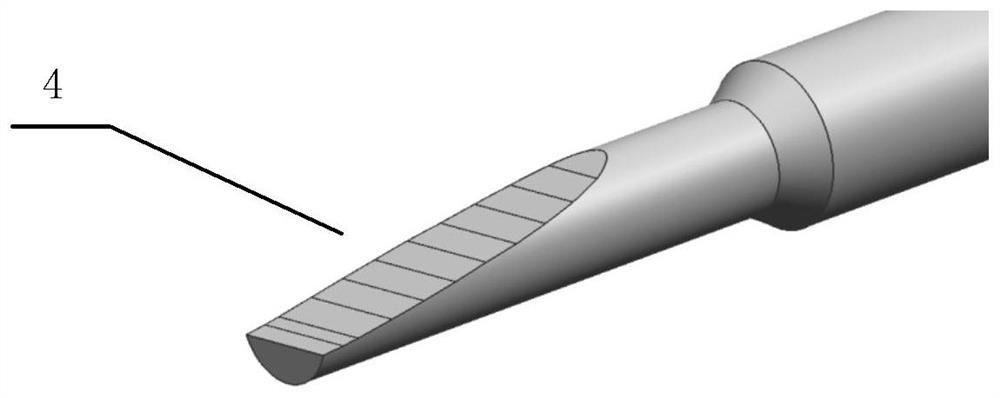

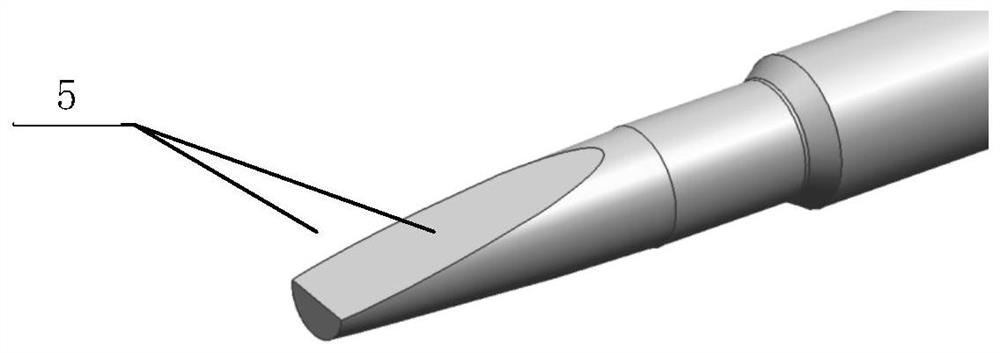

Marking machine two-dimensional code marking head and two-dimensional code marking method

InactiveCN110774775AReduce manufacturing costImprove marking qualityPattern printingTypewritersCode pointMagnetic poles

The invention provides a marking machine two-dimensional code marking head and a two-dimensional code marking method. The marking machine two-dimensional code marking head comprises a supporting seat,a marking needle and a needle shell. A protruding ring is arranged on the supporting seat. A high-frequency pulse electromagnet is installed in the protruding ring. The marking needle is connected with an end opening of one end of the needle shell in a sliding fit manner. The marking needle is further sleeved with a spring, and the two ends of the spring make contact with the inner wall of the marking needle and the inner wall of the end opening of the needle shell. The tail end of the marking needle is further fixedly connected with a permanent magnet. An end opening of the other end of theneedle shell is fixedly connected with the protruding ring through a threaded pair, and in addition, the permanent magnet and the high-frequency pulse electromagnet are oppositely arranged with opposite magnetic poles. The two-dimensional code marking method includes the step of using the marking head to print a two-dimensional code. By the adoption of the technical scheme, due to the cooperativeconnecting structure of the permanent magnet and the high-frequency pulse electromagnet, the code point marking consistency of the two-dimensional code is improved, the marking quality of the two-dimensional code is improved, and the requirement for the manufacturing precision of related composition structure parts of the marking head is lowered.

Owner:GUIZHOU LIYANG INT MFG

Vacuum claw type rubber tube sleeving device

The invention discloses a vacuum claw type rubber tube sleeving device. An opening hole is formed in the spliced center of multiple opening claws, and a vacuum cavity is formed by forming a vacuumizing air hole in the side wall of the opening hole, so that the pipe wall of a first to-be-sleeved rubber tube placed in the opening hole can be evenly sucked to the side wall of the opening hole. The opening claws are driven to expand to evenly expand the sucked first rubber tube outwards, so that the fit clearance between an inner rubber tube and an outer rubber tube is increased, a second rubber tube can be smoothly put into the first rubber tube, and finally the first rubber tube is separated from the side wall of the opening hole and restored by stopping vacuumizing operation. Accordingly, the inner rubber tube and the outer rubber tube are well sleeved. Multi-layer sleeving of rubber tubes with different diameters can be conducted conveniently and rapidly through the device.

Owner:SHANGHAI YIBOW SHIPPING CO LTD

Positioning buffer structure of driver's door of bus

PendingCN111364866AIncrease fit clearanceRemove noisePedestrian/occupant safety arrangementBuilding locksEngineeringStructural engineering

A positioning buffer structure of a driver's door of a bus belongs to the technical field of buses and overcomes the problems in the prior art that the operating force of closing the driver door is increased in order to reduce noise, which affects the operation flexibility of the driver door, and that the existing buffer block can only provide outward pressure and cannot provide inward pulling force, which is not suitable for positioning buffer of the driver's door of the bus, wherein the left side of a first door frame column is provided with a C-shaped groove with an open end at the left, the C-shaped groove is installed with a positioning buffer bar, the main body of the cross section of the positioning buffer bar is a C-shaped open ring with a lower end opening, a first protrusion, a second protrusion, a third protrusion and fourth third protrusion are provided on the outer circumference of the C-shaped open ring of the positioning buffer bar, and the first door column is providedwith a round head protrusion matching the inner circle of the C-shaped open ring. The invention has the beneficial effect of not only improving the suppression of vibration shock between a lock tongueand a lock hole and reducing noise, but also not increasing the operating force of closing the driver's door, and not affecting the operation flexibility of the driver's door.

Owner:湖南晟成汽车零部件有限公司

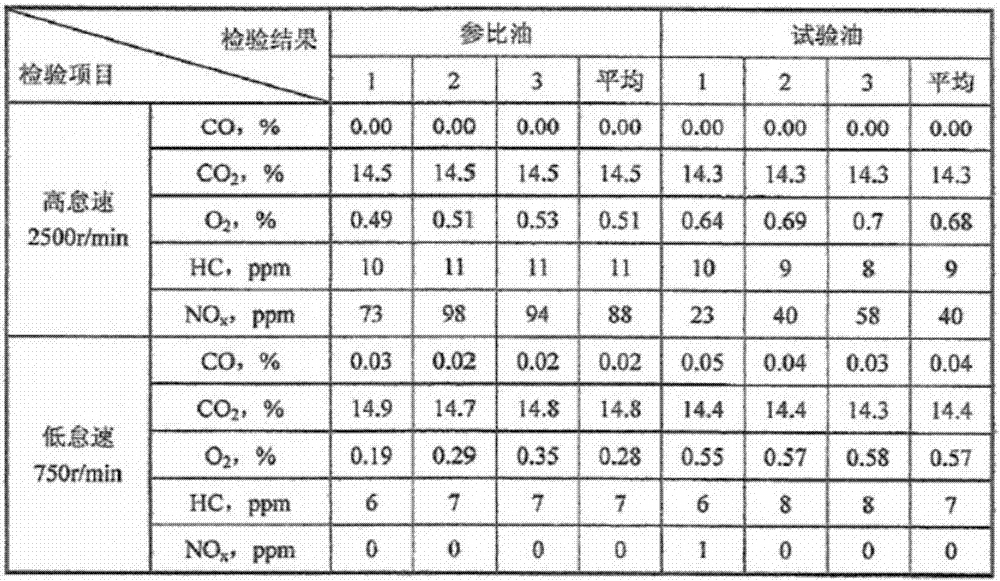

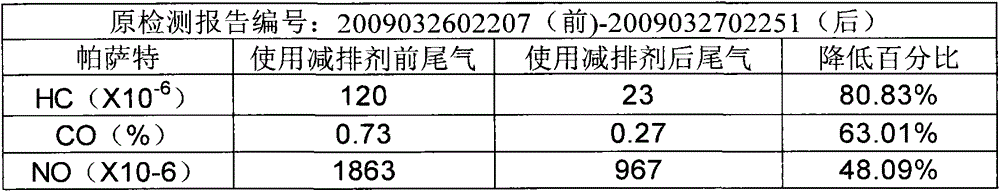

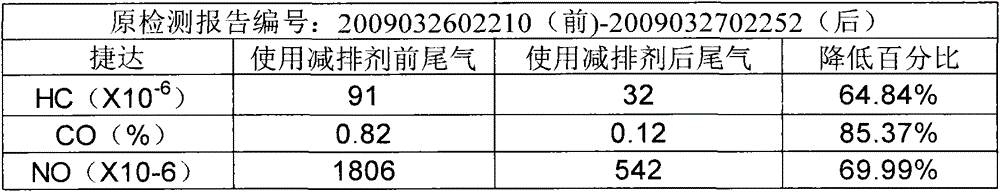

Combustion-supporting emission reduction agent for internal combustion engine

InactiveCN103980965ABurn fullyImprove catalytic performanceLiquid carbonaceous fuelsIndiumChemical reaction

The invention relates to a combustion-supporting emission reduction agent for an internal combustion engine. The agent includes, by mass, 60% of hydroxy silicate, 15% of tin-doped indium oxide ITO, 15% of antimony-doped tin oxide ATO, 7% of titania, 3% of a catalyst, and a carrier. The above components are made into nano-scale powders; the nano-scale powders are fully mixed by stirring; and the mixed nano-scale powders are added to the carrier so as to form the combustion-supporting emission reduction agent for an internal combustion engine. When in use, the emission reduction agent is added to lubricating oil of an internal combustion engine, and the emission reduction agent is brought onto a friction pair surface of a cylinder and a piston of the internal combustion engine and undergoes a mechanochemical reaction under the action of friction. Then, an active layer containing platinum, palladium and rhodium is formed on the inner surface of the cylinder of the engine, and fuel is more fully combusted. Therefore, exhaust emission of the internal combustion engine is reduced.

