Positioning buffer structure of driver's door of bus

A technology of buffer structure and driver's door, applied in the direction of vehicle parts, door/window accessories, building structure, etc., can solve the problem of buffer force and positioning not helpful, increase the weight of door frame or the complexity of structure, and not meet the light weight of vehicles requirements and other issues, to achieve the effect of flexible and convenient opening and closing of the driver's door, eliminating impact and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

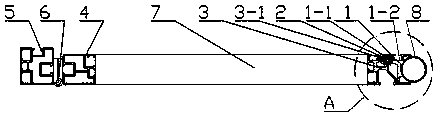

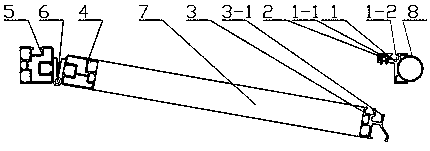

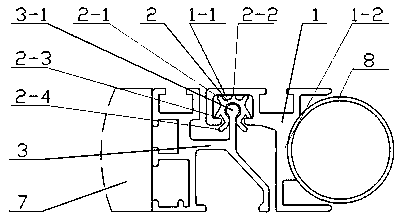

[0028] Such as Figure 1 ~ Figure 4 As shown, the technical solution adopted in the present invention comprises a first door frame column 1, a first door column 3, a second door frame column 5 and a second door column 4, and the second door frame column 5 is installed on the vehicle body floor during use, so The second door column 4 is hinged on the second door frame column 5 through a hinge 6; the second door column 4 and the first door column 3 are connected together by a beam 7 to form a frame structure of the driver's door; When the first door frame column 1 is in use, it is installed on the vehicle body floor, a C-shaped groove 1-1 with a lower end opening is provided on the left side of the first door frame column 1, and a user is provided on the right side of the first door frame column 1. In the concave arc 1-2 matched with the installation column 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com