Intensive lead frame

A technology of dense leads and lead frames, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of low resin utilization, low production efficiency, and glue overflow on the side of the pins, and achieves improvement. The effect of overflowing glue, uniform force and avoiding mucous membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The patent of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

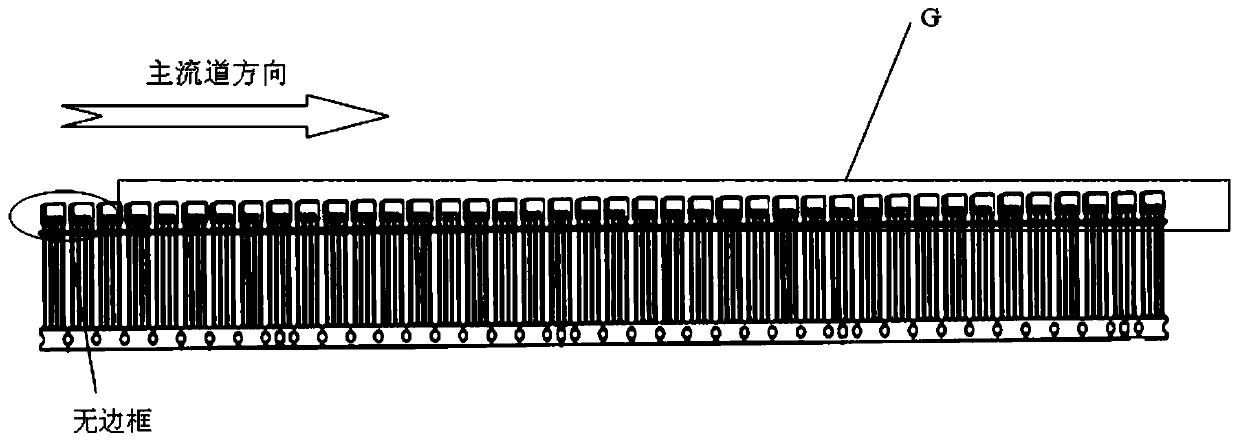

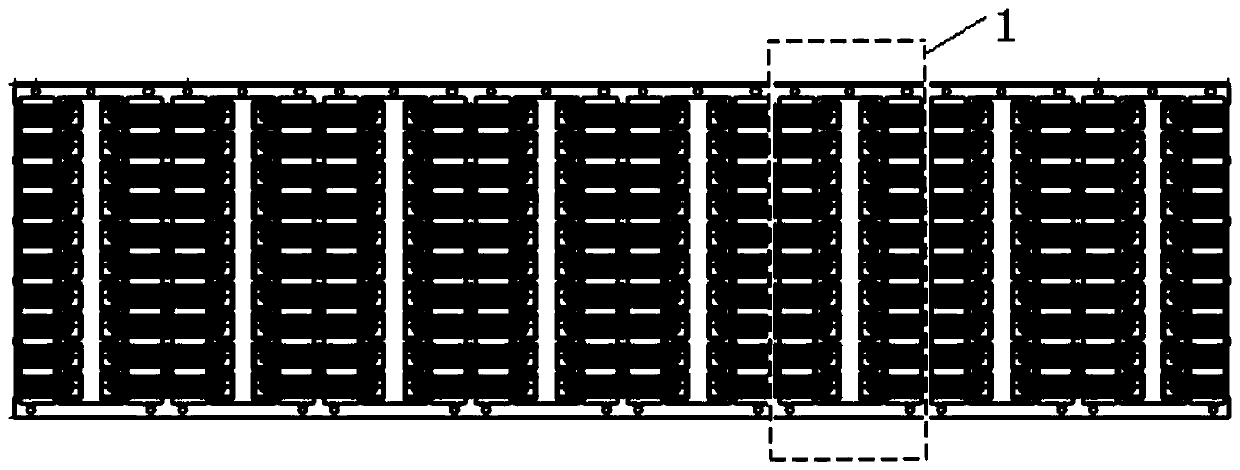

[0024] Such as figure 1 Shown is a dense lead frame according to an embodiment of the present invention. The model of the dense lead frame is TO94, which is formed by die-cutting a metal base tape, and includes a plurality of frame units 1 arranged side by side. In the example, the number of frame units 1 is 8, and the material of the metal base band is copper. In addition, the number of the frame units 1 can also be 7-10.