Owner:ZHUJI WANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Self-adaption lateral-bending-wear-resisting oil cylinder structure

PendingCN110259758AReduce performance requirementsAvoid unilateral stressFluid-pressure actuatorsEngineeringLateral bending

The invention belongs to the technical field of oil cylinders and particularly relates to a self-adaption lateral-bending-wear-resisting oil cylinder structure comprising a cylinder barrel, a piston rod end structure and a piston end structure. A piston rod is arranged in the cylinder barrel. The piston rod end structure and the piston end structure between the cylinder barrel and the piston rod are provided with a separated type supporting structure and a seal structure correspondingly. The piston end structure is located at the end, close to the cylinder bottom, of the piston rod in the cylinder barrel. The piston rod end structure located at the other end of the piston rod is located at the cylinder barrel. A guide sleeve is arranged between a gland and the cylinder barrel. The seal structure is located between the guide sleeve and the piston rod. The self-adaption lateral-bending-wear-resisting oil cylinder structure has the beneficial effects that the independent seal structure is adopted and does not participate in support, a seal piece fluctuates along with the piston rod and the cylinder barrel, and the situation that the seal piece is stressed unilaterally can be effectively avoided; the independent support structure is adopted, so that a larger matching interval can be adopted, and the possibility that relative movement parts except a guide ring make contact due to flexure is effectively lowered.

Owner:无锡市汉为液压气动有限公司

Method for dynamically balancing moving shaft of dynamically tuned gyroscope

ActiveCN101907505BIncrease fit clearanceSolve the high requirements of machining accuracyStatic/dynamic balance measurementProcessing accuracyDynamic balance

The invention belongs to measuring and adjusting technology and relates to a method for dynamically balancing a moving shaft of a dynamically tuned gyroscope. A dynamic balancing disc is arranged on a flexible head shaft of the gyroscope, so that a fit clearance between a flexible head installation hole of a bearing shaft of the gyroscope and the flexible heat shaft is enlarged, and a rotating shaft system of the gyroscope moves slightly, so that a shaft system of the gyroscope is in a dynamic balance state. The method has the advantages of perfectly solving the problems of excessively high requirement on processing accuracy and contradiction between dynamic and stationary balances existing in the conventional dynamic balance mode, reducing movable parts on a gyroscope rotor, improving the dynamic balance accuracy and stability of the gyroscope, and effectively enhancing the repetition accuracy and prolonging the service life of the gyroscope.

Owner:中国航空工业集团有限公司

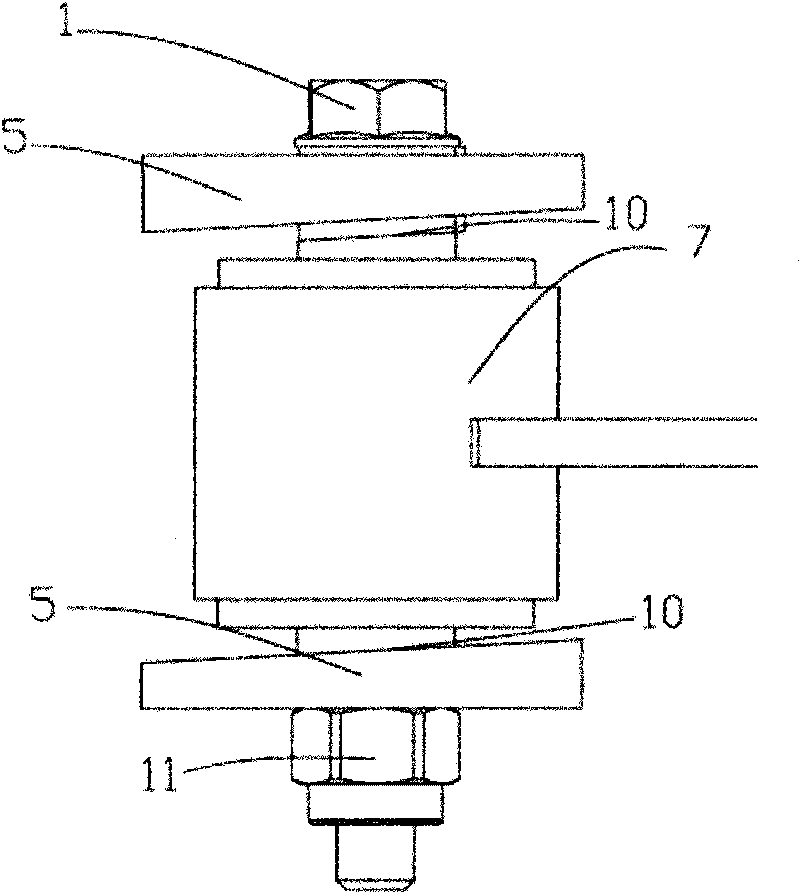

Rapid steam turbine coupling bolt disassembling tool and using method

The invention relates to a rapid steam turbine coupling bolt disassembling tool which comprises an ejection mechanism and a cooling mechanism, the ejection mechanism is arranged between a coupling and a steam turbine, and the ejection mechanism is in contact with one end of a pin shaft bolt of the coupling; and the cooling device is in contact with the other end of the pin shaft bolt. The invention further relates to a using method of the rapid steam turbine coupling bolt disassembling tool, ultralow-temperature liquid nitrogen is rapidly injected into the pin shaft bolt through the adapter, heat is rapidly absorbed through gasification of the liquid nitrogen, the pin shaft bolt is rapidly cooled to subzero temperature, the volume of the pin shaft bolt is shrunk at the low temperature, the fit clearance between the pin shaft bolt and the through hole of the coupling is increased, and the ejector rod of the efficient long-stroke oil jack is driven by the manual hydraulic pump to extend out to eject out the pin shaft bolt. The unit maintenance quality is effectively improved, the labor intensity of maintenance workers is greatly relieved, the unit maintenance period is guaranteed, and the operation safety of constructors is guaranteed.

Owner:广东华电韶关热电有限公司

A Fast Cutting Method of Hinge Point Shaft

ActiveCN106346413BIncrease fit clearanceLow costMetal working apparatusMetal-working hand toolsThermal expansionOxygen

The invention discloses a hinge shaft rapid cutting method. The method includes the steps of melting a hole in one end of a pin shaft by means of an oxygen melting bar, stirring the oxygen melting bar around the center of the pin shaft, expanding the diameter of the hole, melting the other end of the pin shaft to be communicated with the hole to form a through hole penetrating through the pin shaft, injecting condensate into the through hole, cooling the pin shaft, connecting one end of the pin shaft with a lengthening rod, hitting the lengthening rod through a ram, and hitting the pin shaft to form a hinge joint. The hole is rapidly melted in the pin shaft through extremely-high heat output of the oxygen melting bar, the pin shaft is rapidly cooled, the gaps between the pin shaft and a shaft sleeve and between the pin shaft and a hinge joint hole are increased according to the heat expansion and cold contraction effect, the pin shaft is hit out by means of the ram, only the pin shaft is broken in the detachment process, the hinge joint hole and the shaft sleeve of a structural component are not influenced, the detachment cost of fault type pin shafts is reduced, and the high-efficiency and low-cost detachment of fault type pin shafts of cranes is achieved; the method is particularly suitable for detachment of large pin shafts with diameter of 150 mm or above and length of 1000 mm or above.

Owner:XUZHOU HEAVY MASCH CO LTD

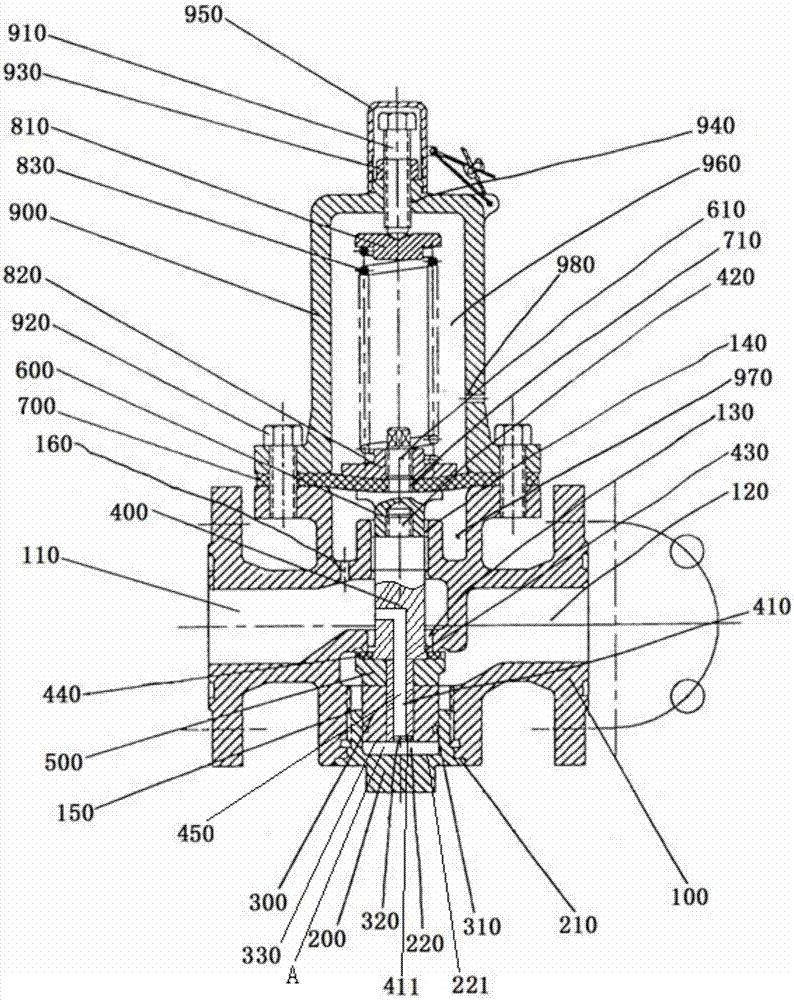

Air pressure reducing valve for ships

InactiveCN105673900BSimple structureHigh technical contentEqualizing valvesSafety valvesEngineeringCylinder pressure

