Large-drift-diameter sectional valve element hydraulic control reversing valve

A segmented valve, large-diameter technology, used in multi-port valves, sliding valves, valve devices, etc., can solve the problems of long sliding valve length and easy damage to the sealing ring, so as to reduce the reversing stroke and reduce the risk of damage , the effect of small pressure impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

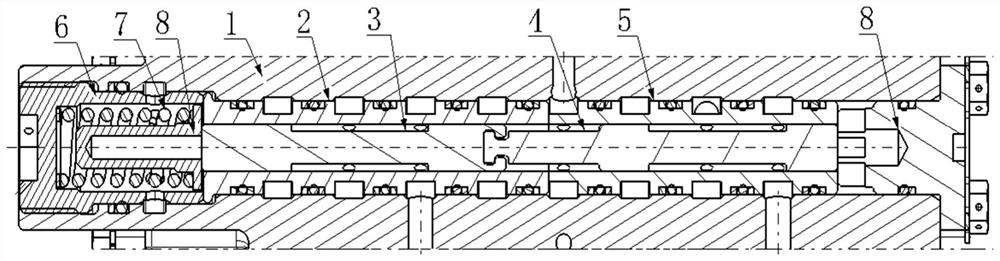

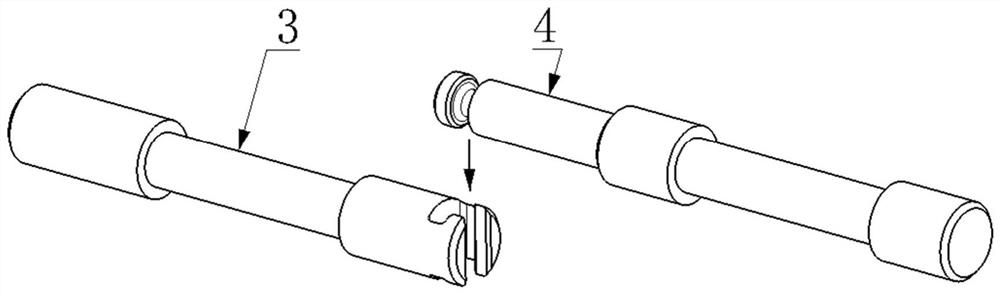

[0013] refer to figure 1 , figure 2 . In the preferred embodiment described below, a hydraulic control reversing valve with a segmented spool with large diameter includes: a slide valve sleeve and a spool assembled in the valve chamber of the valve housing 1 to move axially relative to the valve body, and Assembled at the end of the valve body cylinder and concentrically connected with the spring cylinder plug 6 of the slide valve sleeve, wherein: the slide valve sleeve and the valve core are segmented into the first slide valve sleeve 2 and the second slide valve sleeve 5 The first spool 3 and the second spool 4 move in a straight line in the valve cavity, and the segmented valve sleeve is provided with linear array ring grooves separated by sealing rings, and the segmented spool is provided with The two ends are large, and the middle is small like the H-shaped oil seal section of the connecting shaft with a dumbbell-shaped structure. The oil length value is the sum of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com