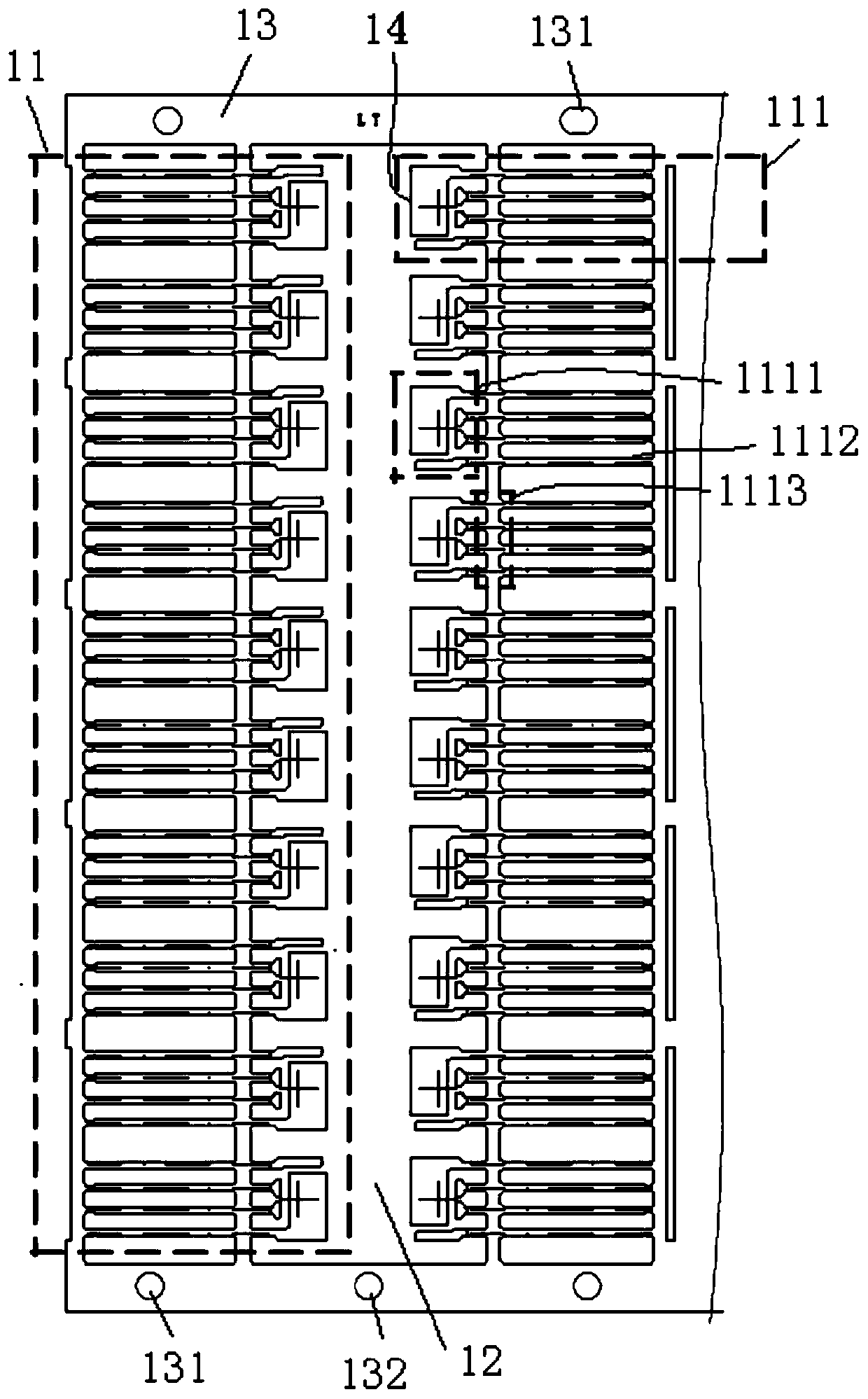

[0025] Such as figure 2 As shown, each frame unit 1 is composed of two symmetrical left and right column units 11, and a vertical main flow channel 12 is arranged between the left and right column units 11, which is used to fill the resin used for molding chips, and each column The upper and lower sides of the unit 11 are provided with metal frames 13, and the metal frames 13 on both sides are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com