The invention discloses an air reducing valve used for ships. The air reducing valve comprises a valve body, a lower cover, a guide sleeve, a valve rod, an upper cover, a membrane, an ejector rod, an adjusting screw, an upper spring cushion, a lower spring cushion and a spring. The interior of the valve body is provided with an upper cavity, a lower cavity and a shutoff valve hole. The upper cavity serves as an air outlet cavity. The lower cavity serves as an air inlet cavity. The shutoff valve hole is used for enabling the upper cavity to communicate with the lower cavity. An air cylinder chamber is formed by the bottom of the guide sleeve and the hole bottom of a guide sleeve hole. An air cylinder pressure adjusting hole is formed in the portion, between the middle and the lower end, of the valve rod. The air cylinder pressure adjusting hole enables the air cylinder chamber to communicate with the upper cavity of the valve body. According to the air reducing valve, the pressure reducing range is adjusted through the combined action of the pressure adjusting screw, the spring, the membrane and downstream pressure, and the air reducing valve has the advantages that the pressure reducing range is wide, the pressure reducing precision and the pressure stabilizing precision are high, and the output pressure of the reducing valve can be automatically kept being a set pressure value.

Owner:SHANGHAI JINGHEHAI MARINE VALVE

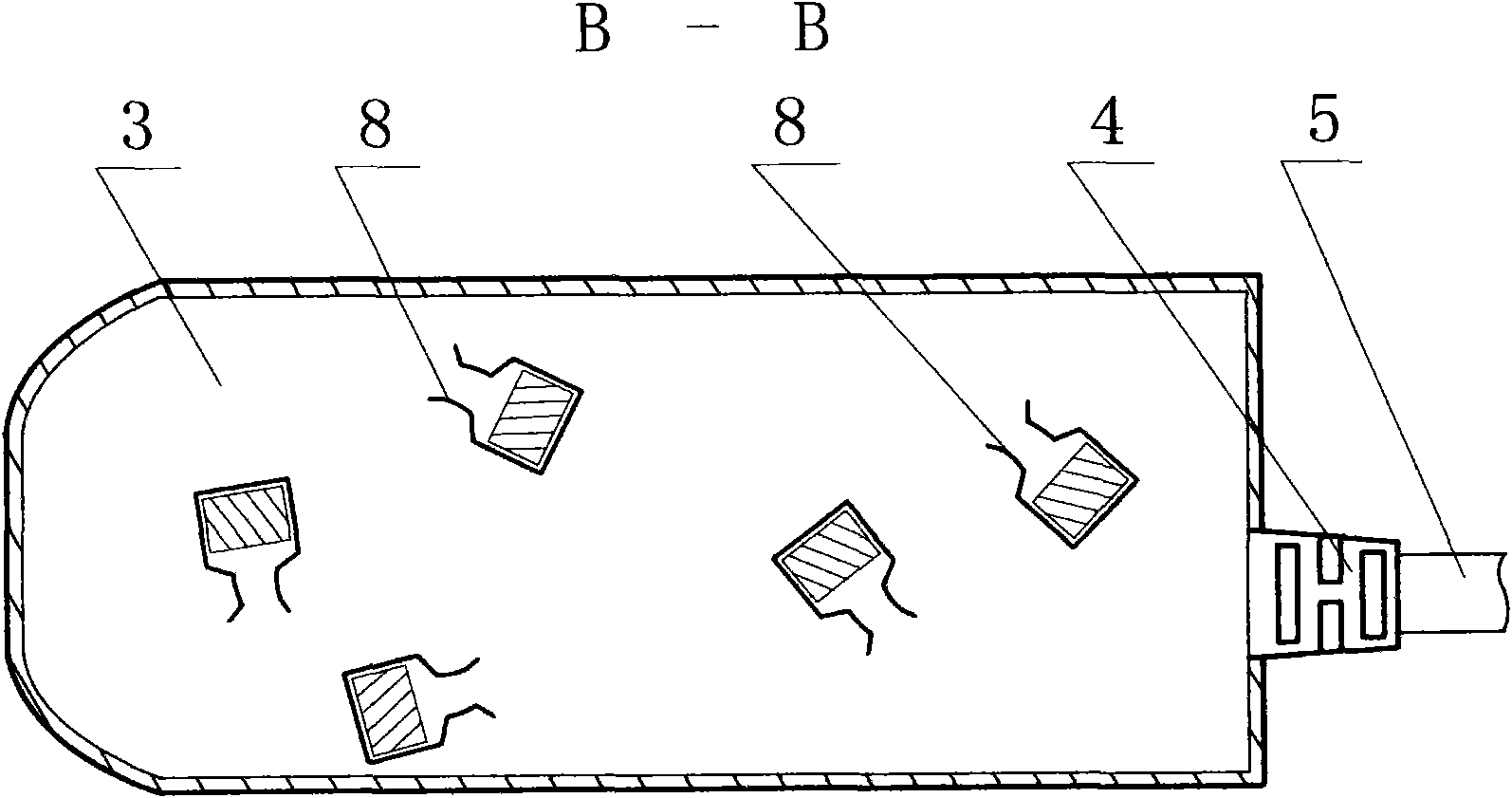

A plunger-free dual-channel output pump system

Owner:SHANGHAI F&S BEARING TECH

Heavy six-link 180-degree casement hinge

InactiveCN112360266AIncrease fit clearanceIncreased load-bearing capacityPin hingesSash windowMetallic materials

The invention discloses a heavy six-link 180-degree casement hinge, and relates to hardware of doors and windows. The casement hinge comprises a groove-shaped bottom plate connected with a window frame, a starting connecting rod connected with a window sash, a long connecting rod, a short connecting rod, a long supporting connecting rod, a middle supporting connecting rod and a short supporting connecting rod, wherein the long connecting rod and the short connecting rod are riveted to the starting connecting rod, the long supporting connecting rod, the middle supporting connecting rod and theshort supporting connecting rod are riveted to the long connecting rod and the groove-shaped bottom plate respectively, and an opening and closing structure composed of nine rivet shafts is formed. According to the casement hinge, the thickness of the connecting rods is increased, and a riveting connection structure is used, so that the bearing capacity is improved; all parts are made of metal materials, and all functions of the hinge do not fail even under the condition of high temperature, so that the fire safety is guaranteed; and the window sash is driven to rotate through the rivet shaft,and extra movement space does not need to be increased, so that screws can be screwed at the groove-shaped bottom plate, the groove-shaped bottom plate is fixed to the window frame, and installationand connection are firm, and therefore, the load-bearing, anti-theft, fire-fighting and installation functions are greatly improved, and safety guarantee is provided for installation and use of a user.

