Shot-blasting cleaning device applied to wheel rails of rail traffic

A shot blasting and rail transit technology, which is applied to used abrasive processing devices, metal processing equipment, manufacturing tools, etc., can solve the problem that rail shot blasting has no practical significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

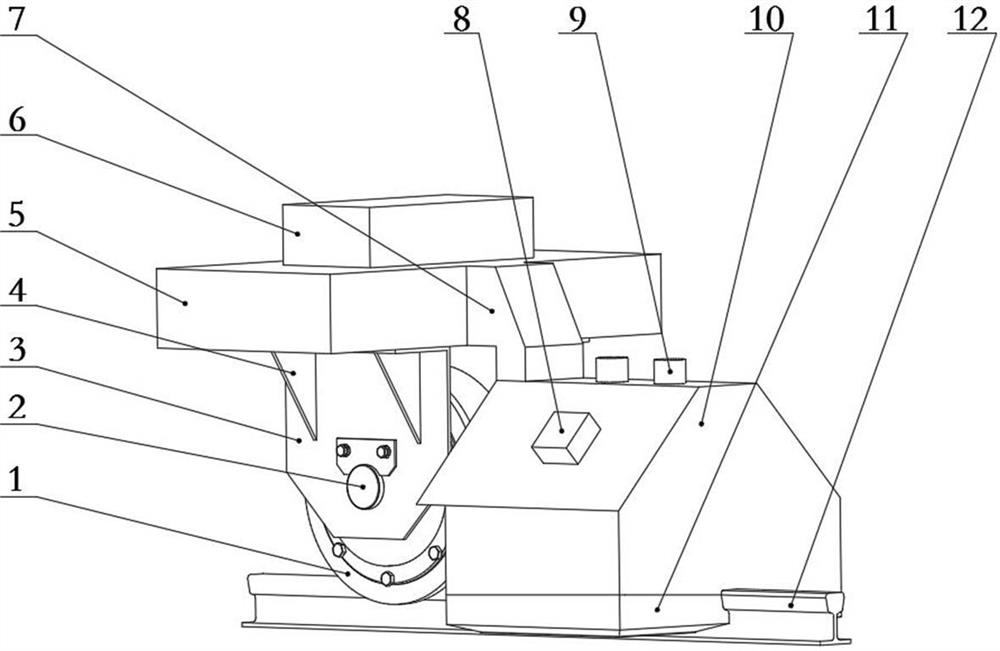

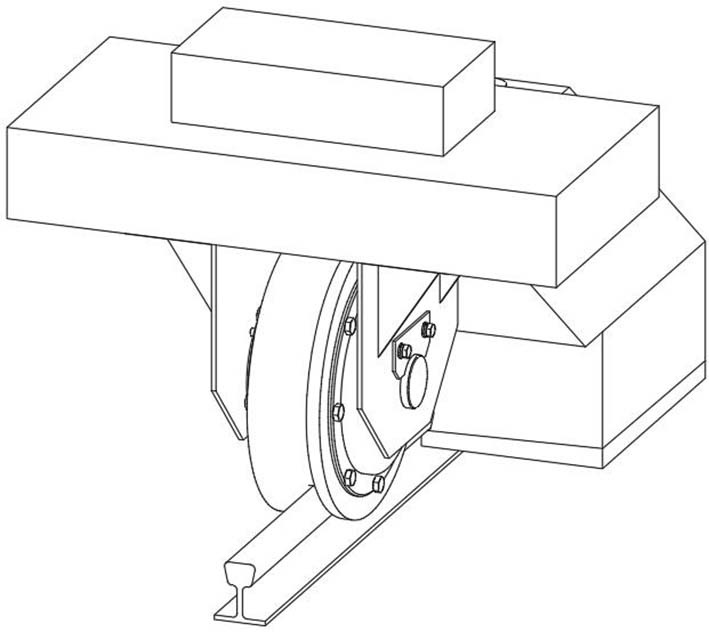

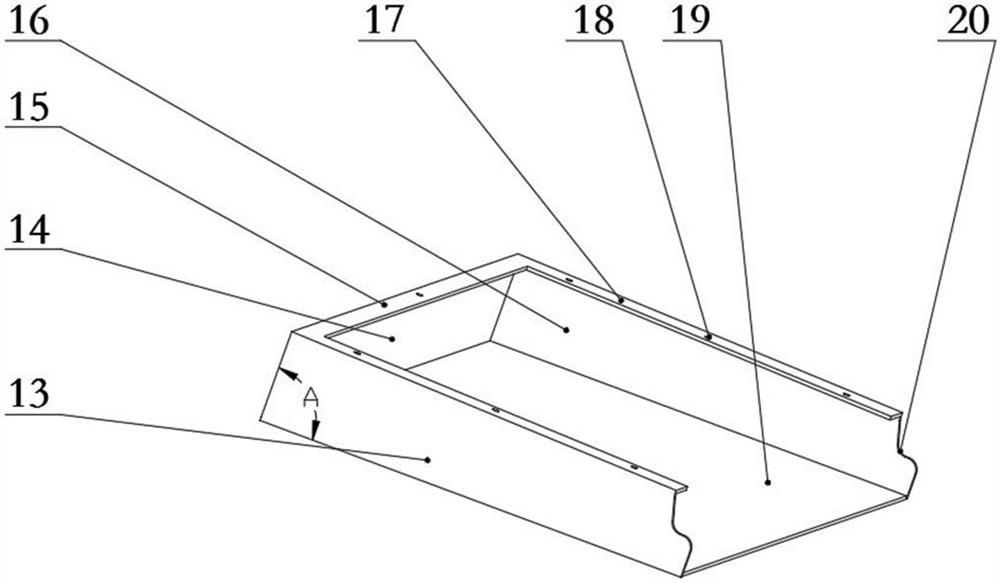

[0033] In order to more clearly show the rail transit wheel rail shot blasting cleaning device in the embodiment of the present invention, in the accompanying drawings of the embodiment of the present invention, the method of omitting unimportant parts is used to assist the text description in the embodiment of the present invention , without affecting the general understanding of those skilled in the art.

[0034] It should be known that the particle size of the projectiles used in shot blasting is different, but the particle size is generally not less than 2mm, and the collection of projectiles in the embodiment of the present invention should not affect the normal operation of the walking mechanism. It is obvious that the 2mm can be adapted The matching gap is relatively large, which can fully meet the design of the matching gap between the seat 11 and the guide rail member 12, and will not cause movement interference during use. For example, the side of the seat 11 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com