A Fast Cutting Method of Hinge Point Shaft

A rapid cutting and hinge point technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of large matching size between the pin shaft and the hinge point hole sleeve of the structural part, difficult to disassemble the pin shaft, and long waiting period for replacement parts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

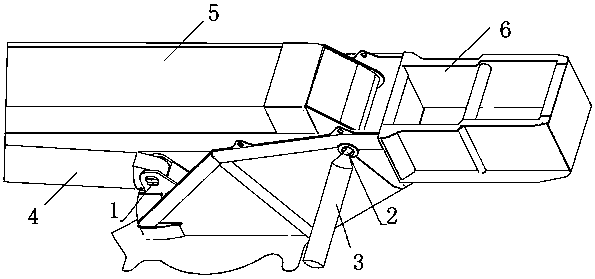

[0028] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0029] A fast cutting method of hinge point shaft:

[0030] Before cutting, prepare for the protection of operators and vehicles. Personnel protection requires comprehensive heat insulation protection for the head, face, arms, torso, legs, and feet.

[0031] The operator holds the cutting gun and aligns the oxygen melting rod at the center of the pin shaft end, gently holds the handle of the cutting tool without current, and supplies a small amount of oxygen. Another operator ignites with an oxyacetylene flame, and when the oxygen fusion rod starts to burn spontaneously, removes the oxyacetylene flame, and the operator increases the oxygen supply to make the oxygen fusion rod burn more intensely.

[0032] The operator aligns the burning oxygen melting rod with the center of one end of the pin shaft, and after the core of the pin shaft st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com