Owner:孙平 +1

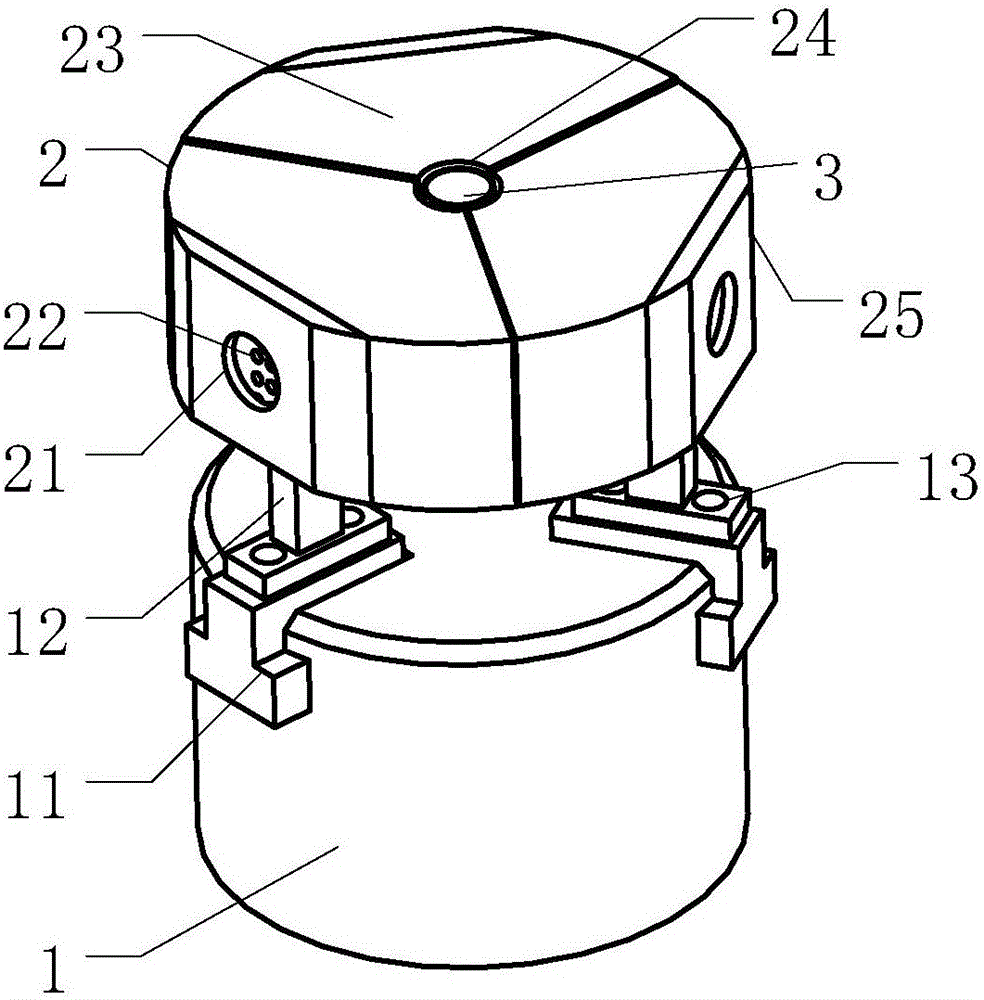

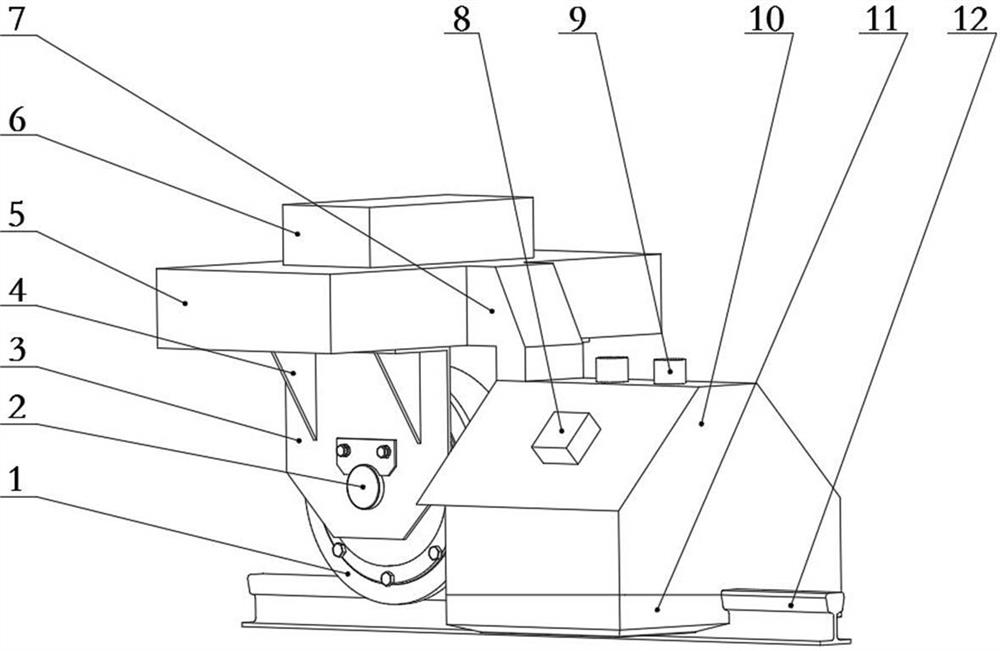

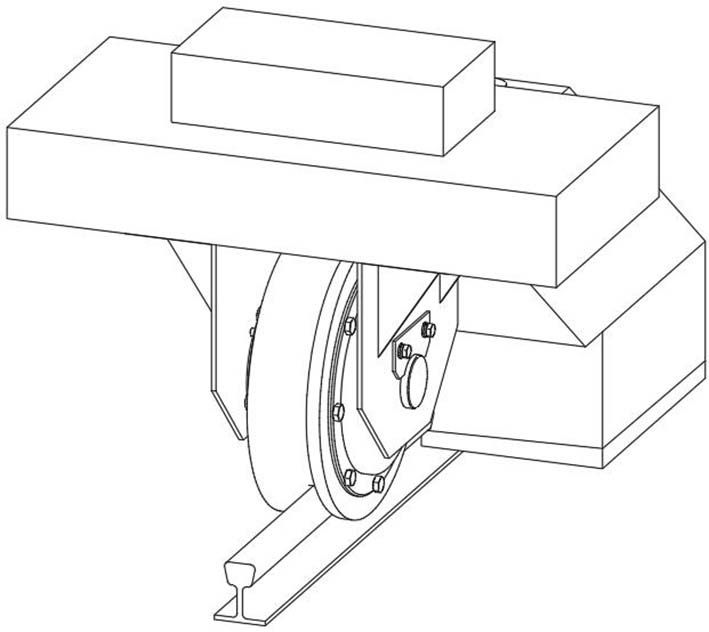

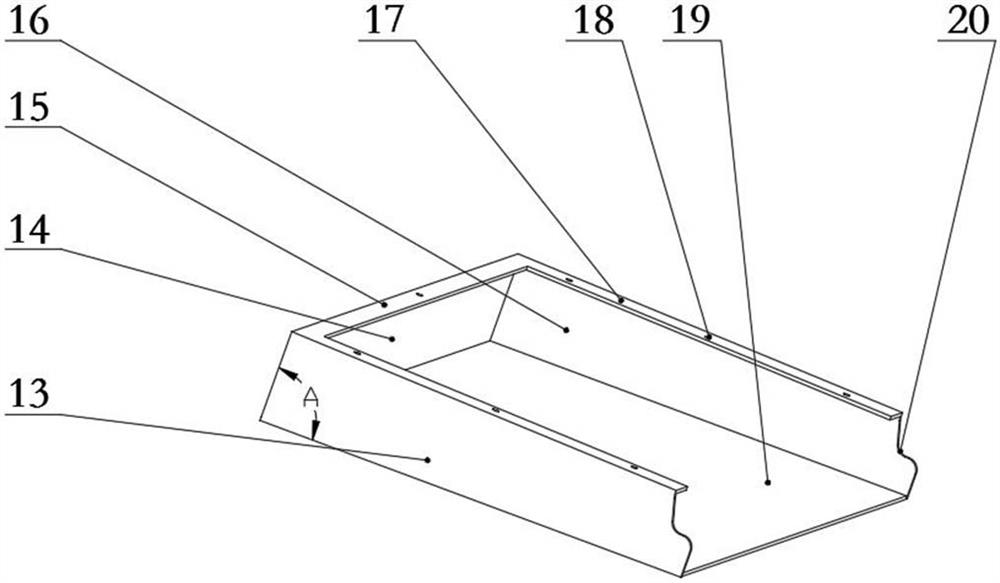

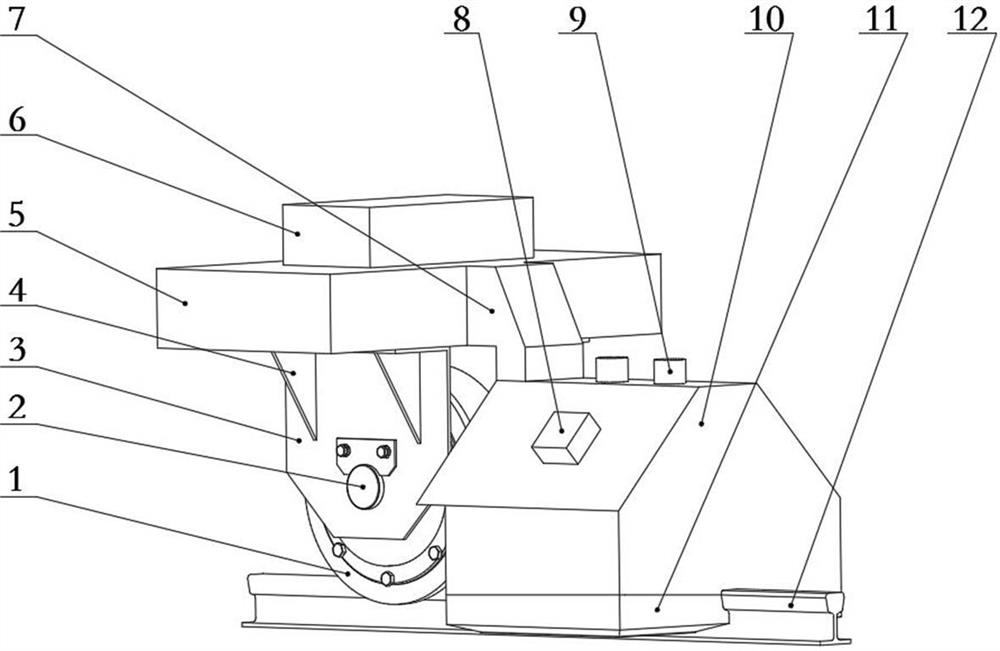

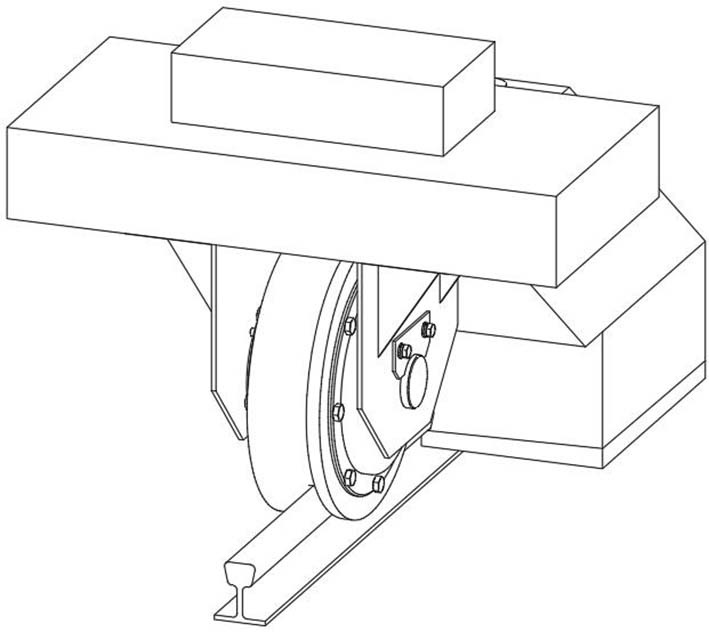

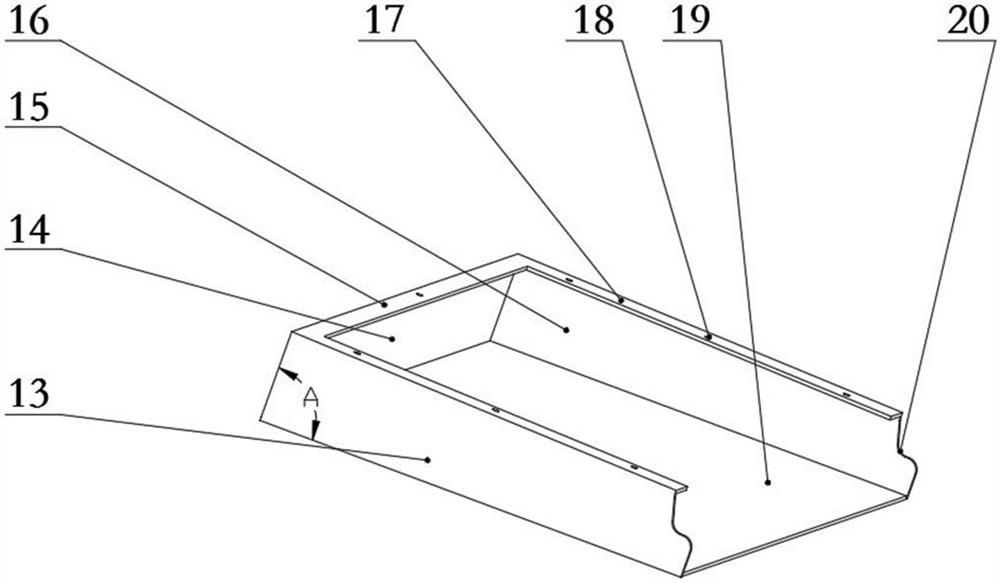

Rail transit wheel and rail shot blasting cleaning device

ActiveCN113146478BNo direct interferenceIncrease fit clearanceAbrasive machine appurtenancesAbrasive blasting machinesStructural engineeringMechanical engineering

The invention discloses a wheel-rail shot blasting cleaning device for rail transit. Its basic structure includes: a traveling mechanism, which is a traveling mechanism equipped with a rail wheel to run on a track to be shot blasted; a shot blasting chamber, which rides on the track On the guide rail member, the shot blasting chamber includes a cover fixedly installed on the traveling mechanism and a seat connected to the lower end of the cover and separated on both sides of the guide rail member to receive the projectiles; correspondingly, between the seat and the cover The connection is detachable; the shot blasting wheel is installed on the shot blasting chamber. Based on the present invention, the wheel rail can be shot blasted, and the wheel rail is not easily damaged.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

Shot-blasting cleaning device applied to wheel rails of rail traffic

ActiveCN113146478ANo direct interferenceIncrease fit clearanceAbrasive machine appurtenancesAbrasive blasting machinesStructural engineeringMechanical engineering

The invention discloses a shot-blasting cleaning device applied to wheel rails of rail traffic. The shot-blasting cleaning device basically structurally comprises a walking mechanism, a shot blasting chamber and a shot blasting machine, wherein the walking mechanism is provided with a rail wheel and runs on a rail to be subjected to shot blasting; the shot blasting chamber straddles on guide rail components of a rail and comprises a cover shell fixedly mounted on the walking mechanism and seat parts which are connected to the lower end of the cover shell and are respectively positioned on two sides of the guide rail components so as to receive shots; correspondingly, the seat parts are removably connected with the cover shell; and the shot blasting machine is mounted on the shot blasting chamber. According to the shot-blasting cleaning device applied to the wheel rails of rail traffic, shot-blasting cleaning can be carried out on the wheel rails; and the wheel rails are not easily damaged.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

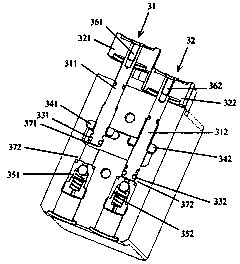

Vibration reduction type electrode tool for mold machining and vibration reduction method

ActiveCN114393263AIncrease stiffnessReduce wearSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansEngineeringCantilever

The invention relates to the technical field of mold machining and manufacturing, in particular to a vibration reduction type electrode tool for mold machining and a vibration reduction method. The vibration reduction type electrode tool comprises a base used for being connected with a main shaft of an electric spark machine tool, a pipe body vertically arranged in the middle of the base, a threaded choke plug connected to the cantilever end of the pipe body in a threaded fit mode, and a threaded connecting column arranged at the front end of the threaded choke plug and used for installing an electrode. The pipe body axial stretching damping device is arranged in the pipe body and comprises a threaded ejector pin and an axial ejector rod, the threaded ejector pin is arranged in the center of the base, and the axial ejector rod is arranged in the pipe body, located between the threaded choke plug and the threaded ejector pin and used for applying axial stretching pre-tightening force to the pipe body. Vibration of the slender electrode tool can be reduced, the machining quality of the mold cavity face is improved, and electrode abrasion is reduced.

Owner:JIANGYIN JINGLI MOLD ENG

Steam power generation equipment configuration power device

InactiveCN105634203AIncrease fit clearanceIncrease freedomMechanical energy handlingElectric machineDrive shaft

The invention discloses a steam power generation equipment configuration power device, and the device also comprises a generating power unit and a power testing unit. The generating power unit comprises a seat and a motor disposed in the seat. The seat comprises a power shaft in power connection with the motor. An extruding screw comprises a driven shaft fixed on the extruding screw, and the driven shaft is connected with the power shaft. A power shaft connection part or / and a driven shaft connection part is / are respectively provided with a flexible connection apparatus. The power shaft connection part or / and the driven shaft connection part is / are respectively provided with the flexible connection apparatus, thereby increasing the fit clearance and freedom degree of the power shaft with the driven shaft, reducing the vibration, and reducing the noise. The device is simple in structure, is convenient to assemble, is easy to manufacture, is high in production efficiency, and is low in cost.

Owner:HEILONGJIANG AOLI FULONG TECH DEV

A vacuum claw type rubber tube set device

The invention discloses a vacuum claw type rubber tube sleeving device. An opening hole is formed in the spliced center of multiple opening claws, and a vacuum cavity is formed by forming a vacuumizing air hole in the side wall of the opening hole, so that the pipe wall of a first to-be-sleeved rubber tube placed in the opening hole can be evenly sucked to the side wall of the opening hole. The opening claws are driven to expand to evenly expand the sucked first rubber tube outwards, so that the fit clearance between an inner rubber tube and an outer rubber tube is increased, a second rubber tube can be smoothly put into the first rubber tube, and finally the first rubber tube is separated from the side wall of the opening hole and restored by stopping vacuumizing operation. Accordingly, the inner rubber tube and the outer rubber tube are well sleeved. Multi-layer sleeving of rubber tubes with different diameters can be conducted conveniently and rapidly through the device.

Owner:SHANGHAI YIBOW SHIPPING CO LTD

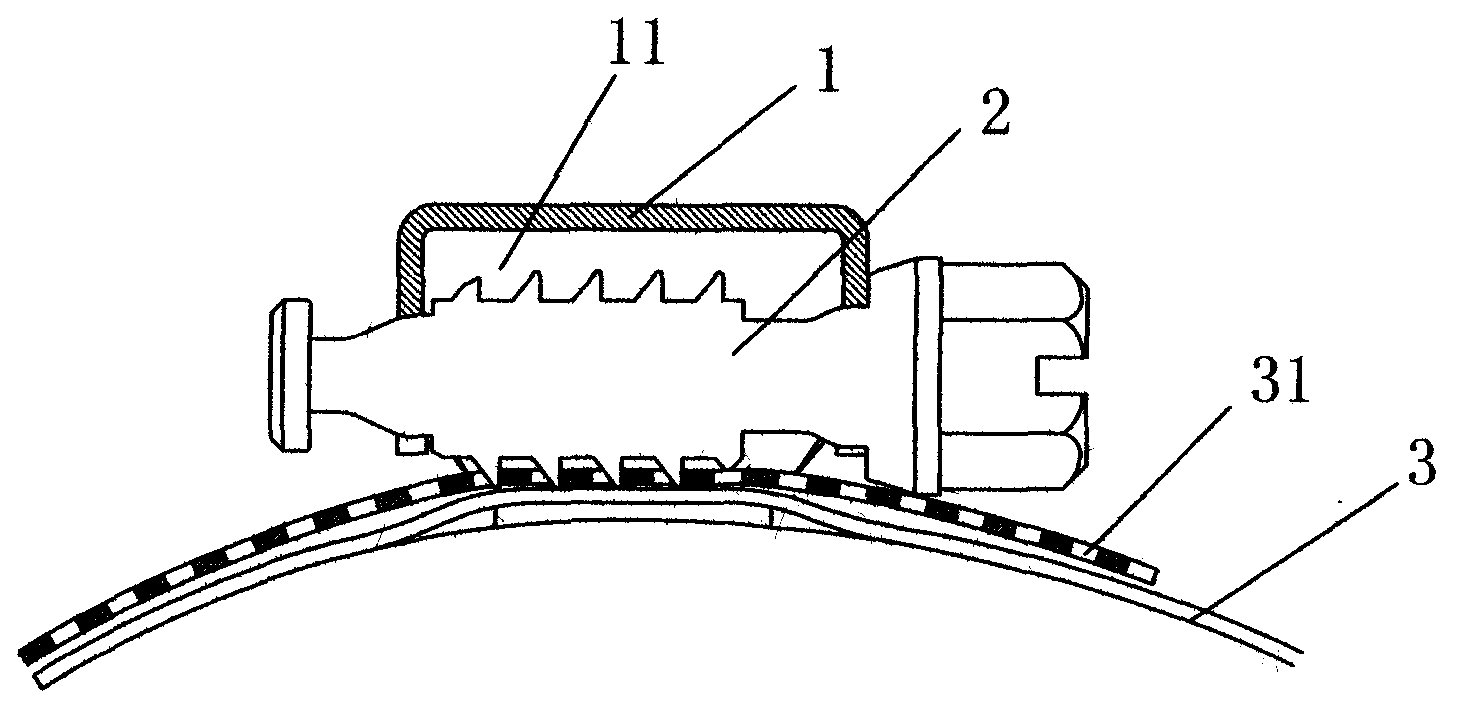

Hose clamp capable of being quickly locked

InactiveCN103062548AAchieve freedom of movementSolve the problem that it is difficult to achieve fast lockingHose connectionsEngineeringScrew head

The invention discloses a hose clamp capable of being quickly locked. The hose clamp comprises a support, a screw and a strap. A cavity is arranged on the support, the screw is mounted in the cavity, a fixed end of the strap is fixedly connected with the support, a movable end of the strap and the fixed end of the strap are enclosed to form a ring and then penetrate out of the cavity, a plurality of slots meshed with the screw in a locking state are arranged on the strap, the screw comprises a screw head, screw necks, threads and a screw tail, the screw necks are respectively positioned among the screw head and the threads and among the screw tail and the threads, and sections of the two screw necks are gradually reduced axially. In a pre-locking state, the small sections of the screw necks are in contact with the support, a fit clearance is increased, the screw is completely prevented from being in contact with the strap, accordingly, the strap can move freely, and in other words, quick action can be implemented; and in the locking state, the large sections of the screw necks are in contact with the support, the fit clearance is reduced, the screw is meshed with the strap, and the hose clamp can be normally locked.

Owner:东莞市海统机电实业有限公司

Large-drift-diameter sectional valve element hydraulic control reversing valve

PendingCN112431944ASensitiveReliable resetMultiple way valvesSlide valveSpool valveHydraulic control

The invention discloses a large-drift-diameter sectional valve element hydraulic control reversing valve. The large-drift-diameter sectional valve element hydraulic control reversing valve is sensitive in action and small in leakage amount. According to the technical scheme, sliding valve sleeves and valve elements are segmented into first sliding valve elements and second sliding valve elements which do linear motion in valve cavities of the first sliding valve sleeves and valve cavities of the second sliding valve sleeves, linear array annular grooves arranged at intervals are formed in thesegmented valve sleeves, and an H-shaped oil sealing section of a dumbbell-shaped structure is manufactured on each valve element; the oil sealing lengths of dumbbell valve element table oil sectionsof the second sliding valve elements are larger than or equal to the oil sealing length value given by the first sliding valve sleeves, and the reversing stroke and the reversing distance of the sum of the width distances of undercutting grooves in valve element necks of two dumbbell valve element tables are basically equal; and in the moving process of the valve elements, the first sliding valveelements are in butt joint with the second sliding valve elements to do linear motion in the cavities of the first sliding valve sleeves and the cavities of the second sliding valve sleeves, one of the two adjacent oil sealing lengths is decreased, the other oil sealing length is increased, the pressure difference of a high-pressure cavity and a low-pressure cavity is formed, and fluid mechanics shows that the annular gap leakage amount is inversely proportional to the oil sealing lengths.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

A combined adjusting pin shaft

ActiveCN103953631BEasy to disassembleReduce disassembly resistanceDowelsEngineeringUltimate tensile strength

A combined regulation pin shaft comprises an outer shaft; positioning steps are arranged at the outer surface of the outer shaft; the outer shaft and an inner shaft are radially matched by a conical surface A; a groove being 2-4mm wide is formed along the longitudinal direction of the outer shaft; a pull rod is inserted in the inner shaft and the head of the pull rod is at the large end part of the conical surface of the inner shaft; the other end of the pull rod is rotationally combined with a nut 8; the left end surface of the nut is abutted against the end surface of the small end of the outer shaft; when the nut is axially tensioned, the outer shaft and the inner shaft relatively slide along the matched conical surface, so the outer shaft is expanded and an outer ring of the outer shaft is expanded, the match precision demand of the outer ring of a pin shaft, a sector section frame and a connection rod bearing is met, and the function need for realizing the fast and precise match between the radial direction and the axial direction is realized; during disassembly, the pull rod is loosened, the inner shaft is knocked to be pushed along the conical surface, the outer diameter of the outer shaft is reduced due to the reduction or removal of the expanding action force of the inner shaft, the match gap between the outer shaft and a match part is increased, the disassembly resistance of the pin shaft is reduced and the pin shaft is convenient to disassemble. The maintenance strength is reduced, the mounting or dismounting efficiency of the pin shaft is enhanced and the service life of the pin shaft is prolonged.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

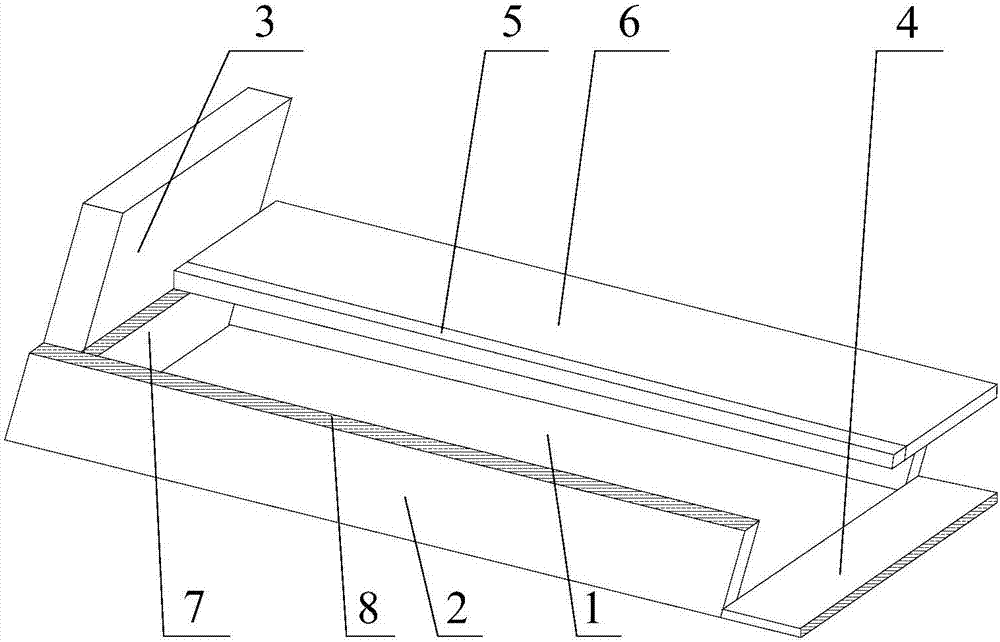

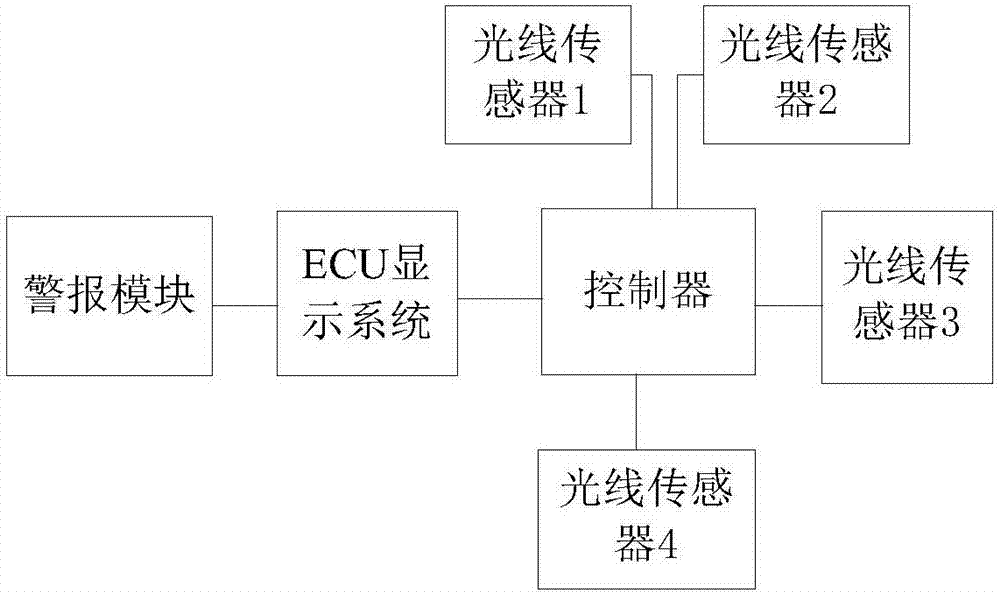

Safety monitoring system of vehicles and ships based on radio frequency technology

InactiveCN107458295AFit clearance is smallImprove sealingSignalling/lighting devicesLoad coveringLine sensorEngineering

The invention discloses a safety monitoring system of vehicles and ships based on radio frequency technology. The system comprises a rectangular packing case which includes a baseboard, two side boards, a top board and a tail board, wherein a top cover is arranged at the top of the rectangular packing case, and light sensors which are connected with a car-self-contained ECU display system by a controller are installed in all the seams between the top cover and the baseboard, two side boards, the top board and the tail board, and the system further comprises an alarm module which is connected with the ECU display system, wherein the light sensors are used to collect light information and transmit the light information to the controller, and the controller is used to receive the light information transmitted by the light sensors, identify the light sensors transmitting the light information, regard the light information as an alarm command and simultaneously send the location information of the light sensors to the ECU display system. The system resolves the problem of damage to goods resulted in that the problem of warehouse seal is not found in time.

Owner:四川鹏尧智运科技有限公司

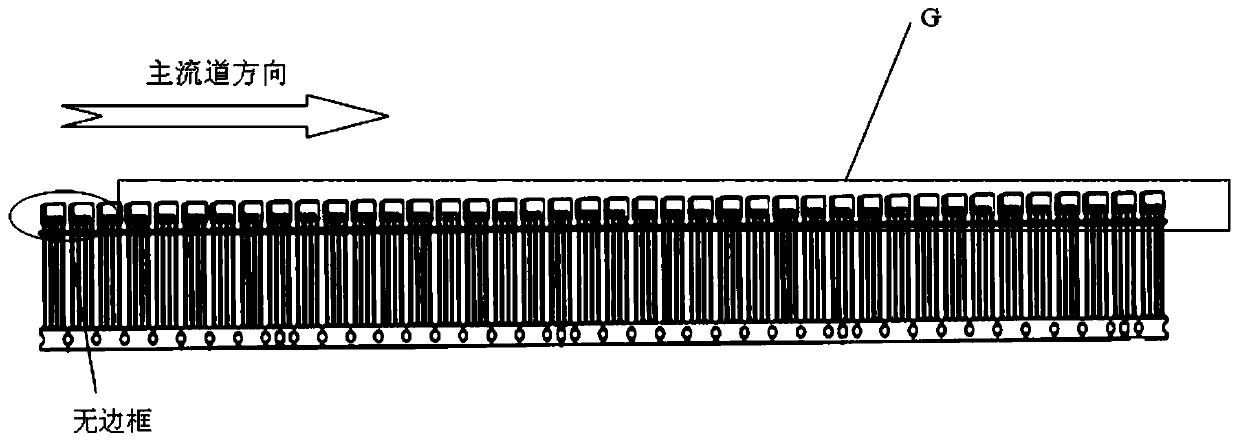

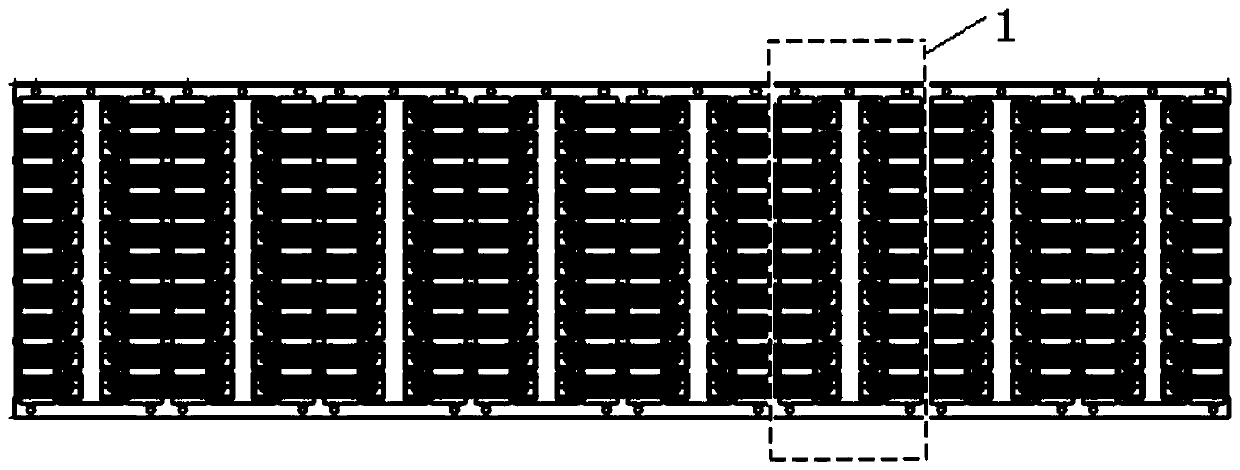

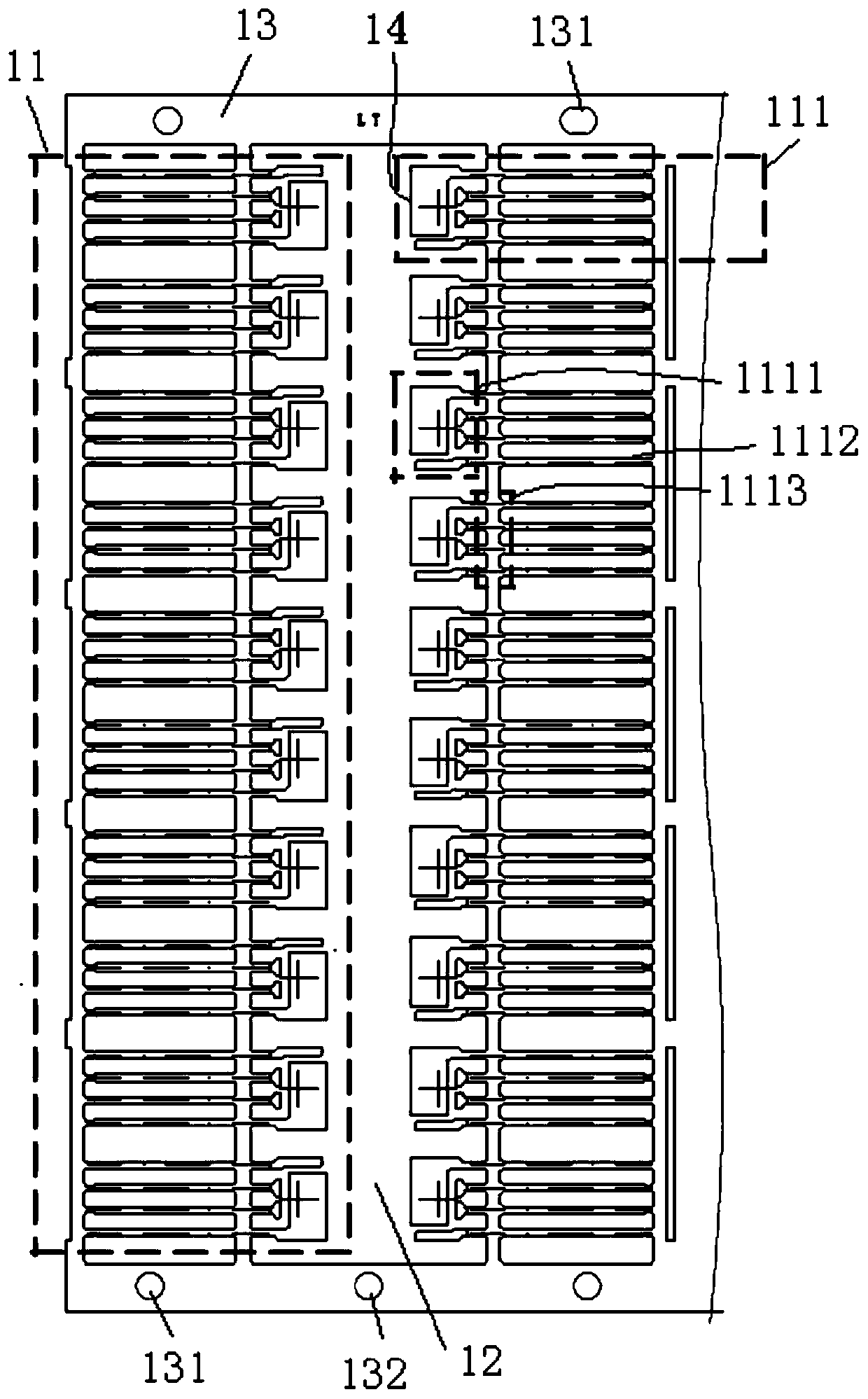

Intensive lead frame

PendingCN110349922AIncrease fit clearanceImprove the forceSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention provides an intensive lead frame. The frame comprises a plurality of frame units which are arranged in parallel in the left-right direction, wherein each frame unit is composed of a leftcolumn unit and a right column unit which are symmetrical, and a main runner is arranged between the left column unit and the right column unit; each column unit is composed of a plurality of rows ofunit structures, and each unit structure comprises a base island which is tightly attached to the main runner and is communicated with the main runner through a pouring gate and a pin which extends outwards relative to the base island. According to the intensive lead frame, the length of the main runner is shortened, so that the fit length of the pins of the intensive lead frame structure and a mold is shortened along with the main runner, the fit clearance between the pins and the mold and the stress of a unit structure are improved, and the situation that glue overflows from the side facesof the pins in the plastic packaging process is further improved; the base island of each unit structure is tightly attached to the main runner and is communicated with the main runner through the pouring gate, so that the stress is more uniform during demolding, thereby avoiding the problems of film sticking, glue breaking, layering and the like of the packaging resin of the product in the demolding process of the packaged product.

Owner:ZHEJIANG HENGTUO ELECTRONIC TECH CO LTD

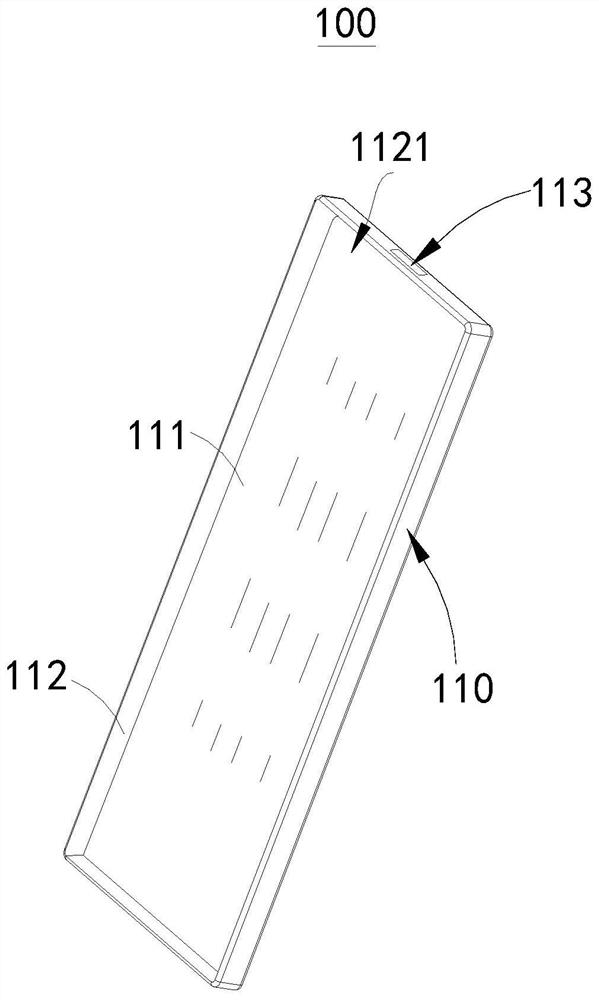

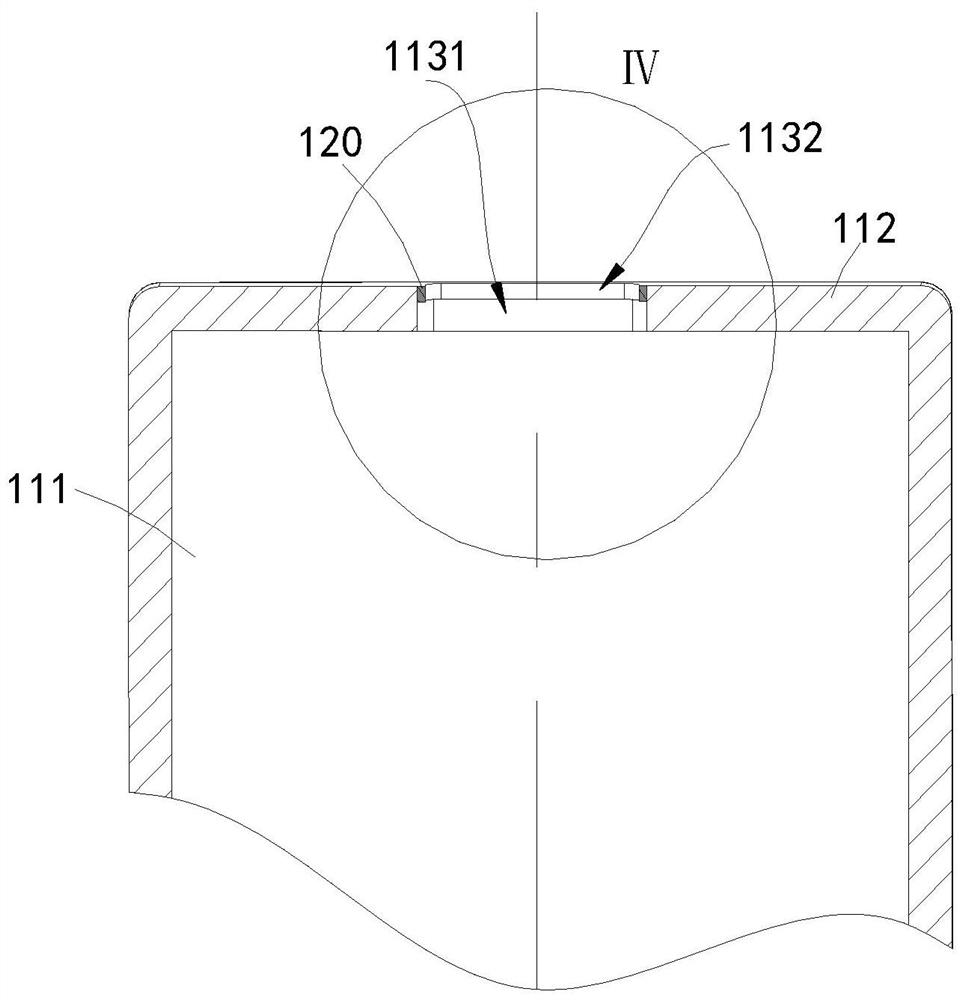

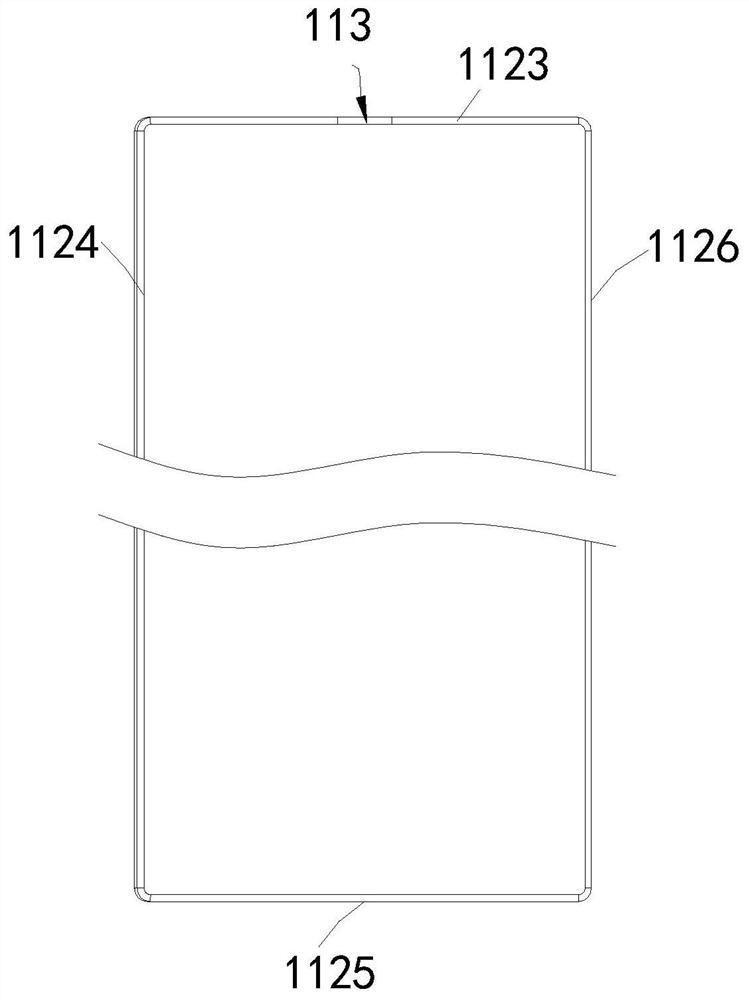

Housing components and electronics

ActiveCN110177157BAvoid exposureIncrease fit clearanceTelephone set constructionsConstruction engineeringStructural engineering

An embodiment of the present application provides a housing assembly, including a housing and a cover part, the housing is provided with a mounting part, the mounting part forms an opening for functional devices to protrude or retract from the housing, and the cover part is connected to the housing Surrounding the edge of the opening and protruding toward the opening, the fit gap in the visible area of the shell can be reduced by setting the cover part, and at the same time, the fit gap is increased in the inner area of the shell to reduce the contact area between the functional device and the shell , to reduce the risk of functional devices being scratched or scratched. In addition, there is also provided an electronic device comprising the above housing assembly and a functional device, the functional device is disposed in the housing and selectively protrudes from the opening or retracts into the housing.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A Fluid Metering Valve for Low Temperature Environment

ActiveCN110566349BLarge effective hole clearanceLittle effect of viscosityGas turbine plantsTurbine/propulsion fuel controlFuel oilMechanical engineering

The invention relates to a fluid metering valve in a low-temperature environment. The metering valve comprises a metering oil needle and a bushing, wherein an oil through hole is formed in the bushingand penetrates the oil through hole; the oil needle and the oil through hole are in clearance fit, and the clearance allows metered fuel oil to pass through; the outer diameter of the oil needle is in clearance fit with the inner diameter of the oil through hole, and the clearance amount is smaller than 0.05 mm; an inclined plane or curved surface is formed on the outer wall surface of the oil needle, and the inclined plane or curved surface and the oil through hole form segmental hole fit; the flow area of the segment hole changes along with axial sliding of the oil needle, and the flow rateof fluid is affected accordingly. The effective hole clearance is larger, actual flow is closer to orifice throttling, and the valve is less influenced by viscosity and has better low-temperature flow characteristic.

Owner:BEIJING HANGKE ENGINE CONTROL SYST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com